Patents

Literature

43 results about "Octadecyl ammonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

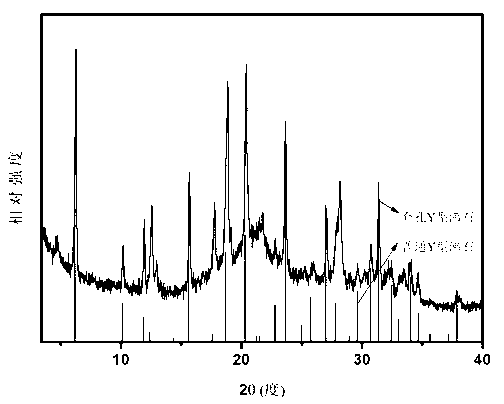

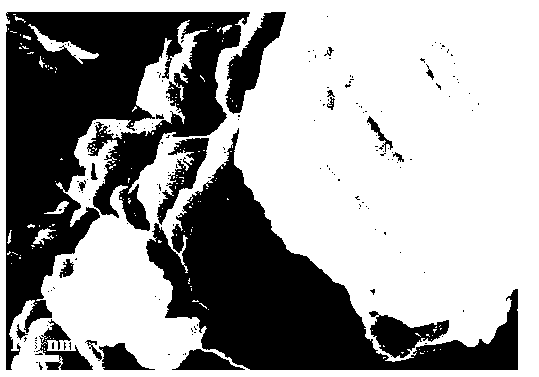

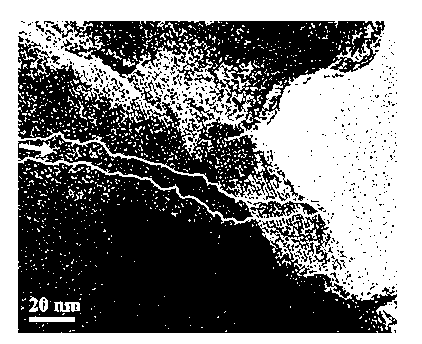

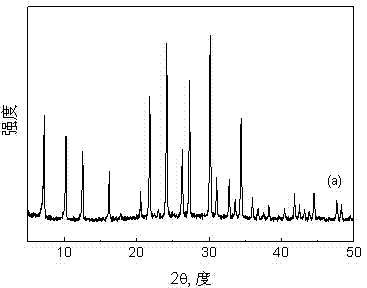

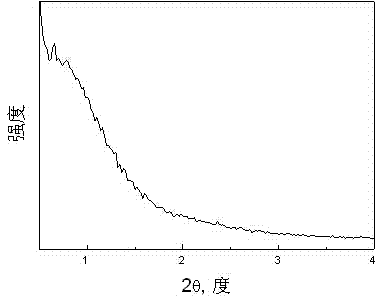

Mesoporous Y-type zeolite molecular sieve and preparation method thereof

InactiveCN103214003APlay a structural roleLow costFaujasite aluminosilicate zeoliteMolecular sieveSilanes

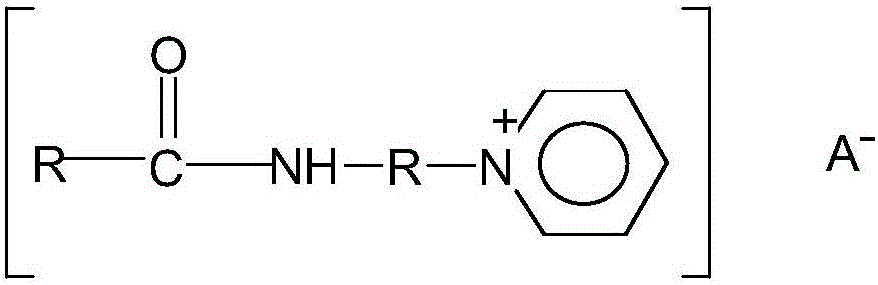

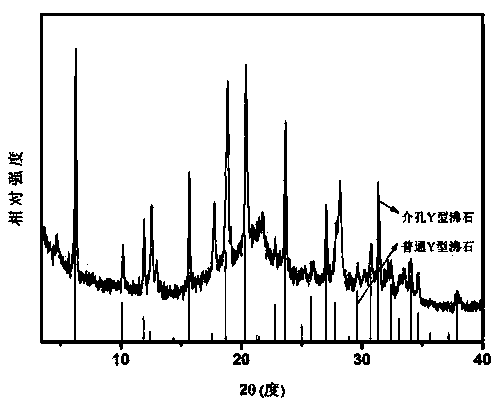

The invention discloses a mesoporous Y-type zeolite molecular sieve and a preparation method thereof. The preparation method comprises the following steps of: firstly preparing a Y-type zeolite guiding agent; and then guiding synthesis of the mesoporous Y-type zeolite molecular sieve by using amphiphilic organosilane N,N-dimethyl-N-[3-(trimethoxysilane)propyl]octadecyl ammonium chloride (TPOAC) as a mesoporous template, wherein siloxane group at the organosilane terminal is firstly hydrolyzed into silicon hydroxyl; then the silicon hydroxyl is linked to a skeleton on the zeolite surface through chemical bonds; and other alkyl terminals are polymerized and then participate in pore expansion. According to the method disclosed by the invention, mesoporous zeolites can be synthesized by using a one-step hydrothermal process; the method is simple in preparation process, easy to operate and low in cost and good in connectivity between mesopores and micropores, and facilitates macromolecular diffusion. As the prepared mesoporous zeolite molecular sieve has the mesopores and the micropores, the defect of a single pore structure is avoided; and the mesoporous Y-type zeolite molecular sieve has broad application prospect in the catalytic field, in particular in macromolecular diffusion-limited reaction.

