Die plate dismantling-free cast-in-place concrete partition wall and construction method thereof

A concrete and formwork-free technology, which is applied to walls, building components, buildings, etc., can solve the problems of complex keel installation formwork installation process, complex block masonry process, and reduced construction efficiency, so as to achieve omission of masonry process, high Strength and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

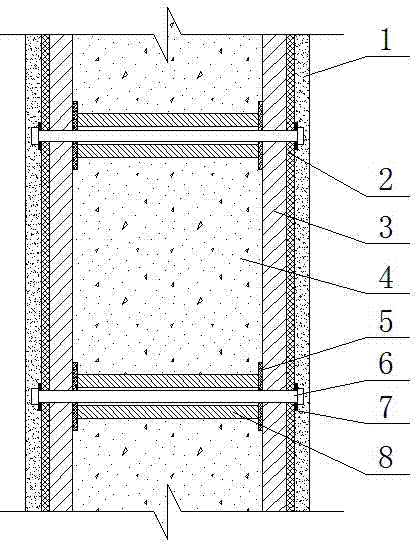

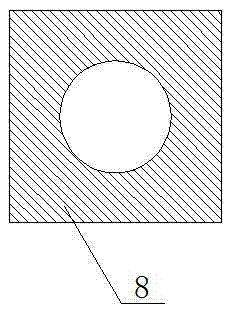

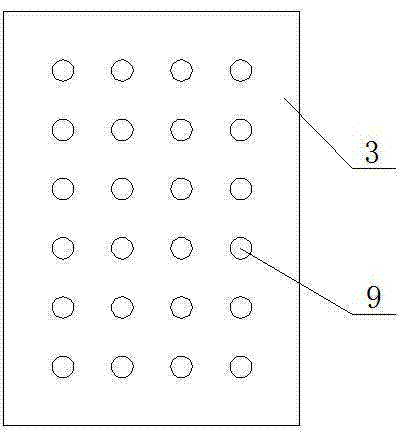

[0026] As shown in the figure, a formwork-free cast-in-place concrete partition wall includes a wall body and a surface layer 1. The wall body is composed of cast-in-place concrete 4 and a demolition-free formwork 3. The demolition-free formwork 3 is composed of formwork tie rods 6 fixed, the formwork tie rod 6 passes through the formwork pad 8 located between the non-demolition formwork 3; the cast-in-place concrete 4 is poured in the gap between the two sides of the non-demolition formwork 3, inside the non-demolition formwork 3, outside the formwork spacer 8, The template pull rod 6 passes through the 3 places of the non-demolition formwork, and an inner gasket 5 is provided; on the outside of the non-demolition formwork 3, the formwork tie rod 6 passes through the 3 places of the non-demolition formwork, and an outer gasket 7 is also provided. An anti-crack layer 2 is provided between the demolition-free template 3 and the surface layer 1, and the material of the anti-crack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com