Patents

Literature

54 results about "Permeation grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permeation grouting is the longest-established and most widely used pressure grouting technique. It involves the filling of cracks, joints, or other small defects in non-cohesive soils, sand, or other porous media. Instability in coastal locations can cause significant structural problems during and after the building process.

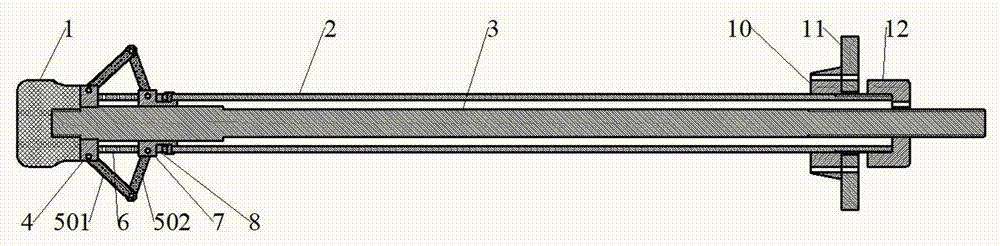

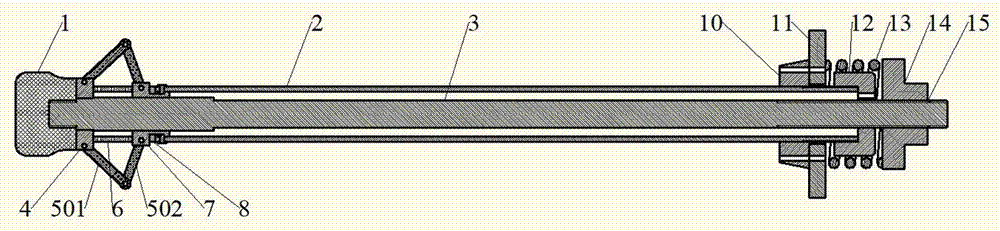

Pressure bearing permeation grouting strengthening test apparatus and method

InactiveCN103267722AEasy to manufactureSimple structurePreparing sample for investigationPermeability/surface area analysisAxial pressureMicro fracture

The present invention relates to a pressure bearing permeation grouting strengthening test apparatus and a method. The apparatus mainly comprises a grouting bucket, a slurry storage device and a manual grouting pressurization device, wherein the grouting bucket comprises a base, a bucket body and a pressing head, a grouting hole is arranged in the base, and is connected with the slurry storage device through a high pressure soft pipe, the slurry storage device is provided with a piston, and the manual grouting pressurization device is placed below the piston. With the test apparatus, influence of axial pressure, confining pressure and other factors of the upper portion of the micro fracture (pores) geology on the grouting can be simulated; the grouting conditions of the geological bodies with different physical and mechanical properties under different grouting parameters and different grouting process conditions can be simulated so as to analyze a mechanism and an effect of grouting strengthening; and with the test apparatus, broken coal rock bodies, soil samples and sand samples can be made into complete samples, can be processed into standard samples through a cutting machine, and then are subjected to related uniaxial and triaxial tests. In addition, the test apparatus has characteristics of simple structure, easy manufacturing, low cost, easy operation, and reliable use.

