Construction structure of cylindrical die

A column and formwork technology, which is applied in the direction of house structure support, house structure support, formwork/formwork/work frame, etc., can solve the problems of circular steel formwork not reaching the number of turnovers, large initial investment, and long customization time. , to achieve the effect of improving pouring quality and construction safety, improving construction technology and strengthening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described now in conjunction with accompanying drawing

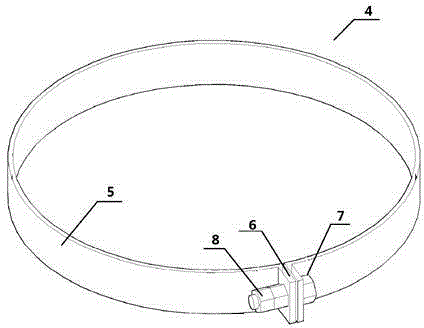

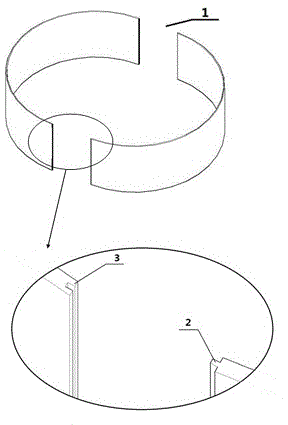

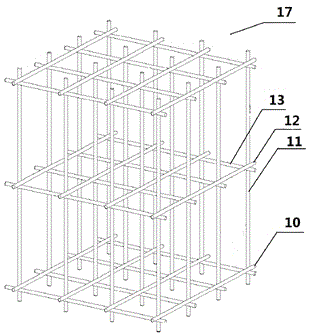

[0013] A construction structure of a cylindrical mold, the cylindrical mold is a formwork for pouring cylindrical concrete, the formwork consists of two formed semicircular formwork 1 with convex grooves 2 and grooves 3 on both sides of the formwork, Two semi-circular formworks bite into each other to form a hollow cylindrical formwork; the feature is: on the outside of the hollow cylindrical formwork, the formwork is surrounded by steel bar hoops at equal intervals and fastened, and the hollow cylindrical formwork is vertically inserted in double rows In the middle of the scaffolding; the templates are stacked to the required height, and the joints are connected by steel column hoops; at the 2 / 3 elevation of the cylindrical formwork, a throwing support structure 14 is set to ensure the verticality and stability of the column.

[0014] Described steel column hoop is that steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com