Single-line single-span railway steel truss girder dragging installation construction method and single-line single-span railway

A construction method and technology of steel truss girders, which are applied in the direction of bridges, truss bridges, bridge construction, etc., can solve the problems of long construction period and high safety risks of bridges, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

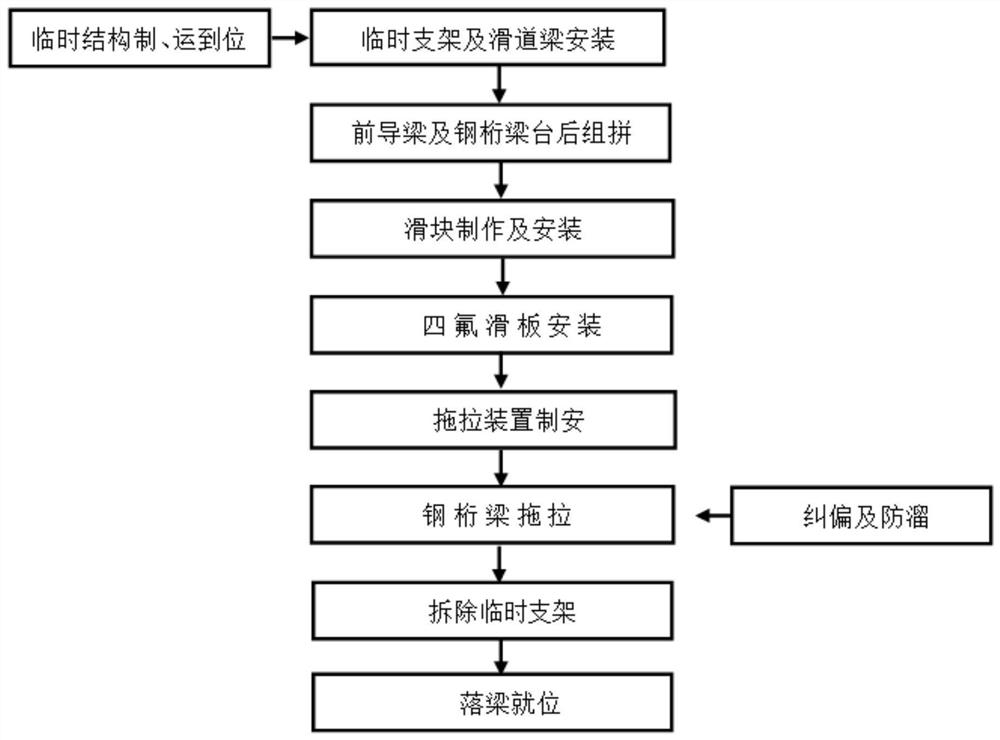

Method used

Image

Examples

Embodiment 1

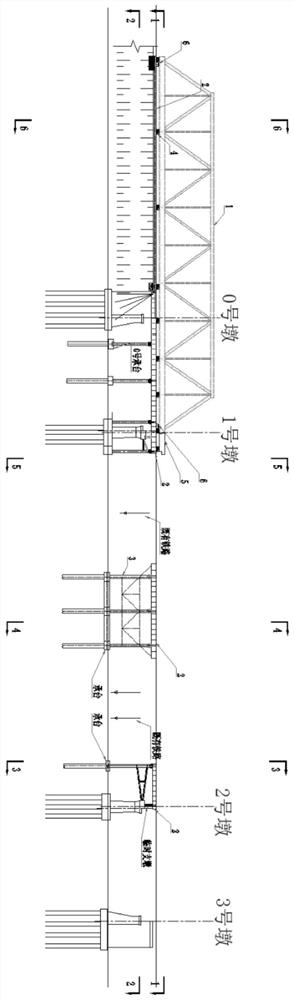

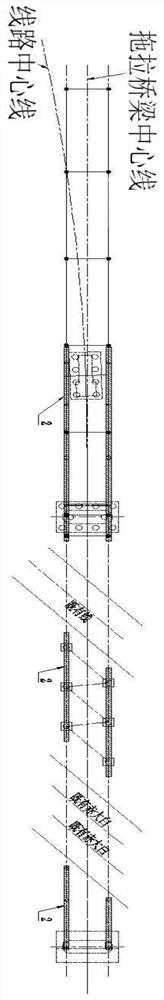

[0213] Embodiment 1: certain railway construction.

[0214] Construction started in August 2019 and was completed on December 20, 2019. The angle between the project and the railway is 42°, the total length is 190.72m, and the span is set as 1-32mT beam + 1-108m steel truss beam 1+1-32mT beam. The second hole is located at DK5+397.53, DK5+449.67, and DK5+457.13 mileage respectively. There are single-line and double-line, and the steel truss beam 1 structure with a span of 108m is adopted.

[0215] The invention effectively shortens the construction period, saves the construction cost, ensures the safety of railway operation and improves the engineering quality.

[0216] In the description of the present invention, it should be understood that the terms "first" and "second" are used for description purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thus, a feature define...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com