Owner:CHINA UNIV OF MINING & TECH

A cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement

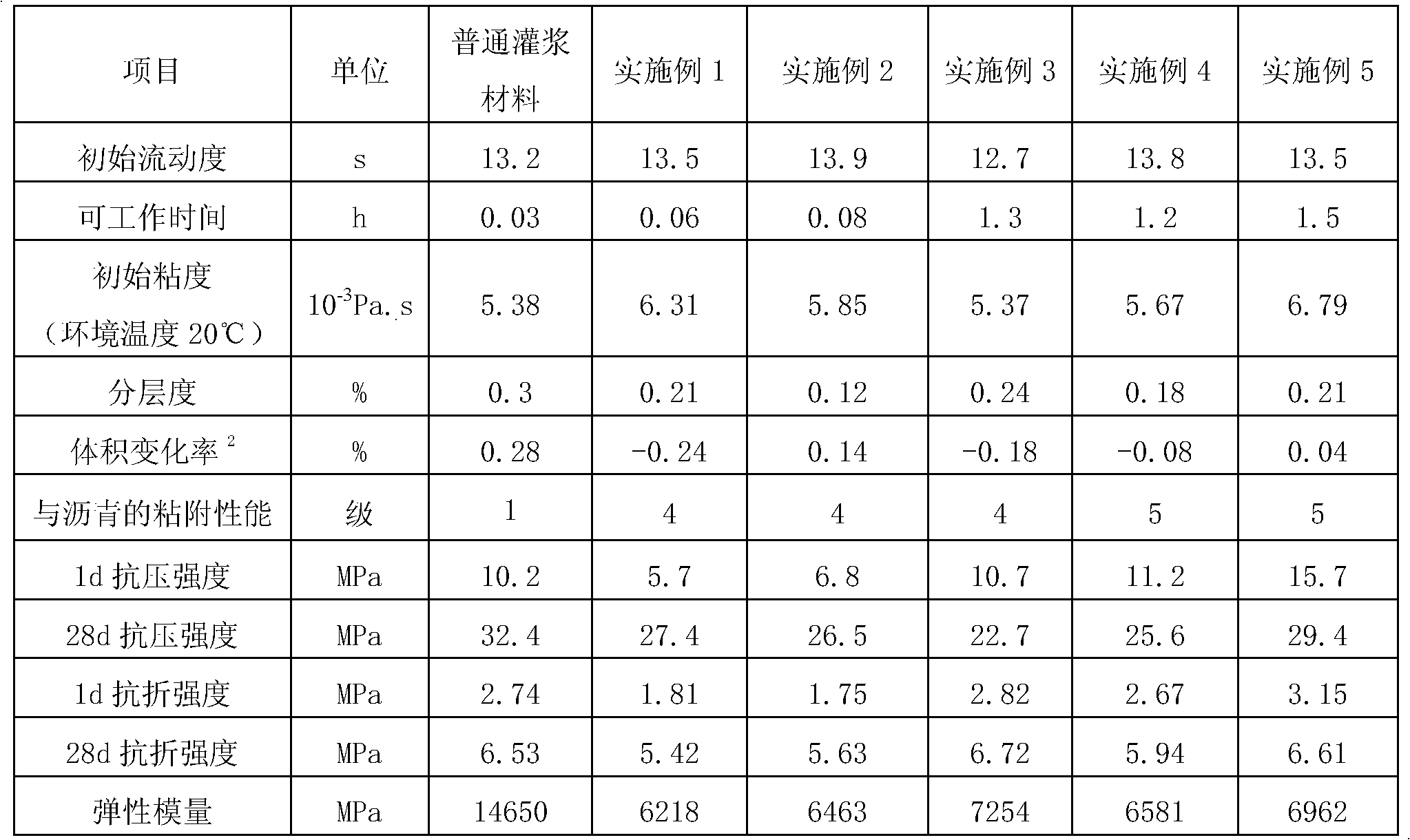

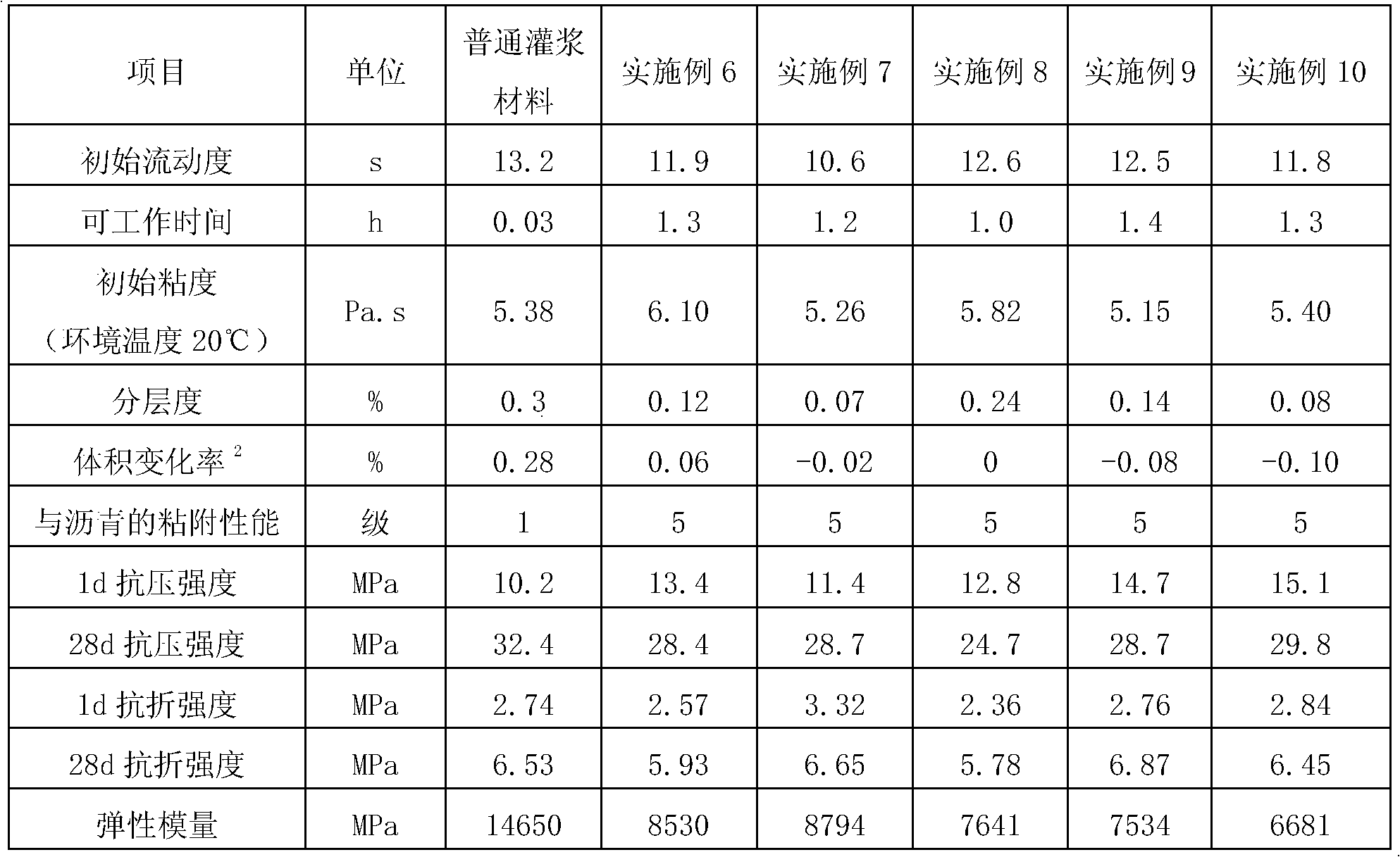

The invention discloses a cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement, which comprises 100 parts of cement, 50-150 parts of mineral admixture, 15-40 parts of expansion agent, 0-80 parts of river sand, 0.5-20 parts of water agent, 60-140 parts of water, and 50-150 parts of emulsified asphalt, all of which are parts by weight. The grouting material of the present invention is low in cost, good in fluidity, long in working time, and satisfies the grouting characteristics of self-permeation of slurry; has good interfacial bonding performance with asphalt, and has a certain early strength function; the volume change rate is small, and the degree of delamination is less than 0.3%, with good volume stability; both cationic emulsified asphalt and anionic emulsified asphalt can be used, with a wide range of applications; applying this grouting material to semi-flexible pavement can greatly improve the fatigue life of flexible pavement The shear performance is effectively improved.

