Composite insulation board and production method thereof

A composite thermal insulation and board technology, which is applied in thermal insulation, chemical instruments and methods, layered products, etc., can solve the problems of low strength, potential safety hazards, and short service life of inorganic thermal insulation materials, achieve good thermal insulation and fire protection, improve Effectiveness of construction efficiency, avoidance of durability and fire protection issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

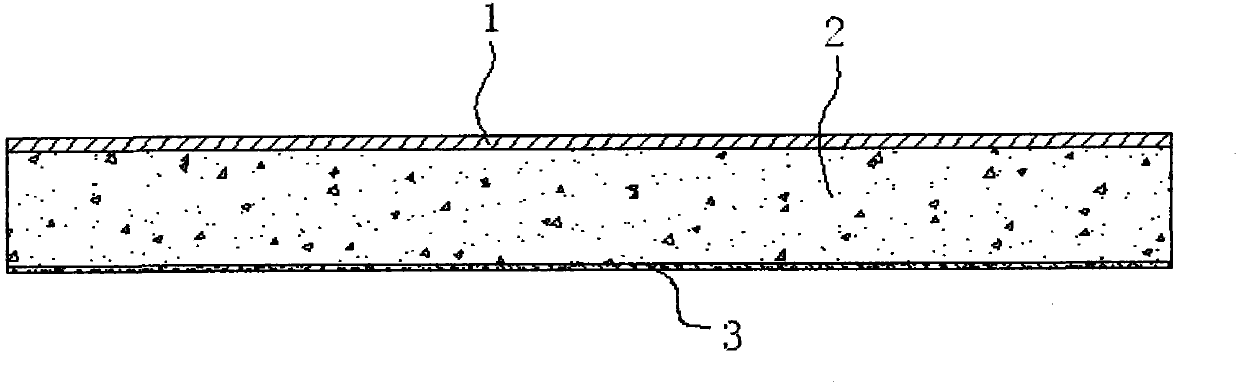

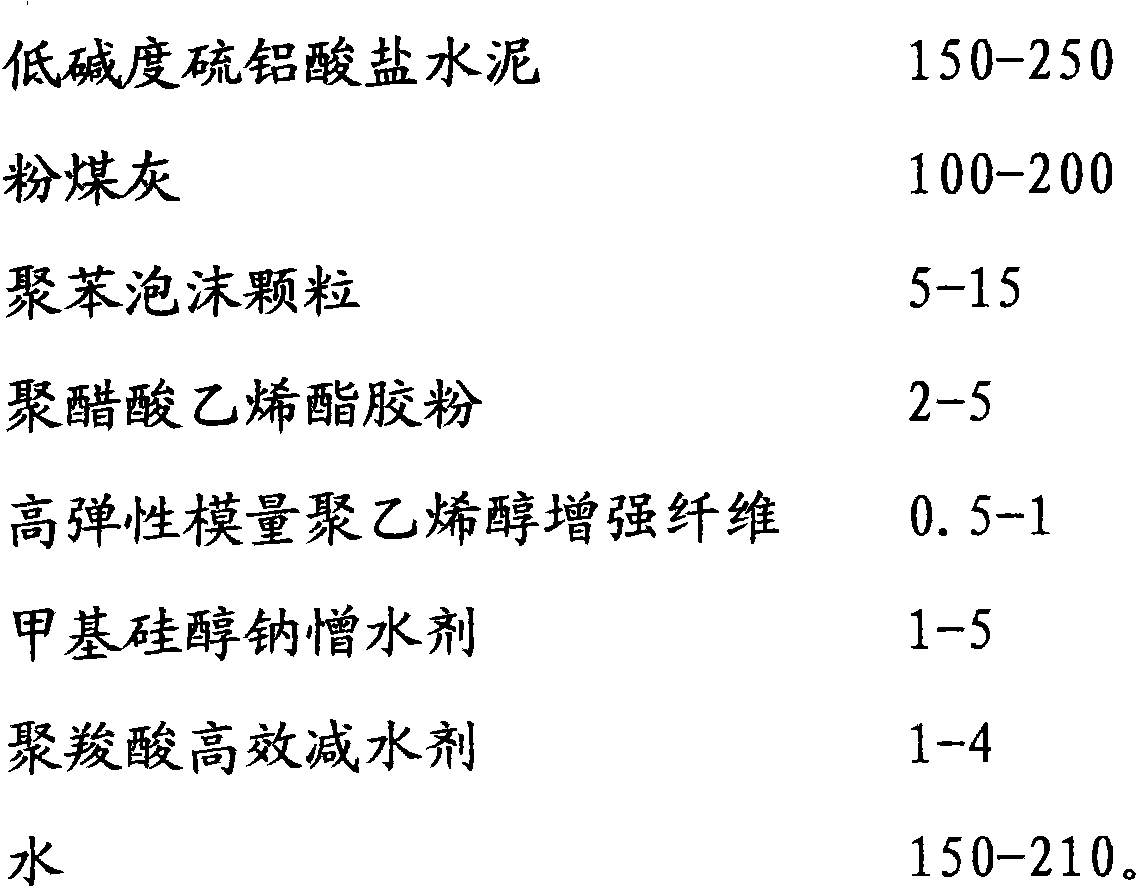

[0018] Embodiment 1: a composite thermal insulation board, the composite thermal insulation board is composed of calcium silicate panel, glass fiber mesh cloth and lightweight concrete, the bottom layer of the composite thermal insulation board is glass fiber mesh cloth, glass fiber mesh cloth Lightweight concrete and calcium silicate panels are arranged on the top in turn, and the weight components of the raw materials of the lightweight concrete are as follows:

[0019]

[0020]

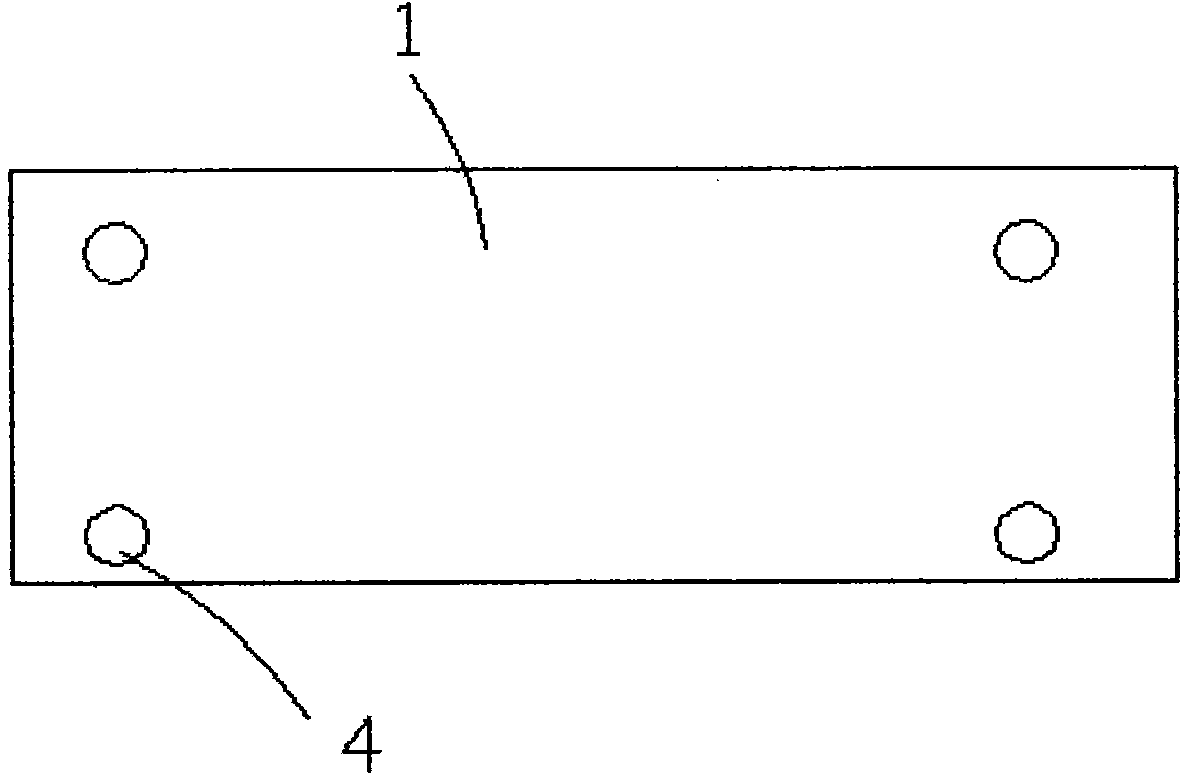

[0021] The thickness of the calcium silicate board is 4 mm, and bonding holes are provided on the calcium silicate board. The glass fiber mesh is alkali-resistant glass fiber mesh.

[0022] The production method of the above-mentioned composite thermal insulation board is to use a vertical group die to produce a composite board, comprising the following production steps:

[0023] S1: Fix the alkali-resistant glass fiber mesh on the inner partition of the vertical mold and stand the calcium s...

Embodiment 2

[0027] Embodiment 2: a composite thermal insulation board, the composite thermal insulation board is composed of calcium silicate panel, glass fiber mesh cloth and lightweight concrete, the bottom layer of the composite thermal insulation board is glass fiber mesh cloth, glass fiber mesh cloth Lightweight concrete and calcium silicate panels are arranged on the top in turn, and the weight components of the raw materials of the lightweight concrete are as follows:

[0028]

[0029]

[0030] The thickness of the calcium silicate board is 10m, and bonding holes are provided on the calcium silicate board. The glass fiber mesh is alkali-resistant glass fiber mesh.

[0031] The production method of the above-mentioned composite thermal insulation board is to use a vertical group die to produce a composite board, comprising the following production steps:

[0032] S1: Fix the alkali-resistant glass fiber mesh on the inner partition of the vertical mold and stand the calcium si...

Embodiment 3

[0036] Embodiment 3: a composite thermal insulation board, the composite thermal insulation board is composed of calcium silicate panel, glass fiber mesh cloth and lightweight concrete, the bottom layer of the composite thermal insulation board is glass fiber mesh cloth, glass fiber mesh cloth Lightweight concrete and calcium silicate panels are arranged on the top in turn, and the weight components of the raw materials of the lightweight concrete are as follows:

[0037]

[0038] The thickness of the calcium silicate board is 5 mm, and bonding holes are provided on the calcium silicate board. The glass fiber mesh is alkali-resistant glass fiber mesh.

[0039] The production method of the above-mentioned composite thermal insulation board is to use a vertical group die to produce a composite board, comprising the following production steps:

[0040] S1: Fix the alkali-resistant glass fiber mesh on the inner partition of the vertical mold and stand the calcium silicate plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com