Owner:SOUTH CHINA UNIV OF TECH

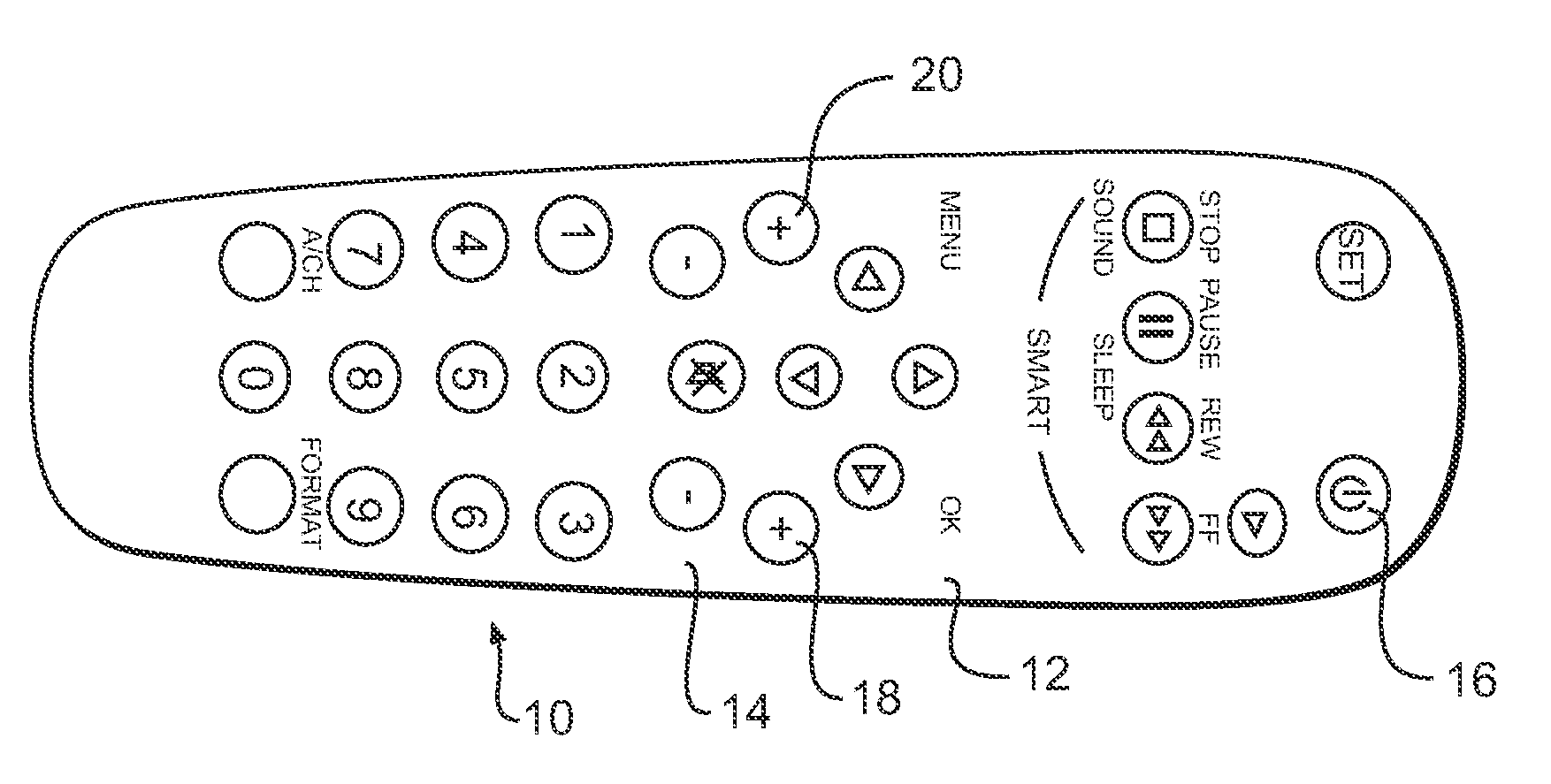

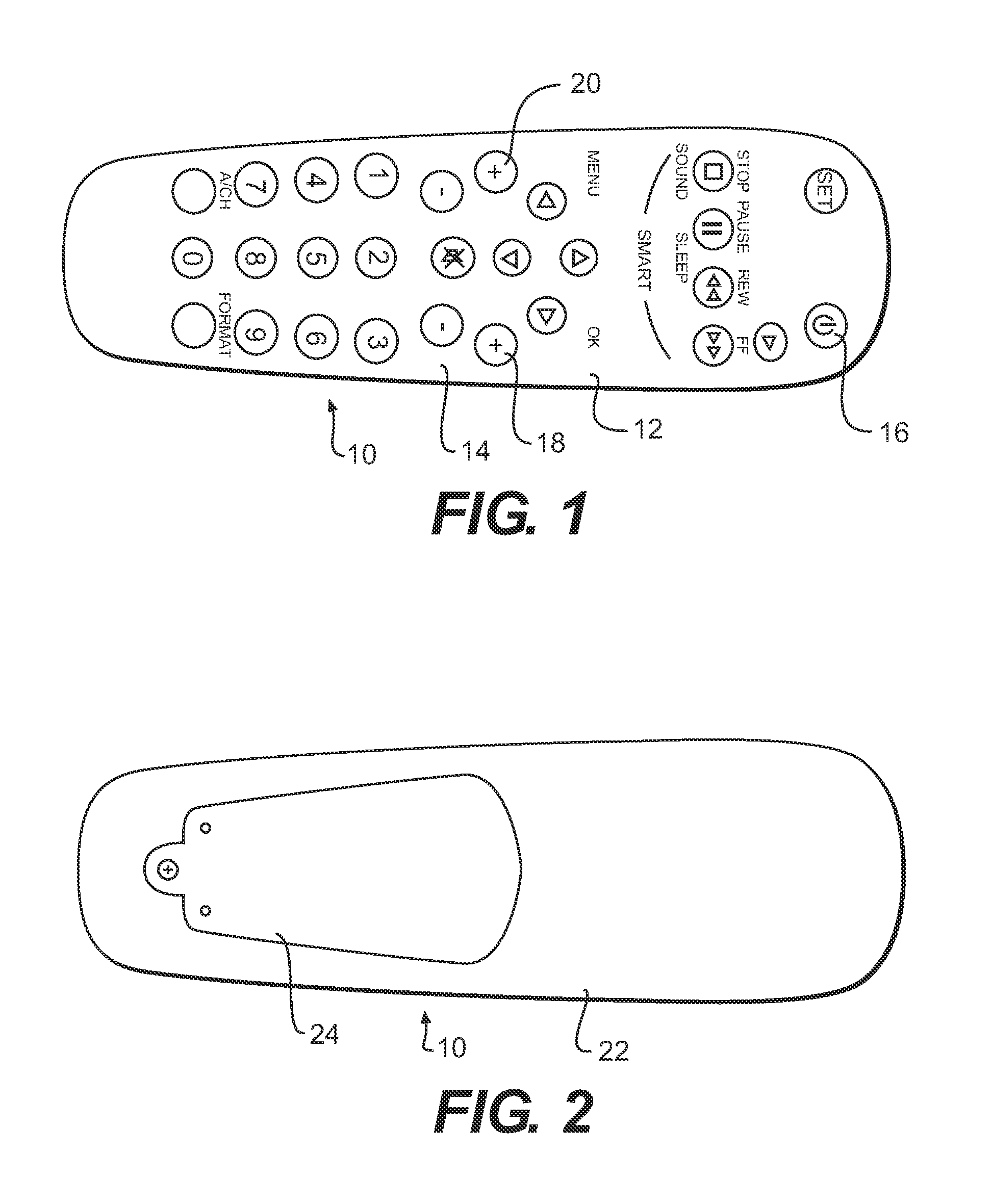

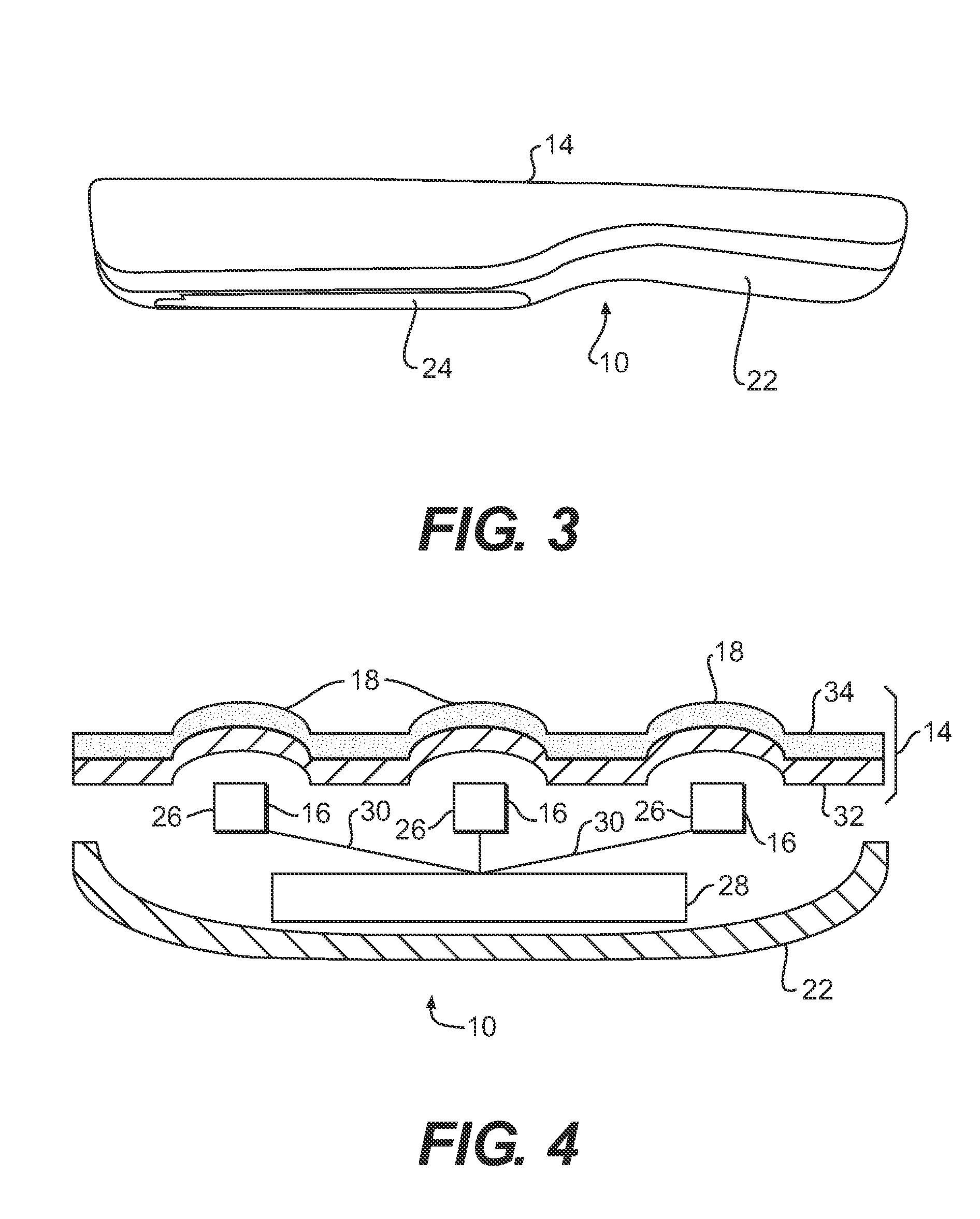

Remote control

InactiveUS20120127375A1Minimize transmissionTelevision system detailsColor television detailsRemote controlEngineering

A remote control includes a top surface, a bottom housing connectable to the top surface, a plurality of protrusions extending outwardly from the top surface, a plurality of buttons associated with the plurality of protrusions such that pressure applied to the protrusions is transferred to the buttons to generate one or more actuation signals, and a transmitter connected to the buttons to receive the actuation signals and generate transmission signals. The transmission signals provide control instructions to a device associated with the remote control. The top surface includes an antimicrobial material, such as 3-Trimethoxy silyl propyl dimethyl octadecyl ammonium chloride.

Owner:GEIER WILLIAM FREDERICK

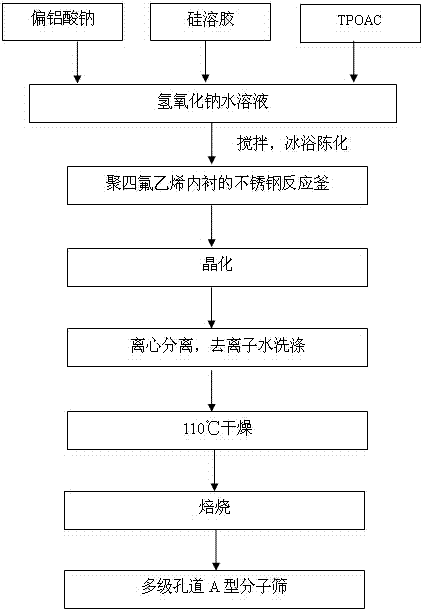

Preparation method of A type molecular sieve with hierarchical duct

InactiveCN104276583AImprove playbackEvenly dispersedAluminosilicate zeolite type-AMolecular sieveHydrothermal synthesis

The invention discloses a preparation method of an A type molecular sieve with a hierarchical duct, belonging to the preparation field of a zeolite molecular sieve. The preparation method comprises the following steps: adding a certain amount of sodium hydroxide and sodium metaaluminate into deionized water, adding silica sol and trimethoxysilylpropyl dimethyl octadecyl ammonium chloride (TPOAC) under stirring, ageing the liquid for 1-5 hours; then, filling the aged liquid into a hydrothermal synthesis kettle for crystallizing for 4-9 hours at 80-110 DEG C; and obtaining the A type molecular sieve with the hierarchical duct by virtue of steps such as filtering, washing, drying and roasting, wherein a molar ratio of reactants is that Na2O / SiO2 / Al2O3 / H2O / TPOAC is (2-4) / (1-5) / (0.5-2) / (90-150) / (0.01-0.2). The preparation method disclosed by the invention is simple, capable of introducing a mesoporous material into a microporous A type molecular sieve, so that the A type molecular sieve has a structure of the hierarchical duct.

