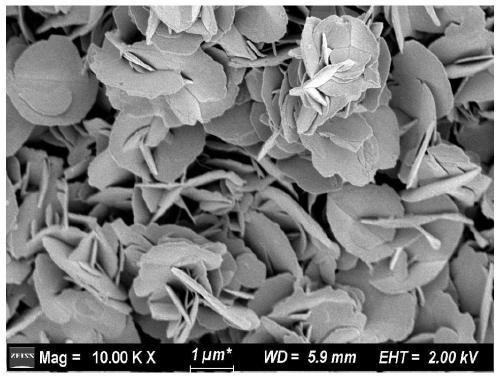

Method for one-step in-situ electro-deposition of layered double hydroxide coating on magnesium alloy surface

A technology of double hydroxide and electrodeposition layer, which is applied in the direction of electrolytic inorganic material coating, etc., to achieve the effect of simple solution formula and steps, fast film formation speed, and reduced safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for one-step in-situ electrodeposition layered double hydroxide coating on the surface of magnesium alloy comprises the following steps:

[0024] (1) Pretreatment

[0025] Including mechanical grinding and degreasing and degreasing;

[0026] Mechanical polishing uses 600# SiC water-based sandpaper to polish and level off on the polishing machine to remove macroscopic mud sand and oxide film, etc.;

[0027] Degreasing includes acetone ultrasonic degreasing and alkaline degreasing. Acetone Ultrasonic Degreasing Put the polished magnesium alloy in acetone at room temperature for 15 minutes; alkaline degreasing uses one or more of sodium hydroxide 60g / L, phosphate 7g / L and carbonate 22g / L For the compound alkaline solution, the washing and soaking time is 12 minutes, and the temperature is 65 degrees Celsius.

[0028] (2) Preparation of electrodeposition solution and electrodeposition

[0029] Preparation of electrodeposition solution: add a certain mass of d...

Embodiment 2

[0033] The method for one-step in-situ electrodeposition layered double hydroxide coating on the surface of magnesium alloy comprises the following steps:

[0034] (1) Pretreatment

[0035] Including mechanical grinding and degreasing and degreasing;

[0036] Mechanical polishing uses 800# SiC water-based sandpaper to polish and level off on the polishing machine to remove macroscopic mud sand and oxide film, etc.;

[0037] Degreasing includes acetone ultrasonic degreasing and alkaline degreasing. Acetone Ultrasonic Degreasing Put the polished magnesium alloy in acetone for 15 minutes at room temperature; for alkaline degreasing, use one or more of sodium hydroxide 17g / L, phosphate 8g / L and carbonate 28g / L For the compound alkaline solution, the washing and soaking time is 15 minutes, and the temperature is 55 degrees Celsius.

[0038] (2) Preparation of electrodeposition solution and electrodeposition

[0039] Preparation of electrodeposition solution: add a certain mass ...

Embodiment 3

[0043] The method for one-step in-situ electrodeposition layered double hydroxide coating on the surface of magnesium alloy comprises the following steps:

[0044] (1) Pretreatment

[0045] Including mechanical grinding and degreasing and degreasing;

[0046] Mechanical polishing uses 1000# SiC water-based sandpaper to polish and level off on the polishing machine to remove macroscopic mud sand and oxide film, etc.;

[0047] Degreasing includes acetone ultrasonic degreasing and alkaline degreasing. Acetone Ultrasonic Degreasing Put the polished magnesium alloy in acetone and ultrasonic at room temperature for 15 minutes; alkaline degreasing uses one or more of sodium hydroxide 50g / L, phosphate 15g / L and carbonate 20g / L For the compound alkaline solution, the washing and soaking time is 10 minutes, and the temperature is 65 degrees Celsius.

[0048] (2) Preparation of electrodeposition solution and electrodeposition

[0049]Preparation of electrodeposition solution: add a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com