Method for constructing road swivel bridge and railway swivel bridge by using turnplate spherical hinge

A bridge construction and spherical hinge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex process, high construction site requirements, inconvenient construction, etc., to achieve safe and reliable construction, saving construction costs, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

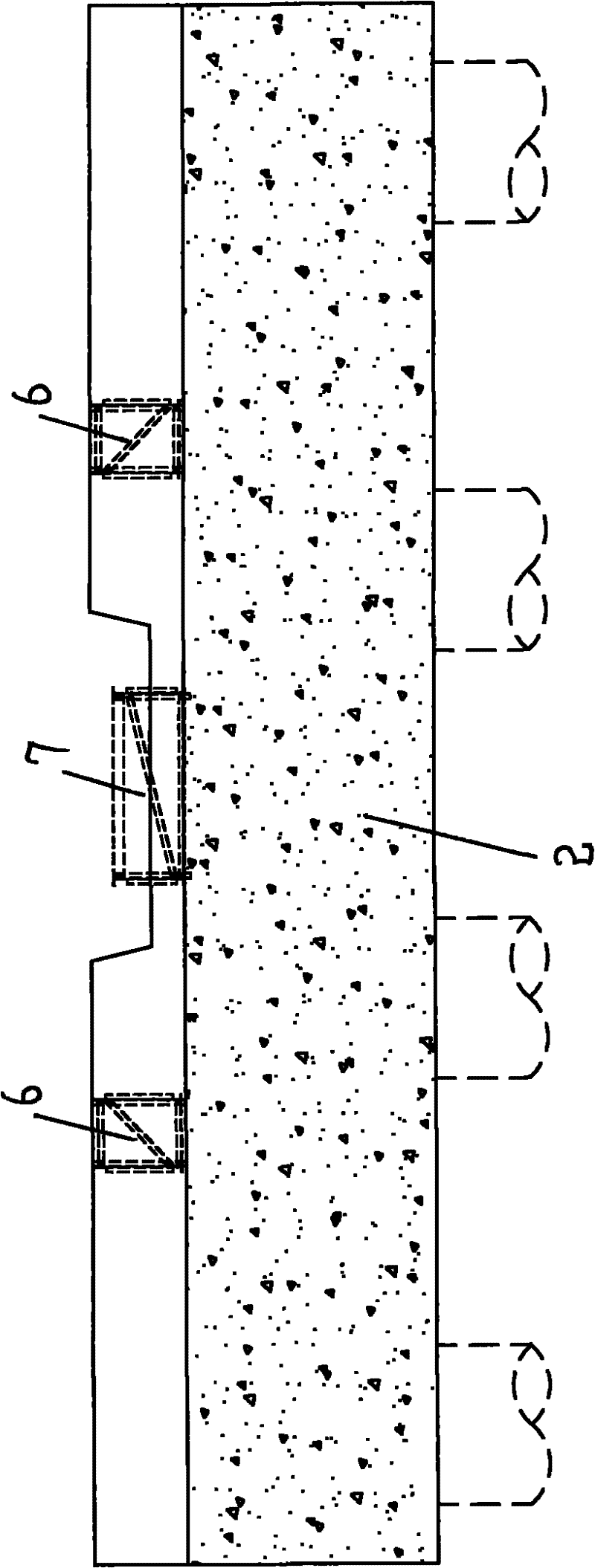

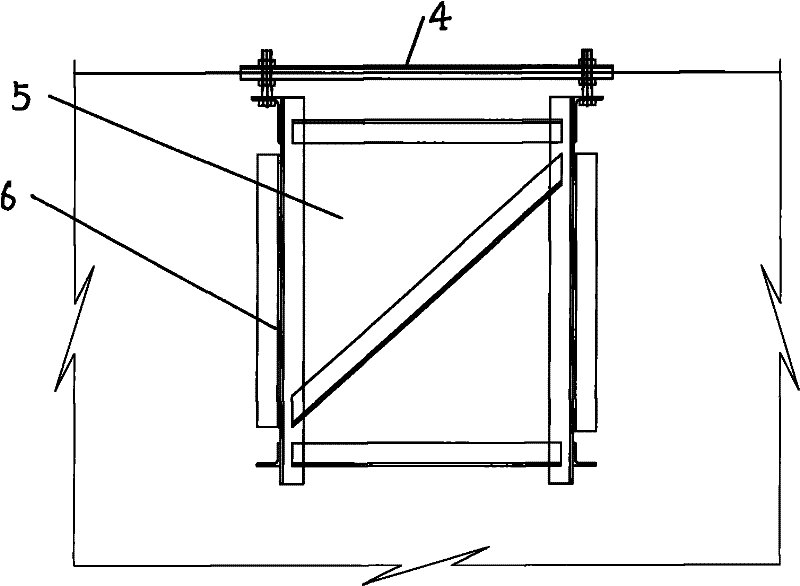

[0026] A method for constructing highway and railway swivel bridges by using a turntable spherical joint, comprising the following steps:

[0027] 1. Turntable spherical hinge processing:

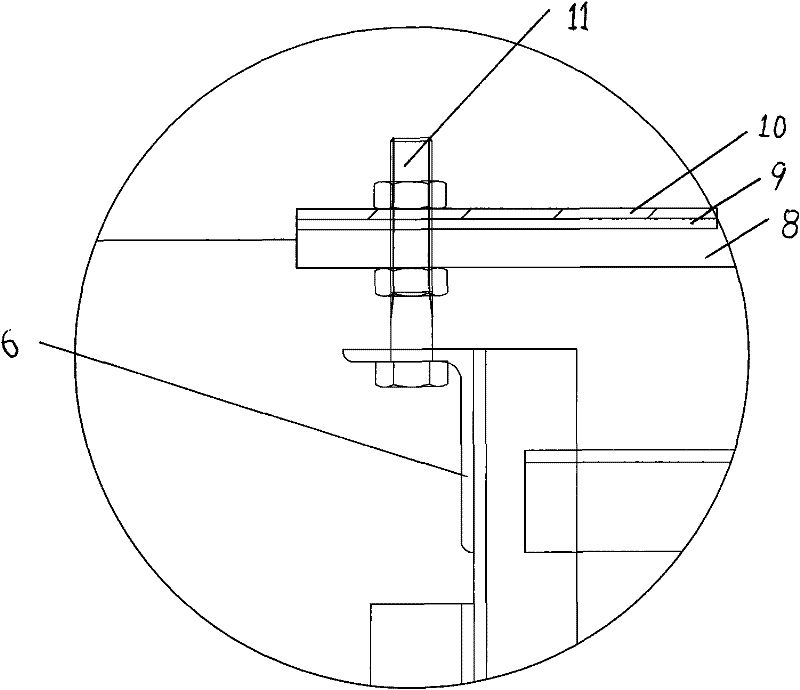

[0028] The spherical joint is entrusted to 725 Institute to design and produce, with a bearing capacity of 5,500t. It is divided into three parts: the upper spherical joint, the lower spherical joint and the center pin shaft. 0.293m, the diameter of the central pin shaft is 300mm. The ball hinge is composed of upper and lower steel ball panels. The upper panel is convex and connected to the upper traction disc through the truncated cone. The upper disc is located on the traction disc. The lower panel is concave and embedded in the top surface of the lower disc. The upper and lower panels are all spherical surfaces pressed by 30mm thick steel plates, and ribs are set on the back to prevent deformation during processing and transportation, and facilitate the positioning of the ball joint and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com