Owner:JIANGSU SUBOTE MATERIAL +4

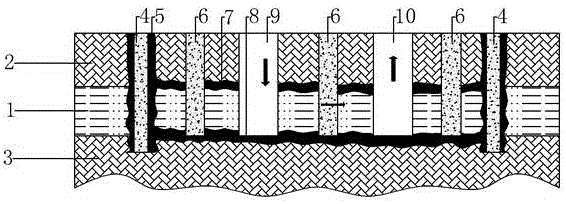

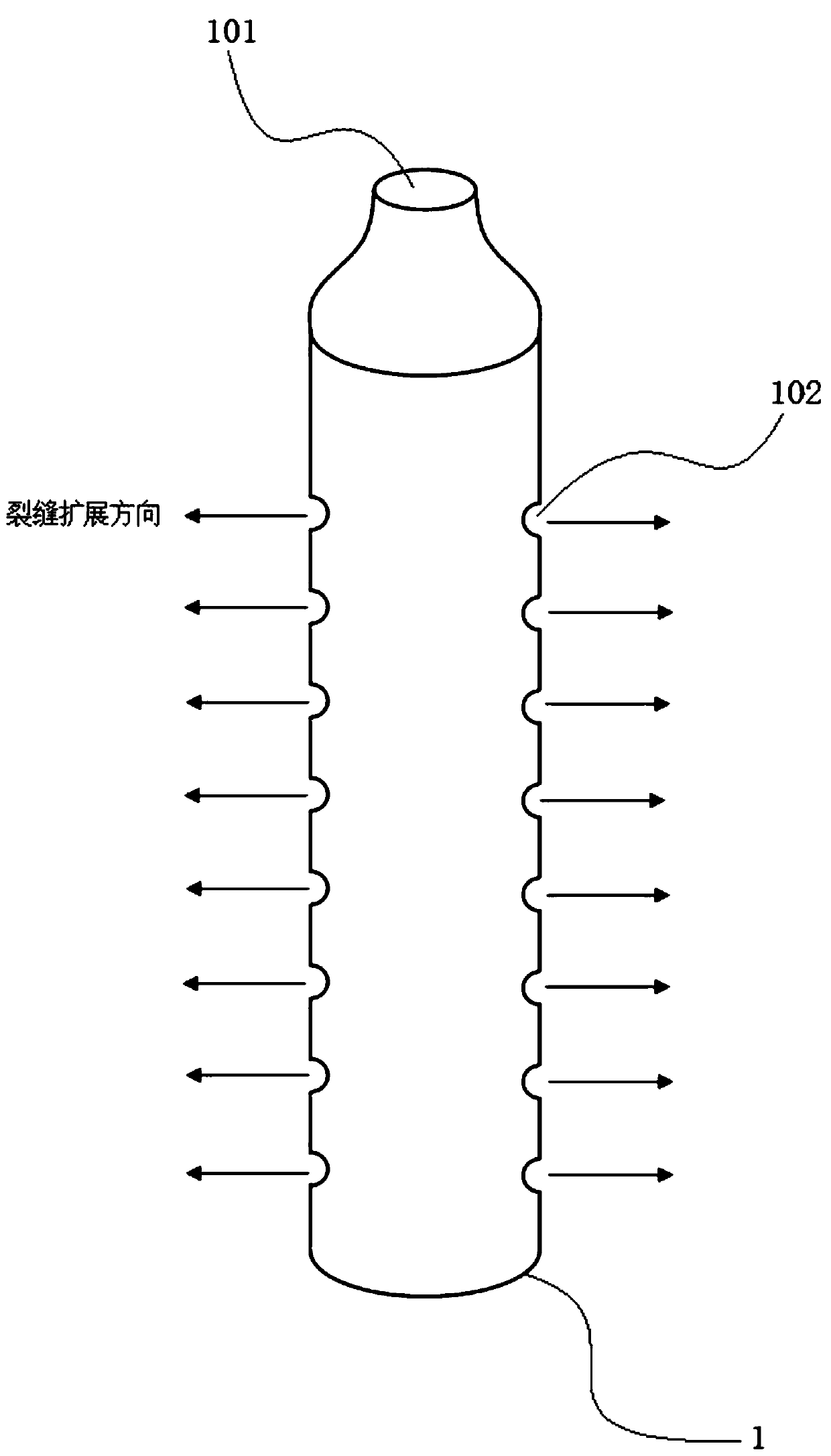

Hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method

The invention discloses a hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method which includes that when roadway drivage reaches a 10m coal layer vertical distance, fracturing holes of a coal layer are drilled, the coal layer is subjected to hydraulic fracturing, and the water injection amount reaches the preset value after above 3MPa pressure drop appears in fracturing; a plurality of grouting holes are drilled when the roadway drivage reaches a 5m coal layer vertical distance; coal layer methane gases are extracted through the fracturing holes and the grouting holes; the coal layer is subjected to quantitative grouting through the grouting holes with grouting pressure to be above 15MPa; and roadway drivage is continued after grouting solidification, and rock cross-cut coal uncovering is completed. Single hole grouting amount includes grouting hole grouting amount M1 and coal layer permeation grouting amount M2 and is calculated according to M=M1+M2=rho*eta / K *(pi*D<2> / 4 *L +pir<2>*l*P)*10<-6>, wherein rho is a grouting density, eta is a storage coefficient, K is a grouting foaming expansion rate, D is a drilling diameter, L is grouting hole length, r is a penetration radius of slurry in the coal layer, l is length of the grouting holes in the coal layer and p is a coal layer porosity. The hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method has the advantages of being capable of fast and safely performing rock cross-cut coal uncovering, avoiding re-handling, and improving social benefit.

