Patents

Literature

84results about How to "Improve construction technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

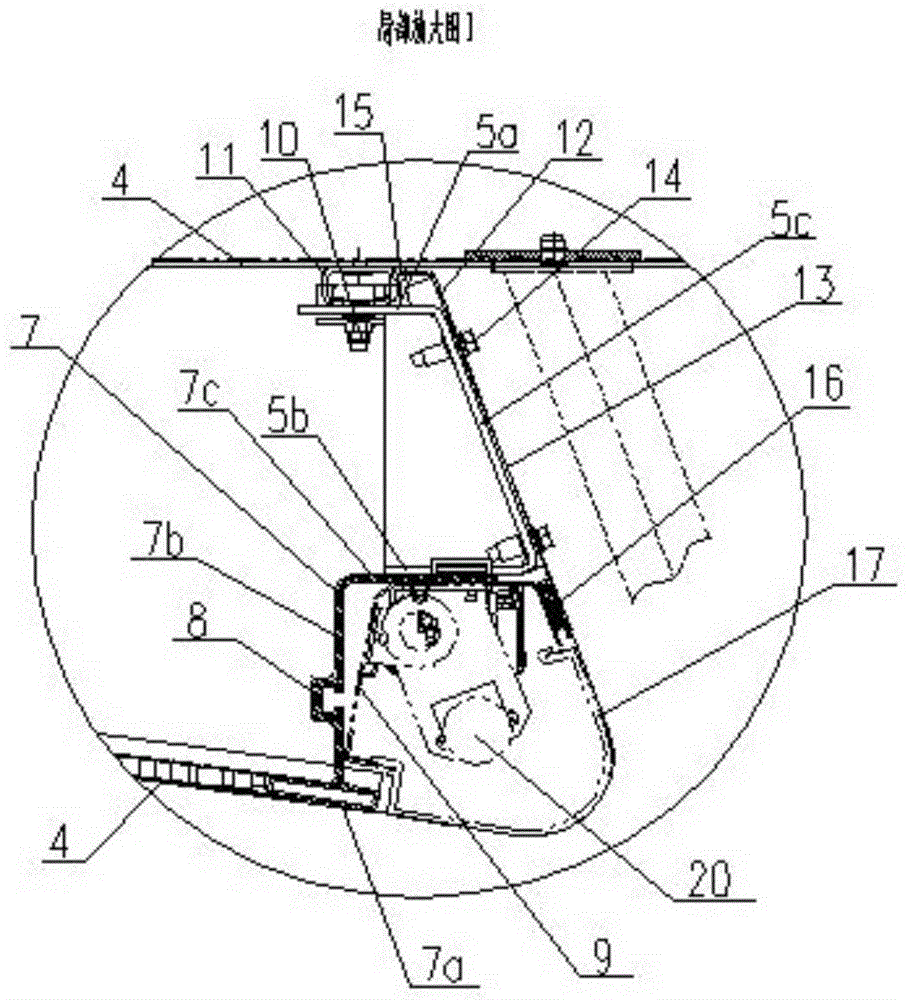

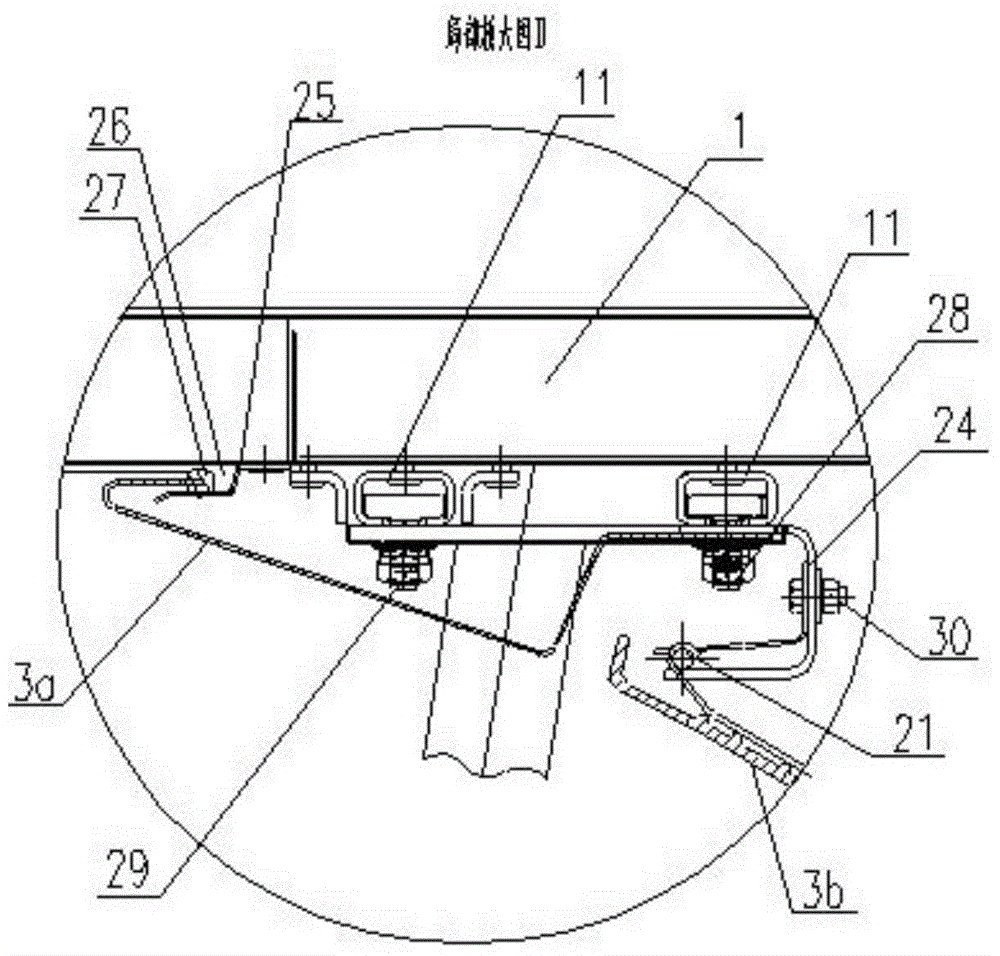

Method for constructing road swivel bridge and railway swivel bridge by using turnplate spherical hinge

ActiveCN101818482AConstruction safetySimple and fast operationBridge erection/assemblyPile capThree stage

The invention relates to a method for constructing a bridge, in particular to the method for constructing a road swivel bridge and a railway swivel bridge by using a turnplate spherical hinge, which aims to solve the problems of the complex process, inconvenient construction, high requirements on construction sites, and the like of the conventional swivel bridge construction. The method specifically comprises the following steps of: machining the turnplate spherical hinge; constructing a lower pile cap and mounting a lower spherical hinge and an endless track, wherein the concrete of the lower pile cap is poured in three stages; constructing an upper pile cap and mounting an upper spherical hinge and a support steel cylinder; and after the upper pile cap and the lower pile cap are swiveled in place under the action of the turnplate spherical hinge, pouring rear sealed concrete between the upper pile cap and the lower pile cap. The method has the advantages of the capacity of changing overhead barrier operation into operation on the coast or near the ground, safe and reliable construction, simple and convenient operation, fast implementation and construction cost reduction, is suitable for both straight bridges and curved bridges, and compared with the conventional construction methods, also has the advantages of shortening construction period, saving a part of big construction machinery and labor force and greatly saving construction cost.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

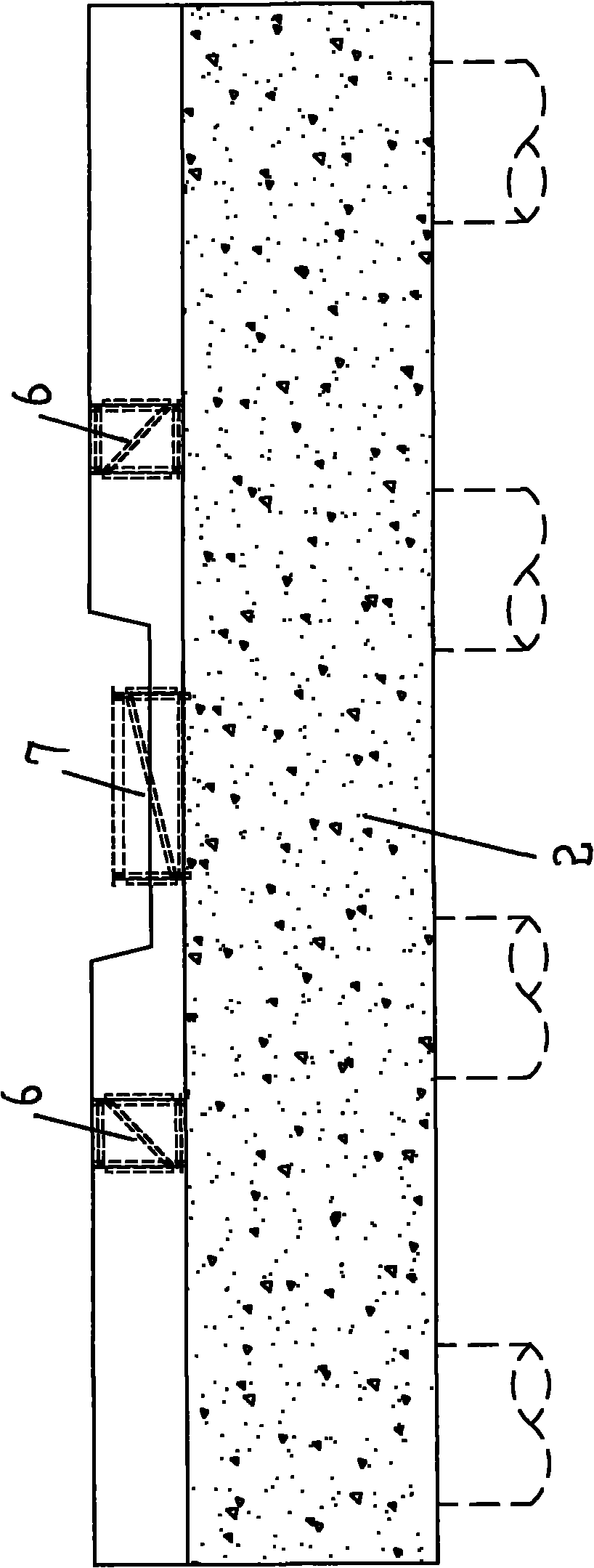

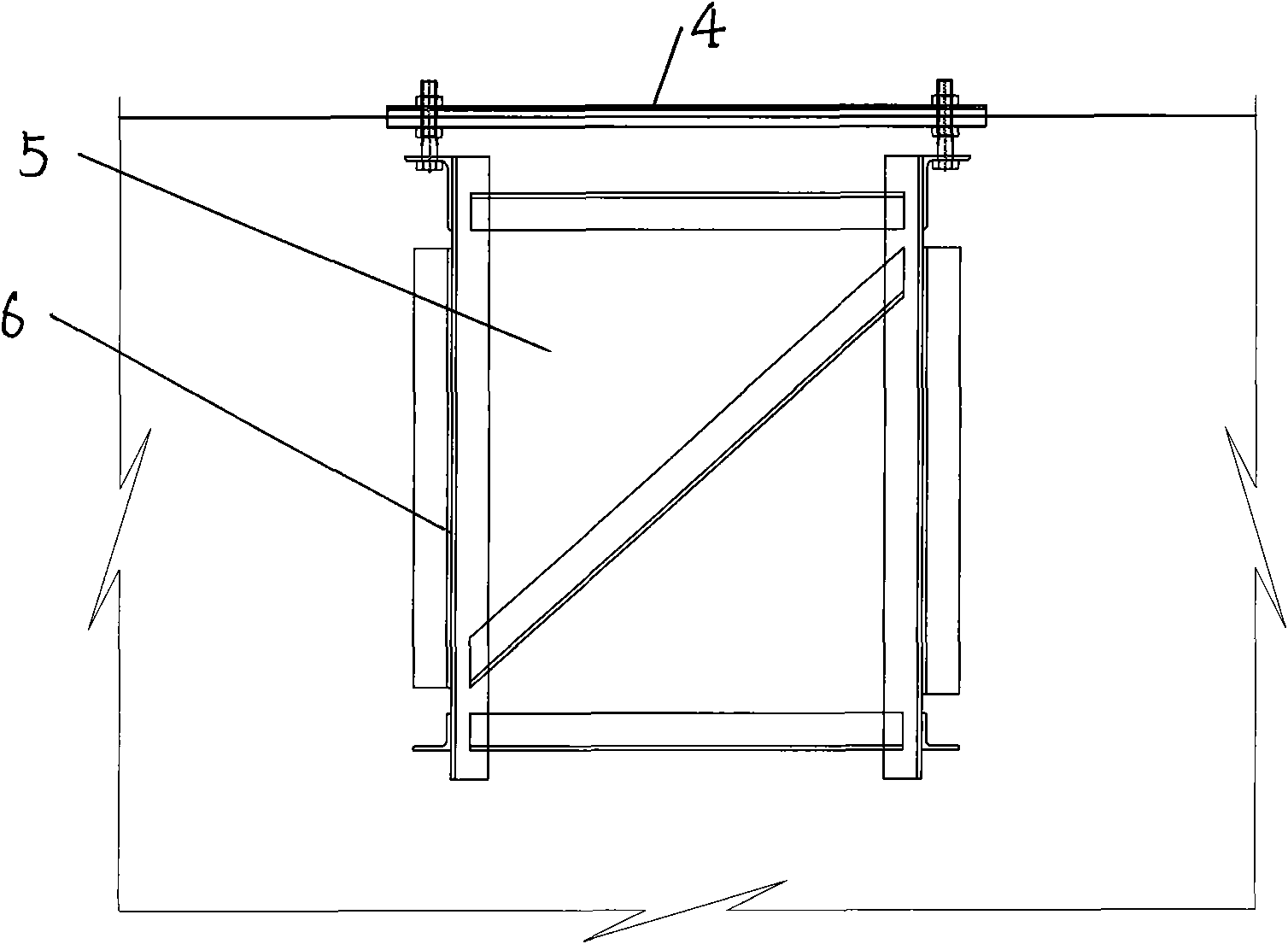

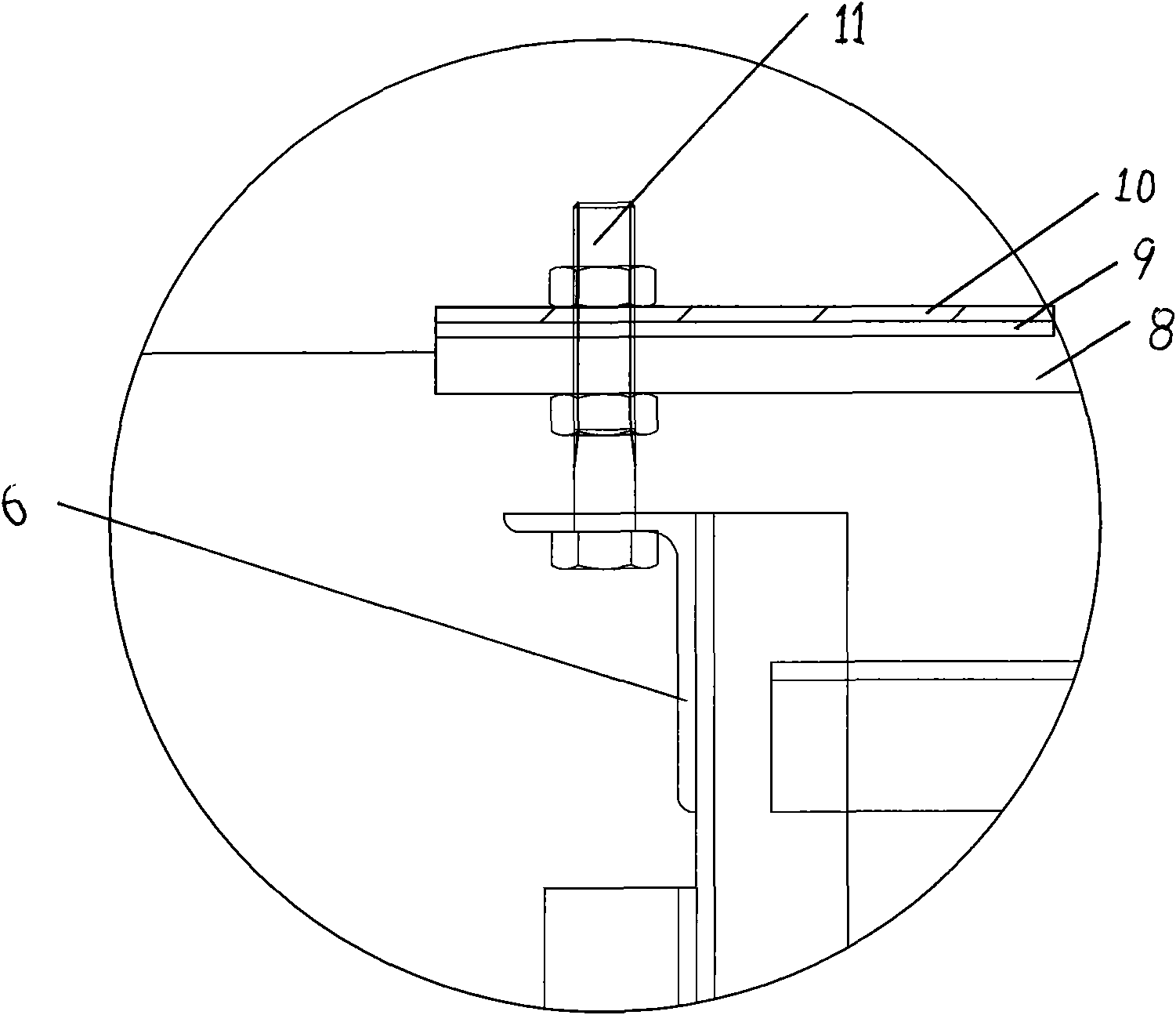

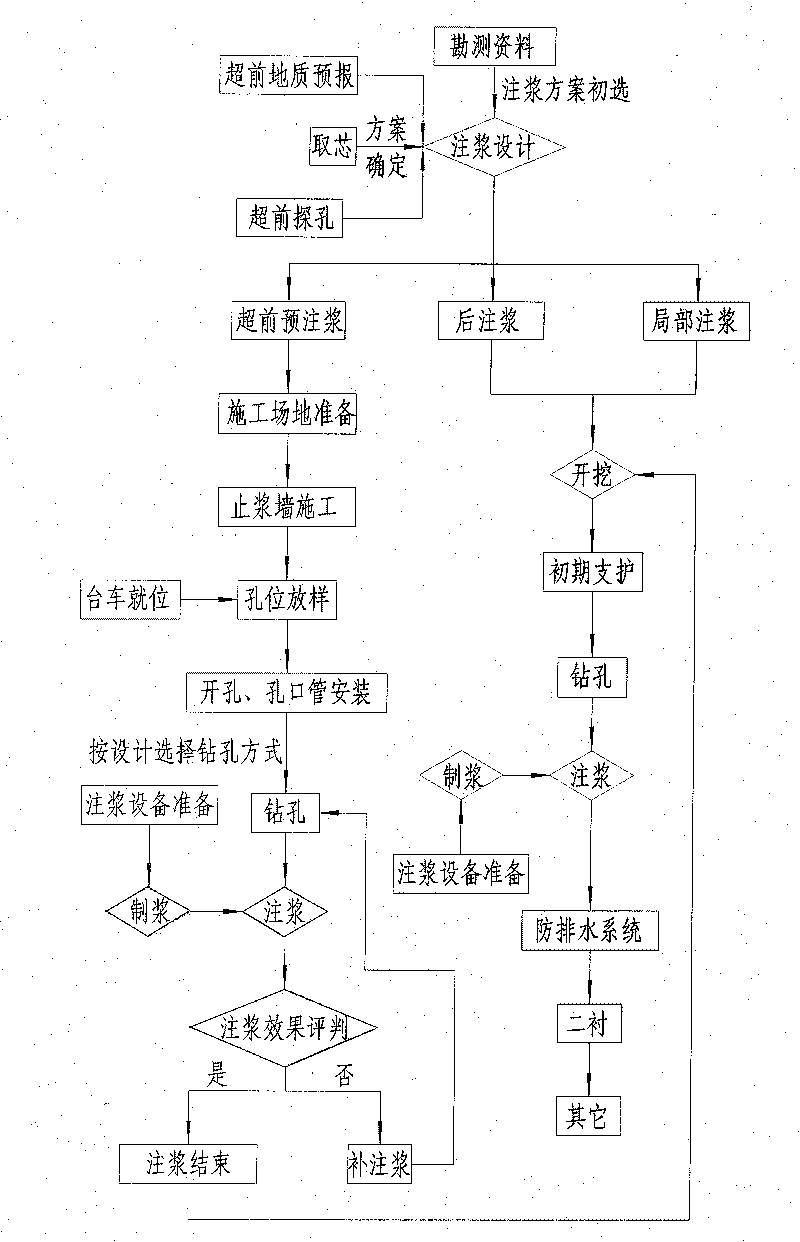

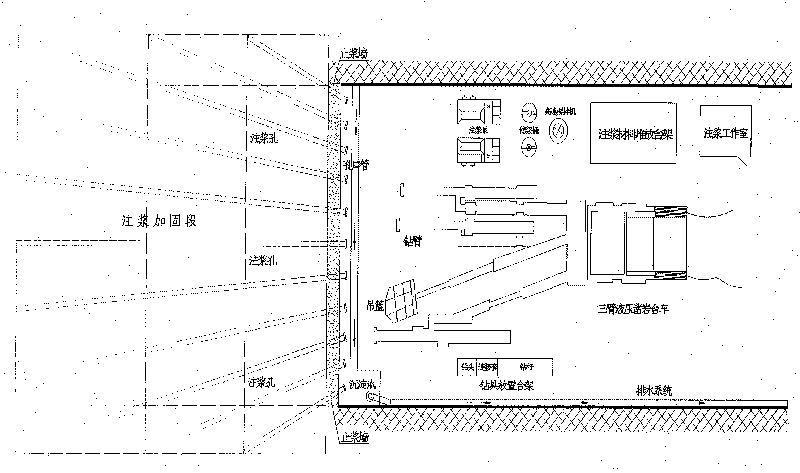

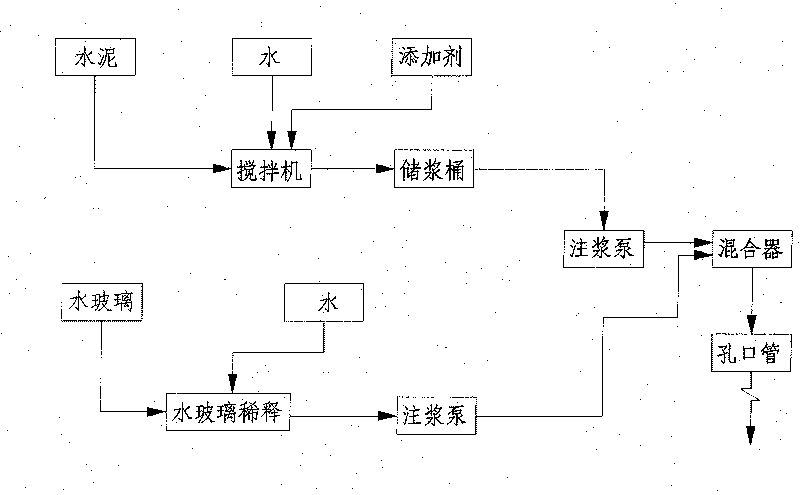

Three-arm hydraulic wagon drill and tunnel drilling and grouting construction method

InactiveCN101691842AImprove applicabilityQuick disassemblyUnderground chambersTunnel liningEnergy conservationDrill hole

The invention discloses a three-arm hydraulic wagon drill and a tunnel drilling and grouting construction method, belonging to the technical field of traffic construction. The invention carries out pertinent improvement on the three-arm hydraulic wagon drill, adopts a T38*3.66 circular extension drill rod to be cooperatively used with the three-arm hydraulic wagon drill, and establishes a water cleaning and wind cleaning dual system to be used in the tunnel drilling and grouting construction. The tunnel drilling and grouting is accomplished by grouting-stop wall construction, drilling, orifice tube installation, grouting and grouting effect evaluation, and a better construction effect is achieved. Compared with the prior equipment, the construction efficiency is increased, the energy conservation and environment protection are realized, the construction conditions are improved, and the grouting water plugging rate reaches more than 98%, thereby having excellent popularization and application values.

