Floating building structure and construction method

A construction method and construction technology, applied in the direction of floating buildings, buildings, infrastructure engineering, etc., can solve the problems of unsuitable coal mining subsidence waters, floating buildings cannot live for a long time, etc. Land contradiction and the effect of meeting the demand for construction land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

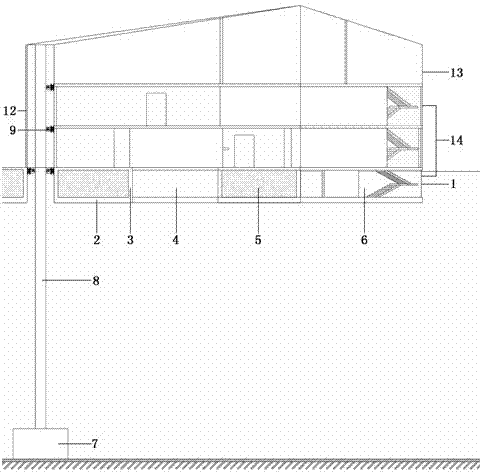

[0025] Embodiment 1: floating building structure and construction method of the present invention:

[0026] The building structure includes: a floating base 1, a structure 13 and a floating module 14. The floating base 1 and the structures 13 carried by it form a floating module 14, which is fixed by an underwater gravity foundation. Between the gravity foundation and the floating module There is a pull connection or pile foundation insertion between them.

[0027] The floating base 1 includes: a floating base bottom plate 2, a floating base side plate 3, a cavity structure 4 and a lightweight filler 5, and the floating base bottom plate 2 and the floating base side plate 3 form a cavity The structure 4 is filled with lightweight filler 5 or utilized as an underwater space 6 .

[0028] The gravity foundation is an underwater foundation 7 or an underwater pier 10 .

[0029] The pulling connection is a telescopic steel cable 11 .

[0030] The pile foundation is plugged into a...

Embodiment 2

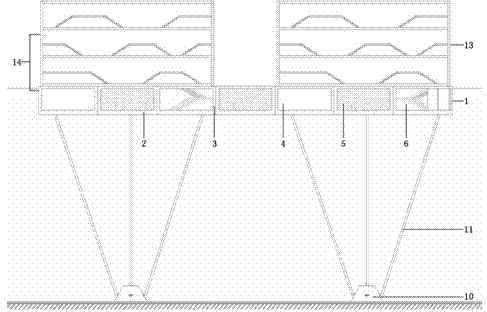

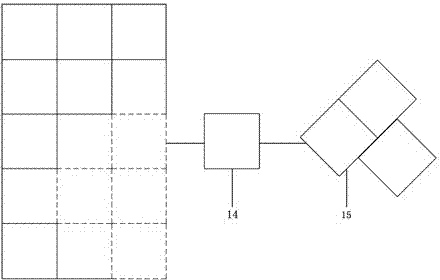

[0035] Example 2: In figure 2 Among them, the floating base 1 is first made, and the hollow structure 4 is formed by the bottom plate 2 and the side plate 3 of the floating base, and the interior is filled with lightweight filler 5 or used as an underwater space 6 . Combine and connect such a plurality of unitary floating bases as required to expand or change the plane of the base. Then, install the structures 13 and supporting facilities mass-produced in the factory on the floating base to form the floating module 14 . exist image 3 Among them, the combined connection method of the unit type makes each module easy to disassemble and move, and realizes the combined connection 15 of the floating modules.

[0036] Finally, the position of the floating module 14 is fixed by pulling: the underwater pier 10 is built, and the floating module 14 is pulled by the telescopic steel cable 11 fixed thereon.

[0037] Others are identical with embodiment 1, identical part is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com