Owner:重庆市能源投资集团科技有限责任公司 +1

System closing method used for oil shale underground in-situ exploitation

The invention discloses a system closing method used for oil shale underground in-situ exploitation. The closing system is composed of a top plate thermal insulation closing layer, a bottom plate thermal insulation closing layer and a horizontal exploitation area closing curtain. The system closing method comprises the steps of 1, the bottom plate thermal insulation closing layer is arranged at an oil shale layer bottom plate to cover an oil shale in-situ exploitation area and to connect the horizontal exploitation area closing curtain into an entirety; 2, the top plate thermal insulation closing layer is arranged at an oil shale layer top plate to cover the oil shale in-situ exploitation area, and a method of fracturing grouting is adopted to arrange the top plate thermal insulation closing layer, so that a grout in all grouting holes is mutually through; 3, the horizontal exploitation area closing curtain is consecutive and sealed, and through a method of permeation grouting, the grout penetrates through the exploitation oil shale layer bottom plate, and arrives at a bottom shale layer with poor water permeability. According to the system closing method used for oil shale underground in-situ exploitation, a sealed heating area is provided for oil shale underground in-situ exploitation, and the method is used for preventing exploitation area longitudinal underground water from entering, preventing heat loss and preventing horizontal underground water from entering and oil gas and side products from outflowing.