Owner:CHINA RAILWAY TUNNEL

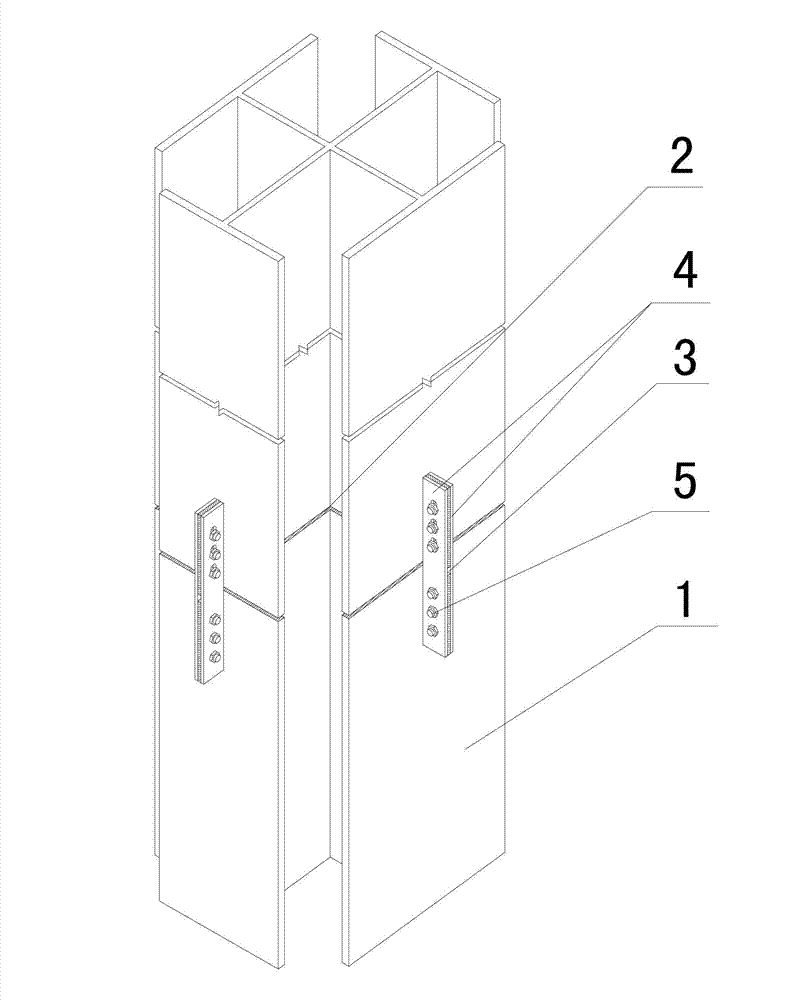

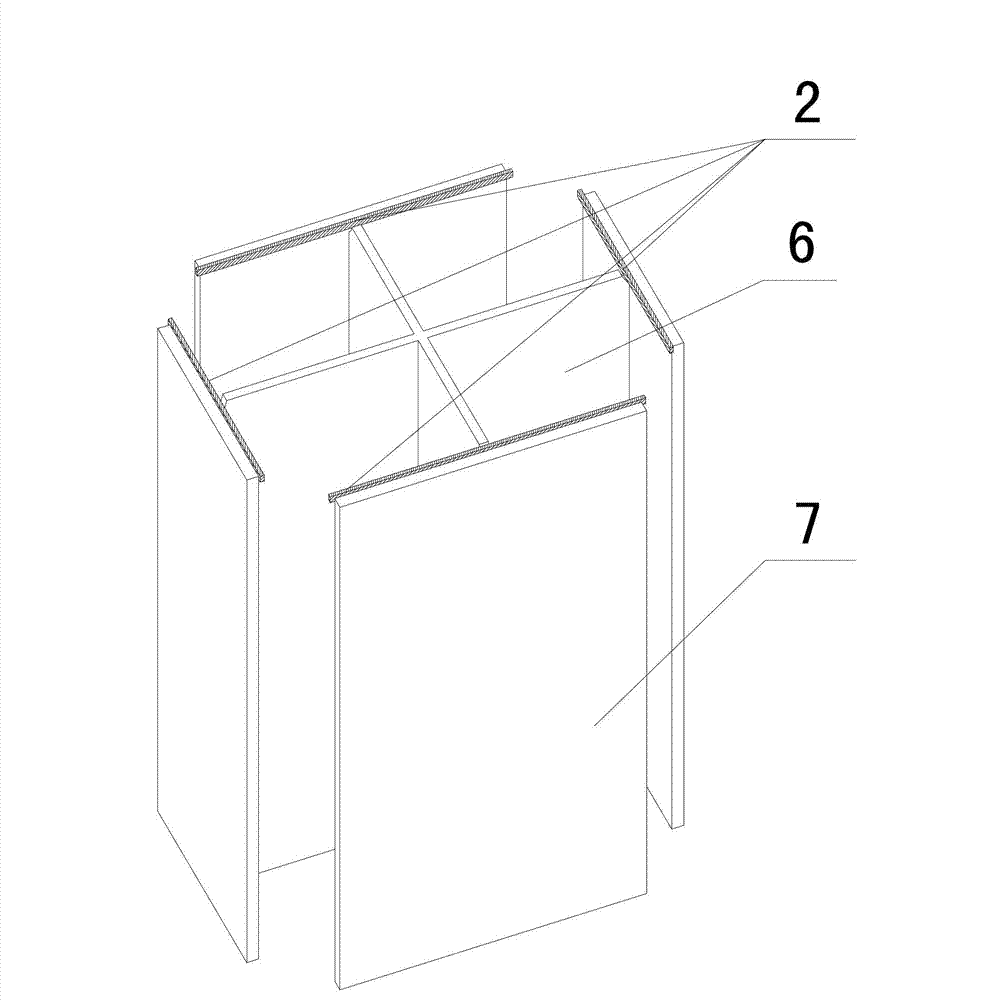

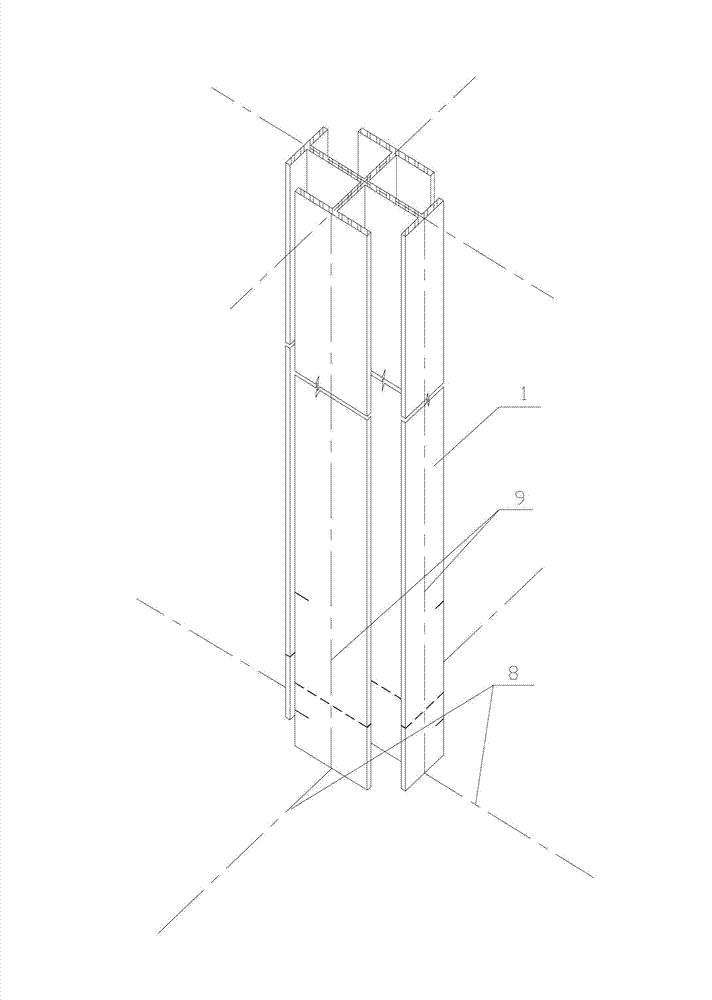

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545AGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a section steel column for a high-rise building section steel concrete combination structure, and a construction method thereof. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

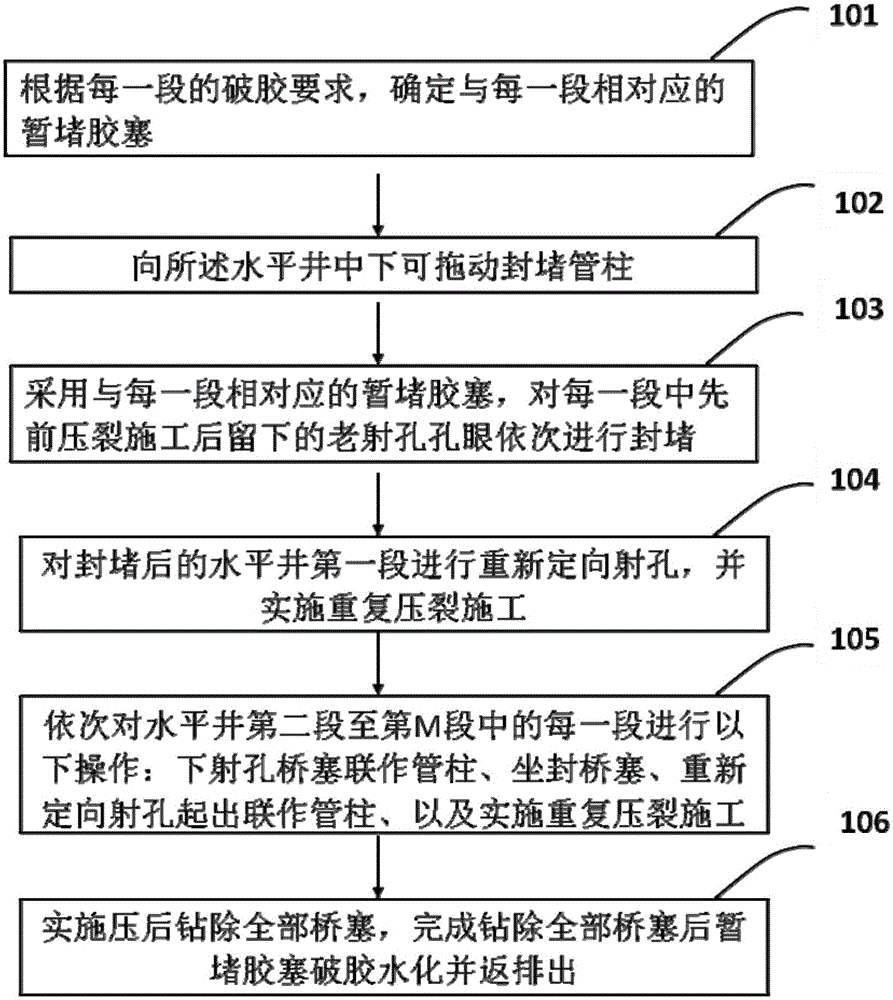

Casing horizontal well multi-segment refracturing method

ActiveCN106351634ASolve many problems such as easy failureGuaranteed successFluid removalSealing/packingMulti segmentMaterial Perforation

A multi-stage refracturing method for casing horizontal wells is proposed. This method is used for refracturing horizontal wells containing multiple stages. The method includes: according to the gel breaking requirements of each stage, determine the corresponding Temporary plugging; the plugging string can be dragged down the horizontal well; the temporary plugging corresponding to each section is used to seal the old perforation holes left after the previous fracturing operation in each section in sequence Re-orientate perforation on the first section of the horizontal well after plugging, and implement refracturing construction; perform the following operations on each section from the second section to the M section of the horizontal well in turn: lower the perforation bridge plug joint Manipulating strings, setting bridge plugs, reorienting perforating strings, and implementing repeated fracturing operations, wherein the first section is the section farthest from the wellhead, and the Mth section is the closest to the wellhead One section; and after the pressure is applied, all the bridge plugs are drilled and removed, and after all the bridge plugs are drilled and removed, the temporarily blocked rubber plug is broken and hydrated and then discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

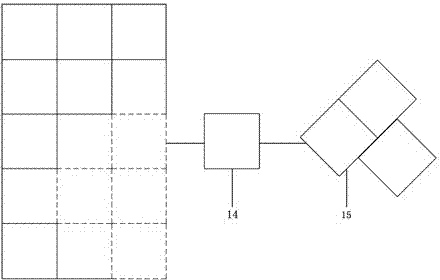

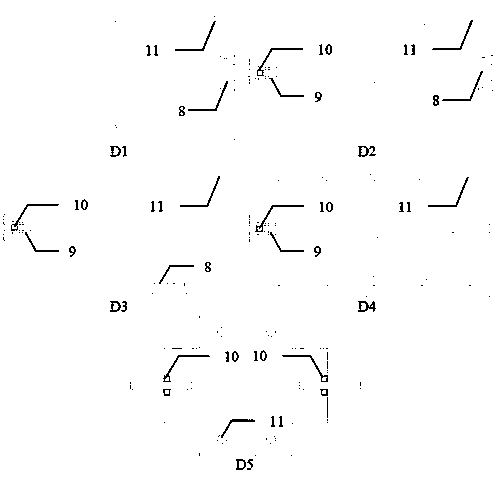

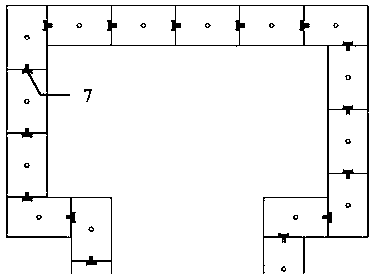

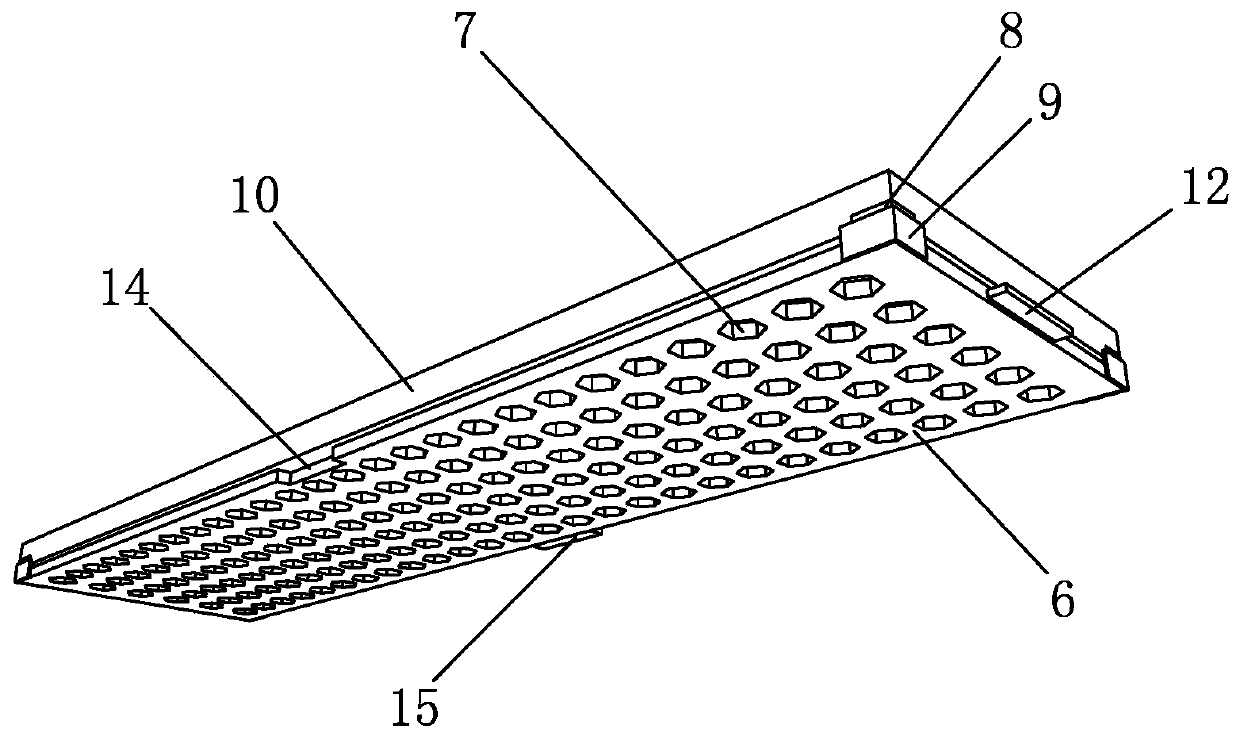

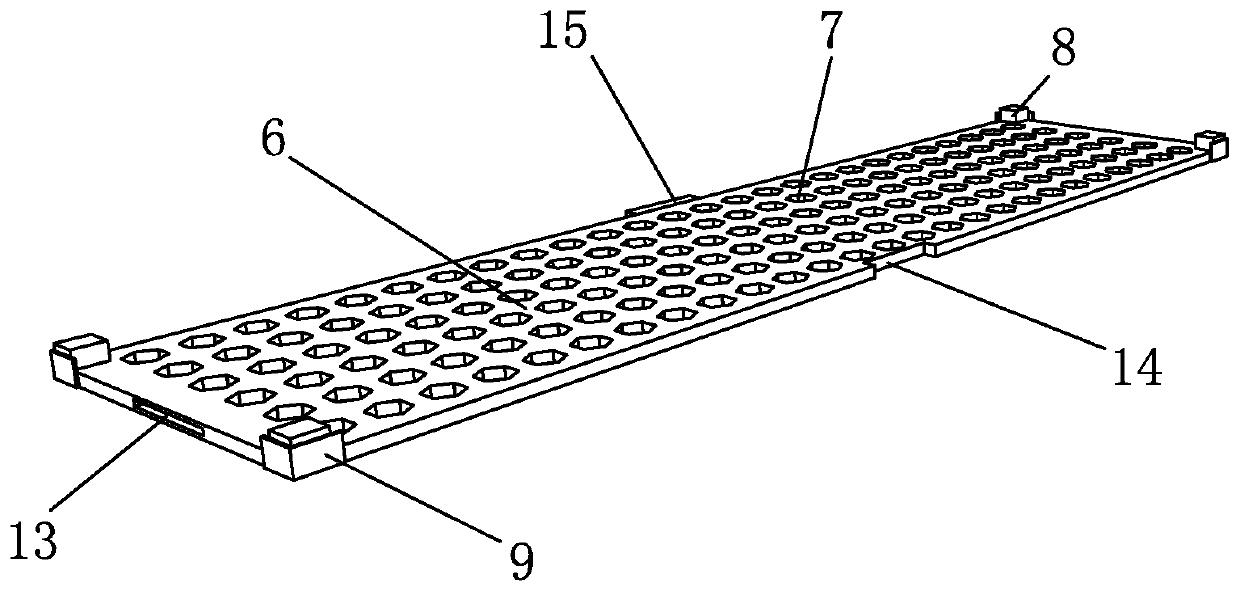

Suspended ceiling system and construction method thereof

ActiveCN104612307AEven by forceStable structureCeilingsBuilding material handlingEngineeringCantilever

The invention provides a suspended ceiling system which is suspended on spherical nodal points of steel structure on a roof. The suspended ceiling system is characterized by comprising a suspended system connected with the spherical nodal points; a diamond unit frame structure system arranged on the lower side of the suspended system; a ribbon board system arranged on the lower side of the diamond unit frame structure system in a lifting mode. The suspended ceiling system is characterized in that the diamond unit frame structure system comprises multiple diamond unit frames which are connected with each other in a splicing mode, the suspended system comprises multiple multi-direction movable cantilever beams which are connected with multiple spherical nodal points respectively, each multi-direction movable cantilever beam is provided with at least two extended frames, and the extended frames are connected with the diamond unit frame arranged on the lower side of the corresponding spherical nodal point in a lifting mode. The suspended ceiling system is forced uniformly in whole, and is firm in structure, good in steady performance, and excellent in displaying the suspended effect.

