Physical antibacterial wet tissue

A wet wipe, physical technology, applied in skin care preparations, cosmetics, cosmetic preparations, etc., can solve the problem of easy precipitation of preservatives and irritation, and achieve the effect of avoiding drug resistance and excellent antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

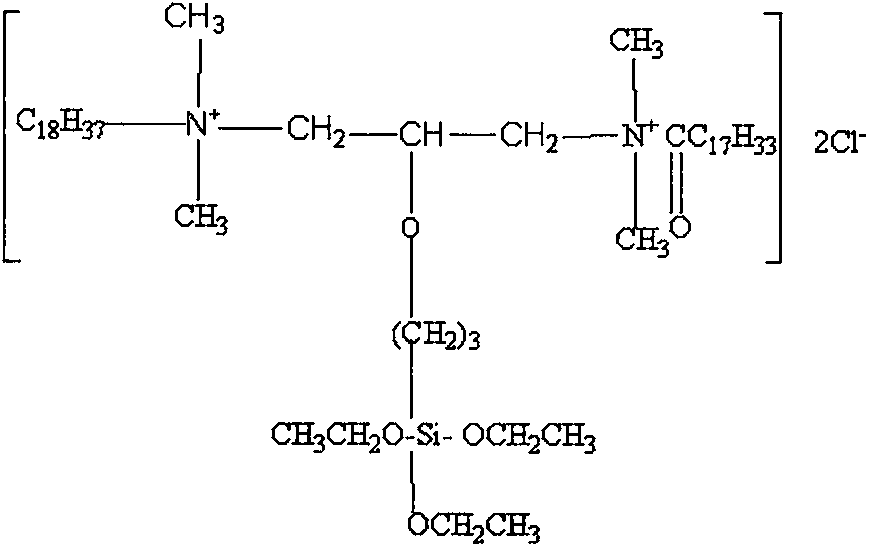

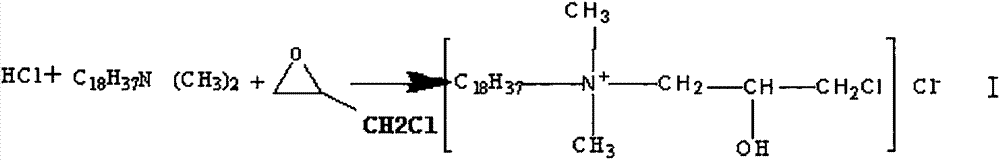

[0048] 1) Reaction of octadecyl dimethyl tertiary amine with epichlorohydrin and hydrochloric acid:

[0049] The dry hydrogen chloride gas was introduced into the anhydrous ether solution of octadecyldimethyl tertiary amine to produce white precipitate. Then use water as the solvent, put a certain amount of epichlorohydrin in the dropping funnel, start to drop it slowly, drop it in 35 minutes, stir evenly at room temperature, react at 80°C for 12h, and titrate the epichlorohydrin quaternary ammonium After the reaction was completed, the solvent was removed by rotary evaporation at room temperature to obtain a light yellow paste residue, which was recrystallized with acetone, filtered under reduced pressure after the crystals were precipitated, and repeated several times. Obtain white powder single quaternary ammonium salt product---intermediate product N-(3-chloro-2-hydroxypropyl)-N,N-dimethyl octadecyl ammonium chloride.

[0050]

[0051] 2) Reaction process: Methyl oleat...

preparation example 2

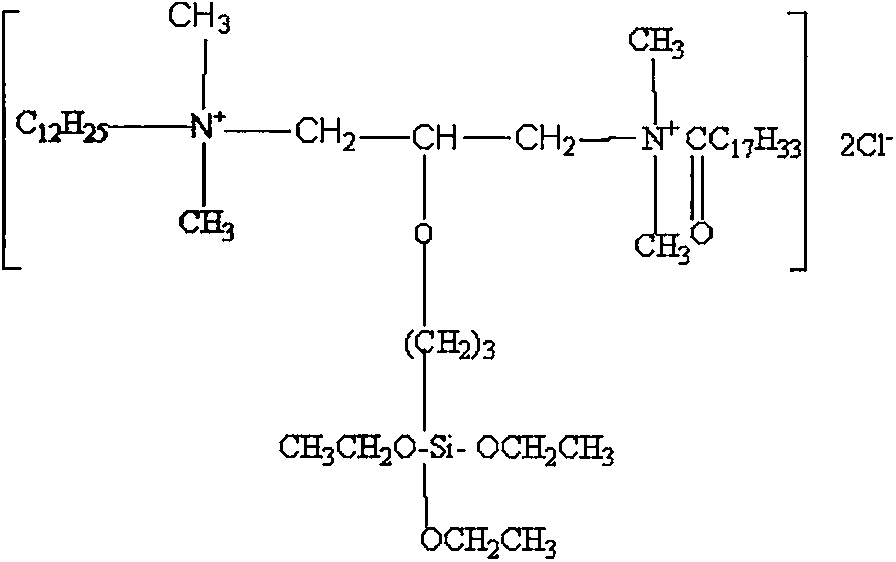

[0059] Same as Preparation Example 1, the only difference is that in the 1) step, anhydrous diethyl ether solution of dodecyldimethyl tertiary amine is used to finally obtain 2-triethoxysilyl propaneoxy-1-N,N -Dimethyloleoyl-3-dodecyldimethylammonium propane dichloride (abbreviation: organosilicon bisquaternary ammonium salt B), the yield is 98.5%.

[0060]

Embodiment 1

[0062] The preparation method of the wet wipe body is as follows:

[0063] (1) adopt length to be 40mm, the bamboo pulp fiber that diameter is 0.08mm is as raw material, through weighing, cotton blending, opening, mechanical carding, messy web laying process, make it form fiber web;

[0064] (2) 10 water needles formed by high-pressure fine water flow are used to puncture the front and back sides of the fiber web respectively, so that the fiber web is completely soaked, and the fiber web is entangled and reinforced; the fine water flow is 0.5% organic The aqueous solution of silicon double quaternary ammonium salt A;

[0065] (3) Then place it at a temperature of 120°C for cross-linking and drying for 8 minutes;

[0066] (4) After cutting and high-temperature sterilization, the non-woven wet tissue body with a thickness of 5 mm is obtained;

[0067] In the preparation process of the wet wipe liquid E, the solution A is 0.35 g of polysorbate-60, 0.1 g of polyglyceryl-2 oleate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com