Owner:JILIN UNIV

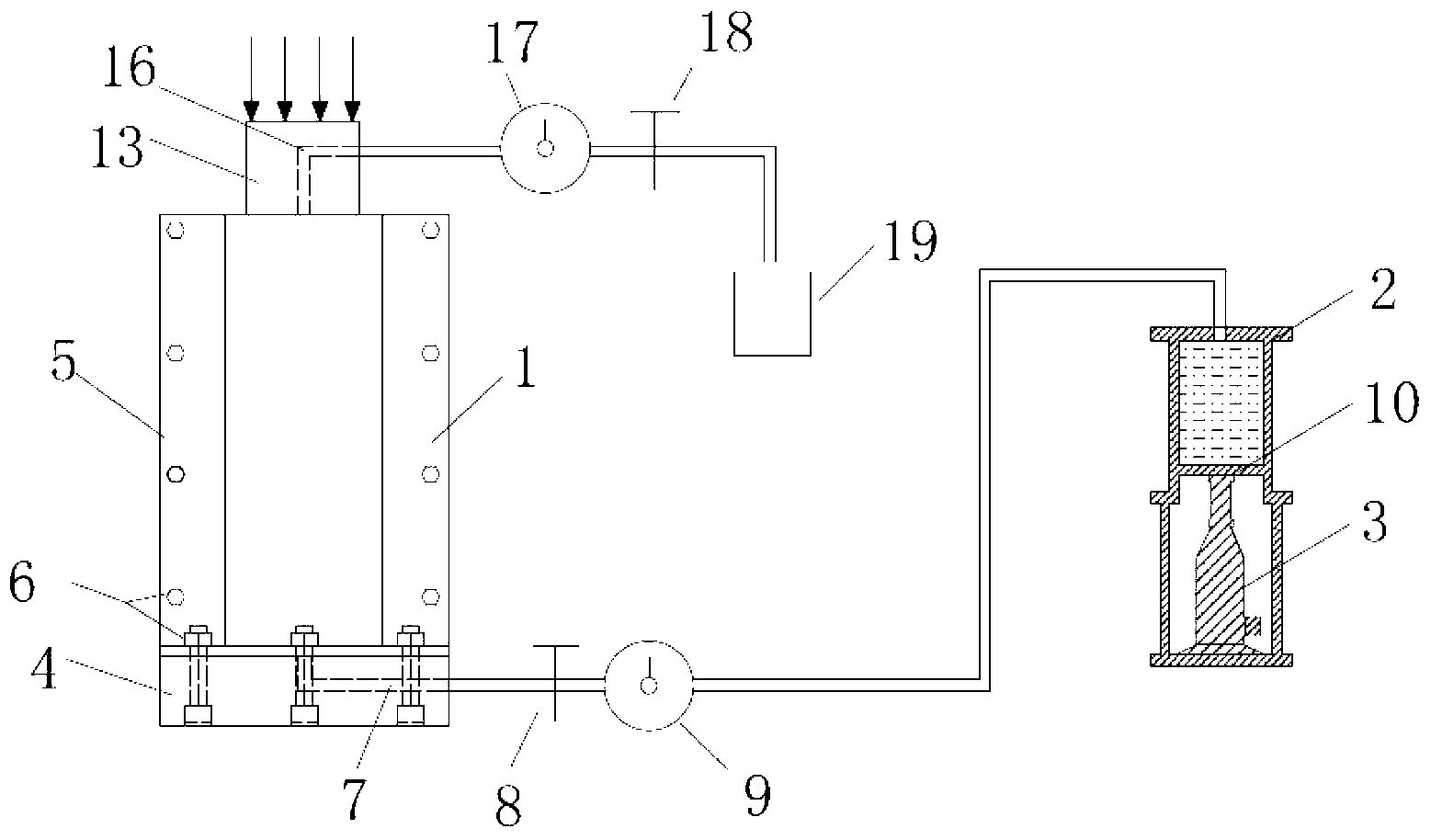

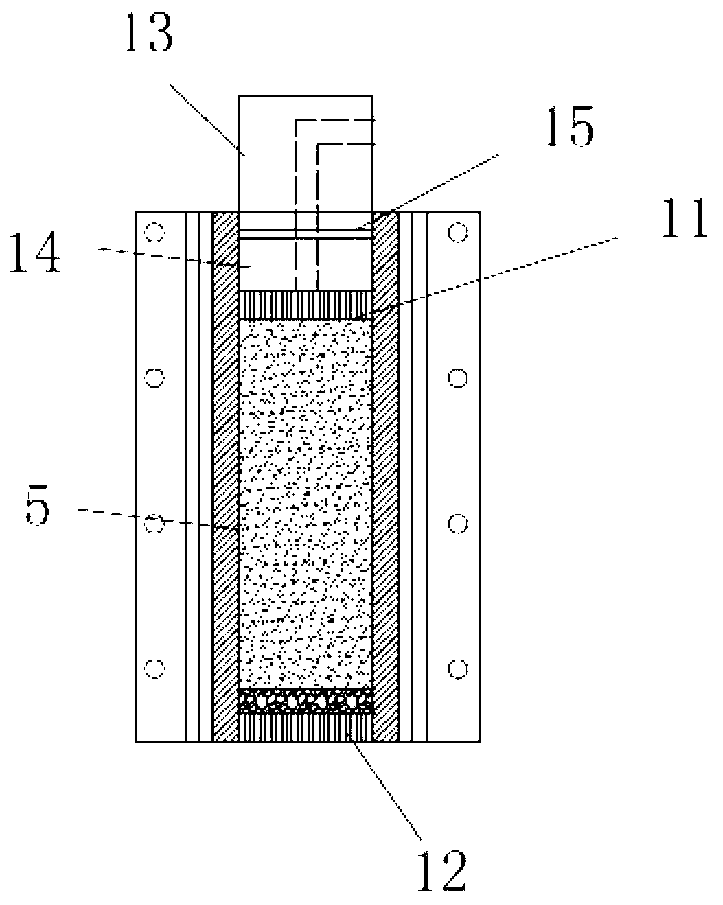