Owner:中建八局装饰工程有限公司

Respirable high-flame-retardance outer-wall facing material

The invention discloses a respirable high-flame-retardance outer-wall facing material, which comprises redispersible latex powder, an organic-silicon water repellent, methylcellulose ether, a defoaming agent, an air-entraining agent, lignocellulose, a thixotropic lubricant, silicate cement, heavy calcium powder, fly ash, calcium hydroxide, starch ether, calcium formate and colored quartz sand. The respirable high-flame-retardance outer-wall facing material has the advantages of reasonable proportion, energy saving and environmental protection, and not only are the quality and the service lifeof an outer-wall heat-preserving system ensured, and heat-preserving heat-absorbing heat-storing performances are enhanced, but also the service life of a building wall body is greatly prolonged.

Owner:SHANDONG FENGYU ENERGY SAVING MATERIAL MFG

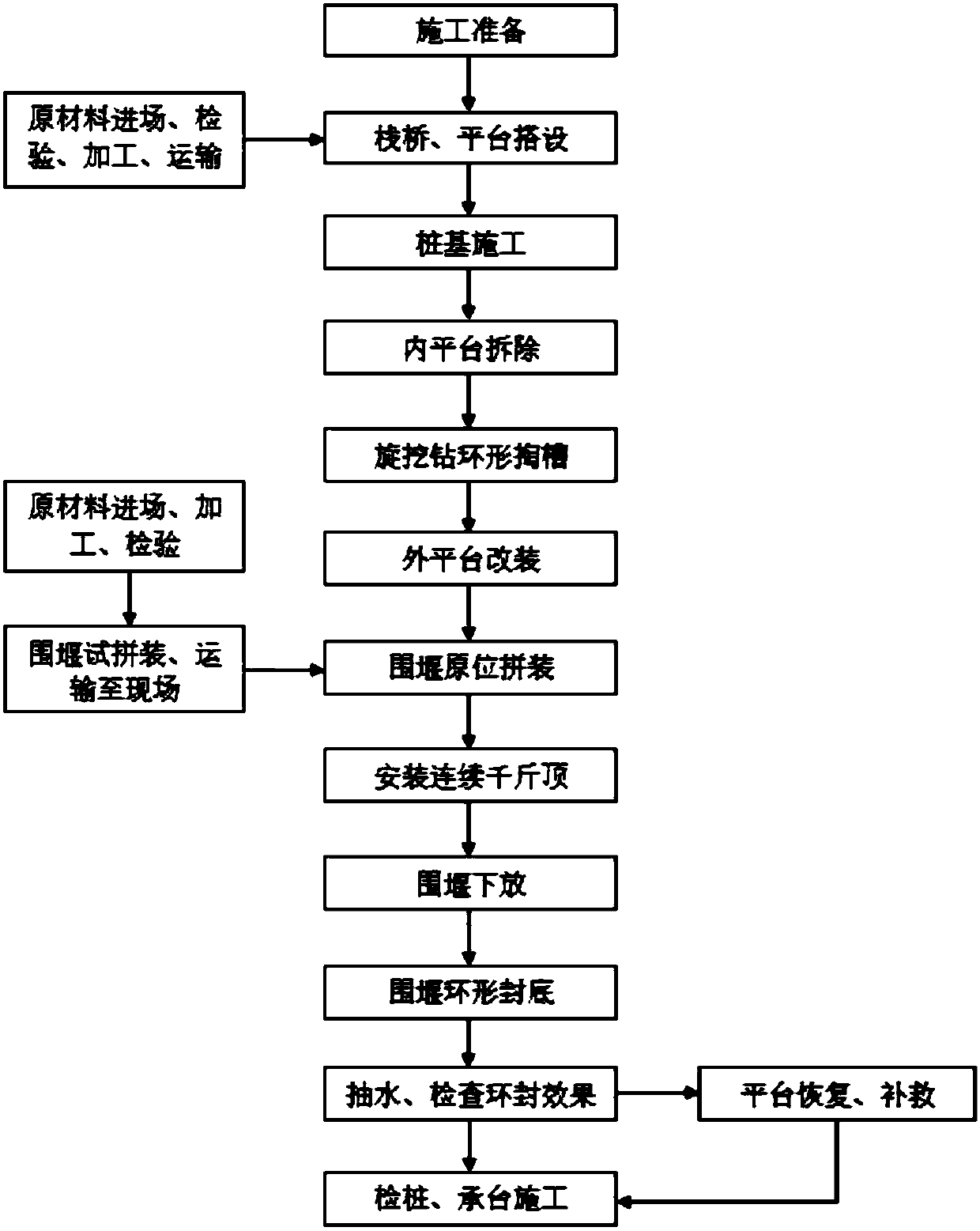

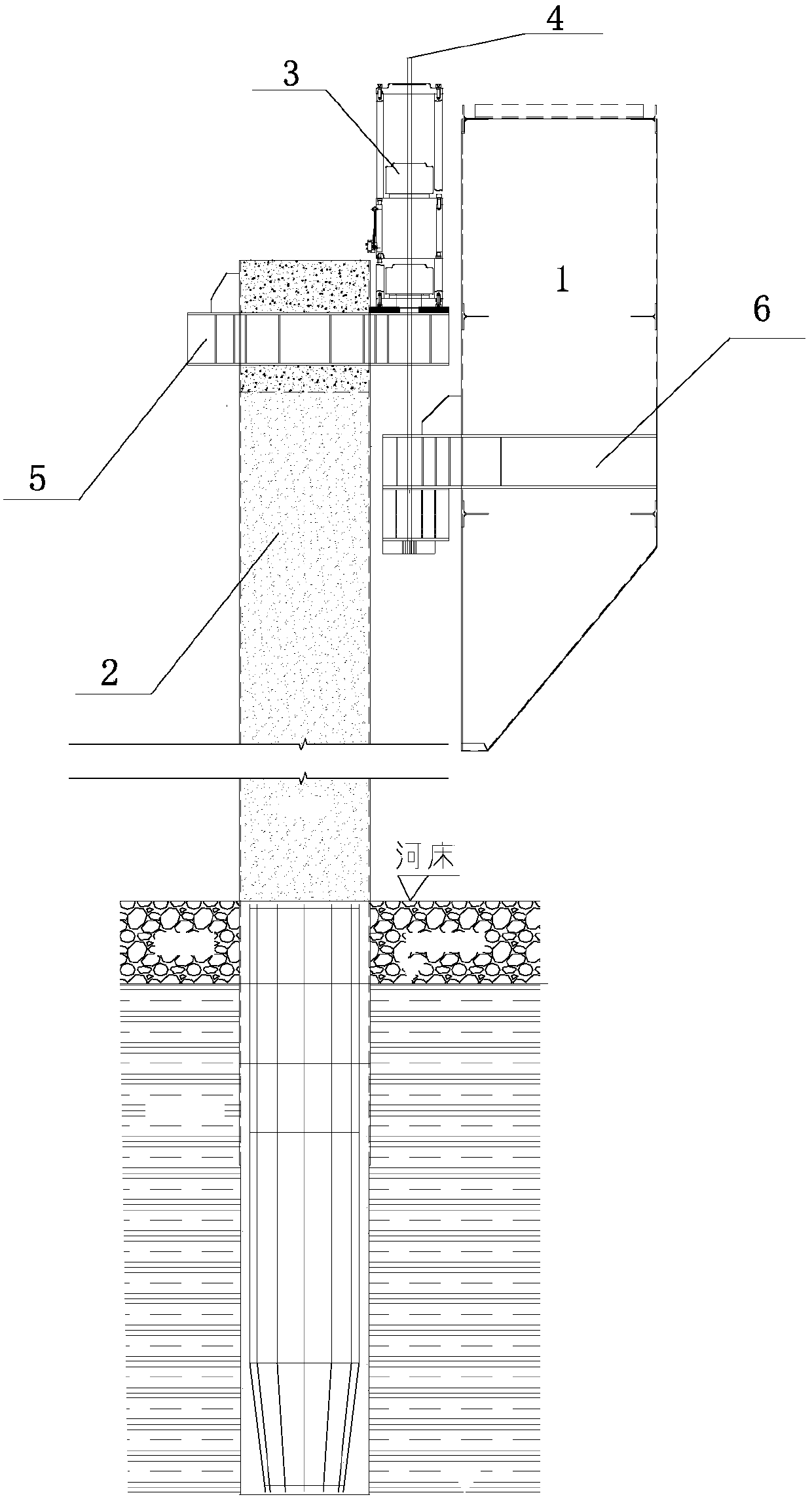

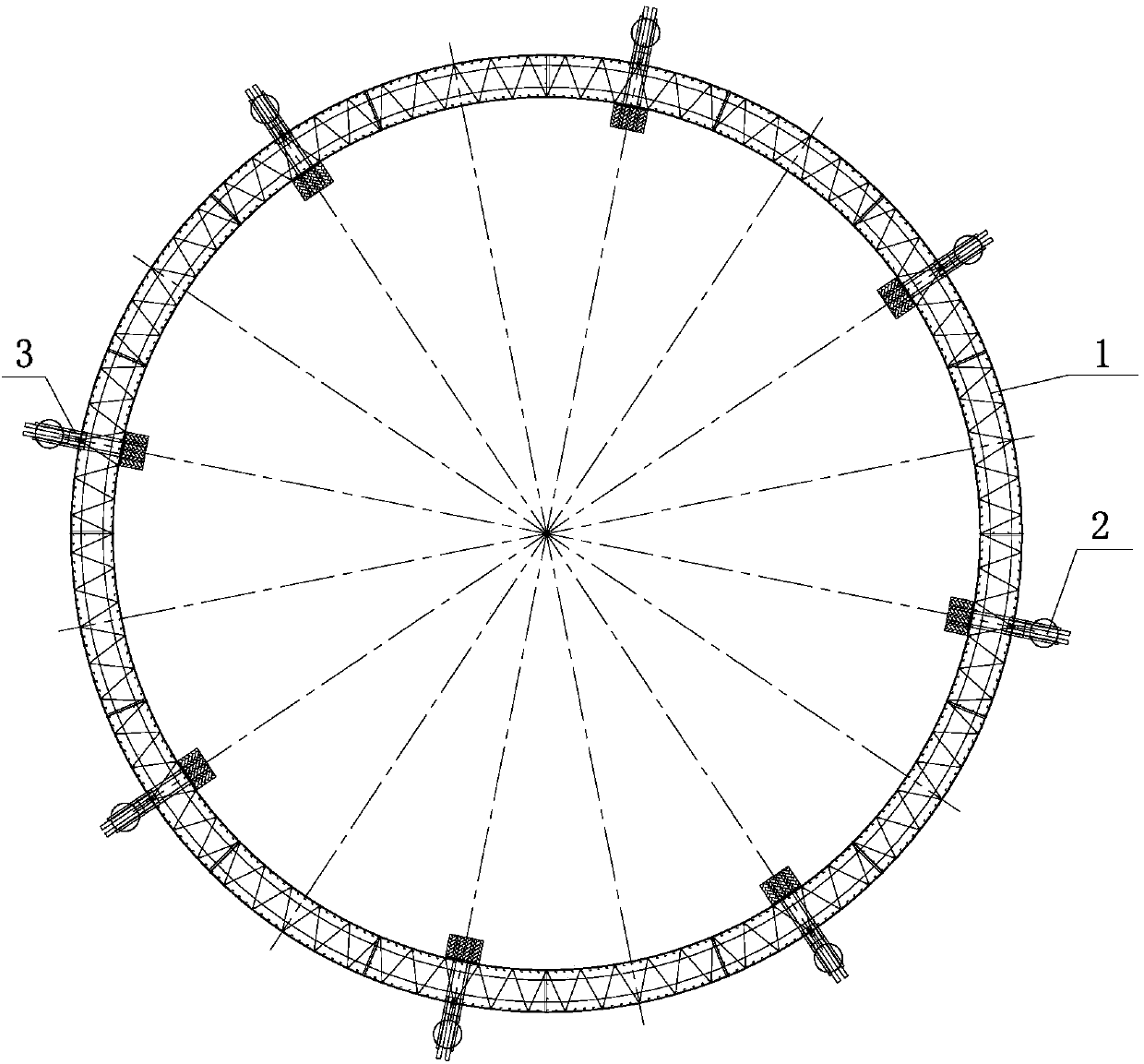

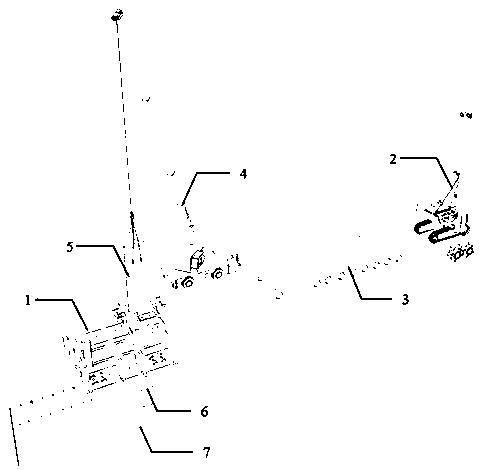

Comprehensive construction method for pre-cut groove loop-sealing double-wall steel cofferdam deep water foundation

ActiveCN107869144AHarm reductionReduce construction difficultyFoundation engineeringHydro energy generationArchitectural engineeringCofferdam

The invention discloses a comprehensive construction method for a pre-cut groove loop-sealing double-wall steel cofferdam deep water foundation. The method includes the following steps that (1) a trestle and a platform are set up; (2) pile foundation construction is performed; (3) a rotary excavating drill is used for precutting of grooves in a riverbed at the double-wall steel cofferdam blade foot position; (4) cofferdam splicing is conducted; (5) a cofferdam tripping system and a continuous jack are installed; (6) cofferdam tripping is carried out; and (7) the cofferdam bottom is sealed. According to the comprehensive construction method for the pre-cut groove loop-sealing double-wall steel cofferdam deep water foundation under complicated geological conditions, the construction technological level is perfected and improved, the purpose that the construction technology is advanced, reasonable, economical and safe is achieved, experience is provided for similar construction, and an important guiding function is provided for deep water foundation construction and cofferdam construction works.

Owner:中铁二十二局集团第四工程有限公司 +1

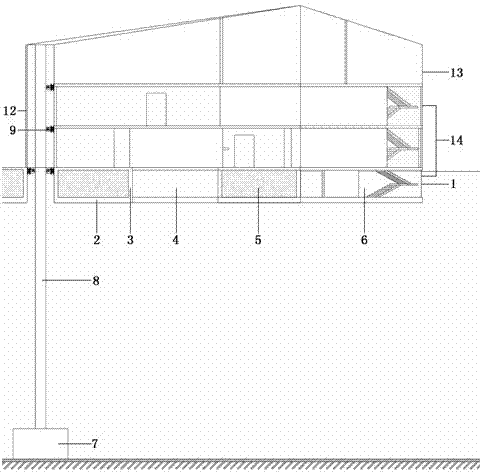

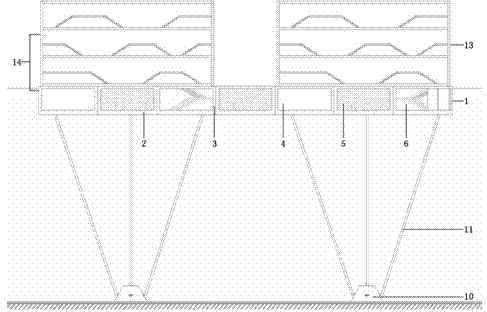

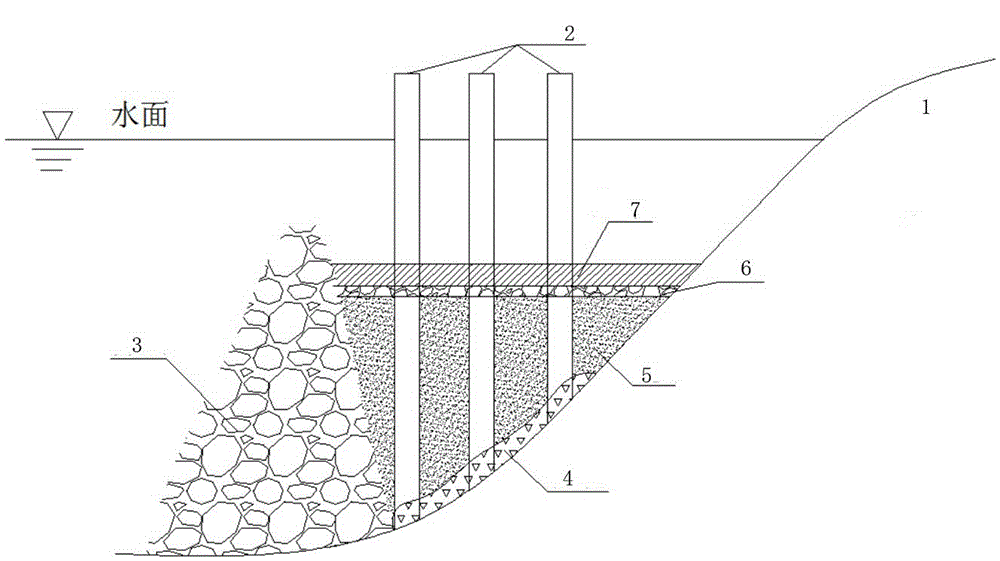

Floating building structure and construction method

InactiveCN103786842AActive connectionMeet bottom buoyancyFoundation engineeringFloating buildingsCoal miningNatural disaster

The invention discloses a floating building structure and a construction method. The floating building structure and the construction method are suitable for floating building structures and construction in coal mining subsidence water areas. The building structure comprises a floating base, a structure body and a floating module. The floating base and the structure body borne by the floating base compose the floating module and are fixed through an underwater gravity type foundation. The gravity type foundation is connected with the floating module through a traction part or connected in an inserted mode through a pile foundation. The construction method includes the following steps that the structure body is borne by the floating base and the position of the structure body is fixed through the traction part or the pile foundation. The floating building structure and the construction method have the advantages that a water floating construction mode has the advantages of being advanced in construction technology, strong in anti-permeability, light in dead weight, good in durability, strong in flexibility and the like on the building technology level, the building can be protected to some extent, and damage caused by natural disasters such as floods can be well dealt with. The problem of resident placement of a coal mining subsidence area can be solved locally, and a novel construction manner and a novel residential pattern are provided for urbanization. New living space is expanded, the requirement for construction land is met, and the contradiction between people and the land is relieved.

Owner:CHINA UNIV OF MINING & TECH

Middle roof modular structure in railway vehicle and railway vehicle

ActiveCN104527679AHigh degree of modularityImprove construction technologyRailway roofsRailway heating/coolingFlueModular structure

The invention relates to a middle roof modular structure and a railway vehicle. The middle roof modular structure comprises a middle roof plate. The two sides of the middle roof plate are fixedly provided with lamp belts, hanging beams are fixedly arranged on the positions above the lamp belts, the middle roof plate, the lamp belts and the hanging beams are of a U-shaped structure as a whole and hung on a vehicle roof steel structure. According to the middle roof modular structure and the railway vehicle, the middle roof plate, the lamp belts and an air flue inner cavity are integrated to form the modular structure, the modular structure is high in modular degree, the assembling efficiency can be improved greatly, and the production cost is lowered.

