Bridge thin-wall high pier hydraulic slip-form construction method

A construction method and hydraulic technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of discontinuous structural integrity, slow construction progress, and high labor consumption, so as to ensure the appearance quality, reduce construction technology, safety high coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

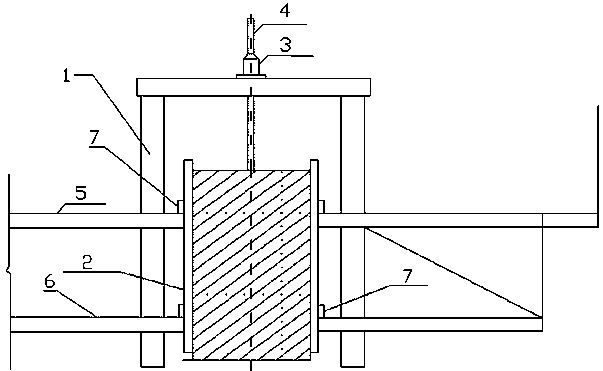

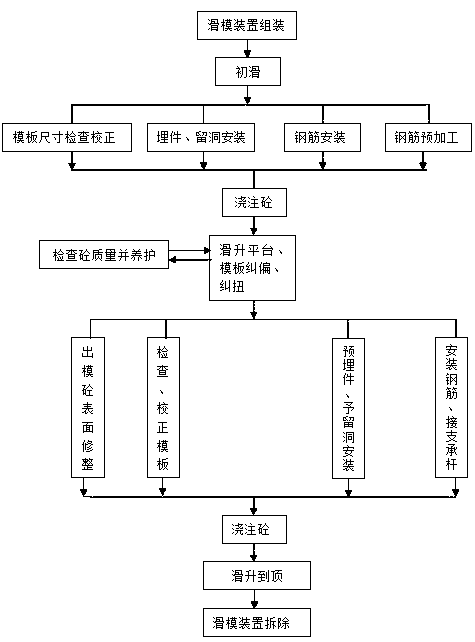

[0023] The technical scheme of the hydraulic sliding form construction method for bridge thin-walled high piers of the present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

[0024] A hydraulic sliding form construction method for thin-walled high piers of bridges, such as figure 1 , 2 As shown, the synovial film construction method of this embodiment is to lift the steel platform upward by driving the supporting steel column connected with the jack through the jacking of the hydraulic jack, so that the hanger and the sliding formwork suspended on the steel platform are lifted upward. A continuous molding construction method in which the pouring edge rises.

[0025] The method comprises the steps of:

[0026] (1) Sliding form device assembly: The hollow pier sliding form system design adopts steel structure, adopts hydraulic internal and external split sliding formwork, and the sliding form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com