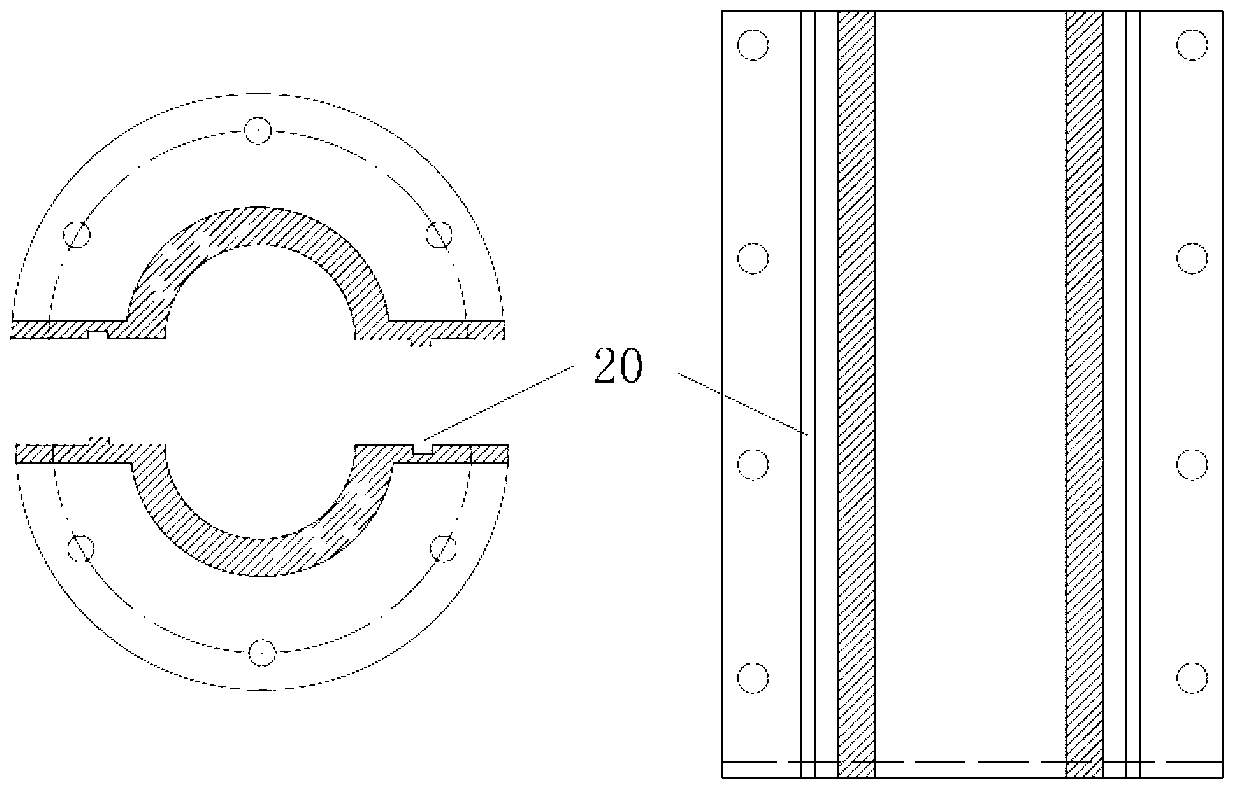

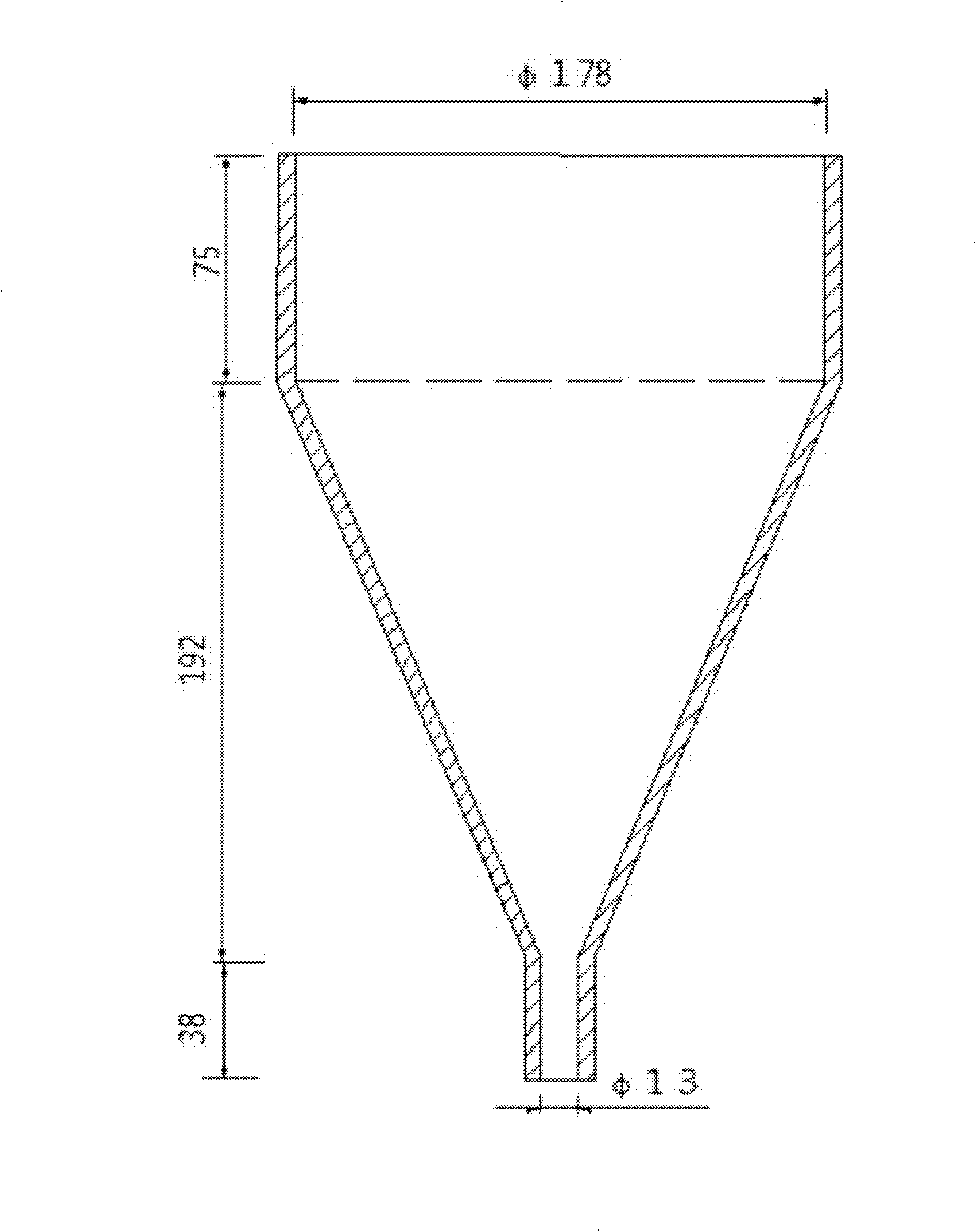

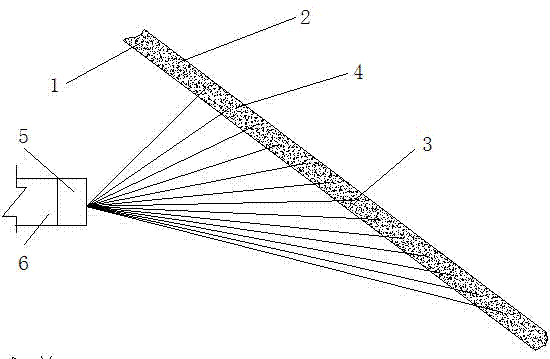