Owner:CRRC QINGDAO SIFANG CO LTD

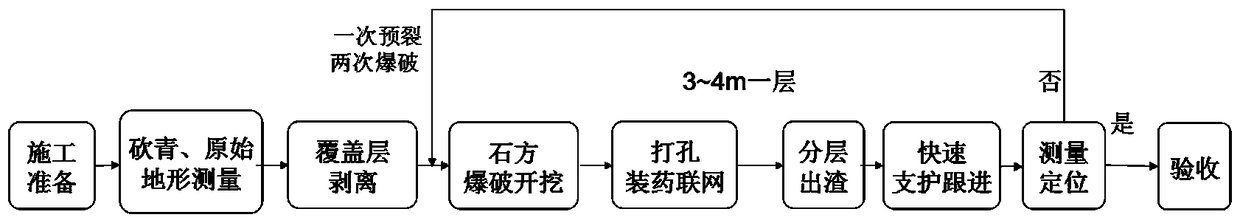

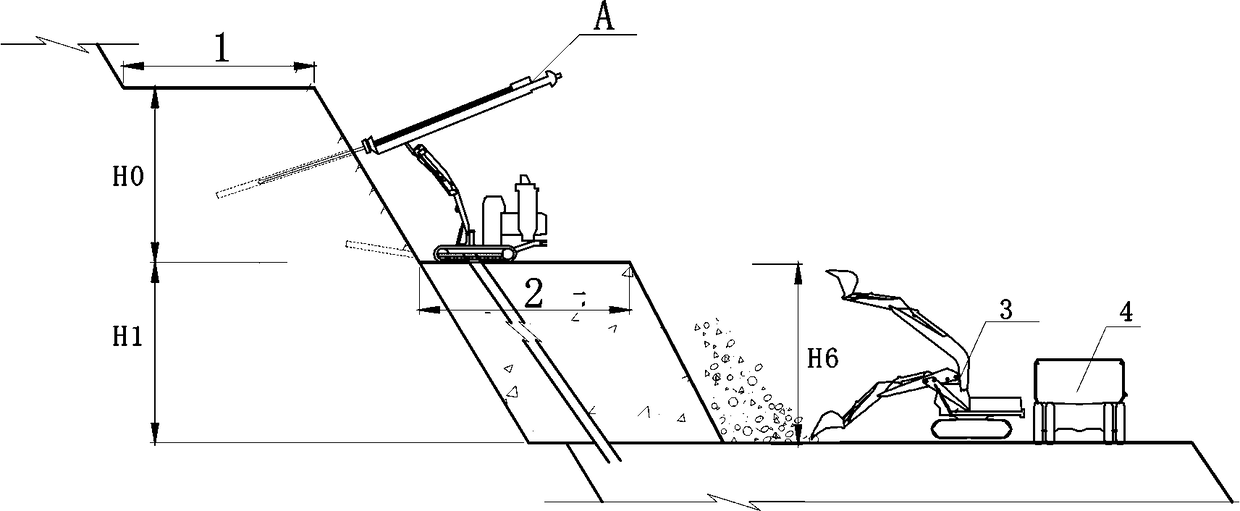

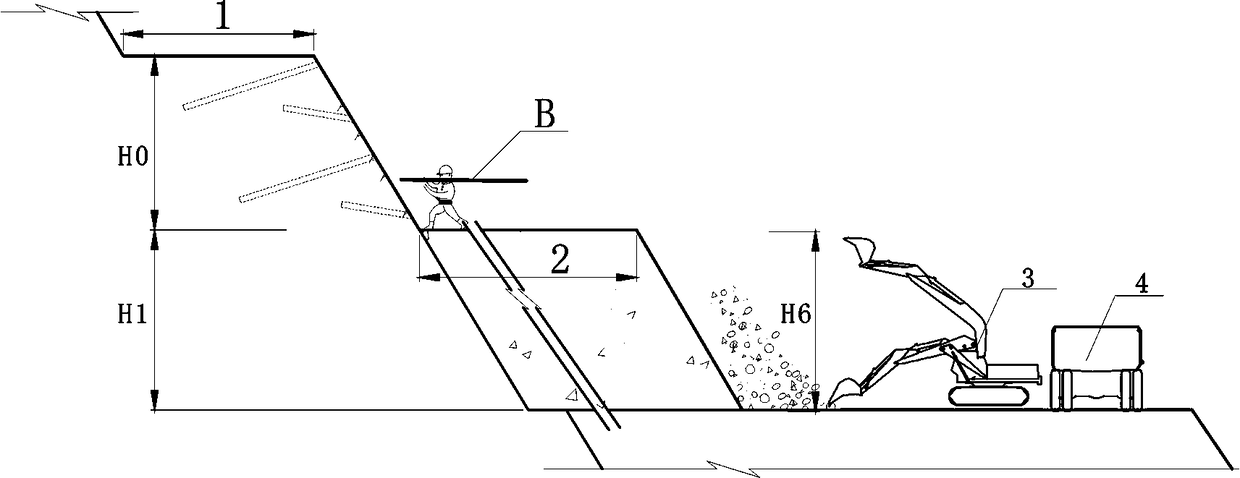

Slope excavation and support fast tracking construction method

InactiveCN108612114AGuaranteed to be scientificPrevent layer-by-layer slippageExcavationsBulkheads/pilesGeomorphologyFast tracking

The invention provides a slope excavation and support fast tracking construction method and relates to the technical field of high slope excavation construction. A CM351 drilling machine is used for rapidly drilling a hole as the core; the high slope fast excavation and support technology is implemented according to the principles of primary presplitting (at the height of 15 m), secondary blasting( the blasting height being 7-8 m per time), layered deslagging ( 3-4 m per layer), platform reserving, bent frame elimination, and support tracking. A bent frame is omitted. The drilling machine cancomplete pore forming operation of anchor rods and drainage holes on the excavated platform (or blasted rock ballast). The requirements for fast construction of water conservancy and hydropower highslope excavation and support are met on the premise of guaranteeing the safety quality.

Owner:中国葛洲坝集团建设工程有限公司

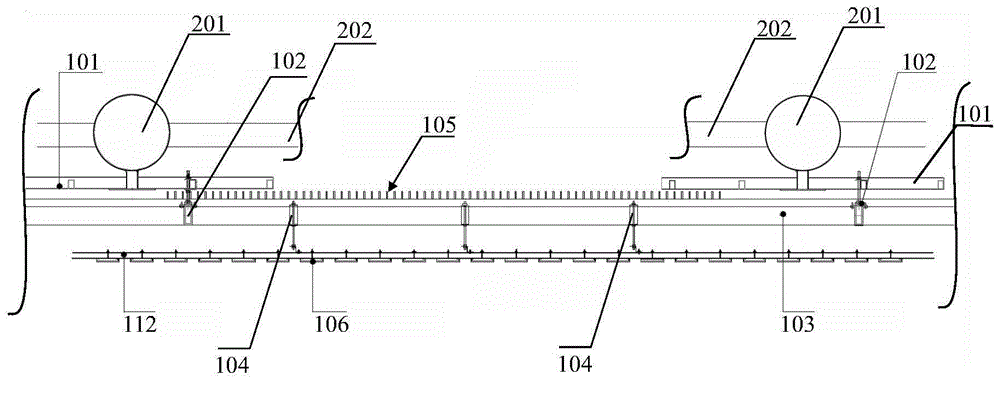

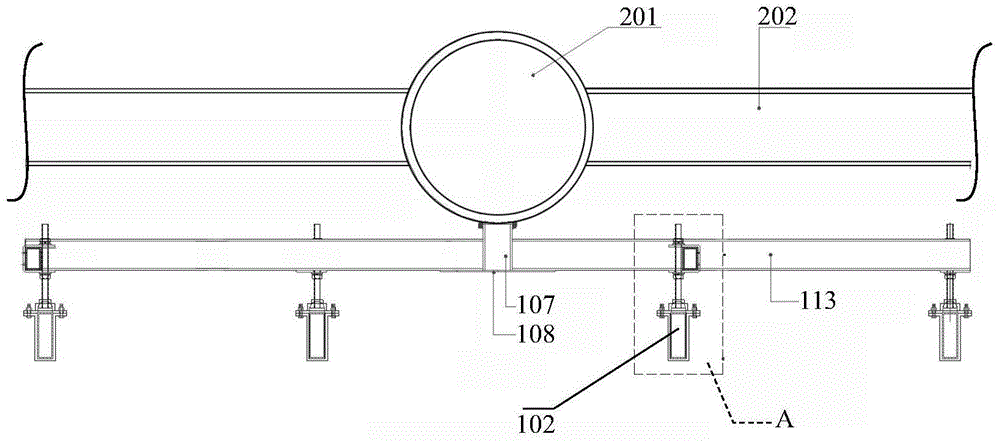

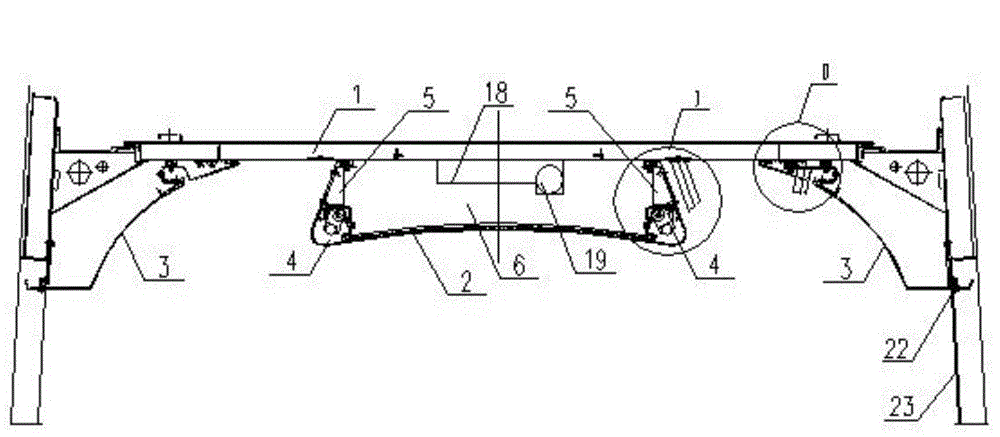

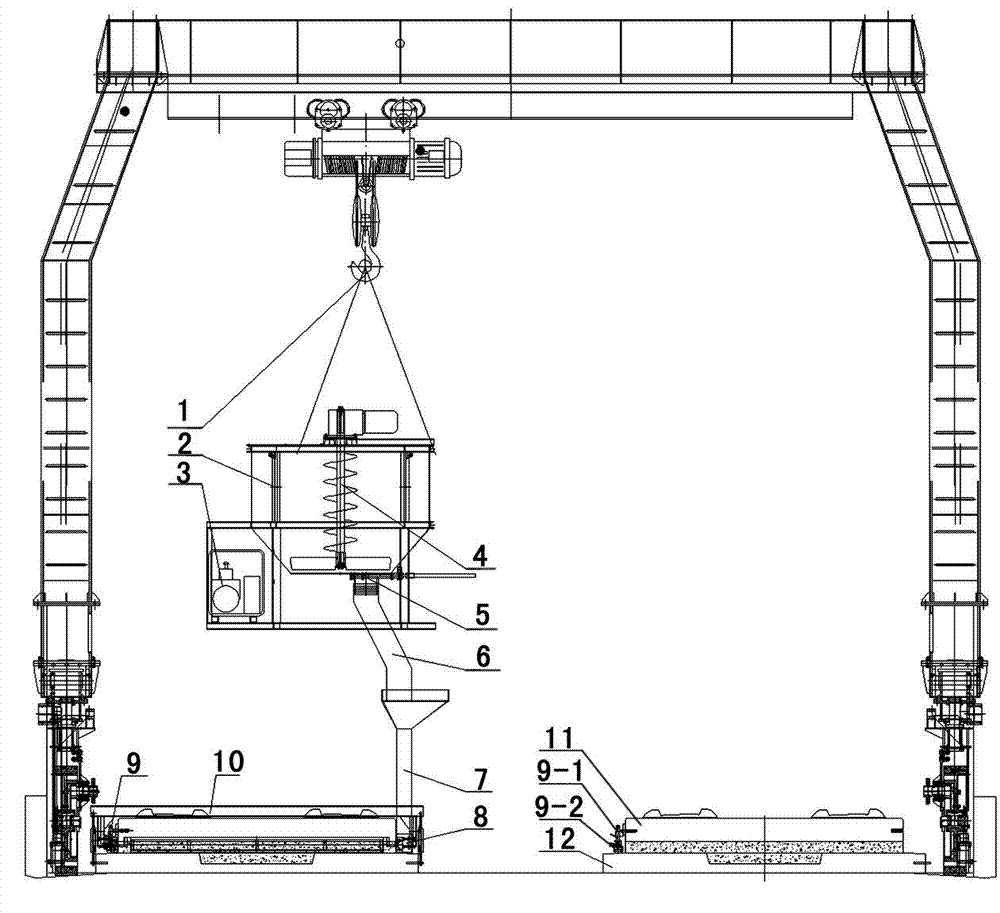

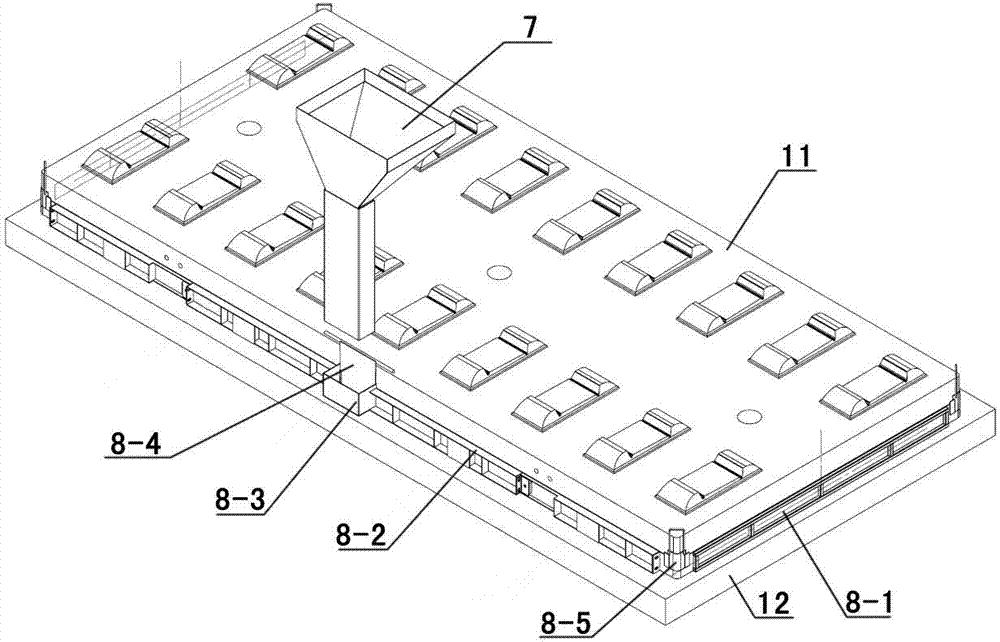

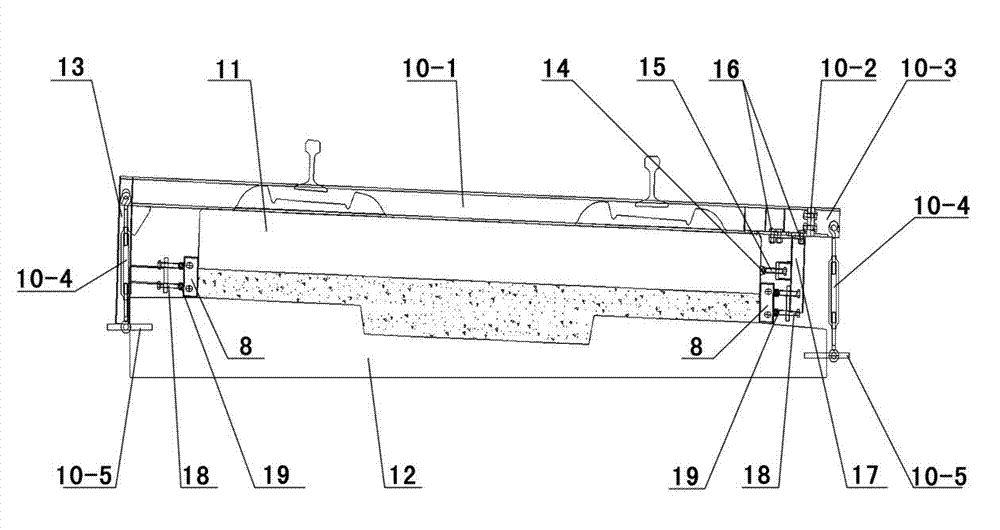

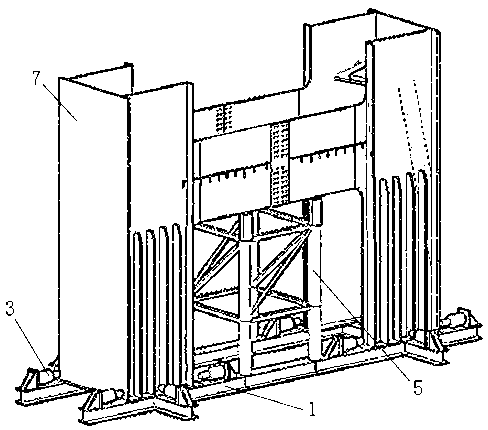

CRTS III type slab ballastless track self-compacting concrete casting tooling and method

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

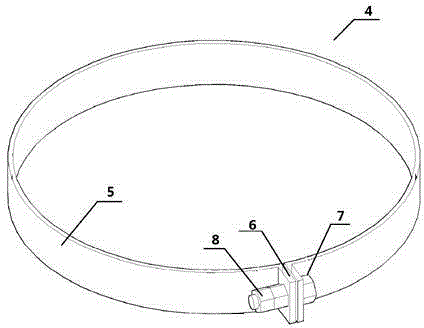

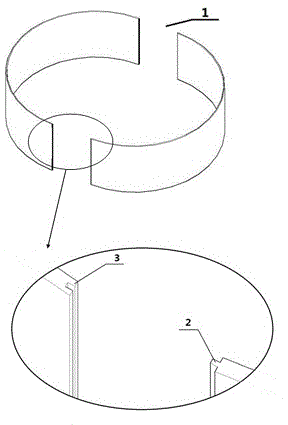

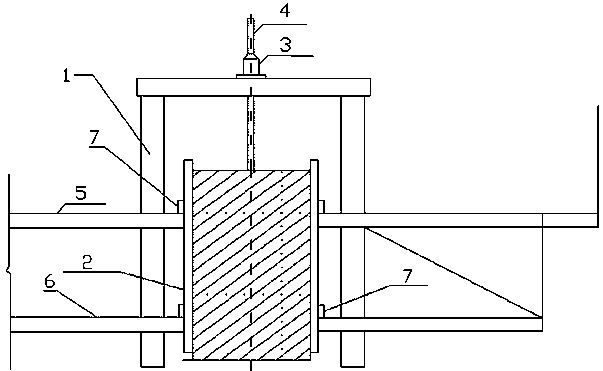

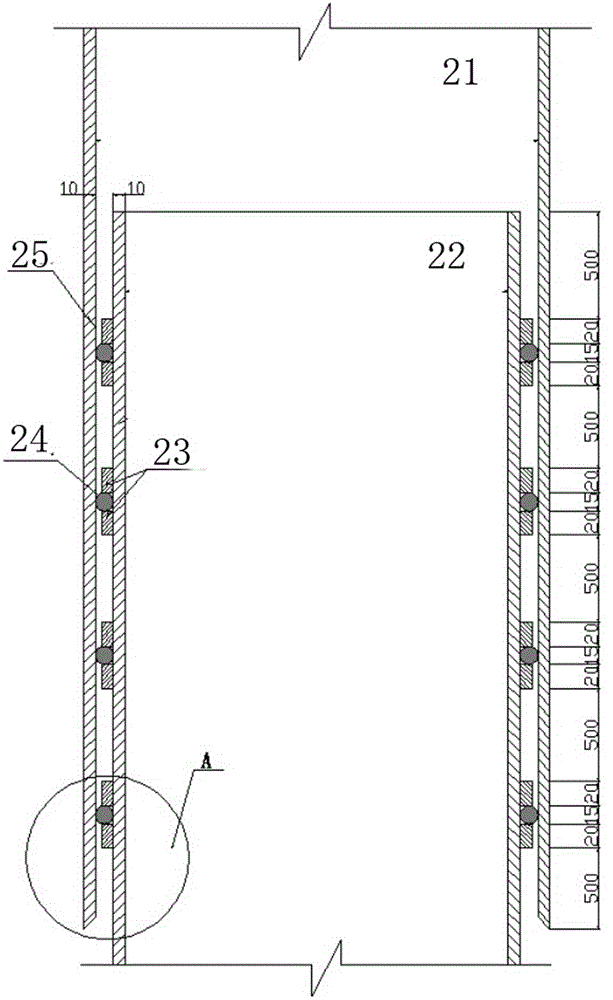

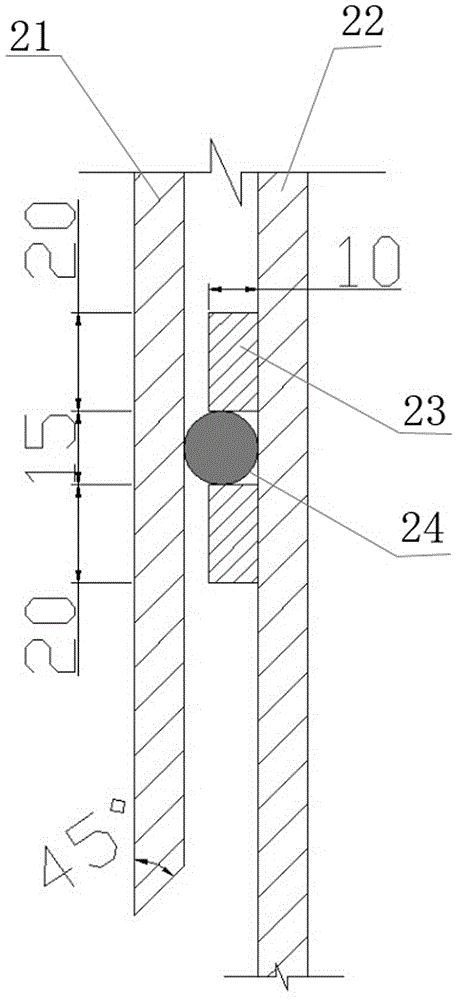

Construction structure of cylindrical die

InactiveCN104563496ASimple materialEasy constructionForms/shuttering/falseworksBuilding scaffoldsFalseworkEngineering

The invention discloses a construction structure of a cylindrical die, relates to the technical field of building construction and relates to design technology of an auxiliary tool for building construction, in particular to the construction structure of the cylindrical die. The construction structure is characterized in that the outer side of a hollow cylindrical template is fastened by muffling the template by steel strip post hoops at equal intervals; the hollow cylindrical template is vertically inserted into the middle of a dual-row scaffold; templates are overlapped to required height, and seams are connected by the steel strip post hoops; at the two thirds elevation of the cylindrical die, a throwing support structure used for guaranteeing the perpendicularity and the stability of a post is arranged. The construction structure has the positive effects that a post hoop material is simple, construction is convenient to perform, and a cylinder reinforcing effect is good; the safety of workers during construction can be guaranteed by the dual-row scaffold which encloses a cylinder; throwing support steel pipes and short steel pipes form a whole, so that the stability of the cylinder and the perpendicularity of concrete can be effectively controlled; the problem of poor reinforcing quality of a cylinder in a construction field is solved by the structure, and the construction process is improved.

