Construction method of fabricated underground diaphragm wall

A technology of underground diaphragm wall and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc. It can solve the problems that the ground diaphragm wall cannot fully meet the needs of urban construction and the shortage of skilled labor resources on the construction site, so as to improve the level of engineering mechanization and construction efficiency, applicability and operability, and the effect of reducing abandoned projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

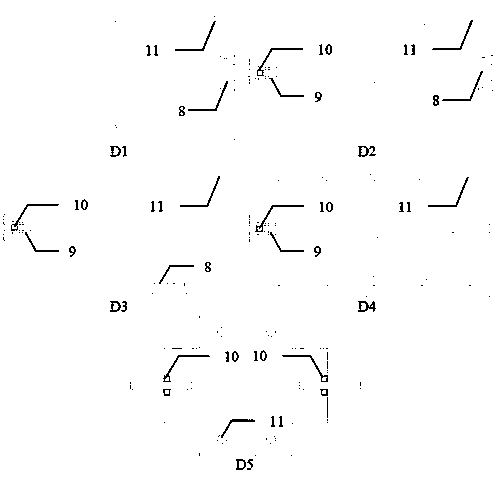

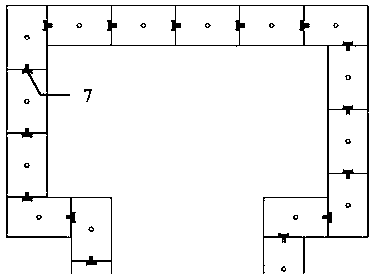

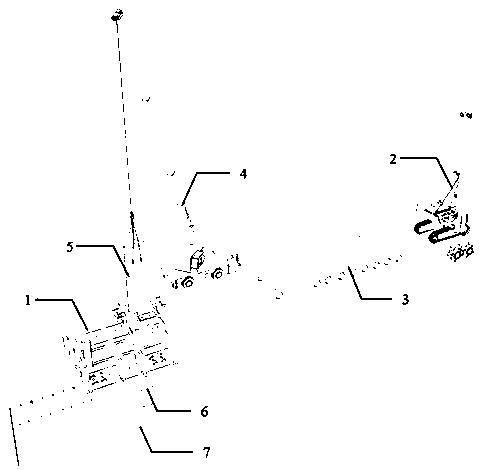

[0037] Such as Figure 1~4 As shown, a construction method of an assembled underground diaphragm wall comprises the following steps:

[0038] ⅰ. Prefabricated ground-to-wall structure

[0039] According to the order and position of the prefabricated ground connection wall, the ground connection wall is divided into wall panels with different cross-sectional structure types; among these wall panels, the prefabricated ground connection wall is vertically divided according to the difference in the upper and lower splicing positions. Divided into segments 5 with three different structural types: upper, middle and lower;

[0040] ⅱ. Pre-grooved or pre-mixed soft ground

[0041] In the construction site where the prefabricated ground connection wall needs to be inserted, use a groover or other soil stirring machine 2 to mix the soil and add water to dilute it to mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com