Owner:KUNMING UNIV OF SCI & TECH

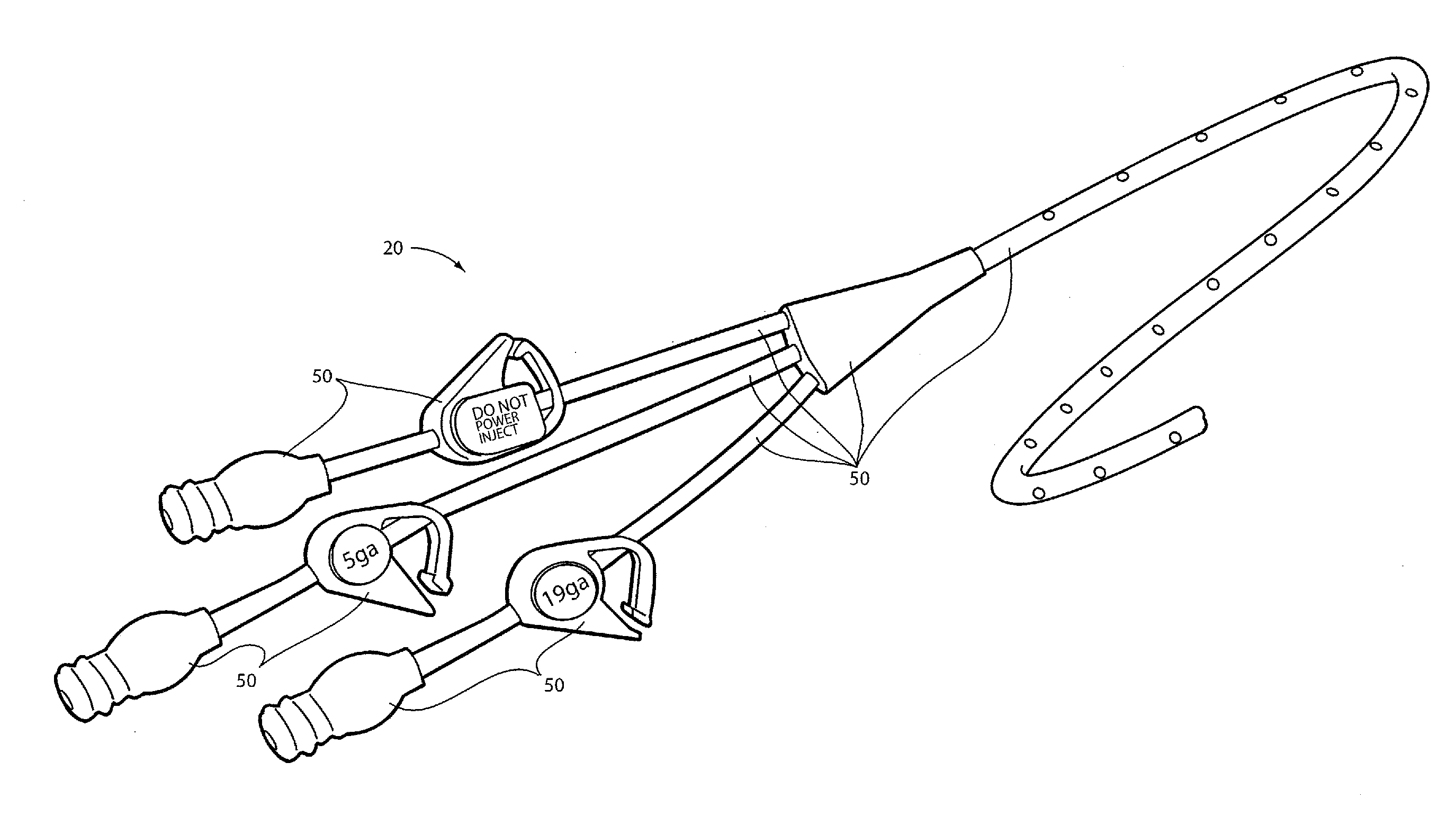

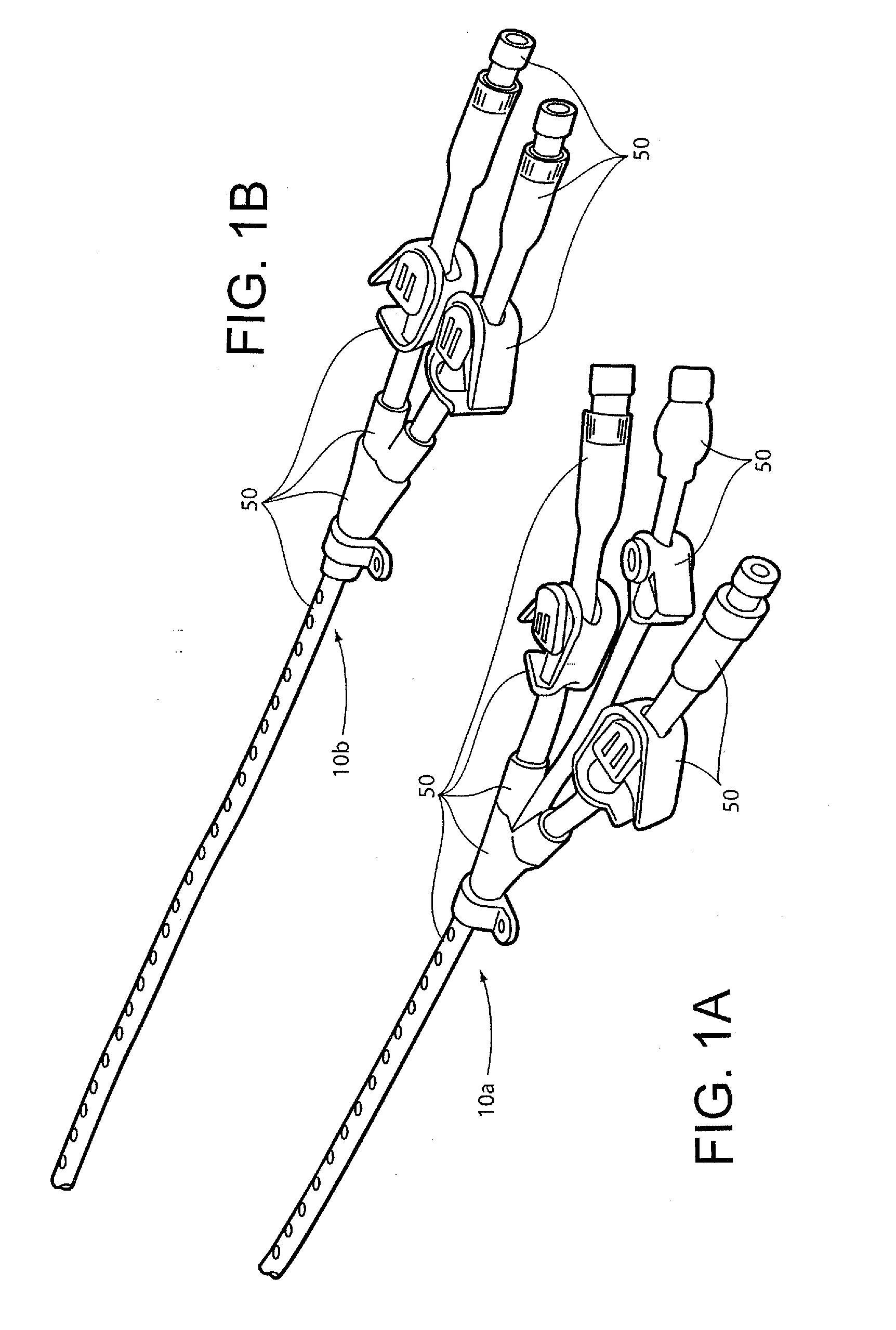

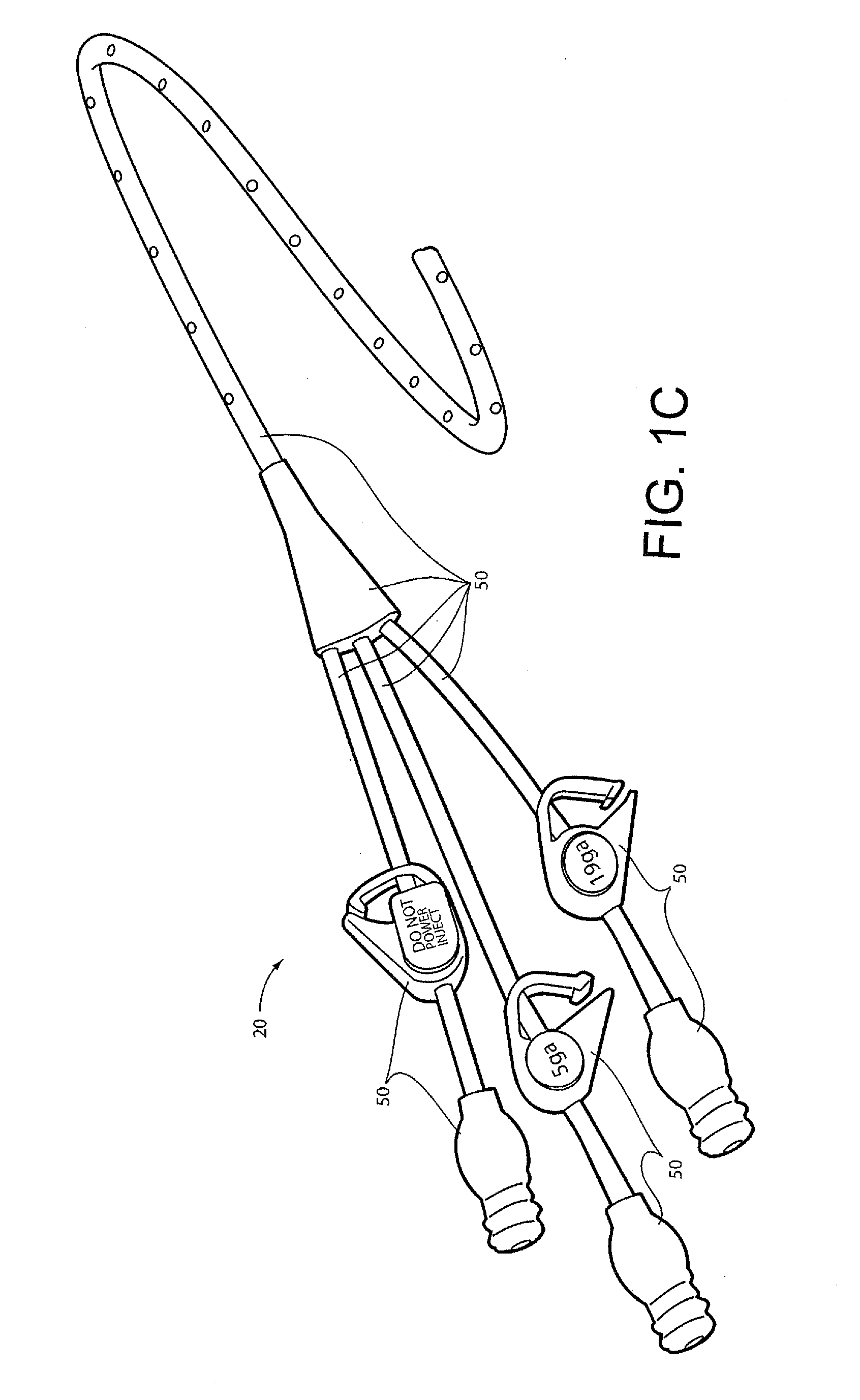

Catheters having an antimicrobial treatment

A vascular access product is provided having a component with a plurality of external surfaces. At least one of the surfaces is coated with an antimicrobial treatment, wherein the antimicrobial material comprises a silane quaternary ammonium salt. The silane quaternary ammonium salt may comprise 3-(trimethoxysilyl) propyldimethyloctadecyl ammonium chloride. The vascular access product may be IV administration tubing, a catheter and the associated caps, luers, Y sites, connectors, drip chambers, PICC lines, stopcocks and similar IV components such as needleless IV connectors having valve mechanisms.

Owner:PARASOL MEDICAL

Method for preparing durable antibacterial finishing agents for textile fabrics

InactiveCN106811972AGood antibacterial durabilityWill not affect the feelBiochemical fibre treatmentGrip property fibresCarboxymethyl celluloseKeratin

The invention relates to a preparation method of a durable fabric antibacterial finishing agent, belonging to the technical field of fabric finishing. In the present invention, wool is used as a raw material, and after being washed and decolorized by alkali solution, a wool keratin solution is prepared, and then sodium hydroxymethyl cellulose is used as a template agent to make nano silicon dioxide into a porous structure nanometer with good dispersibility. Silicon oxide, and then use the porous structure to absorb stearyl ammonium chloride to make an antibacterial agent, and finally use the prepared wool keratin solution to compound the antibacterial agent and silicone oil to obtain a durable fabric antibacterial finishing agent. The durable fabric antibacterial finishing agent prepared by the present invention prepares porous nano-silica, uses its large specific surface area to load quaternary ammonium salt antibacterial agents, and then uses wool keratin solution to coat the antibacterial agent and covers it on the surface of the fabric. , Form a protective film, significantly improve the antibacterial durability of the fabric.

Owner:孙祎

Flow improver for shale gas reservoir fracturing and preparation method thereof

Owner:SOUTHWEST PETROLEUM UNIV

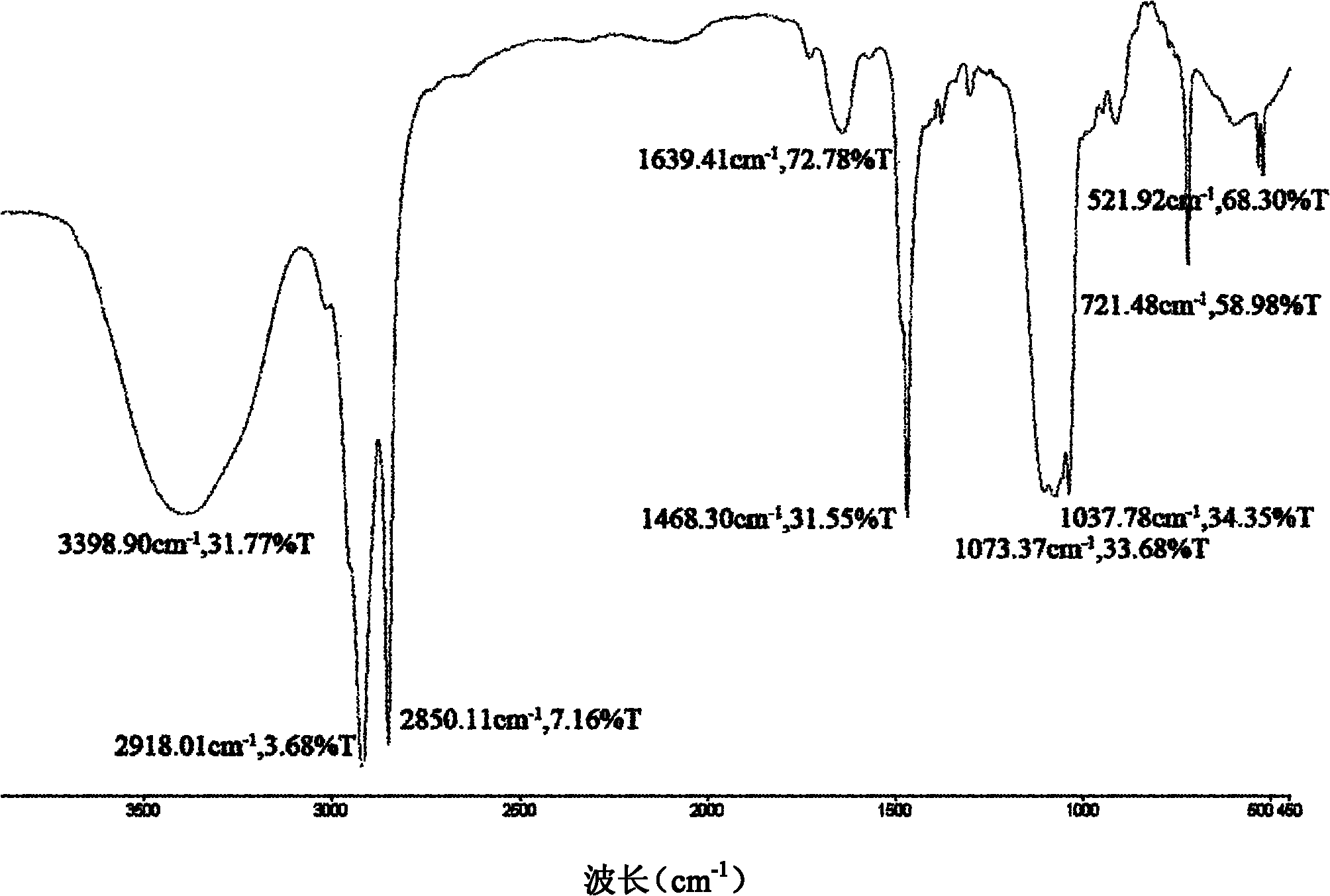

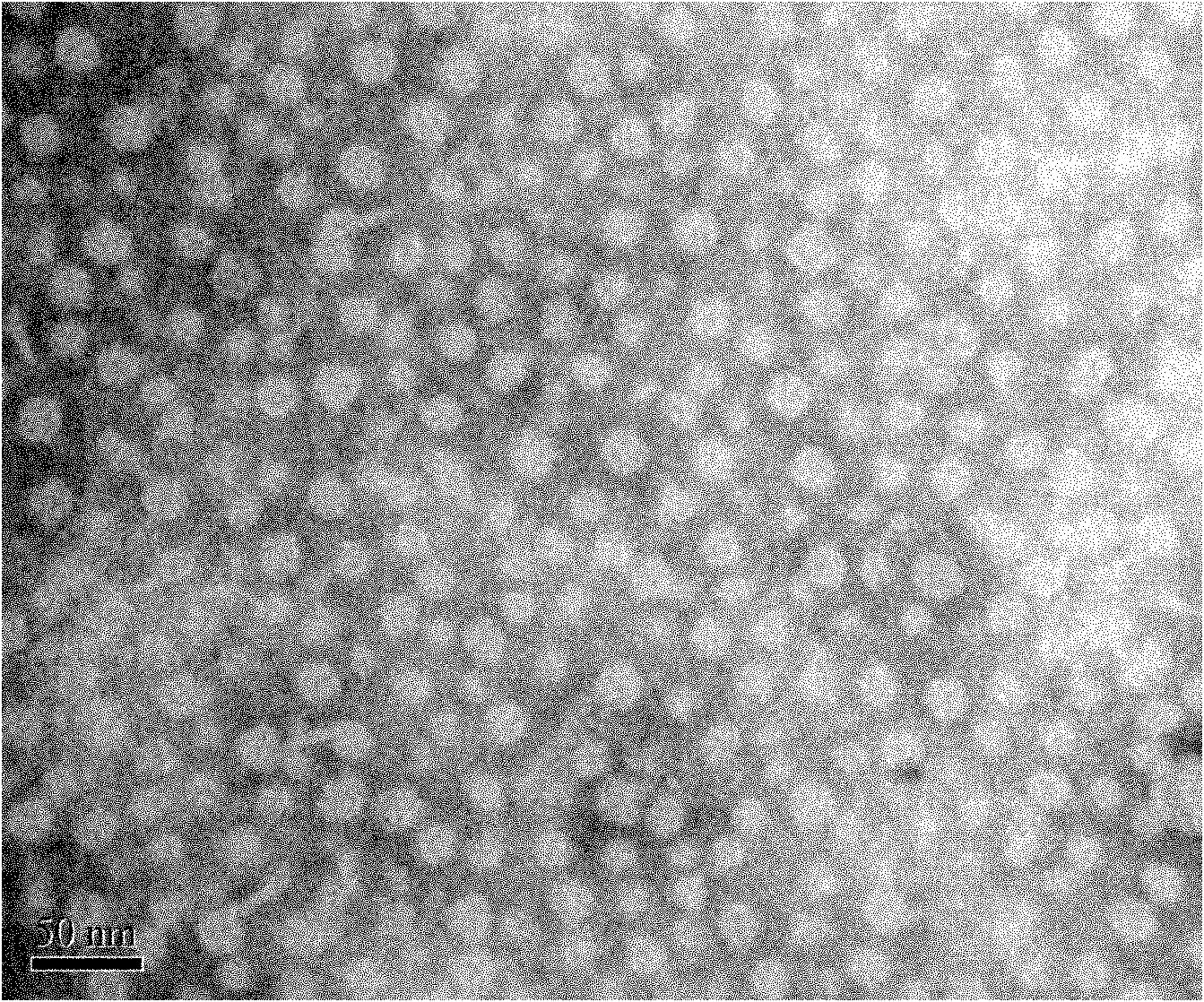

Silicone exfoliated organo montmorillonite and preparation method thereof

InactiveCN101575099AUniform particle size distributionReduce manufacturing costSilicon compoundsMontmorilloniteAqueous solution

Owner:SHANGHAI UNIV OF ENG SCI

Manufacturing method of durable composite antibacterial textile

InactiveCN102839535AImprove antibacterial propertiesImprove bindingFibre treatmentNatural productZirconate

The invention discloses a manufacturing method of a durable composite antibacterial textile, which comprises the following steps of: immersing the textile in an immersing liquid containing a composite anti-bacterial finishing agent at 80-95 DEG C; and then maintaining constant temperature of the textile at 115-130 DEG C for 0.5-2h, wherein the composite anti-bacterial finishing agent consists of the following components by weight: 40-75 parts of zinc oxide, 3-5 parts of urea antibacterial agent, 5-12 parts of 3-(trimethoxy silyl)propyl dimethyl octadecyl ammonium chloride, 0.5-2 parts of sorbic acid and 1-5 parts of aluminum zirconate coupling agent. According to the invention, inorganic, organic and natural product anti-bacterial finishing agents are organically combined, and a specific antibacterial agent and auxiliary agents are selected for compounding, so that the composite anti-bacterial finishing agent has the advantages of three anti-bacterial finishing agents, can be firmly combined with the textile, is strong in durability, has notable antibacterial action to the textile and is nontoxic and safe.