Owner:ZHONGTIAN CONSTR GROUP

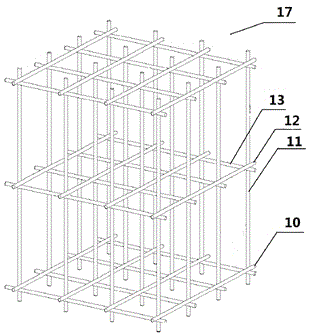

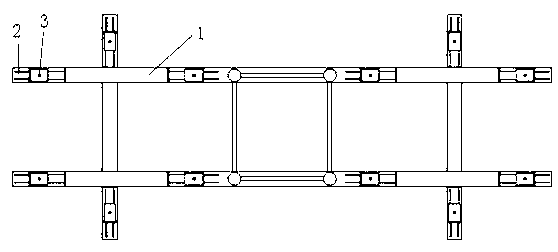

Three-way positioning device for base steel anchor box

ActiveCN103306204AImprove construction technologyEasy to operateBridge structural detailsFlat jointVertical edge

The invention discloses a three-way positioning device for a base steel anchor box. The three-way positioning device comprises a profile steel base, a steel pipe bracket system and a jack fine-adjustment system, wherein concrete embedded steel plates are welded at the bottom of the profile steel base and arranged in a # shape; the steel pipe bracket system comprises steel pipes and flat joints; the four steel pipes are vertical to the middle of the profile steel base respectively; the flat joints are arranged on the four steel pipes and divided into upper and lower layers; the jack fine-adjustment system comprises jacks and jack rear seats; the number of the jacks is 16; the 12 jacks are arranged on the jack rear seats welded on the profile steel base; the 8 jacks are arranged in an X-axis direction; the 4 jacks are arranged in a Y-axis direction; and the rest 4 jacks are flat jacks and are arranged at the two edges on the inner sides of the two vertical edges of the # shape of the profile steel base in a z-axis direction respectively and directly arranged on the bottom concrete surface. The three-way positioning device solves the problem of difficulty for positioning in the cable tower base steel anchor box, has the characteristics of simplicity for operation, convenience for construction, accuracy for positioning, high work efficiency and the like, lowers the construction difficulty and saves the construction cost.

Owner:THE SECOND CONSTR OF CTCE GROUP +2

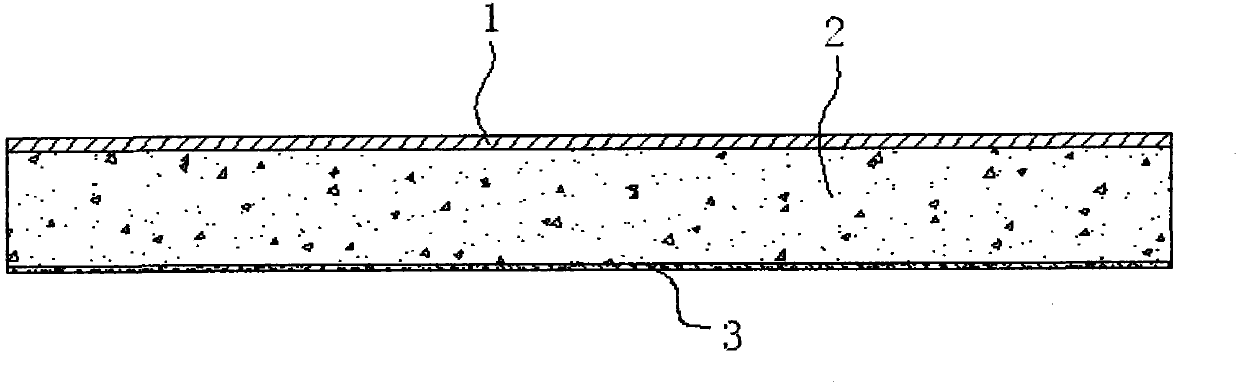

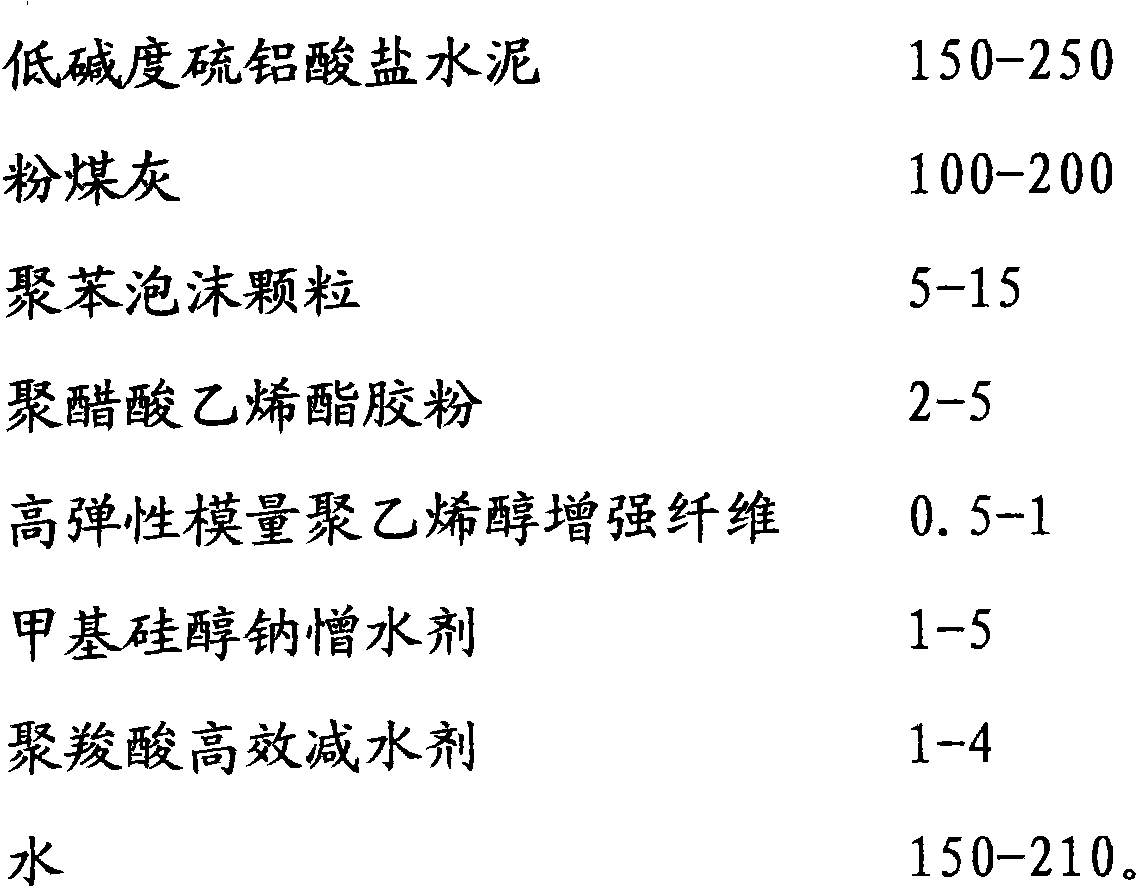

Composite insulation board and production method thereof

InactiveCN104863277AGood thermal performanceRealize integrationSolid waste managementHeat proofingCalcium silicateFiber

The invention discloses a composite insulation board and a production method thereof. The composite insulation board is formed by compositing a calcium silicate panel, glass fiber gridding cloth and lightweight concrete. The production method of the composite insulation board comprises steps as follows: the alkali-resistant glass fiber gridding cloth is fixed on an inner parathion of a vertical mold, and the calcium silicate panel with bonding holes leans in the mold; fly ash, polyphenyl foam particles, low-alkalinity sulphoaluminate cement, polyvinyl acetate glue powder, polyvinyl alcohol reinforced fibers with high modulus of elasticity, a sodium methylsilanolate water repellent, an efficient polycarboxylic acid water reducer and water are sequentially added to a stirrer in proportion and evenly stirred to form slurry; the slurry is pumped into a vertical mold through a high-pressure slurry pump; the slurry is demolded after curing and hardening and subjected to film winding, packaging and curing. The composite insulation board is high in strength and good in thermal insulation and fire prevention; the production method is simple and easy to implement due to adoption of ingredient stirring and pouring molding by the vertical mold. During usage, the construction technology is simple, the speed is high, time and labor are saved, and the economic benefit is significant.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

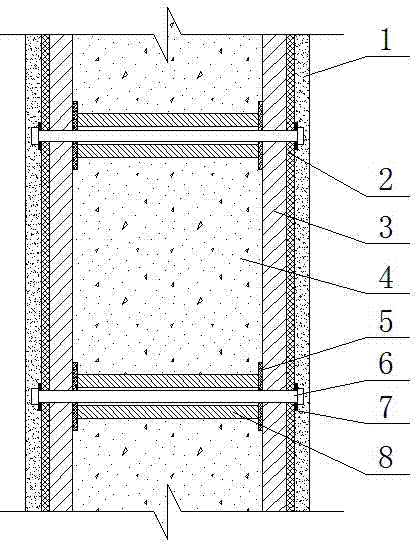

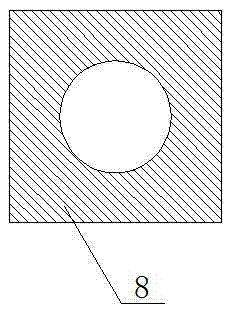

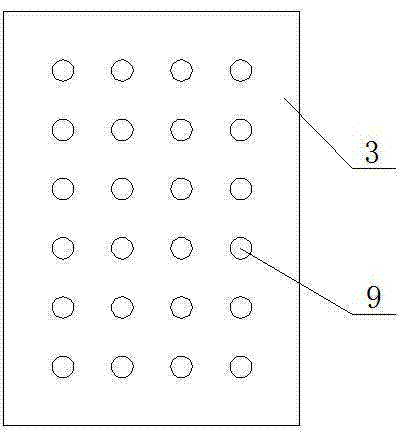

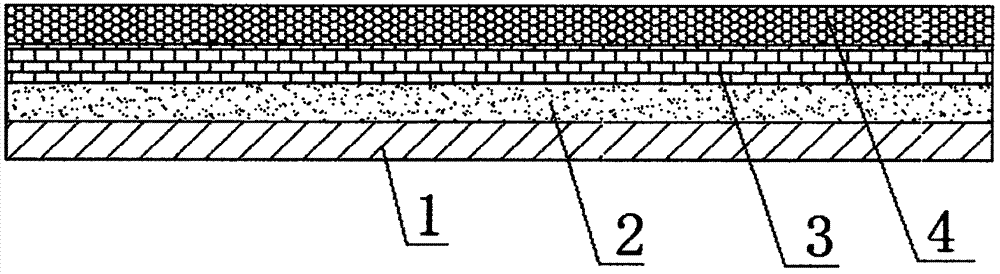

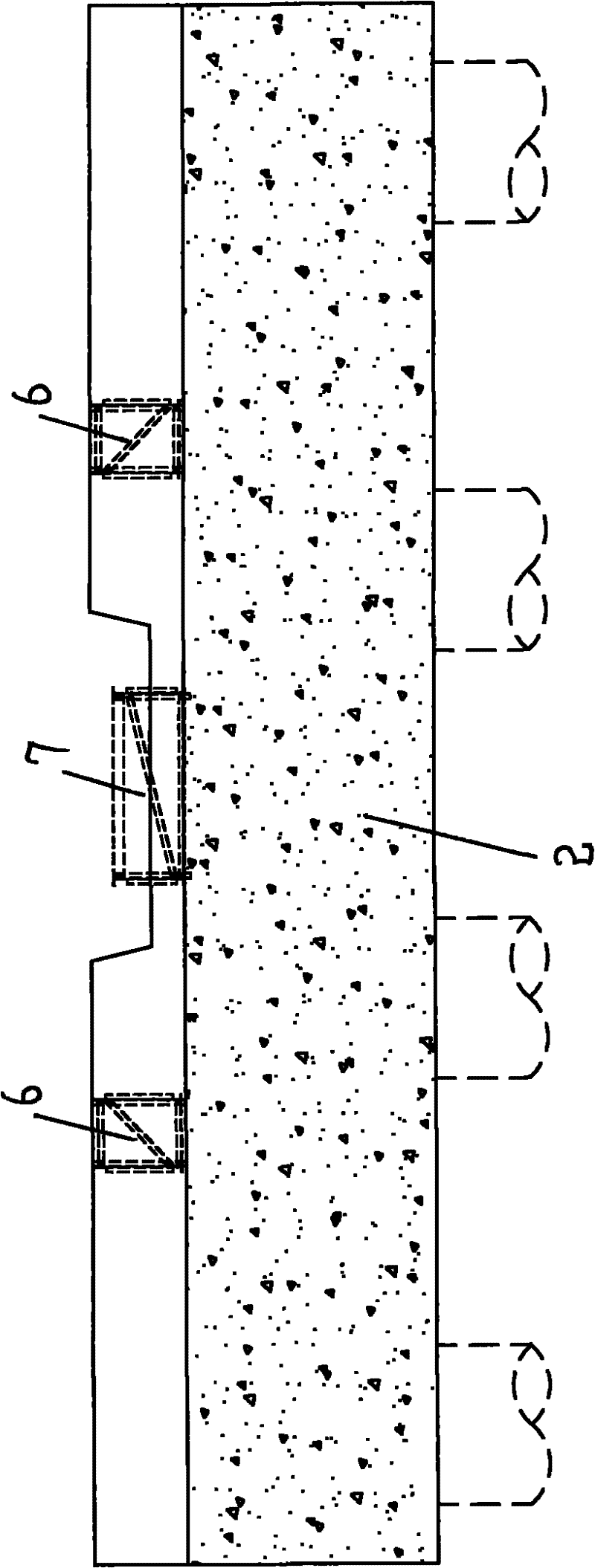

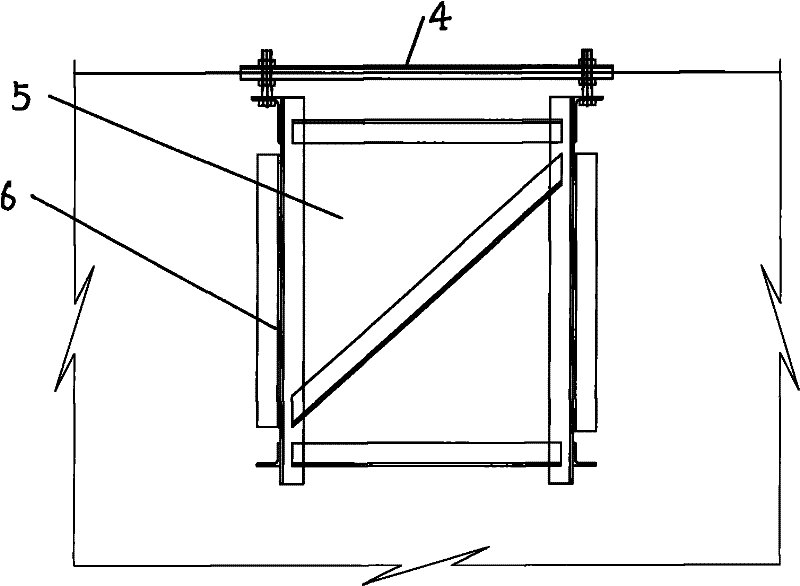

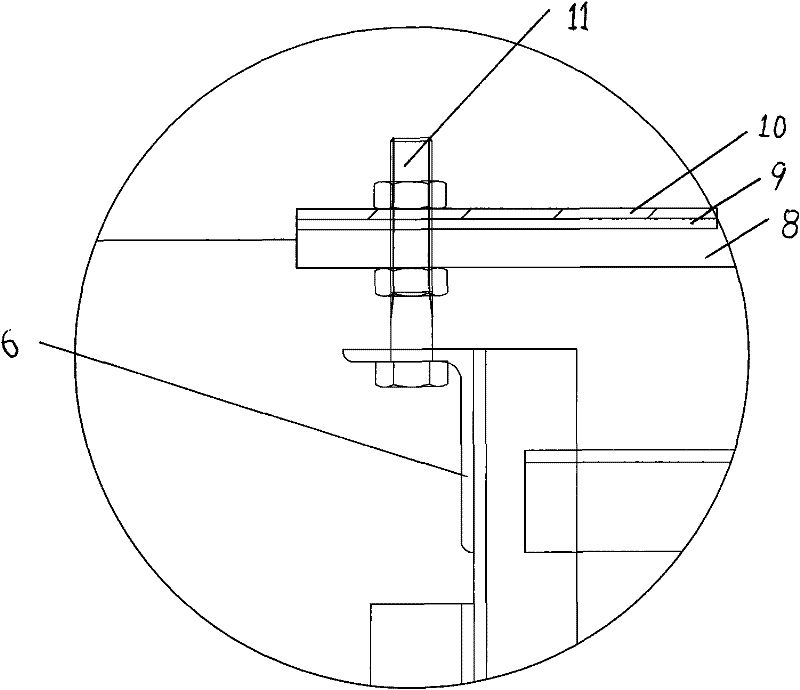

Die plate dismantling-free cast-in-place concrete partition wall and construction method thereof

The invention relates to a die plate dismantling-free cast-in-place concrete partition wall. The die plate cast-in-place concrete partition wall comprises a wall body and a surface layer, wherein the wall body consists of cast-in-place concrete and dismantling-free die plates; each dismantling-free die plate is fixed by a die plate pull rod; each die plate pull rod penetrates through a die plate cushion block positioned between the dismantling-free die plates; the cast-in-place concrete is cast in a gap between the dismantling-free die plates on both sides; an inner gasket is arranged on a position, where each die plate pull rod penetrates through the corresponding dismantling-free die plate, on the inner side of each dismantling-free die plate and the outer side of each die plate cushion block; an outer gasket is also arranged on a position, where each die plate pull rod penetrates through the corresponding dismantling-free die plate, on the outer side of the corresponding dismantling-free die plate.

