Hoisting construction method for oversized span steel truss of roof of stadium grandstand

A stadium, steel truss technology, applied in the direction of roofs, building components, buildings, etc., can solve the problems of difficult to control unloading accuracy, difficult quality control, high cost, and achieve the effect of maintaining stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

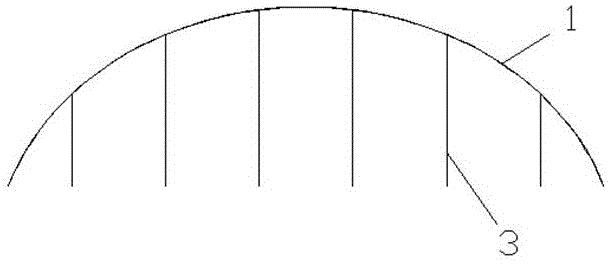

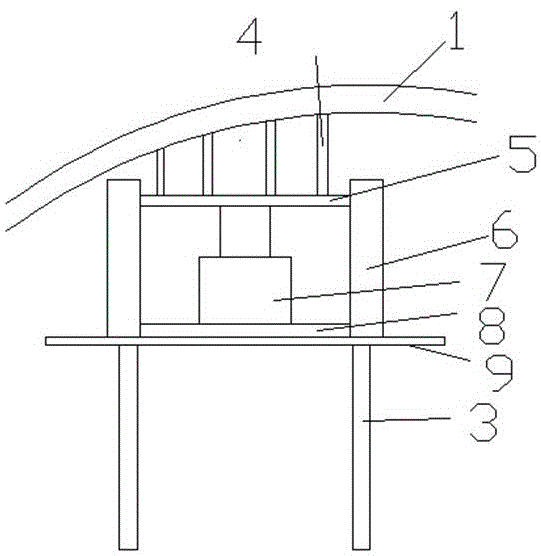

[0046] A super-large-span stadium stand roof steel truss hoisting construction method, including the following steps:

[0047] A. Construction preparation work

[0048] Compilation and approval of the hoisting scheme and disclosure to the personnel of the parameters; determine the position of the temporary support frame, segment the steel truss and assemble them on the ground for the overall installation of the high-altitude segment; determine the hoisting sequence of each segment, lifting weight, Selection of hoisting equipment, travel route, and safety measures; leveling and compaction of the site to meet the requirements of large cranes for travel and hoisting;

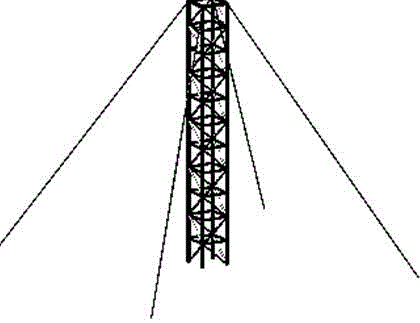

[0049] B. Fabrication and installation of temporary support frame

[0050] (1) The temporary support is made of round tube 4 tubes or large angle steel lattice support. The standard segment length is 6m. The splicing and installation of the support frame uses 2 sets of 100T truck cranes, and each standard segment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com