Owner:KUNSHAN TIENIU SHIRT FACTORY

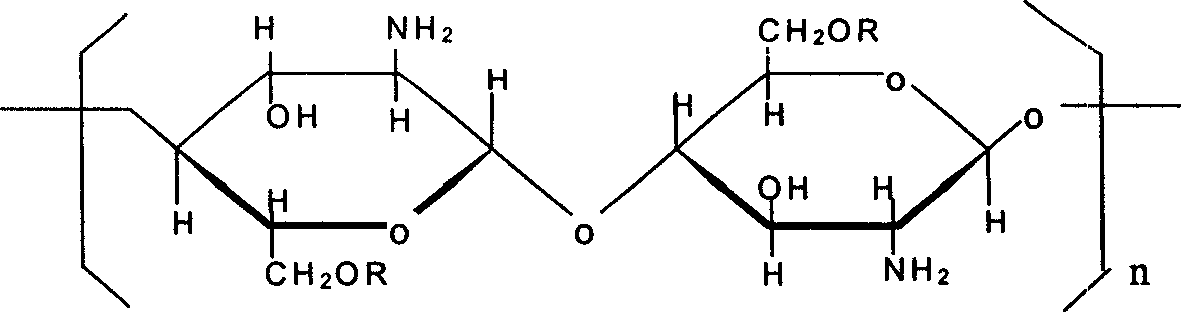

Water and oil soluble O-chitosan derivatives and their preparation and use

InactiveCN1594365AImprove adsorption capacityObvious weight loss effectOrganic active ingredientsMetabolism disorderEpichlorohydrinHydrochloride

Water and oil soluble O-chitosan derivatives, their preparation and use thereof, wherein the synthesized chitosan upper substitutive derivative comprises o-ethlamine hydroxide ethyl chitosan and 0-2' -hydroxylpropyl -N, N-dimethyl octadecyl ammonium chloride chitosan, which is prepared through the reaction of N-phthaloyl chitosan with chlorohydrin, chlorethamin hydrochlorate and N,N dimethyl octadecyl amine hydrochlorate and epichlorohydrin in dimethyl carbinol medium.

Owner:TIANJIN UNIV

Aid low-mobility polyvinyl chloride preservative film

InactiveCN101935426ASimple processLow costFruit and vegetables preservationPolyvinyl chlorideStearic acid

The invention discloses an aid low-mobility polyvinyl chloride preservative film formula, which comprises 100 parts of polyvinyl chloride resin (SG-4 type), 25 to 30 parts of dioctyl phthalate (DOP), 15 to 25 parts of polyneopentanediol adipate, 2 to 5 parts of nano montmorillonite, 1 to 2 parts of octadecyl ammonium chloride, 4 to 6 parts of calcium-zinc composite stabilizer, 0.5 to 1 part of stearic acid and 0.5 to 1 part of paraffin. The components are prepared into a film with certain thickness for keeping fruits and vegetables fresh by processes of colloid mill homogenization, high-temperature kneading, melt extrusion, blow molding, traction, longitudinal and transverse stretching and the like. The mobility of the DOP is effectively reduced, the DOP mobility tolerance of the preservative film is increased by adding the organic modified montmorillonite particles, and the preservative film keeps good mechanical property. The aid low-mobility polyvinyl chloride preservative film has the main characteristics of tolerating plasticizer mobility and meeting the national standards on stretching property, tearing property, friction coefficient, light transmittance and thermal sealing property.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing bacteriostatic textile finishing agent from ursolic acid extract

ActiveCN110499644ALow extraction rateRaw materials are easy to obtainBiocideBiochemical fibre treatmentSolubilitySilanes

The invention relates to the field of preservation of textile relics, and discloses a method for preparing a bacteriostatic textile finishing agent from an ursolic acid extract. A dual-phase extraction method and a microwave-assisted extraction method are combined to be used for shortening the extracting time and improving the extraction efficiency. A mixed solution of a (NH4)2SO4 solution and ethyl alcohol is used as an extracting agent, the viscosity is easily reduced, the diffusivity and the solubility of the liquid are improved, and therefore, the content of extracted ursolic acid is increased. The ursolic acid and nanometer zinc oxide are used as a bacteriostatic agent, and the antibacterial activity of a textile is improved; by adding 3 (trimethoxy silane) propyl dimethyl octadecyl ammonium chloride and 3-imino-N-nitrided acetamidocyclic buty amide in the preparation process of the textile finishing agent, the finishing agent can be chemically bonded with cellulosic fibers and can be polycondensated to form a film, and the antibiotic constituents of the finishing agent have the washability.

Owner:ZHEJIANG SCI-TECH UNIV

Antibacterial fresh keeping packaging bag

The invention relates to an antibacterial fresh keeping packaging bag, and belongs to the technical field of packaging bags. The packaging bag is prepared from, by weight, 80-100 parts of polypropylene resin, 3-7 parts of polyvinyl alcohol, 20-40 parts of starch, 0.2-1.5 parts of nano titanium dioxide, 2-5 parts of epoxidized soybean oil, 18-22 parts of dioctyl phthalate, 28-32 parts of polypropylene glycol adipate, 2-5 parts of organic modified nano calcium carbonate, 2-4 parts of modified copper sulfate, 3-5 parts of octadecyl-ammonium chloride, 2-4 parts of stearic acid, 1.5-2.5 parts of liquid paraffin, 0.5-1.5 parts of thymol, 0.5-1.5 parts of vanillic aldehyde, 1-2 parts of titanium dioxide and 0.02-0.09 part of brofenvalerate through melting, blending, extruding and film blowing. The dense bag has the insecticidal and antibacterial properties, people do not need to worry about that bacteria and insects can damage substances in the dense bag, and the bag is closer to life of people.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

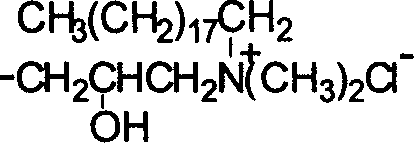

Textile color fixing agent containing chitosan quaternary ammonium salt and preparation method thereof

The invention relates to a textile color fixing agent containing chitosan quaternary ammonium salt and a preparation method thereof, and belongs to the field of research and development and application of textile dyeing auxiliary. At present, the color fixing effect of applying chitosan quaternary ammonium salt to a textile color fixing agent is not good enough. The textile color fixing agent provided by the invention is prepared from the following components in parts by mass: 5-30 parts of chitosan quaternary ammonium salt, 5-20 parts of N,N-dimethyl-N-hydroxyethyl octadecyl ammonium chloride, 0-5 parts of glacial acetic acid, 1-5 parts of TO7 nonionic surfactant, 5-10 parts of epoxy modified silicone oil and 30-60 parts of water. With chitosan quaternary ammonium salt as main color fixing component, the textile color fixing agent provided by the invention is nontoxic, harmless, readily biodegradable and easy and convenient to prepare and process, and realizes a good color fixing effect and causes little influence on the fabric handfeel.

Owner:ZHEJIANG SILK TECH

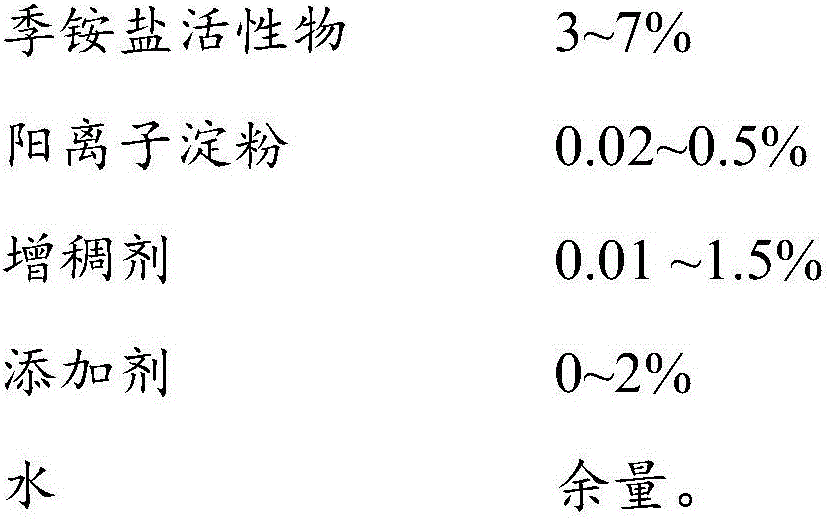

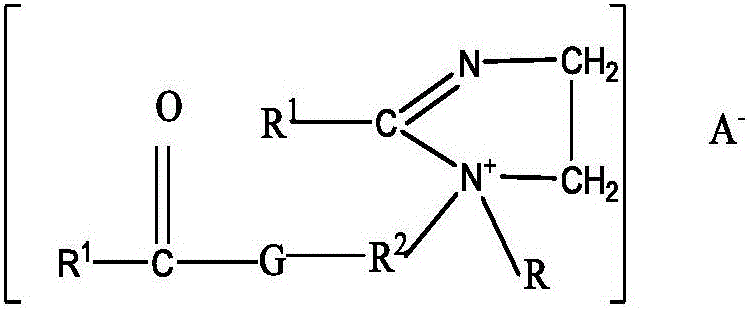

Softener compound

ActiveCN106835698AImproves the ability to soften fabricsImprove abilitiesGrip property fibresQuaternary ammonium cationDodecylammonium chloride

The invention relates to a softener compound which comprises the following components by weight percent: 3-7% of quaternary ammonium salt active matter, 0.02-0.5% of cationic starch, 0.01-0.5% of thickening agent, 0-2% of additive and the balance of water, wherein the cationic starch is prepared from starch and 2,3-glycidyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl dimethyl-dodecyl ammonium chloride or 3-chlorine-2-hydroxypropyl dimethyl-octadecyl ammonium chloride. The softener compound is formed by compounding cationic starch with quaternary ammonium salt active matter; less cationic starch (accounting for 0.02-0.5wt% of the compound) is used together with quaternary ammonium salt; the softening fabric effect is better than that of singly used quaternary ammonium salt; the oily hand feel caused by the quaternary ammonium salt in higher saturability is relieved to some extent; a smoother experience is brought.

Owner:GUANGZHOU TINCI MATERIALS TECH

Mesoporous Y-type zeolite molecular sieve and preparation method thereof

InactiveCN103214003BPlay a structural roleLow costFaujasite aluminosilicate zeoliteMolecular sieveSilanes

The invention discloses a mesoporous Y-type zeolite molecular sieve and a preparation method thereof. The preparation method comprises the following steps of: firstly preparing a Y-type zeolite guiding agent; and then guiding synthesis of the mesoporous Y-type zeolite molecular sieve by using amphiphilic organosilane N,N-dimethyl-N-[3-(trimethoxysilane)propyl]octadecyl ammonium chloride (TPOAC) as a mesoporous template, wherein siloxane group at the organosilane terminal is firstly hydrolyzed into silicon hydroxyl; then the silicon hydroxyl is linked to a skeleton on the zeolite surface through chemical bonds; and other alkyl terminals are polymerized and then participate in pore expansion. According to the method disclosed by the invention, mesoporous zeolites can be synthesized by using a one-step hydrothermal process; the method is simple in preparation process, easy to operate and low in cost and good in connectivity between mesopores and micropores, and facilitates macromolecular diffusion. As the prepared mesoporous zeolite molecular sieve has the mesopores and the micropores, the defect of a single pore structure is avoided; and the mesoporous Y-type zeolite molecular sieve has broad application prospect in the catalytic field, in particular in macromolecular diffusion-limited reaction.