Owner:SHANDONG UNIV OF SCI & TECH +1

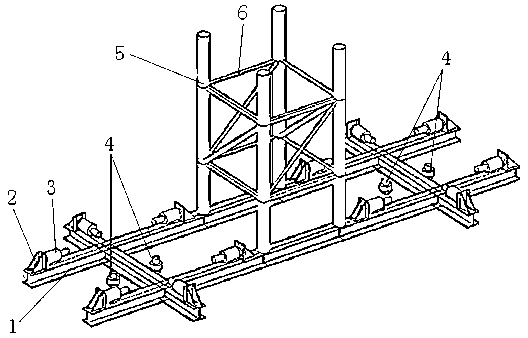

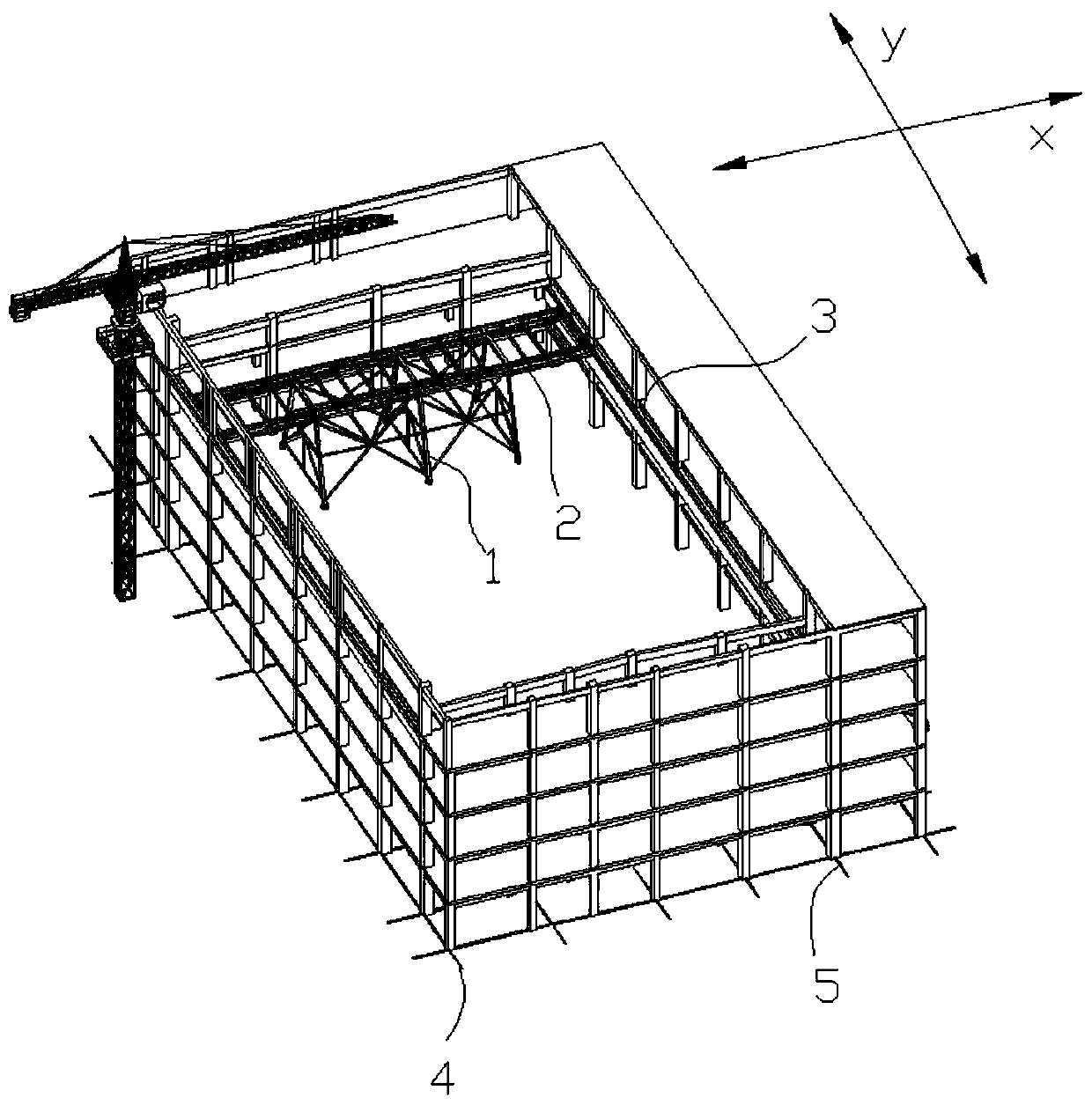

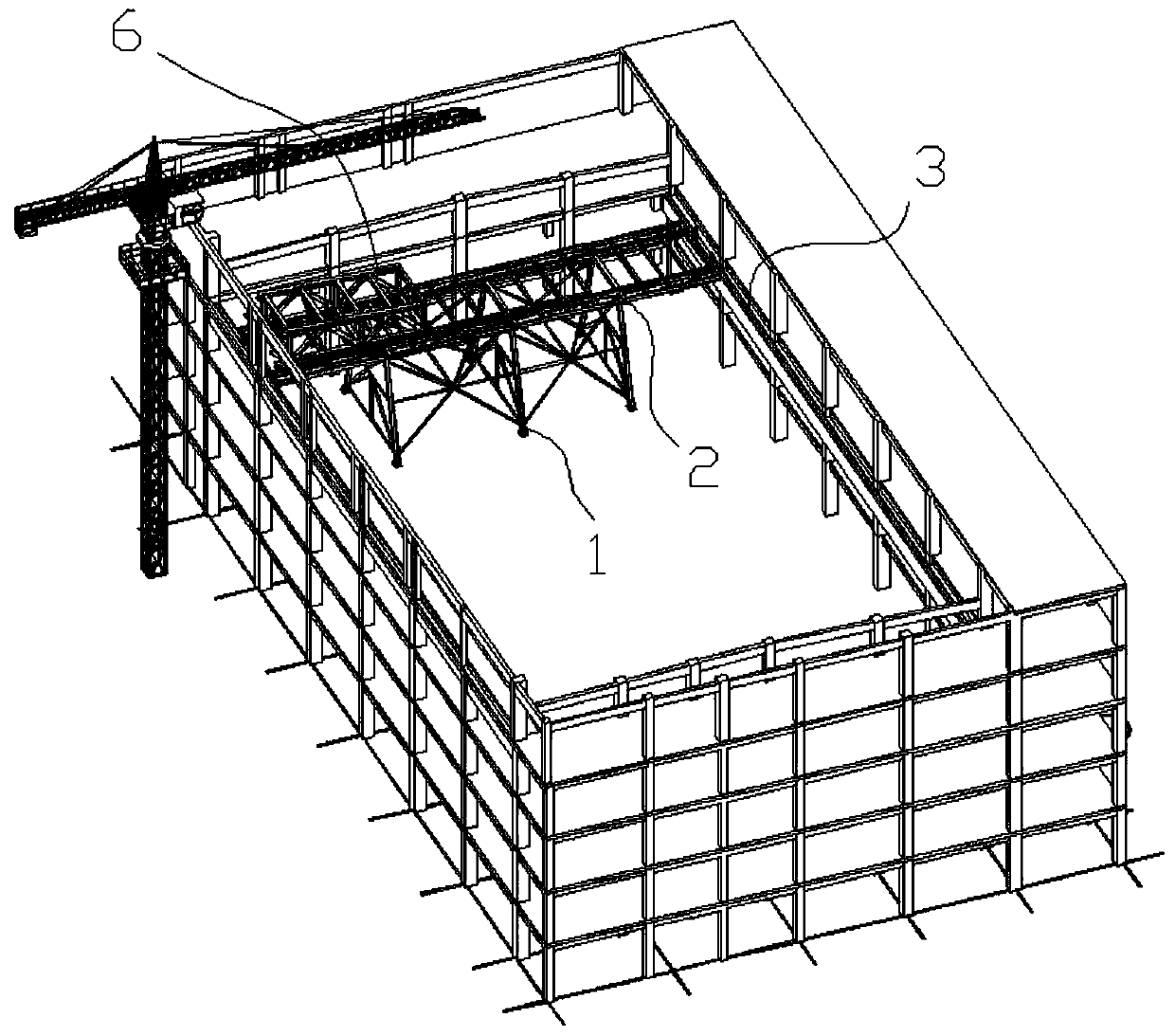

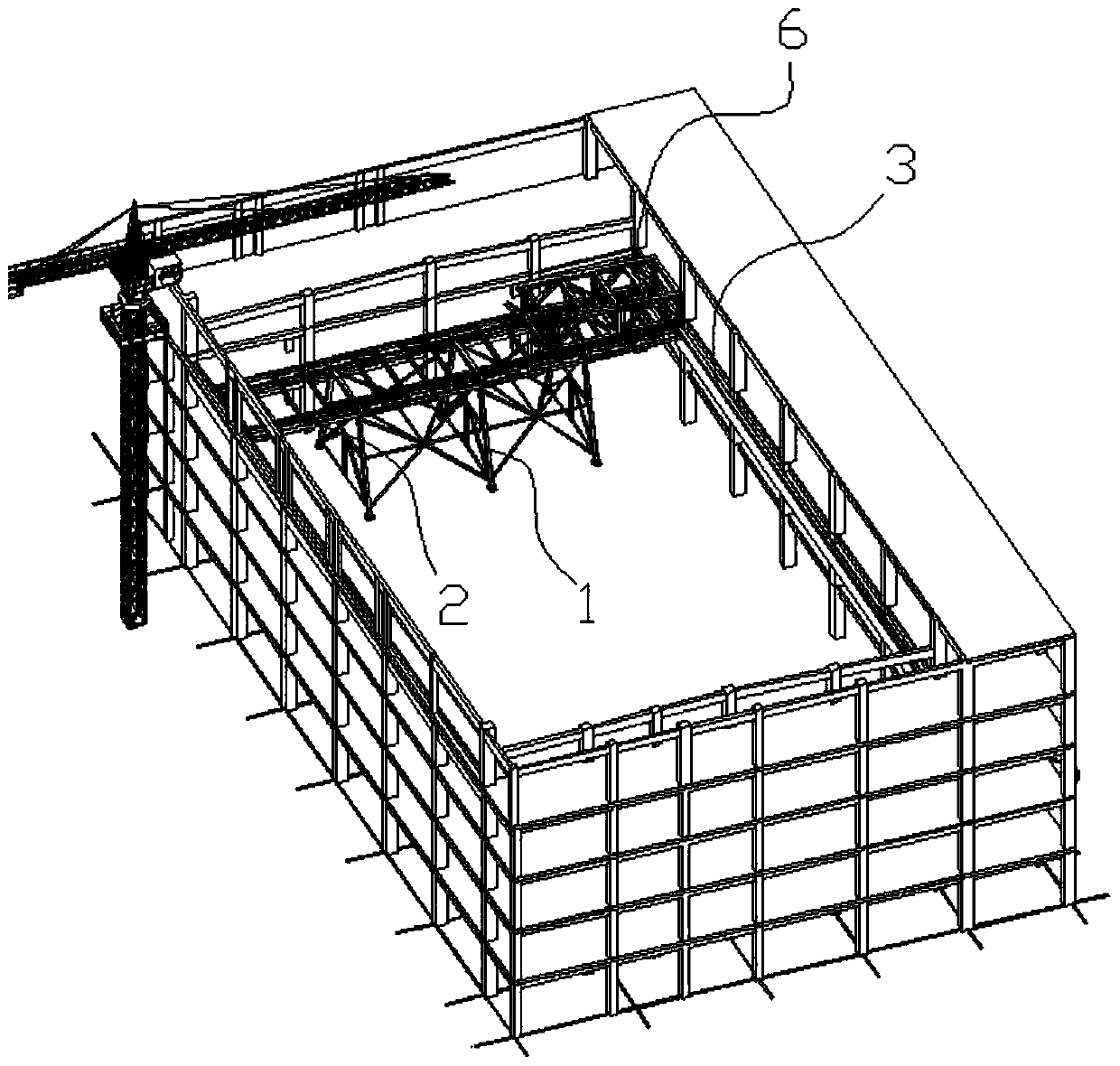

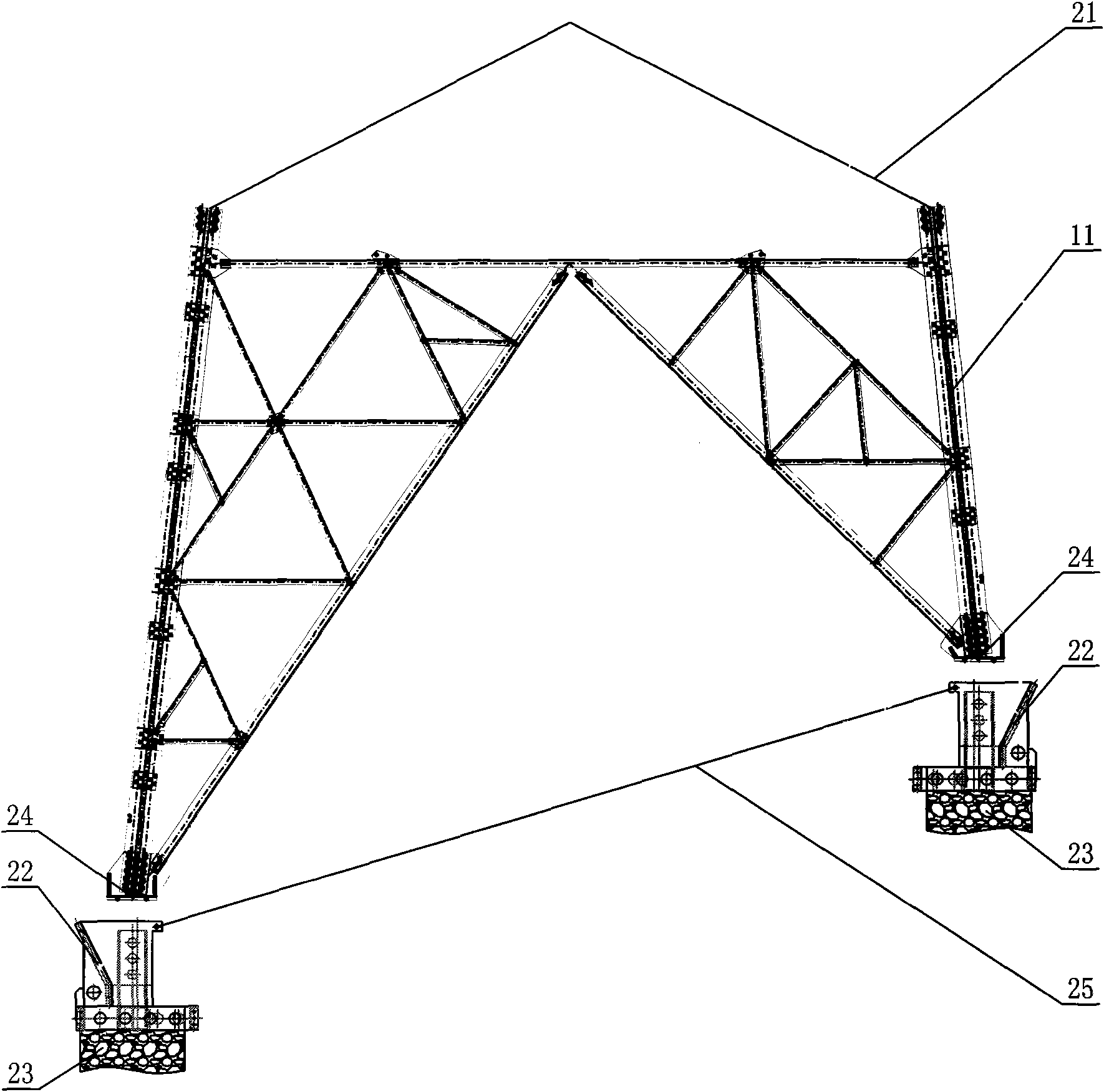

Large-span truss construction method and large-span truss structure

ActiveCN110847375AReduce construction costsFast constructionBuilding constructionsEngineeringLong span

The invention discloses a long-span truss construction method and a long-span truss structure. The construction method includes steps that a, preparatory workis performed, specifically, a1, supportingscaffolds are erected, a2, lateral sliding tracks are laid, and a3, longitudinal sliding tracks are laid; b, truss assembly and lateral sliding are performed, specifically, b1, space stabilizing frames are assembled, b2, the space stabilizing frames are subjected to synchronous traction to slide, and b3, the steps b1 and b2 are repeated to form a group frame; c, jacking in position and track transition of the group frame are performed, specifically, c1, the group frame is jacked in position and then supporting legs are installed on the group frame, and c2, the group frame is placed on the longitudinal sliding tracks; and d, longitudinal sliding of the group frame and frame assembly forming are performed, specifically, d1, the group frame is slid, d2, the group frame is jacked up and supports are cut off and the tracks are partially slid, and then finished supports are installed on the group frame, and d3, the steps d1 and d2 are repeated, and a frame assembly is formed.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

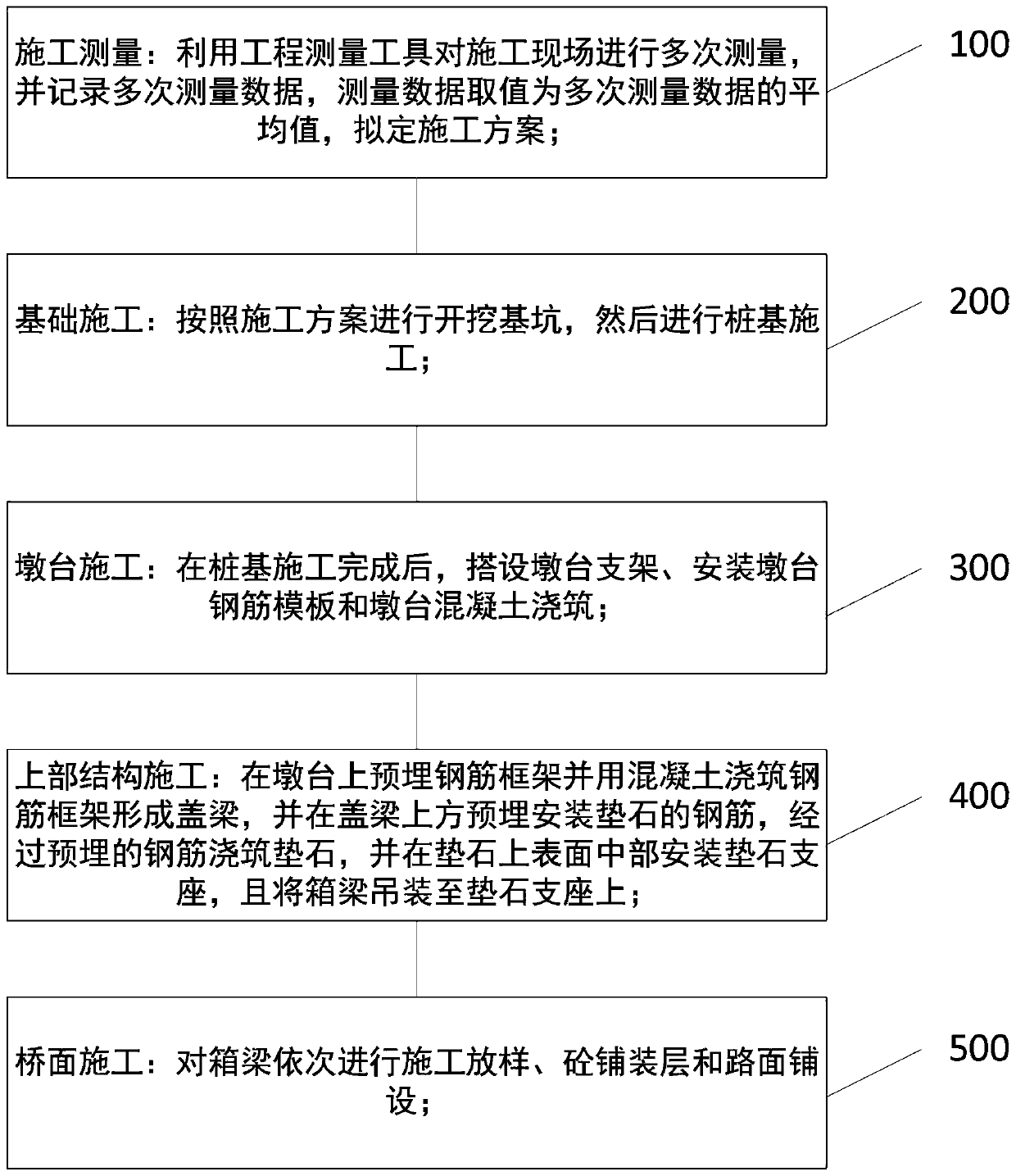

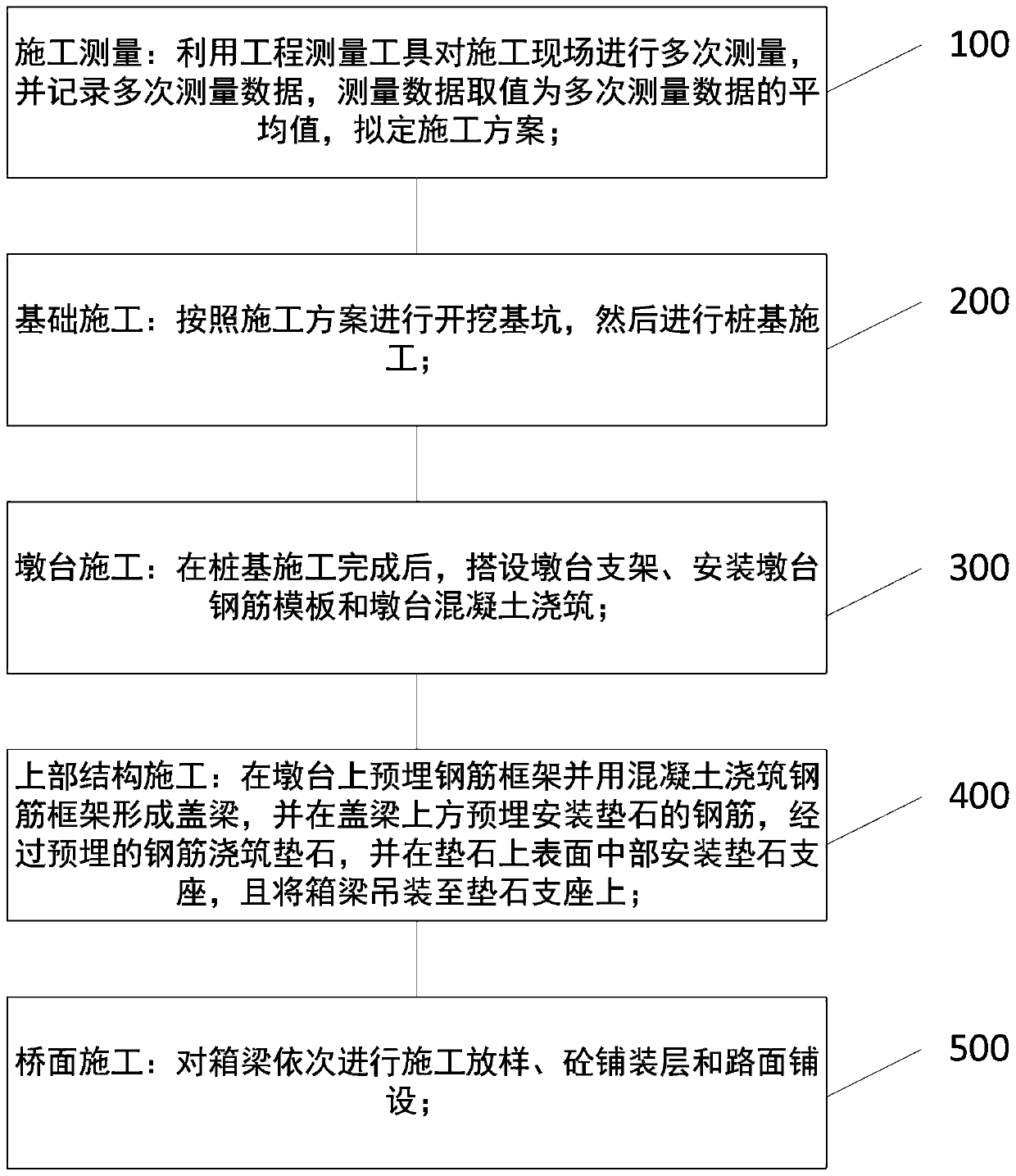

Road and bridge construction process

InactiveCN111155430ASimple construction processImprove construction technologyIn situ pavingsFoundation engineeringArchitectural engineeringBridge deck

The invention discloses a road and bridge construction process, which comprises the following steps of: construction measurement: measuring a construction site for multiple times by using an engineering measurement tool, recording measurement data for multiple times, taking an average value of the measurement data for multiple times as the value of the measurement data , and drawing up a construction scheme; foundation construction: specifically, excavating a foundation pit according to the construction scheme, and then conducting pile foundation construction; abutment construction: specifically, after the pile foundation construction is completed, erecting an abutment support, installing abutment steel bar formworks, and pouring abutment concrete; upper structure construction: pre-buryinga steel bar frame on the abutment, pouring the steel bar frame by using concrete to form a cover beam, pre-burying steel bars for mounting a padstone above the cover beam, pouring the padstone through the pre-buried steel bars, mounting a padstone support in the middle of the upper surface of the padstone, and hoisting the box girder to the padstone support; bridge deck construction, conducting construction lofting, concrete pavement layer laying and pavement laying on the box girder in sequence. The purposes of improving the road and bridge construction process and improving the quality of the built bridge are achieved.