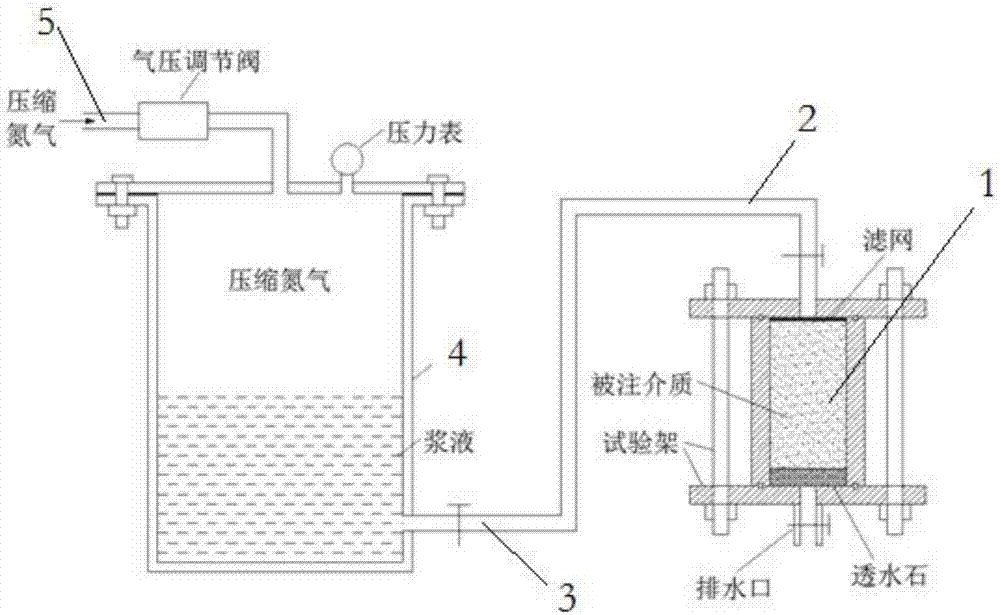

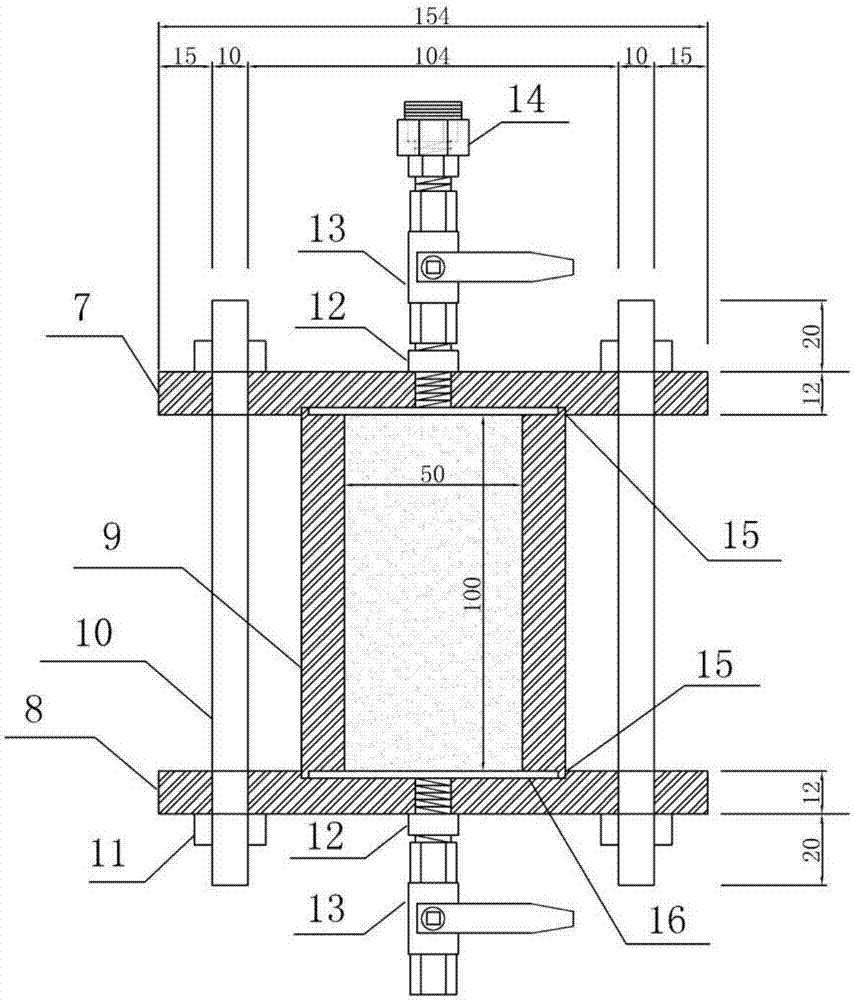

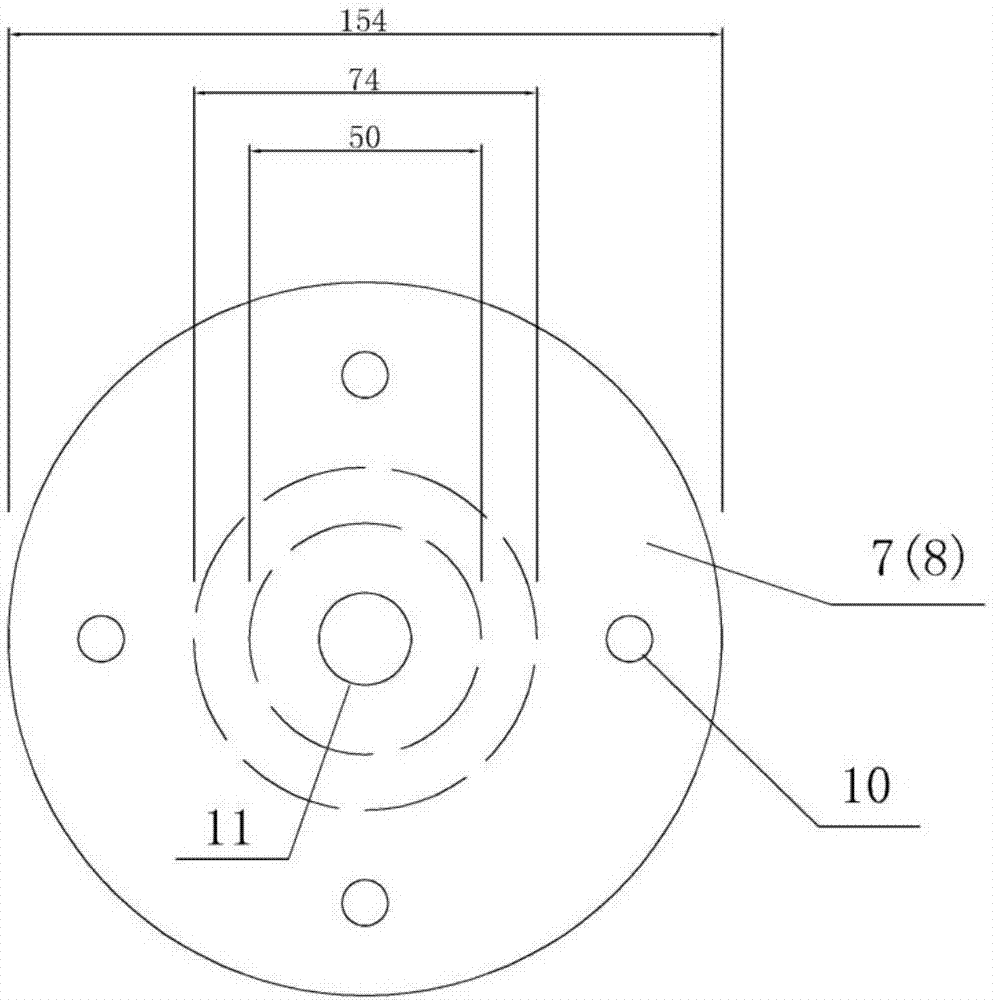