Owner:SOUTH CHINA UNIV OF TECH

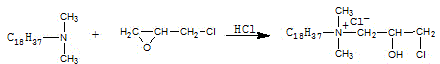

Preparation method of novel polyester filament yarn fabric alkali weight reduction accelerant FY-01

ActiveCN104358122AUniform penetrationGood moisture wicking effectFibre typesReduction rateMoisture absorption

The invention discloses a p reparation method of a novel polyester filament yarn fabric alkali weight reduction accelerant FY-01. The novel polyester filament yarn fabric alkali weight reduction accelerant FY-01 is prepared by compounding the following components in percentage by weight: 25%-35% of 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride, 15%-25% of N,N-dimethyldiallyl ammonium chloride, 10%-12% of AE-07 polyoxyethylene ether, 5%-8% of iso-ol polyoxyethylene ether, and the balance of water. The 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride and N,N-dimethyldiallyl ammonium chloride of the alkaline weight reduction accelerant are mixed, so that the uniform adsorption amount of cationic alkali weight reduction accelerants on the surface of the polyester filament can be increased so as to achieve better weight reduction effect, the uniformity is good, and the weight reduction rate is easily controlled; the polyoxyethylene ether is added for compounding, substances can be added into grooves in the surface of the polyester stripped and etched by sodium hydroxide, so that the hydrophilicity of the fiber can be increased to achieve the moisture absorption and sweat releasing functions, and the wearing comfortableness can be promoted.

Owner:南通科沃纺织有限公司

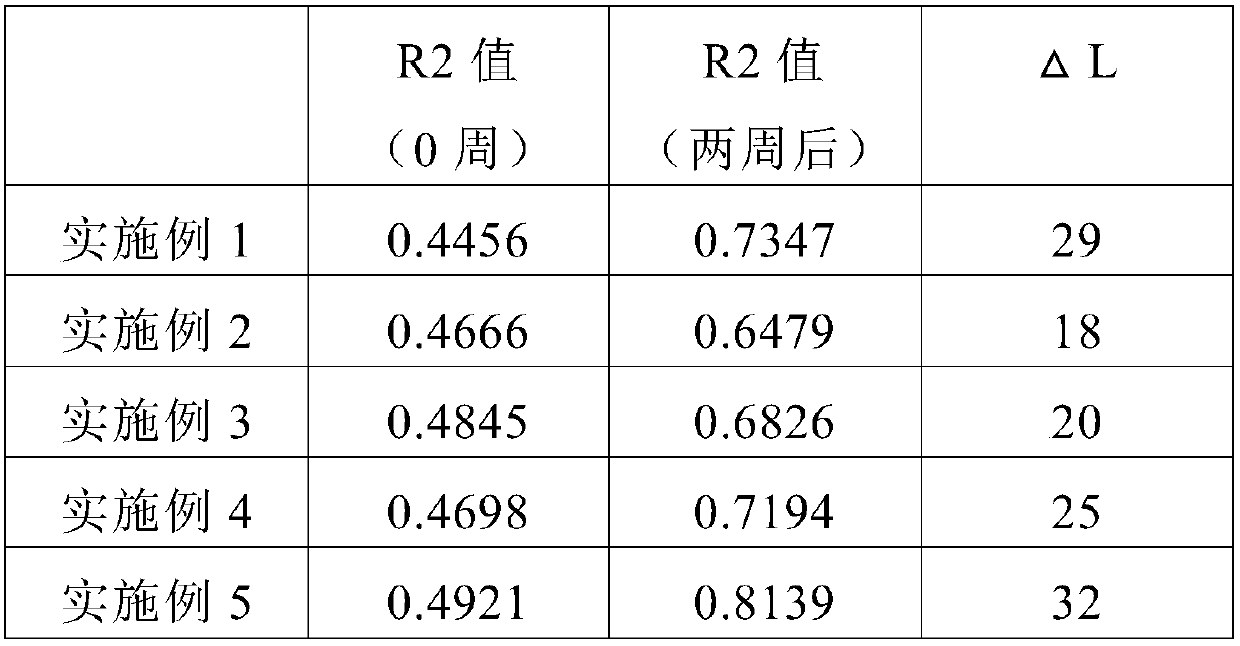

Liquid cosmetic paste

ActiveCN109568218APromote growthPromote generationCosmetic preparationsToilet preparationsCuticleHydroxyethyl cellulose

The invention discloses liquid cosmetic paste which is prepared from the following raw materials: carbomer, hydroxyethyl cellulose modifier, growth factor, honeysuckle flower extracting solution, radix dipsaci extracting solution, moisturizing additive and water. The moisturizing additive is at least one of amphiphilic carboxymethyl chitosan octadecyl ammonium chloride and quaternary ammonium hyaluronate. Compared with the prior art, the liquid cosmetic paste and the preparation method thereof have the advantages that the liquid cosmetic paste is safe and non-irritant and has nourishing and moistening functions; the liquid cosmetic paste has special functions of nourishment, anti-aging, stable emulsification, antisepsis and anti-inflammation, promotion for wound healing, repairing of damaged cells, and the like; the liquid cosmetic paste has effects of efficient moisturizing and long-term water retaining and is capable of continuously keeping water content of skin cuticle, guaranteeingskin moistening and keeping skin compact, elastic and glossy; after long-term use, the skin will become more fine, smooth and elastic.

Owner:知佰幸细胞库(浙江)有限公司

Antimicrobial packing bag for grains

The invention discloses an antimicrobial packing bag for grains. The thin film of the packing bag comprises the following ingredients in parts by weight: 60-80 parts of polyvinyl chloride resin, 10-20 parts of polypropylene resin, 18-22 parts of dioctyl phthalate, 28-32 parts of polypropylene glycol adipate, 2-5 parts of organic modified nano calcium carbonate, 2-4 parts of modified copper sulfate, 3-5 parts of octadecyl ammonium chloride, 4-6 parts of a calcium-zinc composite stabilizer, 2-4 parts of stearic acid, and 1.5-2.5 parts of liquid paraffin.

Owner:WUXI HUANGSHENG PACKING PROD

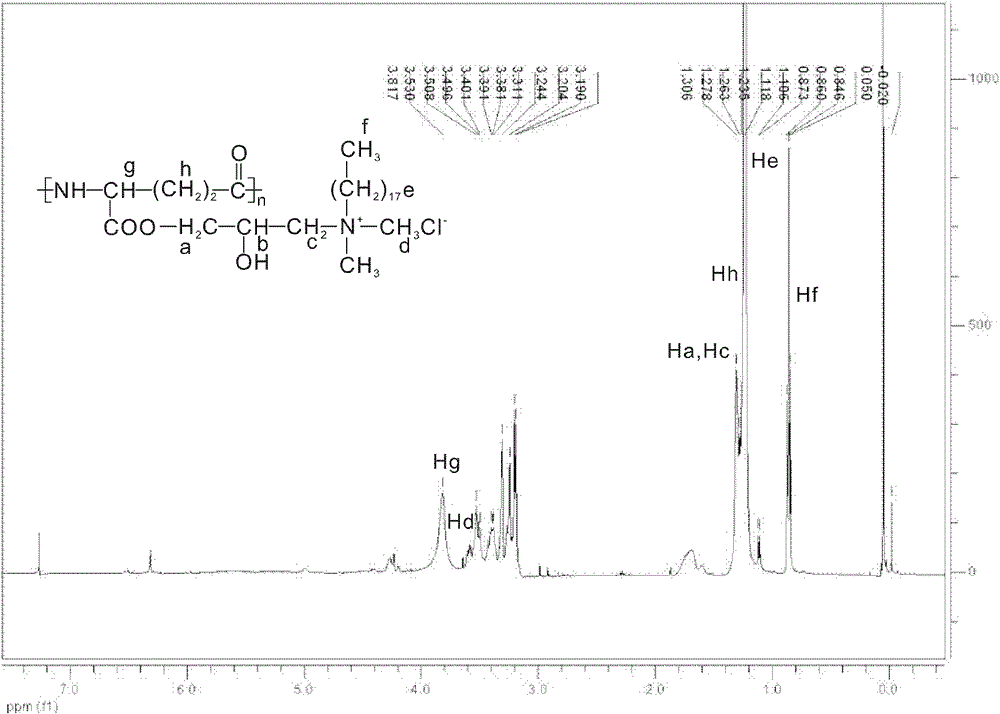

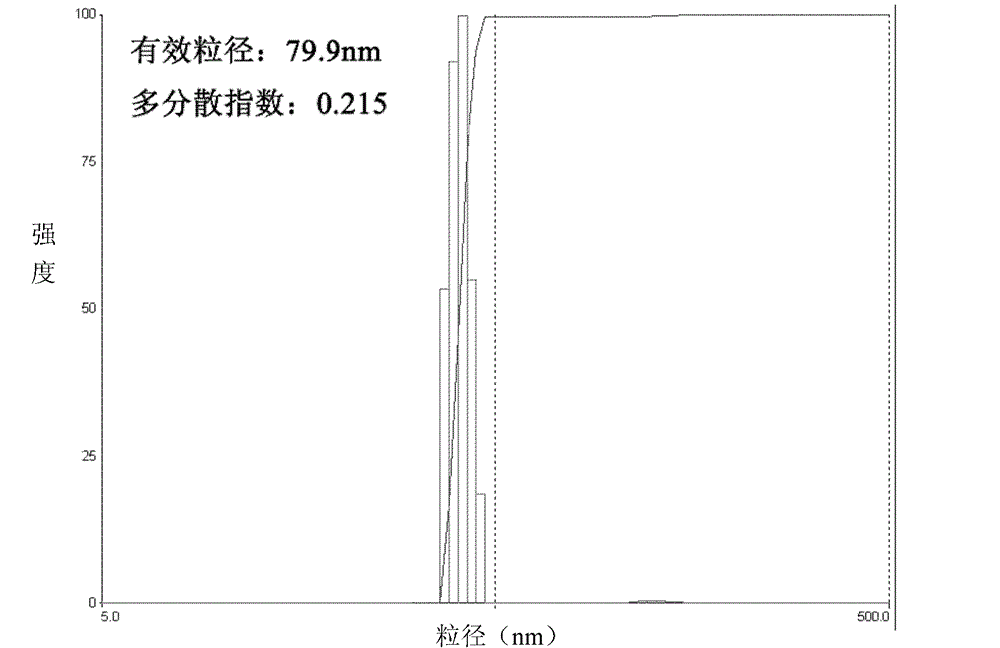

Polymer liposomes based on polyamino acid and quaternary ammonium salt and preparation method for polymer liposomes

ActiveCN102304225BHigh yieldSimple and fast operationPharmaceutical non-active ingredientsLiposomal deliveryQuaternary ammonium cationCholesterol

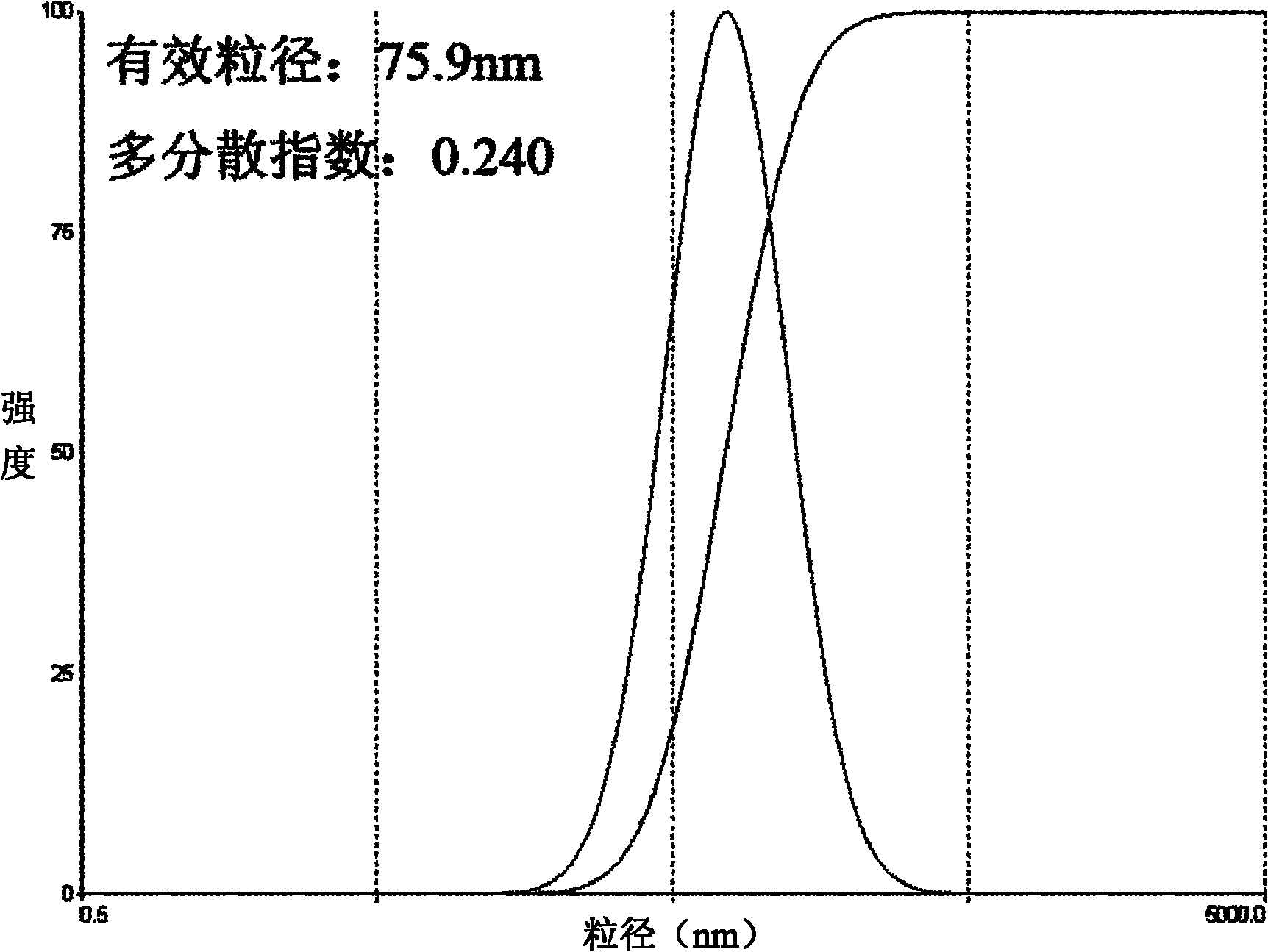

The invention relates to polymer liposomes based on polyamino acid and quaternary ammonium salt and a preparation method for the polymer liposomes. The preparation method comprises the following steps of: reacting dimethyl epoxypropyl octadecyl ammonium chloride with polyamino acid to obtain amphiphilic polymer polyamino acid octodecyl quaternary ammonium salt; and dissolving the amphiphilic polymer polyamino acid octodecyl quaternary ammonium salt and cholesterol in dichloromethane in different mass ratios, and preparing the polymer liposomes by using a reverse-phase evaporation method or a film dispersion method. Compared with the conventional products and technologies, the invention has the characteristics that: the whole preparation process is simple, and suitable for industrial production; the prepared product has uniform and controllable grain size and the effective grain size of 50-200nm; and a preparation is high in stability, the preparation process is simple and the like.