Owner:重庆浩正公路园林工程有限公司

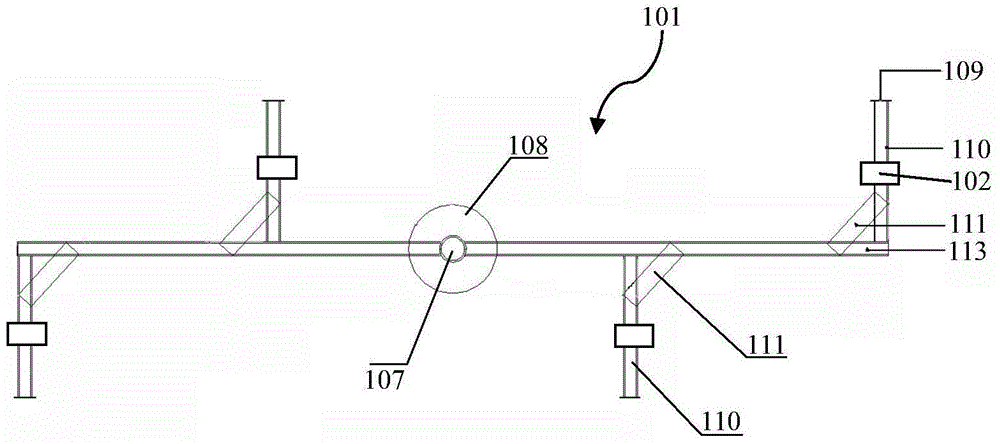

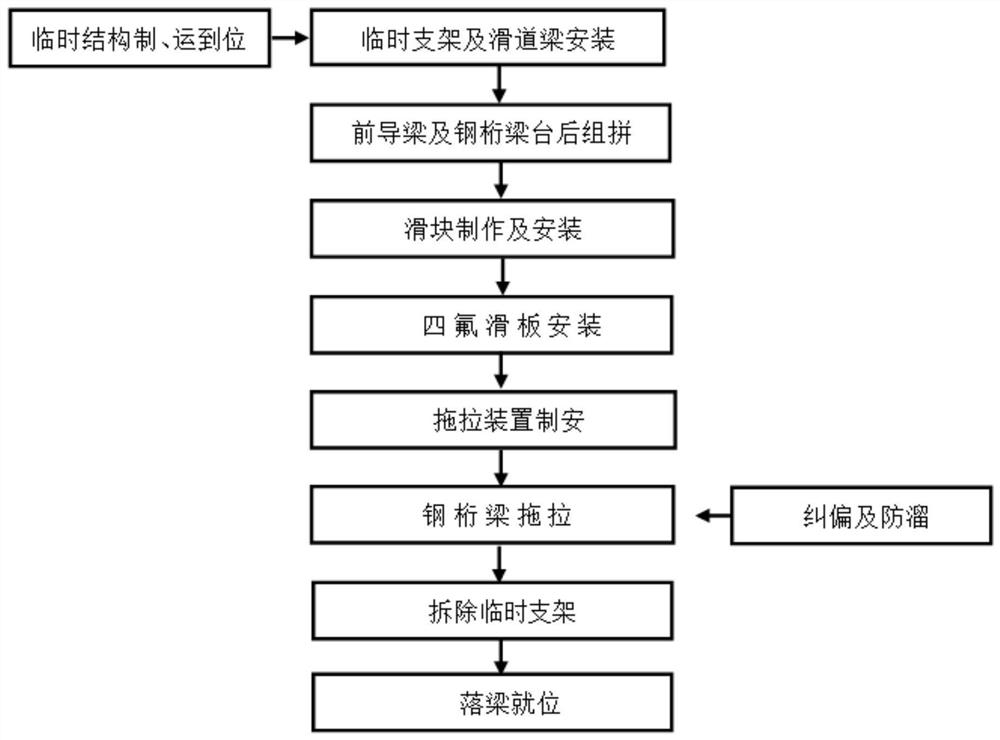

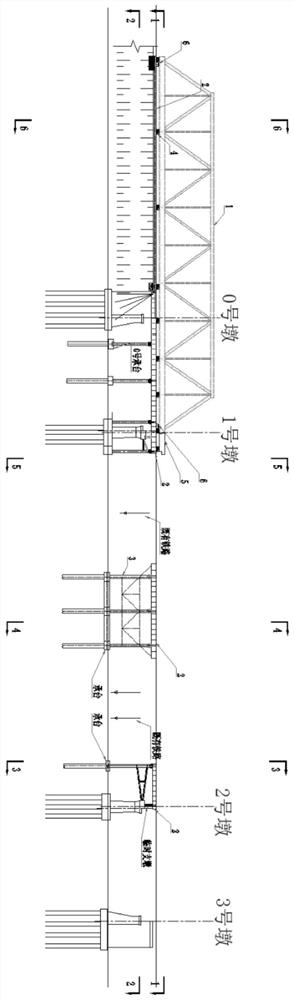

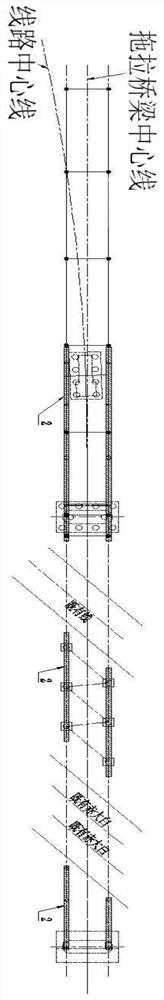

Single-line single-span railway steel truss girder dragging installation construction method and single-line single-span railway

InactiveCN112176867AImprove construction technologyShorten the construction periodTruss-type bridgeBridge erection/assemblyArchitectural engineeringJackscrew

The invention relates to a single-line single-span railway steel truss girder dragging installation construction method. The method comprises the following construction steps of S1, temporary supportand slide way girder installation, including behind-abutment roadbed section temporary support and slide way girder installation, inter-abutment temporary support and slide way girder installation, inter-pier temporary support and slide way girder installation and pier side temporary support and slide way girder installation; S2, front guide beam and steel truss girder behind-abutment assembling;S3, manufacturing and installing of a sliding block, including arrangement of the sliding block at a lower chord part between the large sections of the steel truss girder; S4, manufacturing and installing of a dragging device, including manufacturing and installing of a jack dragging horizontal counter-force seat, manufacturing and installing a rear anchoring device and penetrating and dragging ofa steel strand bundle; S5, dragging of a part of the steel truss girder; S6, dismounting of the temporary support, including dismounting of the sliding block and dismounting of the support; and S7, beam falling in place. The invention further relates to a single-line single-span railway obtained through the construction method. The construction method is advanced, engineering quality, safety andcontrollability are achieved, and the construction period is effectively shortened.

Owner:CHINA RAILWAY NO 9 GRP NO 7 ENG CO LTD

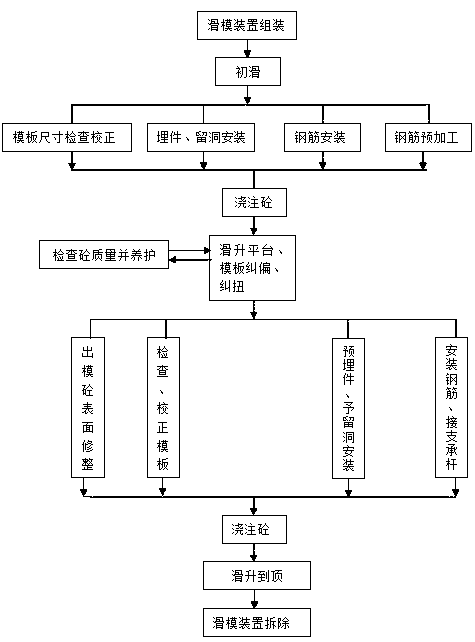

Bridge thin-wall high pier hydraulic slip-form construction method

InactiveCN108914780ASolve layeringGuarantee the appearance qualityBridge structural detailsBridge erection/assemblyTime rangeCement mortar

The invention discloses a bridge thin-wall high pier hydraulic slip-form construction method. The method includes the steps that (1) the thickness of concrete poured for the first time ranges from 60cm to 70 cm, the concrete is poured in three layers, and trail lifting can be conducted when the intensity of the concrete in the bottom layer reaches 0.2 MPa to 0.4 MPa; (2) before the concrete is grouted, a layer of 1:1 cement mortar with the thickness between 2 cm and 3 cm should be poured into a formwork, the concrete is peripherally evenly and symmetrically poured into the formwork and vibrated through an immersion vibrator, the vibration direction is changed frequently, a climbing rod and the sliding lift formwork are prevented from being directly vibrated, the immersion depth of the vibrator cannot exceed 50 mm in the concrete in the lower layer, and vibration is stopped in the sliding lift process of the sliding lift formwork; and (3) after initial sliding lift is conducted, the sliding lift formwork is lifted once each time one layer of the concrete is poured, at the normal air temperature, the pouring thickness of each layer of the concrete is 20 cm, and the lifting time doesnot exceed 1 hour. The bridge thin-wall high pier hydraulic slip-form construction method is provided and has the beneficial effects that a pier body is continuously poured to the designed height atone time, the automation degree is high, the speed is high, and work efficiency is high.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

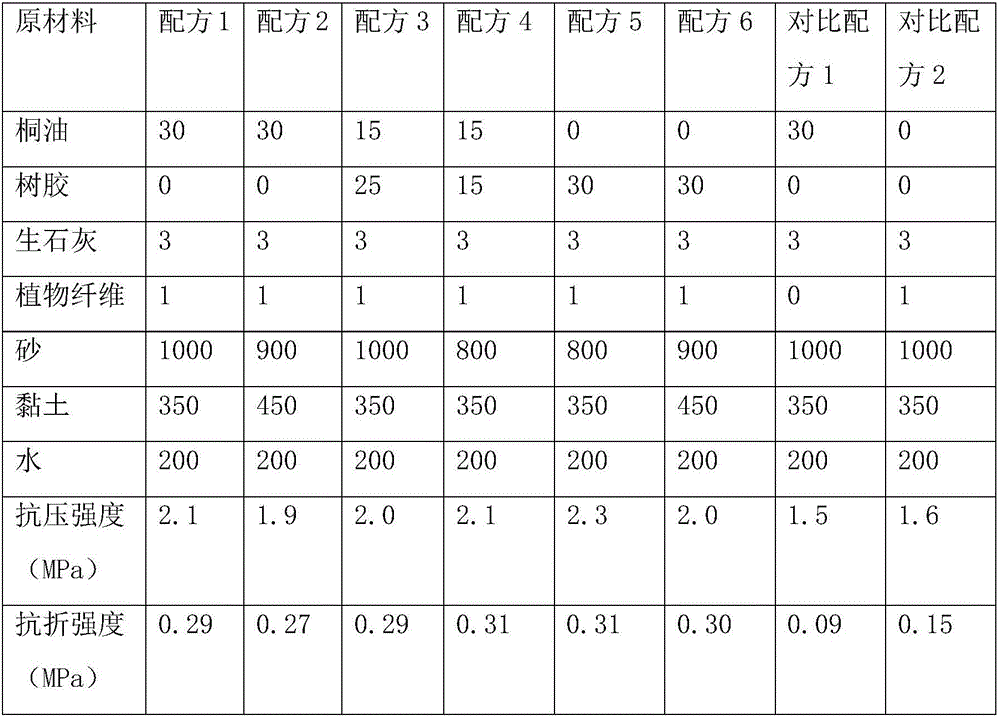

Immature soil composite and construction technology of wall structure thereof

The invention provides an immature soil composite and a construction technology of a wall structure thereof. The immature soil composite comprises the following components in parts by weight: 200-500 parts of clay, 20-50 parts of vegetable fat, 0.5-2.0 parts of plant fiber, 0-5 parts of quick lime, 500-1200 parts of sand and 150-250 parts of water. The immature soil composite provided by the invention mainly takes plant fiber, vegetable fat and sand as modifying materials; the plant fiber has reinforcing and toughening functions, can promote the strength and shock resistance of the immature soil composite and can reduce the shrinkage of the material; the vegetable fat, the clay and the quick lime are mixed and used together, so that the mutual physical and chemical reactions are generated, the strength of the composite is higher than the strength of the traditional lime soil composed of clay and quick lime and the toughness is better; the sand is mainly used for increasing the volume stability of the immature soil composite; and the plant fiber, the vegetable fat, the sand, the clay and the quick lime are formed into the immature soil composite.

Owner:重庆建之新科技有限公司

Construction method of fabricated underground diaphragm wall

The invention discloses a construction method of a fabricated underground diaphragm wall. The construction method comprises the following steps of prefabricating a fabricated underground diaphragm wall structure, carrying out pre-trenching or pre-stirring of a soft soil stratum, inserting the fabricated underground diaphragm wall structure into a trench or the stratum through fabricated underground diaphragm wall structure insertion equipment for connection, excavating a foundation pit, carrying out pouring on crown beams and permanent and temporary combined purlin structures, erecting supports in a following mode, constructing a waterproof layer and a body structure, and then dismantling a supporting structure. According to the construction method, construction is flexible, the structureis simple, and the construction process is reliable; space occupation of a construction site, for example, space occupation of steel bar processing and concrete pouring can be reduced, influences on the surroundings are reduced, the mechanical level and construction efficiency of a project can be improved, the workload of the construction site is reduced, moreover, the underground diaphragm wall pouring quality can be improved, and the project scrap rate is decreased; and the construction method has high applicability and operability and is safe and reliable.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Glass and benzene composite thermal insulation mortar and preparation method thereof

InactiveCN102010165AGuaranteed mixing effectGuaranteed homogeneityThermal insulationPolystyrene particle

The invention discloses glass and benzene composite thermal insulation mortar, which is prepared by the following steps of: weighing cement and mineral powder according to weight part, putting into a mixer, weighing polypropylene fibers, redispersible latex and cellulose ether, putting into the mixer, and uniformly stirring to form a premix; respectively weighing the premix, vitrified micro bubbles and polystyrene granules, adding into a spiral ribbon mixer, stirring the three materials uniformly, and completely opening a bin gate at the bottom of the mixer to obtain the uniformly stirred glass and benzene composite thermal insulation mortar; and packaging the glass and benzene composite thermal insulation mortar by using a packaging machine. The glass and benzene composite thermal insulation mortar has the advantages of low water absorption, small conductivity factor, high strength, and good thermal insulation performance, the flammability can be greatly reduced, the construction efficiency is improved and the manpower is saved.

Owner:SHANDONG QINHENG TECH

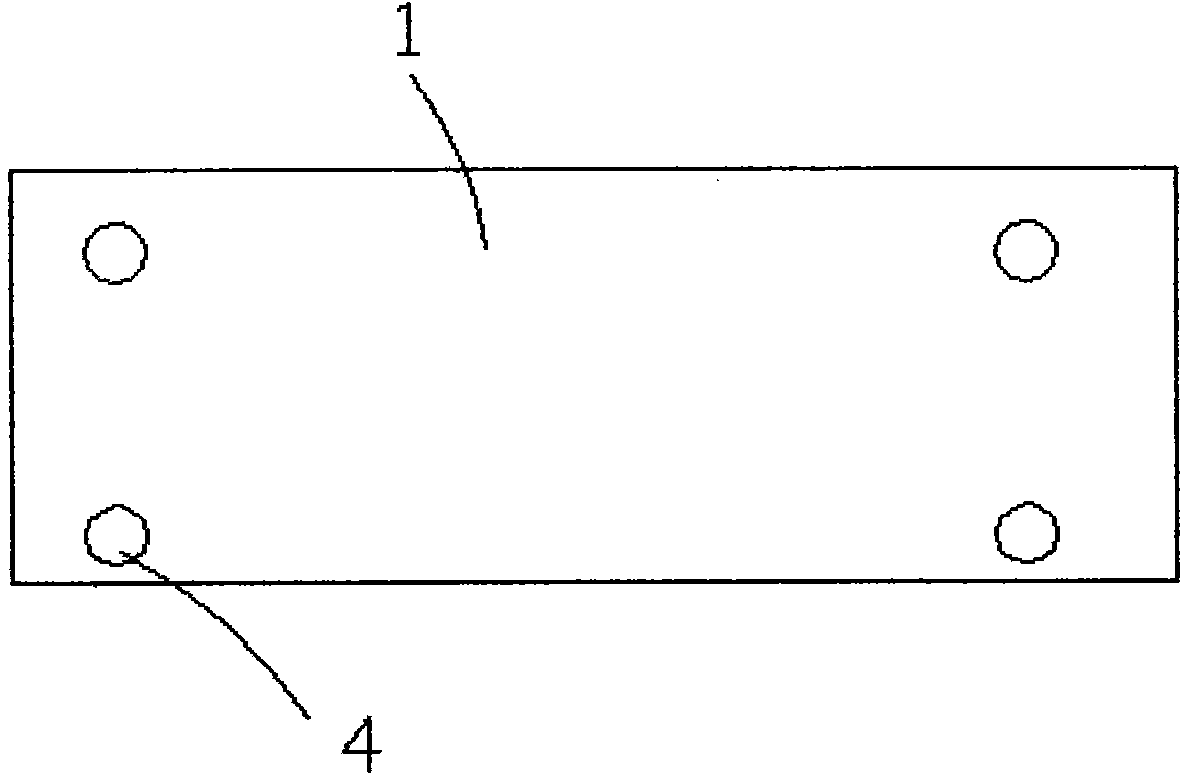

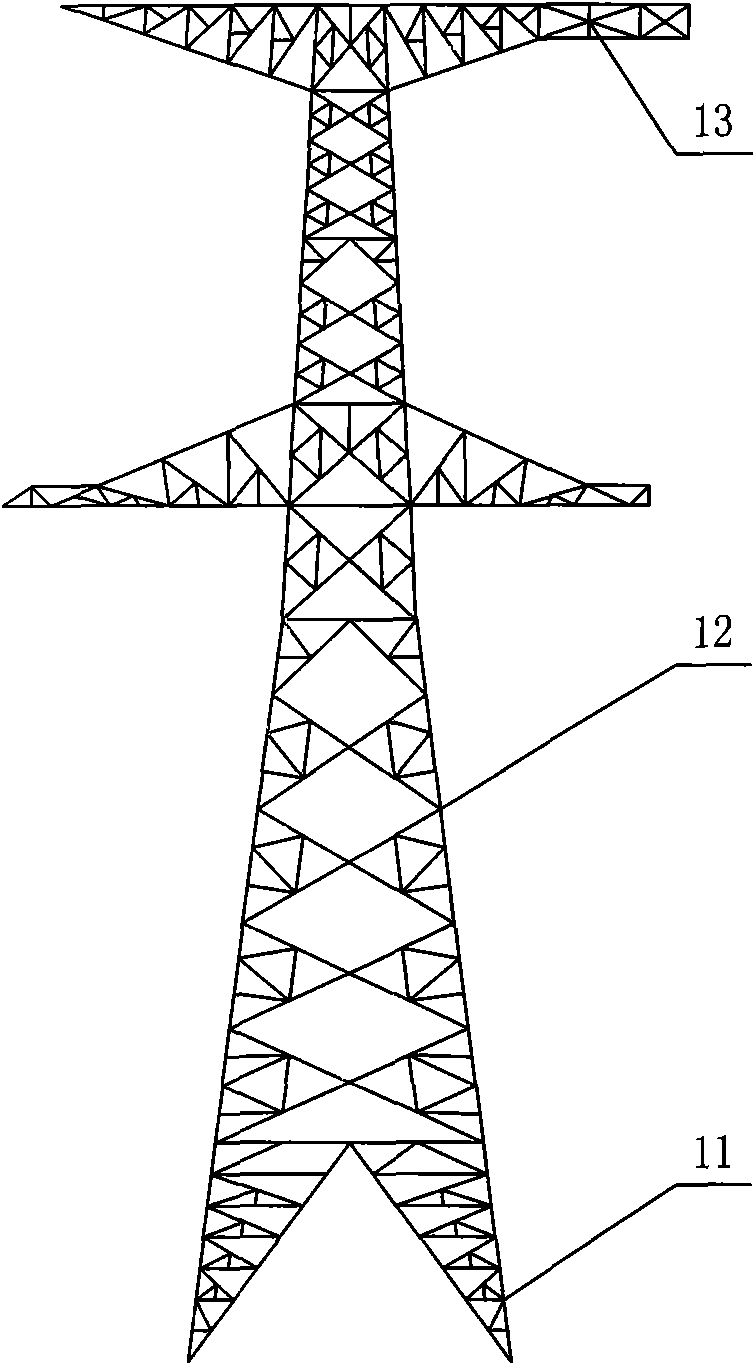

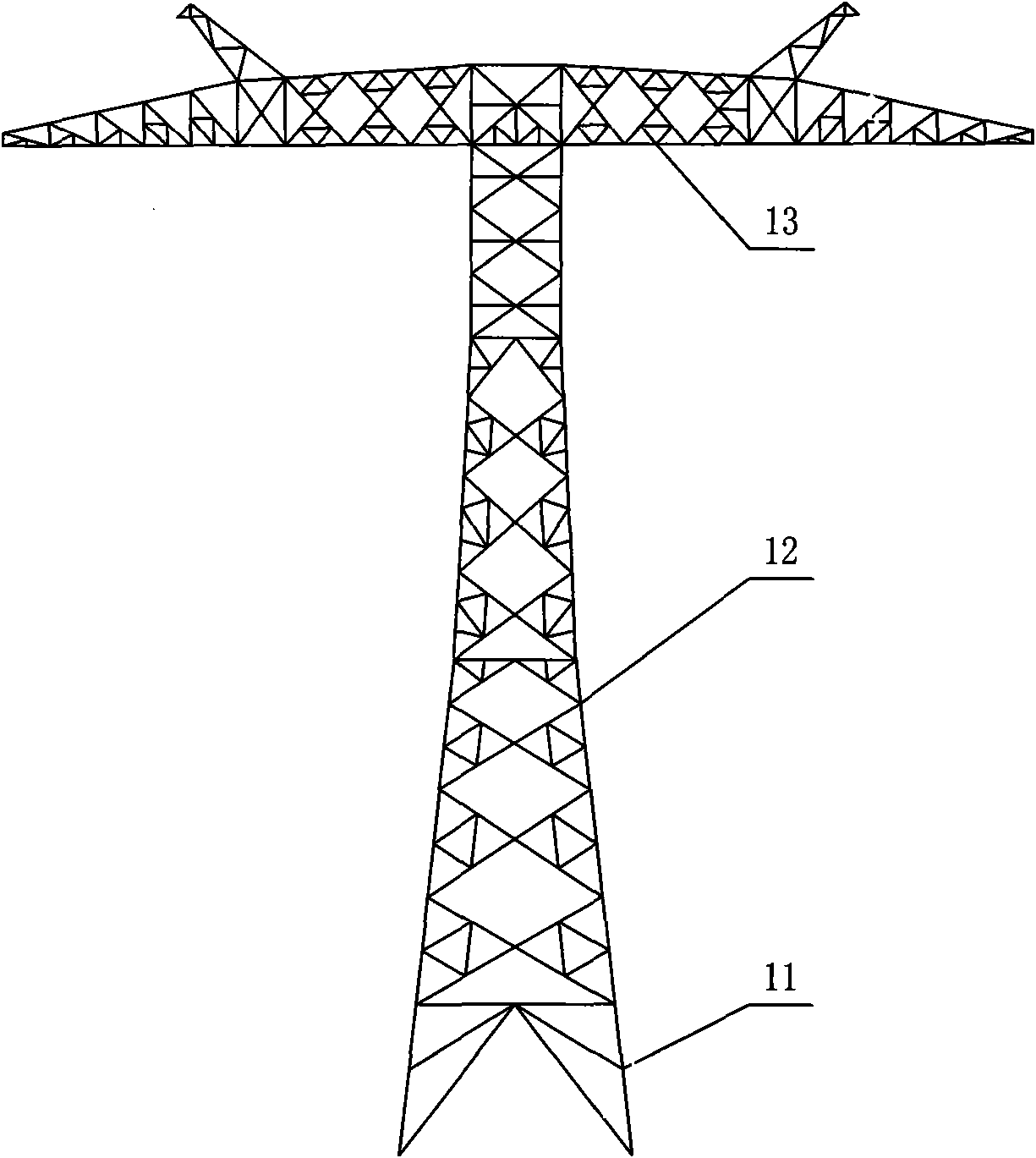

Basic guide rail for helicopter assembly transmission line iron tower leg section

