A kind of preparation method of polyester filament fabric alkali weight reduction accelerator fy-01

An alkali weight reduction accelerator, the technology of FY-01, is applied in the direction of textiles and papermaking, fiber treatment, fiber type, etc. It can solve the problems of improving the moisture absorption and perspiration of polyester filaments, and achieve easy control of weight reduction rate. Good uniformity and the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

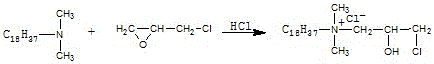

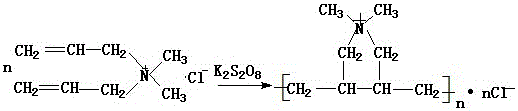

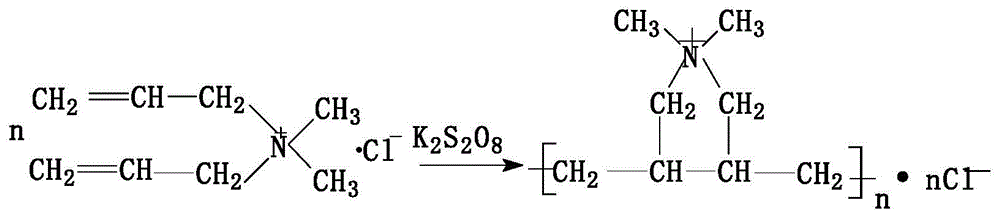

[0027] Such as figure 1 , 2 As shown, the preparation method of the polyester filament fabric alkali weight reduction accelerator FY-01, the following four components are compounded according to the weight percentage, and the polyester filament fabric alkali weight reduction accelerator FY-01 can be obtained:

[0028] (1) 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride: 25%;

[0029] (2) N, N-dimethyl diallyl ammonium chloride polymer: 15%;

[0030] (3) AE-07 polyoxyethylene ether: 10%;

[0031] (4) Isomerized alcohol polyoxyethylene ether: 5%;

[0032] (5) The balance is water.

[0033] The preparation of described (1) 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride comprises the steps:

[0034] At a constant temperature of 40°C, add 14.0 g of octadecyl tertiary amine and 100 g of distilled water into a 250 mL four-neck flask with a condenser placed in a water bath, and slowly add 8.578 g of 36% HCl dropwise under stirring, and the dropwise ad...

Embodiment 2

[0041] Such as figure 1 , 2 As shown, the preparation method of the polyester filament fabric alkali weight reduction accelerator FY-01, the following four components are compounded according to the weight percentage, and the polyester filament fabric alkali weight reduction accelerator FY-01 can be obtained:

[0042] (1) 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride: 35%;

[0043] (2) N, N-dimethyl diallyl ammonium chloride polymer: 25%;

[0044] (3) AE-07 polyoxyethylene ether: 12%;

[0045] (4) Isomerized alcohol polyoxyethylene ether: 8%;

[0046] (5) The balance is water.

[0047] The preparation of described (1) 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride comprises the steps:

[0048] At a constant temperature of 80°C, add 14.0 g of tertiary octadecylamine and 100 g of distilled water into a 250 mL four-neck flask with a condenser tube placed in a water bath, slowly add 13.153 g of 36% HCl dropwise under stirring, and the addition i...

specific Embodiment 3

[0054] Such as figure 1 , 2 As shown, the preparation method of the polyester filament fabric alkali weight reduction accelerator FY-01, the following four components are compounded according to the weight percentage, and the polyester filament fabric alkali weight reduction accelerator FY-01 can be obtained:

[0055] (1) 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride: 30%;

[0056] (2) N, N-dimethyl diallyl ammonium chloride polymer: 20%;

[0057] (3) AE-07 polyoxyethylene ether: 11%;

[0058] (4) Isomerized alcohol polyoxyethylene ether: 6%;

[0059] (5) The balance is water.

[0060] The preparation of described (1) 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride comprises the steps:

[0061] At a constant temperature of 60°C, add 14.0 g of octadecyl tertiary amine and 100 g of distilled water into a 250 mL four-neck flask with a condenser tube placed in a water bath, and slowly drop in 11.573 g of 36% HCl while stirring, and the addition i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com