Owner:南通药享科技有限公司

Nano-magnesium hydroxide flame-retardant material and preparation method thereof

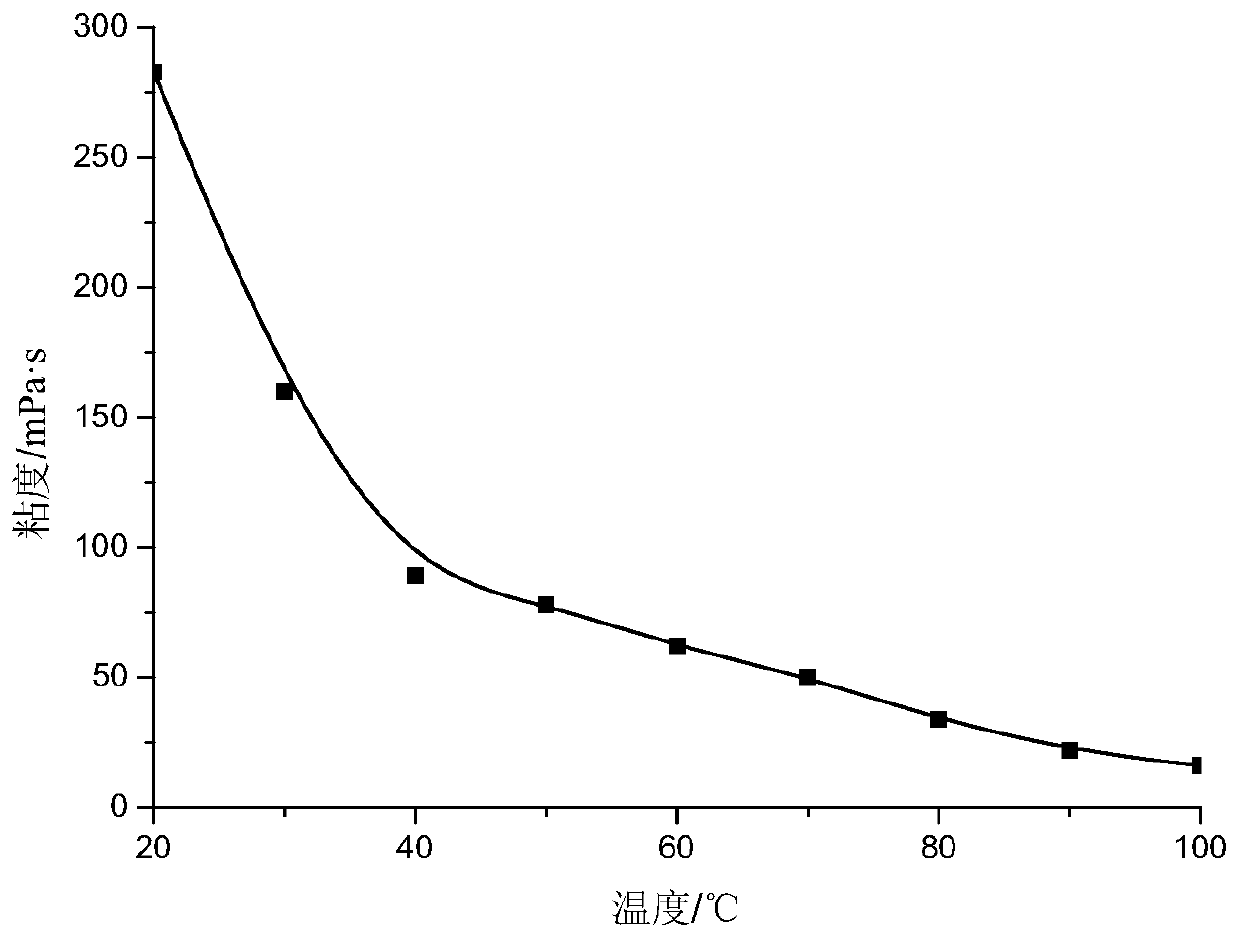

InactiveCN106893141AImprove suspension stabilityShort preparation cycleMagnesium hydroxidePolymer scienceEther

The invention relates to a nano-magnesium hydroxide flame-retardant material and a preparation method thereof and belongs to the field of material chemistry. Thenano-magnesium hydroxide flame-retardant material is prepared by conducting modification reaction on magnesium hydroxidenanoparticles and 3-(trimethoxysilicon propyl)-dimethyl octadecyl ammonium chloride, then conducting blended reaction on the reactant and sodium polyoxyethylene nonylphenyl ether sulphate and then performing dialysis and drying. The process of preparing the nano-magnesium hydroxide flame-retardant material is simple and easy to achieve, a reaction cycle is short, and the preparation method is environmentally friendly. The prepared nano-magnesium hydroxide flame-retardant material is uniform in particle size distribution and easy to disperse. Compared with anordinarymagnesium hydroxide flame-retardant material, the nano-magnesium hydroxide flame-retardant material prepared by adopting the preparation method has oil-wet hydrophilicityand amphiphilicity,has a liquid flow like behavior under the temperature conditionof 45 DEG C or above and is high in suspension stabilityand wide in application prospect, and the flame retardant performance, filling performance and the like of the material are better than those of other ordinary magnesium hydroxide flame-retardant materials.

Owner:WUHAN TEXTILE UNIV

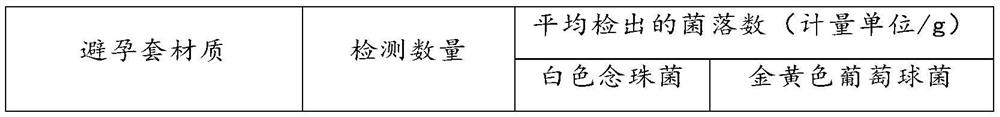

Active agent, oxygen-free hyaluronic acid production method and product thereof

ActiveCN112341664AReduce in quantityWith physical sterilization functionSurgeryMicroorganism based processesActive agentCombinatorial chemistry

The invention provides an active agent, a hyaluronic acid production method and a product thereof, the active agent is used for cross-linking treatment of hyaluronic acid, and the active agent comprises the following components in parts by mass: 4-6 parts of 3- (trihydroxy) silyl propyl dimethyl octadecyl ammonium chloride, 0.03-0.07 part of chloropropyl silane and 90-97 parts of deionized water.In the hyaluronic acid cross-linking link, the active agent is added into a hyaluronic acid fermentation solution, hydroxyl silicon molecules in the active agent and hyaluronic acid small molecules are fully cross-linked, and modification and immobilization are carried out in a covalent bond mode to form a new group. Experiments prove that the group has positive charge characteristics of cations,good deoxidation and antioxidant effects and a good physical sterilization effect.

Owner:桂林恒保健康防护有限公司

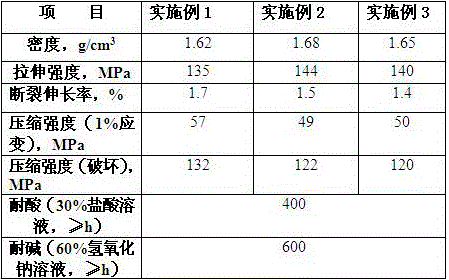

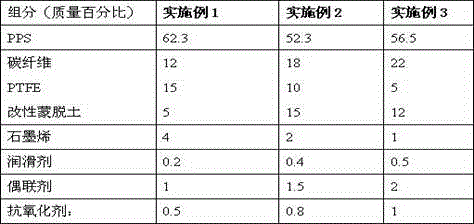

PPS (polyphenylene sulfide) resin composite material for corrosion-resistant end surface sealing strips and preparation method thereof

The invention discloses a PPS resin composite material for corrosion-resistant end surface sealing strips. The PPS resin composite material for the corrosion-resistant end surface sealing strips is composed of, by weight percentage, 12-22% of carbon fiber, 5-15% of PTFE (polytetrafluoroethylene), 5-15% of modified montmorillonite, 1-4% of graphene, 1-2% of coupling agent, 0.2-0.5% of lubricant, 0.5-1% of antioxidant and PPS as balance, wherein the modified montmorillonite is obtained by modifying Na-montmorillonite through vinylbenzyl-dimethyl-octadecyl ammonium chloride. The invention also discloses a preparation method of the PPS resin composite material for the corrosion-resistant end surface sealing strips. According to the PPS resin composite material for the corrosion-resistant end surface sealing strips, the carbon fiber added into the PPS can improve the impact resistance, the tensile performance, the bending performance and the compression performance and reduce creep deformation; the added PTFE can reduce the friction coefficient and improve the tenacity and the corrosion resistance; the modified montmorillonite and the graphene can effectively improve the mechanical performance and the corrosion resistance. The end surface sealing strips prepared from the PPS resin composite material is high in corrosion resistance and can maintain good tenacity during long-term contact with refrigerant oil, thereby achieving a long service life.

Owner:NANJING COMPTECH COMPOSITES CORP

Novel macromolecule liposome and preparation method thereof

InactiveCN102058534ALow toxicityHigh yieldPharmaceutical non-active ingredientsLiposomal deliveryZeta potentialCholesterol

The invention relates to a novel macromolecule liposome and a preparation method thereof. The preparation method comprises the steps of: preparing an amphiphilic macromolecule gamma-polyglutamate octadecyl alkylammonium salt through the reaction of dimethyl glycidyl octadecyl ammonium chloride with gamma-polyglutamate; and secondly, dissolving the gamma-polyglutamate octadecyl alkylammonium salt and cholesterol into dichloromethane according to different mass ratios, and preparing the macromolecule liposome according to a reverse-phase evaporation process or film dispersing process. Compared with the traditional product and the prior art, the invention has the characteristic of simple preparation process and is suitable for industrialized production. The prepared product has the characteristics of uniform and controllable particle diameter, effective particle diameter of 70-130nm, Zeta potential of 6-8mV, good preparation stability, simple preparation process and the like.

Owner:TIANJIN UNIV

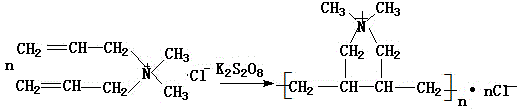

A kind of anti-temperature and anti-salt polymer oil displacement agent and preparation method thereof