The invention provides a basic guide rail for a helicopter assembly transmission line iron tower leg section, which comprises a guide plate, a guide plate rib plate, a hoop and a small rib plate, wherein the guide plate rib plate is arranged under the guide plate; the hoop is arranged at the lower end of the guide plate rib plate; and the small rib plate is arranged between the guide plate rib plate and the hoop. The guide plate provides guiding function for hoisting and positioning a tower leg section by a helicopter; the guide plate rib plate provides support for the guide plate and transmits the impact force of the hoisted tower leg section stressed by the guide plate to the hoop; the hoop is used for connecting the guide rail and a tower leg base; and the small rib plate can improve the local impact resistance of the guide rail. The basic guide rail has the advantages of simple structure, convenience of manufacture, load transmission without connecting piece with the tower leg base, installation of the basic guide rail without modification of the tower leg base, use for helicopter assembly for various self-supporting iron tower leg sections, high universality and wide application range.

Owner:CHINA ELECTRIC POWER RES INST +1

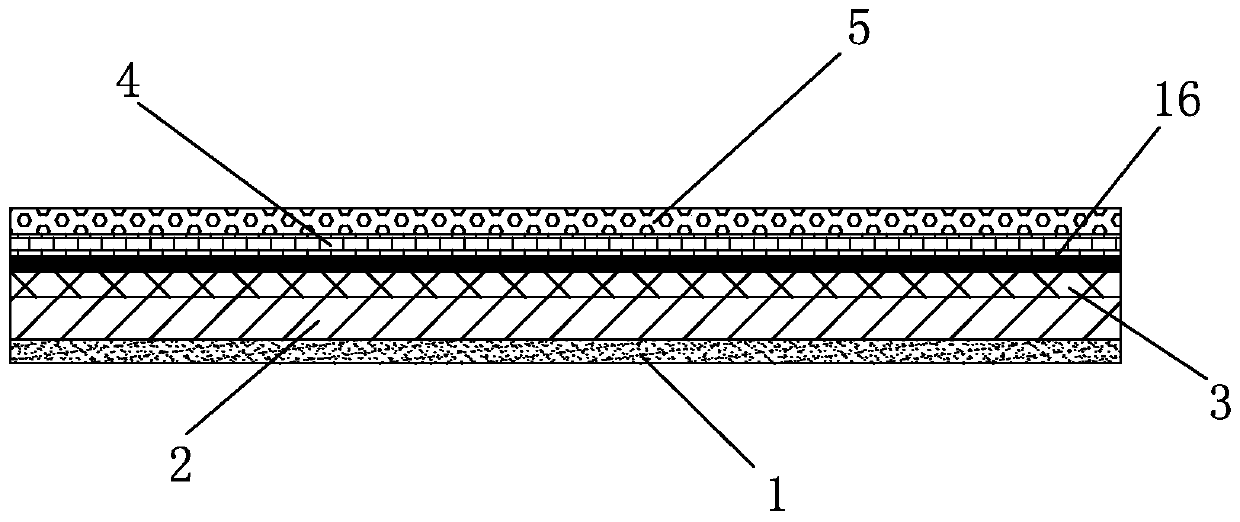

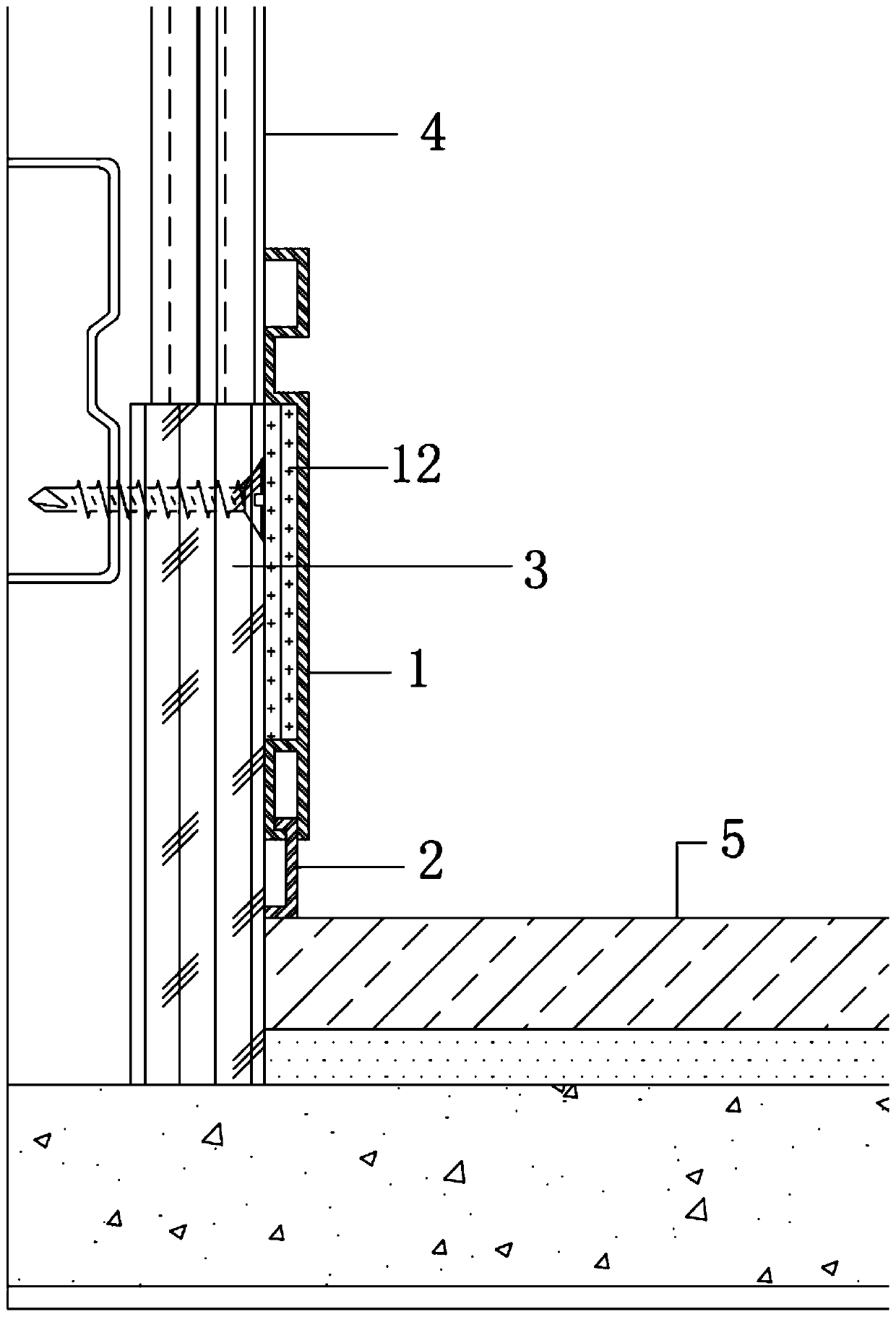

Anti-seepage structure for balcony and construction method of anti-seepage structure

InactiveCN110005049AStable structureNot easy to deform and misplaceBalconiesBuilding insulationsEngineeringProtection layer

The invention discloses an anti-seepage structure for a balcony. The anti-seepage structure comprises a waterproof coating layer, a coiled material waterproof layer, an anti-seepage film layer and a protecting layer, the protecting layer comprises a supporting plate layer and a ceramic tile layer which are arranged from bottom to top, the supporting plate layer is formed by supporting plates in anassembled mode, clamping blocks are arranged on the corners around the top face of each supporting plate correspondingly, the ceramic tile layer is formed by ceramic tiles in an assembled mode, clamping grooves are formed in the corners around the bottom face of each ceramic tile correspondingly, and the clamping blocks and the clamping grooves are matched. A construction method comprises the following steps of (1) base layer treatment, (2) treatment of the waterproof coating layer, (3) laying of the coiled material waterproof layer, (4) layering of the anti-seepage film layer and (5) layingof the protecting layer. The anti-seepage structure for the balcony is ingenious and reasonable in overall structural design, through the anti-seepage structure, the anti-seepage effect of the balconycan be improved effectively, the protecting layer is divided into the supporting plate layer and the ceramic layer, the waterproof effect of the balcony can be further improved under the situation ofensuring the surface attractive degree of the balcony, and the upper ceramic tile layer can also be conveniently laid through the supporting plate layer.

Owner:ZHEJIANG COLLEGE OF CONSTR

Self-adhesion type ethylene propylene diene monomer waterproof roll

PendingCN107459942AImprove aging resistanceGood adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWater leakageEthylene-propylene-diene-monomer

The invention discloses a self-adhesion type ethylene propylene diene monomer waterproof roll. The self-adhesion type ethylene propylene diene monomer waterproof roll comprises a silicone oil paper layer, a butyl adhesive layer, an EPDM layer and a PE film which are arranged from bottom to top in turn; the butyl adhesive layer comprises the following components in parts by weight: 40-60 parts of butyl rubber (1751), 30-50 parts of polyisobutene (1200), 5-10 parts of C5 resin, 10-20 parts of chlorinated paraffin and 100-200 parts of talcum powder; the EPDM layer comprises the following components in parts by weight: 40-60 parts of EPDM (3092), 50-60 parts of carbon black (N550), 10-20 parts of softening agent, 5-10 parts of vulcanizing agent and 10-20 parts of talcum powder. According to the structure arrangement of the device, the butyl adhesive material is used as an adhesive layer, so that the phenomena of high adhesion and water leakage under low temperature can be effectively solved; the adhesive layer can be coated on the EPDM roll in advance, so that the trouble of on-site adhesive coating required in the construction process can be avoided; and the release paper of the roll can be directly torn off and the roll can be directly paved in the construction process.

Owner:杨志武

Method for constructing road swivel bridge and railway swivel bridge by using turnplate spherical hinge

ActiveCN101818482BConstruction safetySimple and fast operationBridge erection/assemblyPile capThree stage

The invention relates to a method for constructing a bridge, in particular to the method for constructing a road swivel bridge and a railway swivel bridge by using a turnplate spherical hinge, which aims to solve the problems of the complex process, inconvenient construction, high requirements on construction sites, and the like of the conventional swivel bridge construction. The method specifically comprises the following steps of: machining the turnplate spherical hinge; constructing a lower pile cap and mounting a lower spherical hinge and an endless track, wherein the concrete of the lower pile cap is poured in three stages; constructing an upper pile cap and mounting an upper spherical hinge and a support steel cylinder; and after the upper pile cap and the lower pile cap are swiveled in place under the action of the turnplate spherical hinge, pouring rear sealed concrete between the upper pile cap and the lower pile cap. The method has the advantages of the capacity of changing overhead barrier operation into operation on the coast or near the ground, safe and reliable construction, simple and convenient operation, fast implementation and construction cost reduction, is suitable for both straight bridges and curved bridges, and compared with the conventional construction methods, also has the advantages of shortening construction period, saving a part of big constructionmachinery and labor force and greatly saving construction cost.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

Protection material for marble energy curing surface treatment and production technology

InactiveCN107057554AImprove construction efficiencyImprove construction technologyPolyurea/polyurethane coatingsPolyester coatingsTripropylene glycolPolyester

The invention discloses a protection material for marble energy curing surface treatment and a production technology, relates to improvement of marble chemical materials, and particularly relates to a protection material for marble curing surface treatment. In order to achieve the target, the protection material for marble energy curing surface treatment is prepared from the following components in the formula: diethylene glycol diacrylate, tripropylene glycol diacrylate, trimethylol propyl triacrylate, trimethyl benzoyldiphenyl phosphine oxide, hydroxycyclohexyl ketone, a photoinitiator, high-functionality urethane acrylate, aliphatic polyester, a modified dilute acid ester polymer defoaming agent, a fluorine-modified polysiloxane polymer and silsesquioxane. Existing multiple materials with a single function are replaced, the procedures are combined, and existing air drying or heat drying non-environment-friendly auxiliary raw materials are replaced with energy (UV / EB) curing, so that the construction efficiency is increased, the technology is improved, the density, the glossiness and the surface protecting performance of a stone are improved, the waterproofing, antifouling and corrosion-resistant targets are achieved, the production cost is directly reduced and multiple items of indirect cost are reduced.

Owner:广东理奥新材料科技有限公司

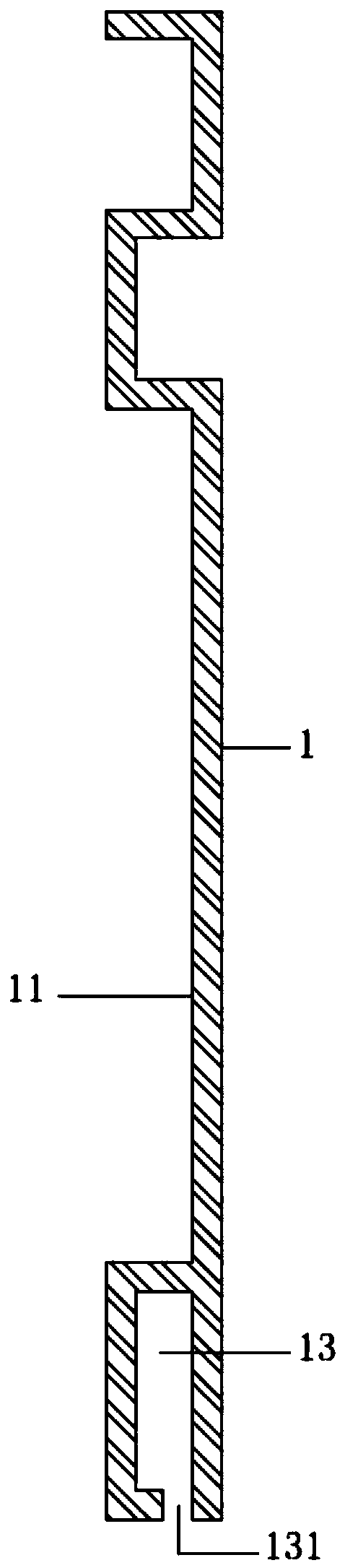

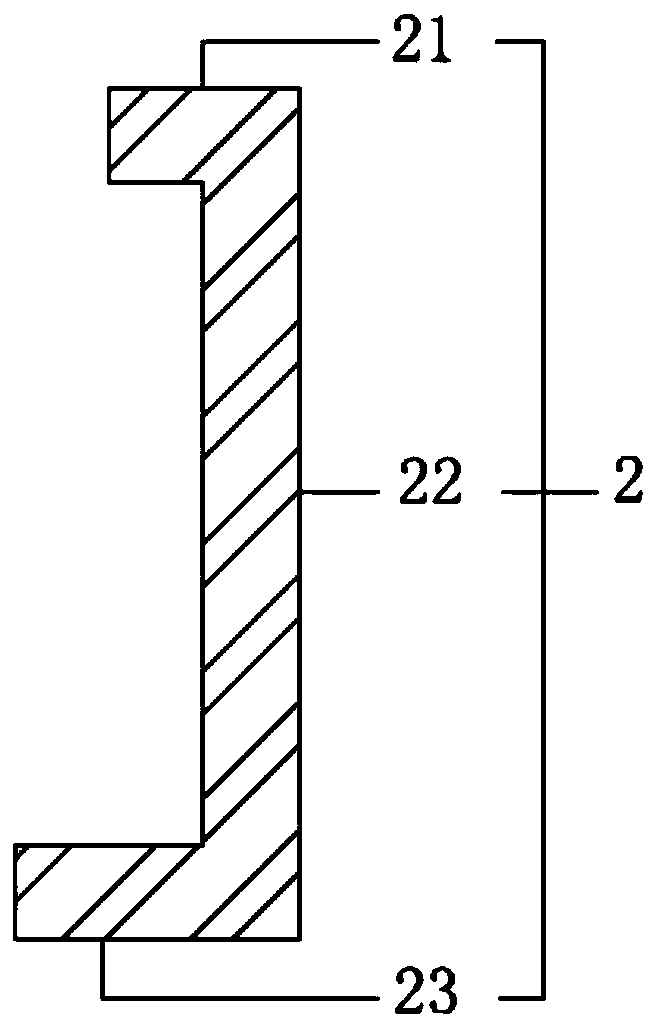

Self-adjusting baseboard installation structure

PendingCN111075159AImprove aestheticsSimple construction processBuilding constructionsWall plateEngineering

The invention provides a self-adjusting baseboard installation structure. The self-adjusting baseboard installation structure includes a baseboard main board and a baseboard hanging board, a groove isformed in the back of the baseboard main board, the groove is internally provided with an adhesive, a clamping groove is formed in the bottom of the baseboard main board, the opening direction of theclamping groove is vertical downward, the structure of the baseboard hanging board is in a C shape, the top of the baseboard hanging board is clamped in the clamping groove, and the opening directionof the baseboard hanging board is towards the base course surface. The baseboard main board and the baseboard hanging board clamped in the clamping groove are integrally glued to the base course surface through the adhesive. The top of the baseboard main board extends upwards to the wall panel finish, and the bottom of the baseboard hanging board abuts against the ground finish. According to theself-adjusting baseboard installation structure, self adjusting can be carried out to complete the installation in the case of uneven ground. The construction process is simple, disassembly and assembly are convenient, the construction efficiency is greatly improved, and the construction cost is reduced.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Cement mortar masonry building system based on BIM building model and working method of cement mortar masonry building system

InactiveCN109797977AHigh dimensional accuracyAvoid wastingBuilding material handlingSpecial data processing applicationsNumerical controlCement mortar

The invention discloses a cement mortar masonry building system based on a BIM building model and a working method of the cement mortar masonry building system. The system comprises a BIM design unit,a numerical control unit, an intelligent feeding unit, a masonry unit, a display unit, a monitoring unit and a detection and alarm unit.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

Embedding and fixing method for protective tubes of deep water slope basement under variable water levels

The invention discloses an embedding and fixing method for protective tubes of a deep water slope basement under variable water levels. The embedding and fixing method comprises the following steps that the telescopic protective tubes are manufactured; pay-off is conducted, and the position of a bridge pier is located; a construction platform is manufactured on floating boats and is dragged to the position of the bridge pier and fixed; pay-off is conducted on the construction platform, and the pile positions are determined; the inner protective tubes are placed through a crane and fixed to the construction platform; pebbles are thrown on the periphery of the construction platform; red soil is added in the protective tubes; a mixture of big sand and the red soil is added within the range of the construction platform; sand gravel is thrown on the upper portion of the big sand layer within the range of the construction platform; and underground concrete is poured on the upper portion of the sand gravel, and the outer protective tubes are mounted. According to the embedding and fixing method, the pebbles, the big sand and the red soil are placed in a throwing and filling manner, then the underground concrete is poured, and installing and fixing of the bottoms of the protective tubes on the slope basement are achieved; the self-developed protective tubes capable of extending and contracting freely are adopted so that the protective tubes can ascend and descend in a stepless manner to adapt to the water level changes; the protective tubes capable of extending and contracting freely and the construction platform are connected through universal wheels, and it is guaranteed that the positions of the protective tubes are fixed; and operation is facilitated, and the effect is good.

Owner:HUANGHE ENG BUREAU HENAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com