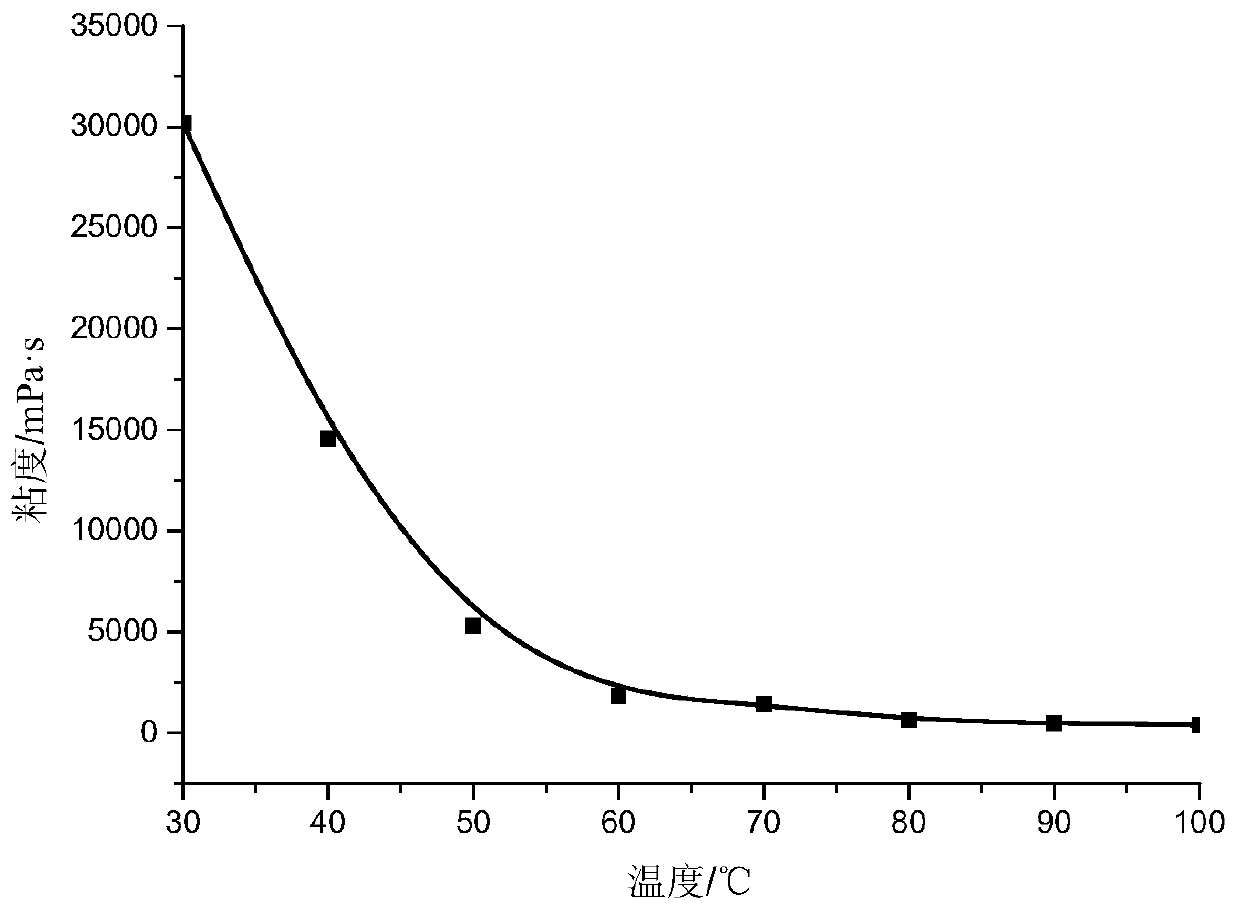

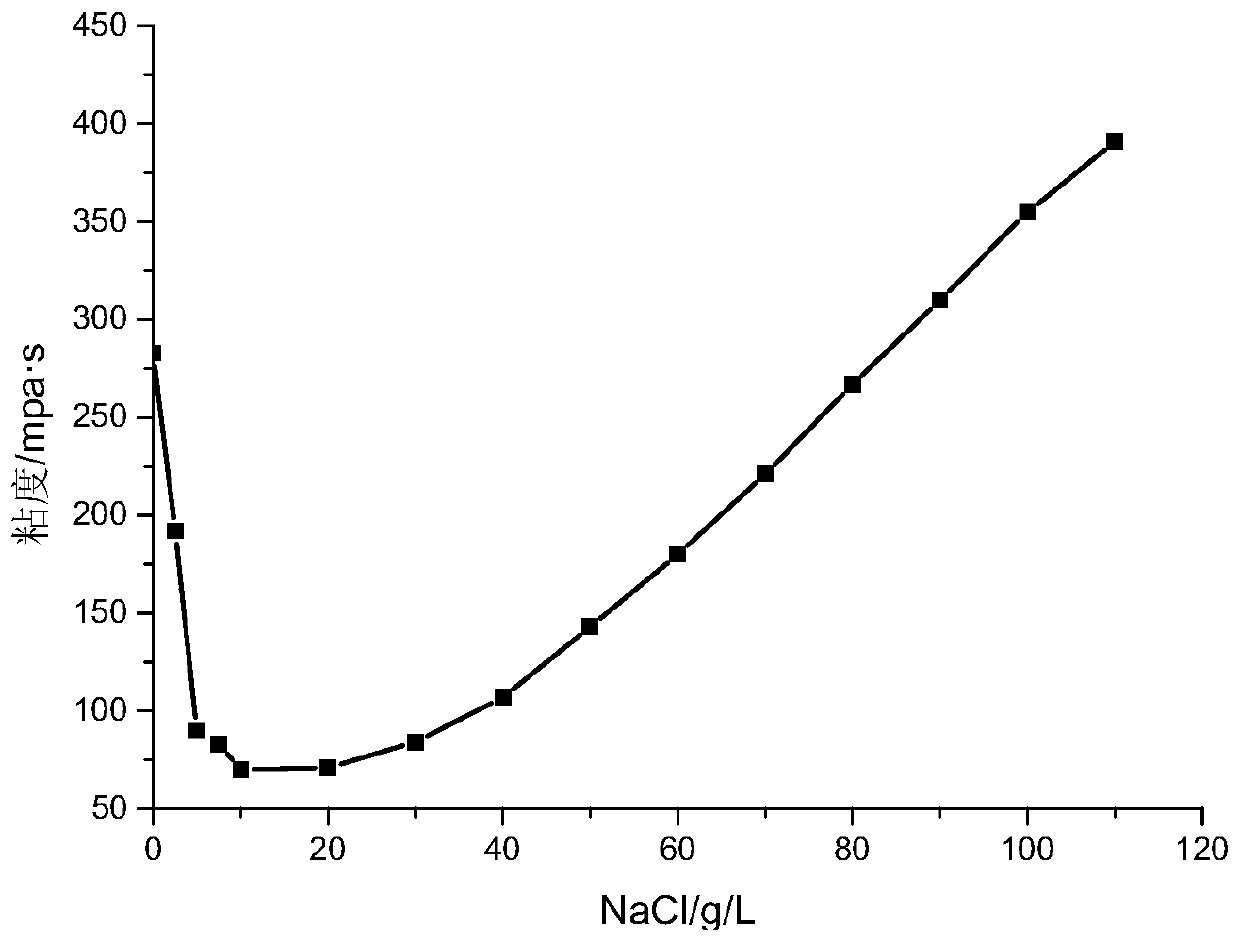

ActiveCN106939158BGood viscosity increaseGood temperature and salt resistance and shear resistanceDrilling compositionSulfonatePolymer science

The present invention discloses a temperature-resistant and salt-resistant polymer oil displacement agent and a preparation method thereof, wherein the temperature-resistant and salt-resistant polymer oil displacement agent is formed by polymerizing acrylamide, allyl polyethylene glycol, sodium p-styrene sulfonate, and dimethyl allyl octadecylammonium chloride according to a molar ratio of (94-97):(1.7-4.7):(0.3-1.0):(0.3-1.0). According to the present invention, the polymer oil displacement agent can maintain good tackifying effect at a high temperature in a salt solution having a certain concentration, and has characteristics of good temperature resistance, good salt resistance, good shear resistance, low raw material monomer cost, mild polymerization reaction condition, and simple process.

Owner:SOUTHWEST PETROLEUM UNIV +1

Packing bag for preventing mold of grain

The invention discloses a packing bag for preventing mold of grain. The thin film of the packing bag comprises the following ingredients in parts by weight: 100 parts of polyvinyl chloride resin, 15-25 parts of polypropylene resin, 24-26 parts of dioctyl phthalate, 14-18 parts of dioctyl sebacate, 6-8 parts of nano silicon dioxide, 2-4 parts of nano titanium oxide, 4-6 parts of light calcium carbonate, 4-6 parts of activated carbon, 3-5 parts of octadecyl ammonium chloride, 4-6 parts of a calcium-zinc composite stabilizer, 2-4 parts of stearic acid, and 1.5-2.5 parts of liquid paraffin.

Owner:WUXI HUANGSHENG PACKING PROD

Production method of organobentonite

The invention discloses a production method of organobentonite. The method comprises the following steps: step 1, taking 55-65 parts of N,N-dimethyl octadecyl amine in weight and 10-15 parts of absolute alcohol in weight into a reaction vessel, enabling the inner side temperature of the reaction vessel to be 20 DEG C, starting stirring for 1.5 hours, stirring while adding 25-30 parts of liquid chloromethane in weight, and keeping the temperature at 20-60 DEG C for 60 minutes after the stirring is completed to prepare octadecyl ammonium chloride; step 2, taking 50 parts of bentonite, adding water to dilute the bentonite to be a suspending liquid, starting stirring for 40 minutes, stirring while adding 2 parts of prepared octadecyl ammonium chloride, and keeping the temperature at 20-60 DEG C for 60 minutes after the stirring is completed to produce the organobentonite. According to the organobentonite produced by the method, the whiteness is increased, the viscosity is enhanced, and the combustion amount is improved.

Owner:FUJIAN HONGQIANG ORGANIC BENTONITE

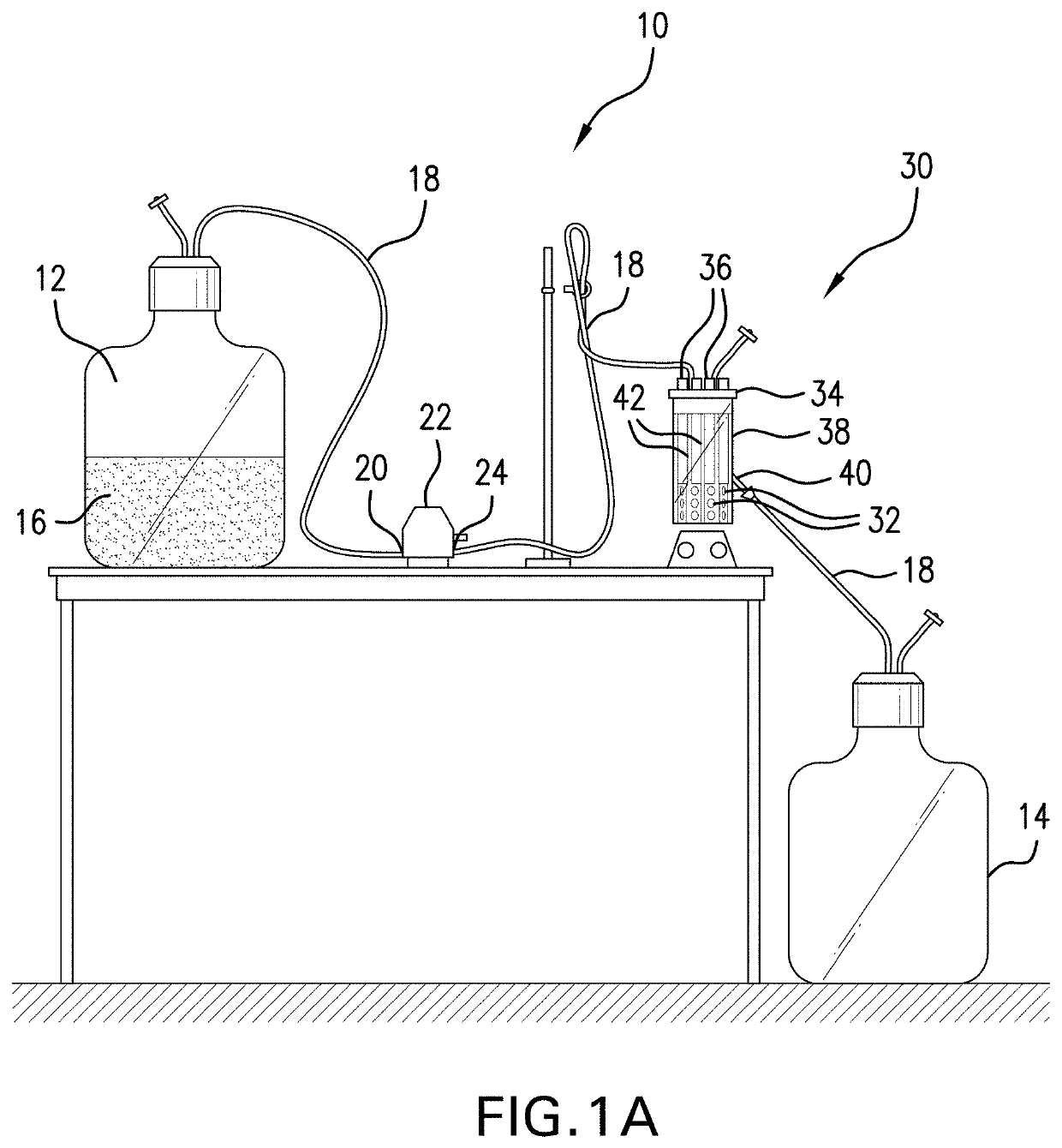

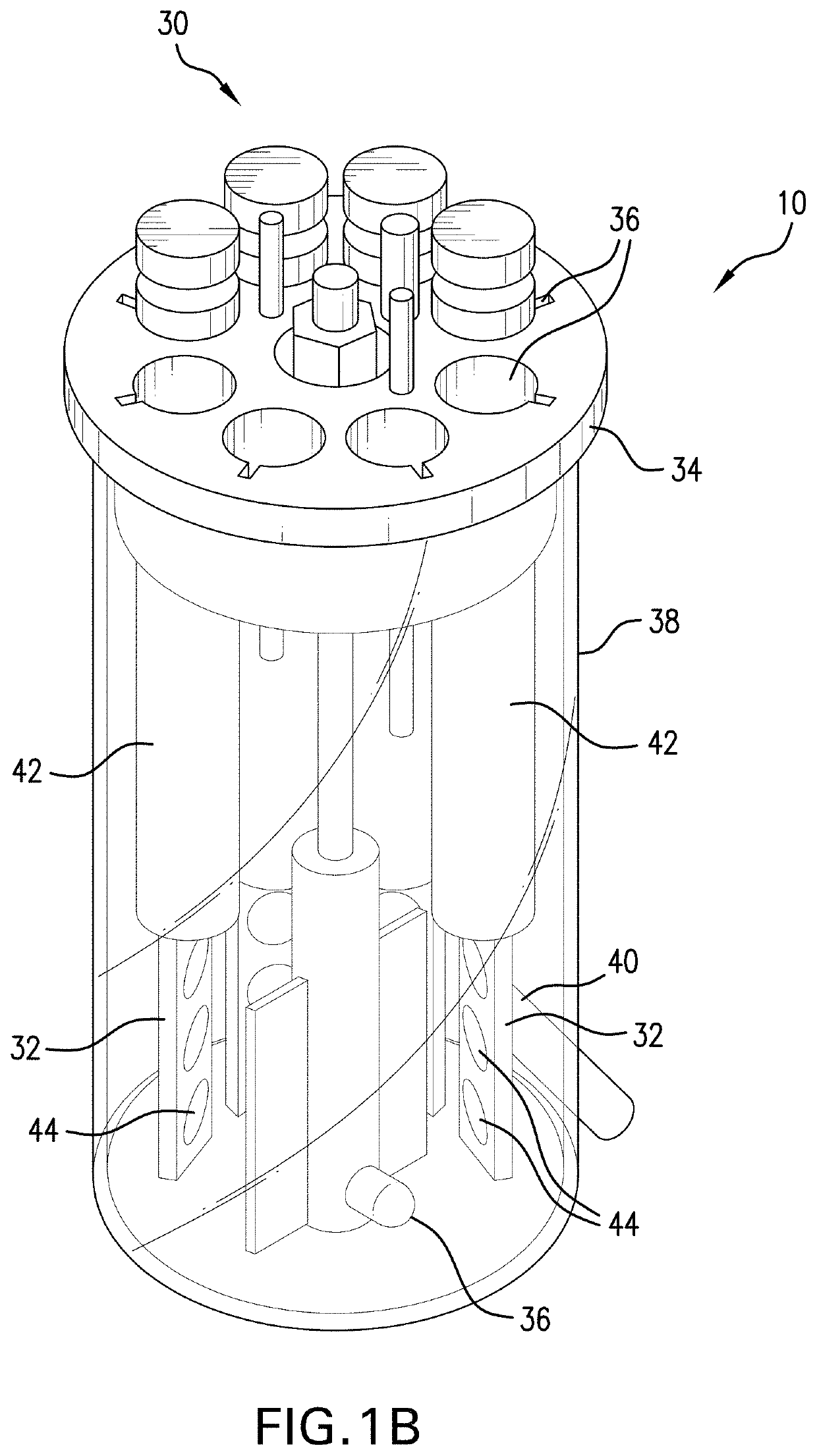

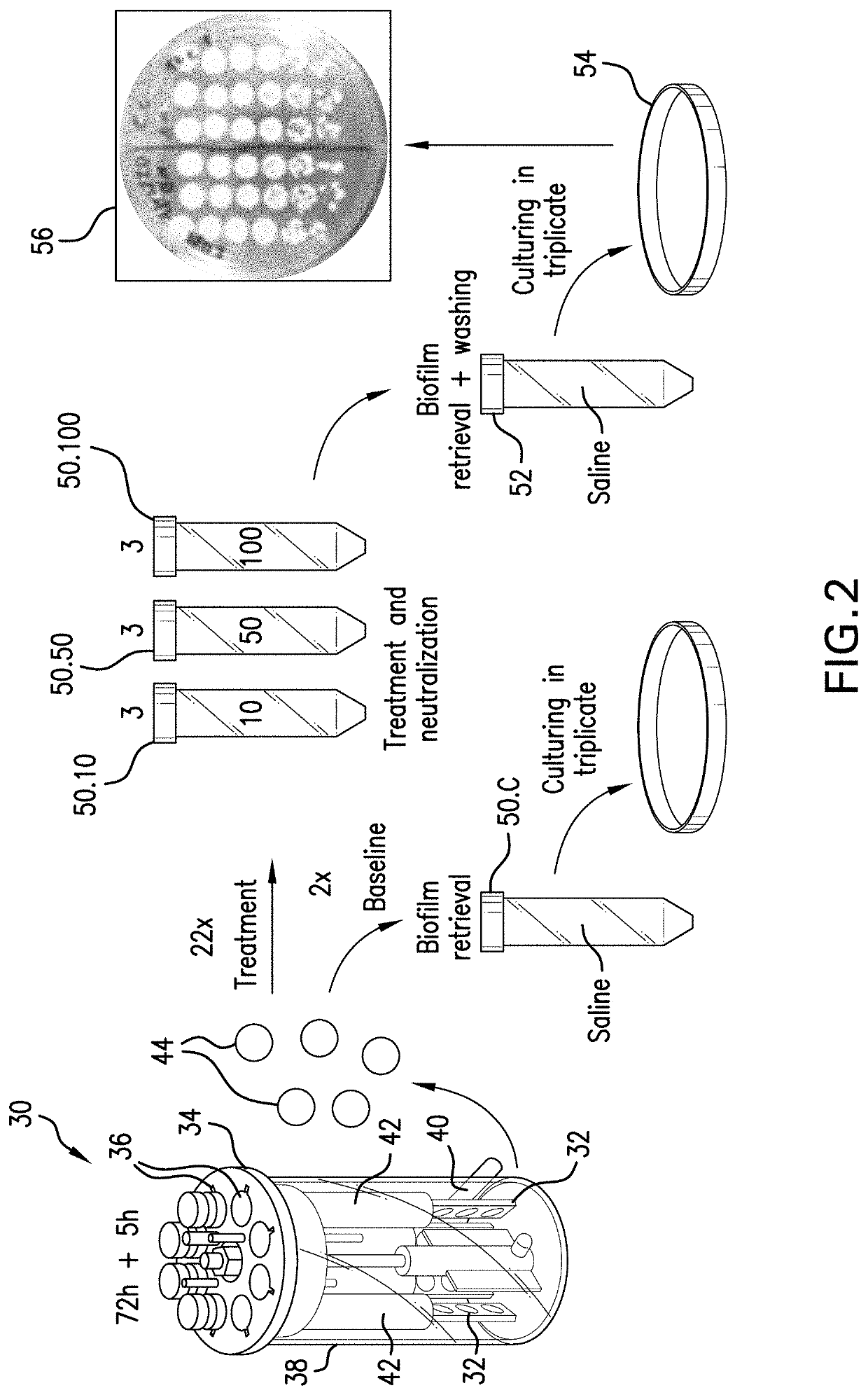

Antibiofilm Compositions, Wound Dressings, Cleaning Methods And Treatment Methods

PendingUS20220265894A1Effectively eradicateImprove abilitiesBiocidePeroxide active ingredientsAnti biofilmBiology

The patent disclosure covers antibiofilm compositions, wound dressings, cleaning methods and treatment methods. The antibiofilm composition is comprised of between about 0.05% (w / w) to about 0.20% (w / w) benzalkonium chloride; between about 0.20% (w / w) to about 0.50% (w / w) 3-(tri-methoxysilyl)propyldimethyl octadecyl ammonium chloride; between about 0.25% (w / w) to about 0.75% (w / w) phenoxyethanol and between about 98.55% (w / w) to about 99.5% (w / w) deionized water. Disclosed are wound dressings having a reservoir of the antibiofilm composition. In the field of inanimate surfaces, disclosed are methods to clean and clean and protect inanimate surfaces. In the field of animate surfaces, disclosed are methods for the treatment of nose, ear and skin / facial disorders associated with biofilms.

Owner:ZOONO GRP LTD

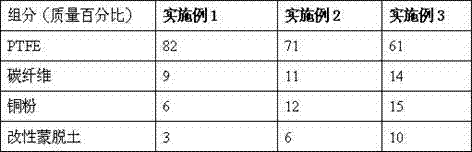

Sealing strip PTFE resin composite material with high temperature resistance in high-temperature region and preparation method thereof

The invention discloses a sealing strip PTFE resin composite material with high temperature resistance in a high-temperature region. The sealing strip PTFE resin composite material contains the following components by weight percent: 9-14% of carbon fiber, 6-15% of copper powder, 3-10% of modified imvite and the balance of PTFE, wherein the modified imvite is the Na-montmorillonite modified with ethylene benzyl dimethyl octadecyl ammonium chloride. The invention also discloses a preparation method thereof. According to the invention, the carbon fiber is added, so that the coefficient of thermal expansion can be reduced and the leakage hidden danger caused by expansion after temperature rise can be reduced; creep can be reduced, the hardness can be increased and the heat resistance of the material can be increased; the addition of the copper powder is beneficial to the reduction of the abrasion of the material, the reduction of creep, the reduction of deformation under load and the promotion of the thermal stability and conductivity of a thermal PTFE composite material; the modified imvite is capable of forming uniform nanoscale dispersing in PTFE, so that the composite material has higher heat-resisting stability; the sealing strip with high temperature resistance in the high-temperature region can be used for a long term under the environment of 300 DEG C without deformation.

Owner:NANJING COMPTECH COMPOSITES CORP

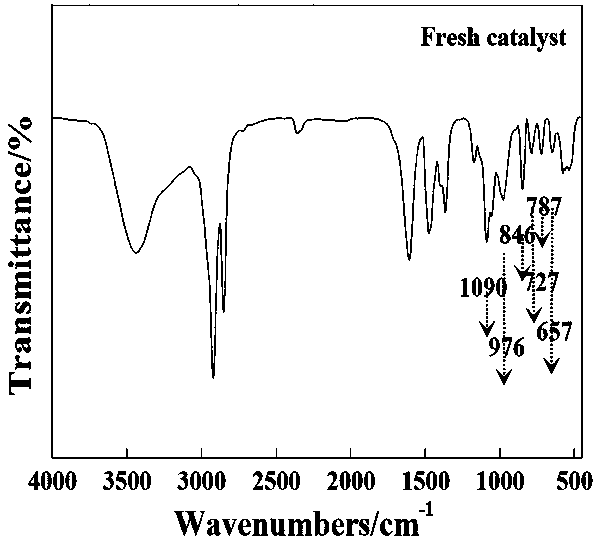

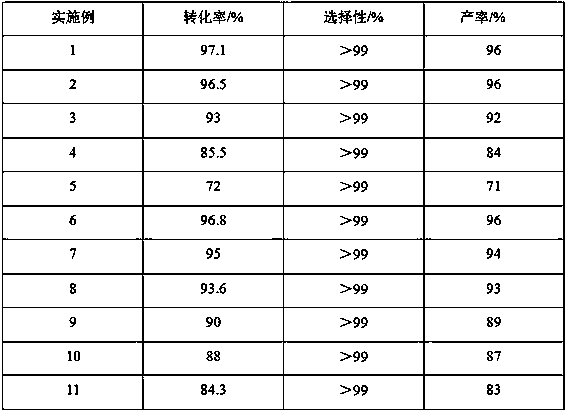

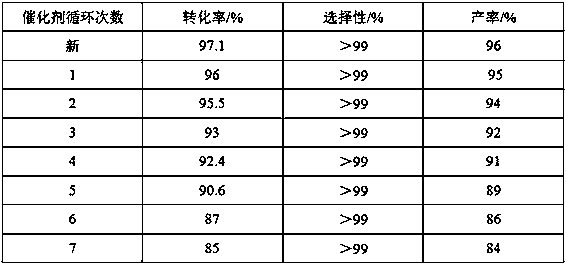

Phosphotungstic heteropolyacid salt catalyst for synthesizing epoxy chloropropane and preparation method thereof

InactiveCN110479374ASimple methodMild reaction conditionsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyVacuum drying

The invention discloses a preparation method of a temperature control phase transfer catalyst for synthesizing epoxy chloropropane, and belongs to the field of catalytic chemistry. The preparation method comprises the following steps: dissolving K-type phosphotungstic acid in 30% hydrogen peroxide, carrying out an oxidation reaction to obtain a peroxyphosphotungstic acid aqueous solution, dropwiseadding the peroxyphosphotungstic acid aqueous solution into an ethanol solution of dimethyl dioctadecyl ammonium chloride, and carrying out a stirring reaction at 40 DEG C for 2 h; and after the reaction is finished, filtering a reaction product to obtain white powder, and carrying out water washing, absolute ethyl alcohol washing and vacuum drying to obtain the dimethyl dioctadecyl peroxy phosphotungstic acid catalyst. According to the method, the dimethyl dioctadecyl peroxyphosphotungstic acid is used as a catalyst, chloropropene and hydrogen peroxide are used as raw materials, and under the condition of no solvent or additive, the yield of epoxy chloropropane prepared by a one-pot method reaches 97.1%, the selectivity is greater than 99%, and the product yield is up to 96% or above. After the reaction is finished, the catalyst is dissolved in epoxy chloropropane, the catalyst is separated out when the temperature is reduced to 10 DEG C, and the catalyst is recycled through a filtering method. The catalytic reaction process is simple to operate, mild in reaction condition, low in production cost, stable in catalyst property, convenient to recycle and beneficial to industrial production.

Owner:UNIV OF JINAN

A kind of preparation method of polyester filament fabric alkali weight reduction accelerator fy-01

ActiveCN104358122BUniform penetrationGood moisture wicking effectFibre typesReduction rateMoisture absorption

The invention discloses a p reparation method of a novel polyester filament yarn fabric alkali weight reduction accelerant FY-01. The novel polyester filament yarn fabric alkali weight reduction accelerant FY-01 is prepared by compounding the following components in percentage by weight: 25%-35% of 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride, 15%-25% of N,N-dimethyldiallyl ammonium chloride, 10%-12% of AE-07 polyoxyethylene ether, 5%-8% of iso-ol polyoxyethylene ether, and the balance of water. The 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride and N,N-dimethyldiallyl ammonium chloride of the alkaline weight reduction accelerant are mixed, so that the uniform adsorption amount of cationic alkali weight reduction accelerants on the surface of the polyester filament can be increased so as to achieve better weight reduction effect, the uniformity is good, and the weight reduction rate is easily controlled; the polyoxyethylene ether is added for compounding, substances can be added into grooves in the surface of the polyester stripped and etched by sodium hydroxide, so that the hydrophilicity of the fiber can be increased to achieve the moisture absorption and sweat releasing functions, and the wearing comfortableness can be promoted.

Owner:南通科沃纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com