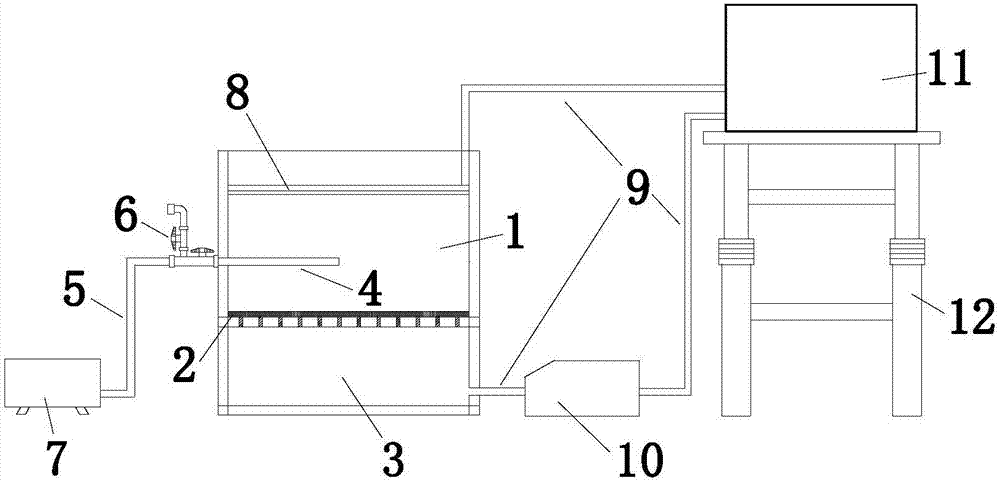

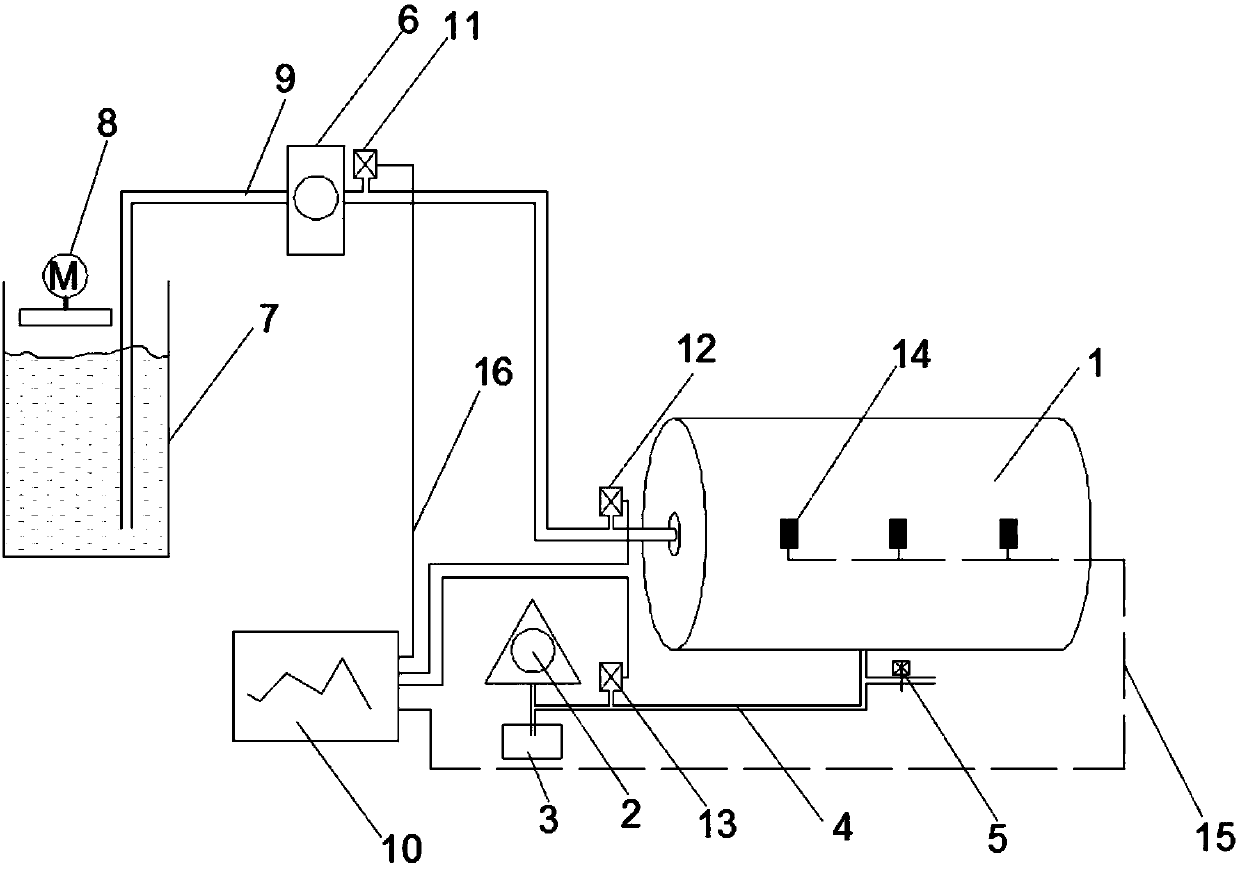

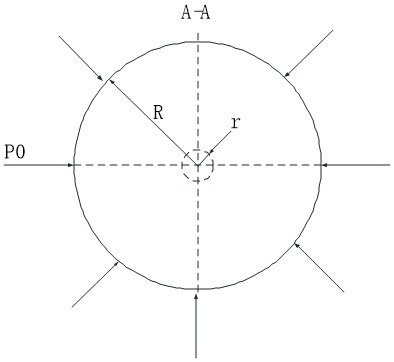

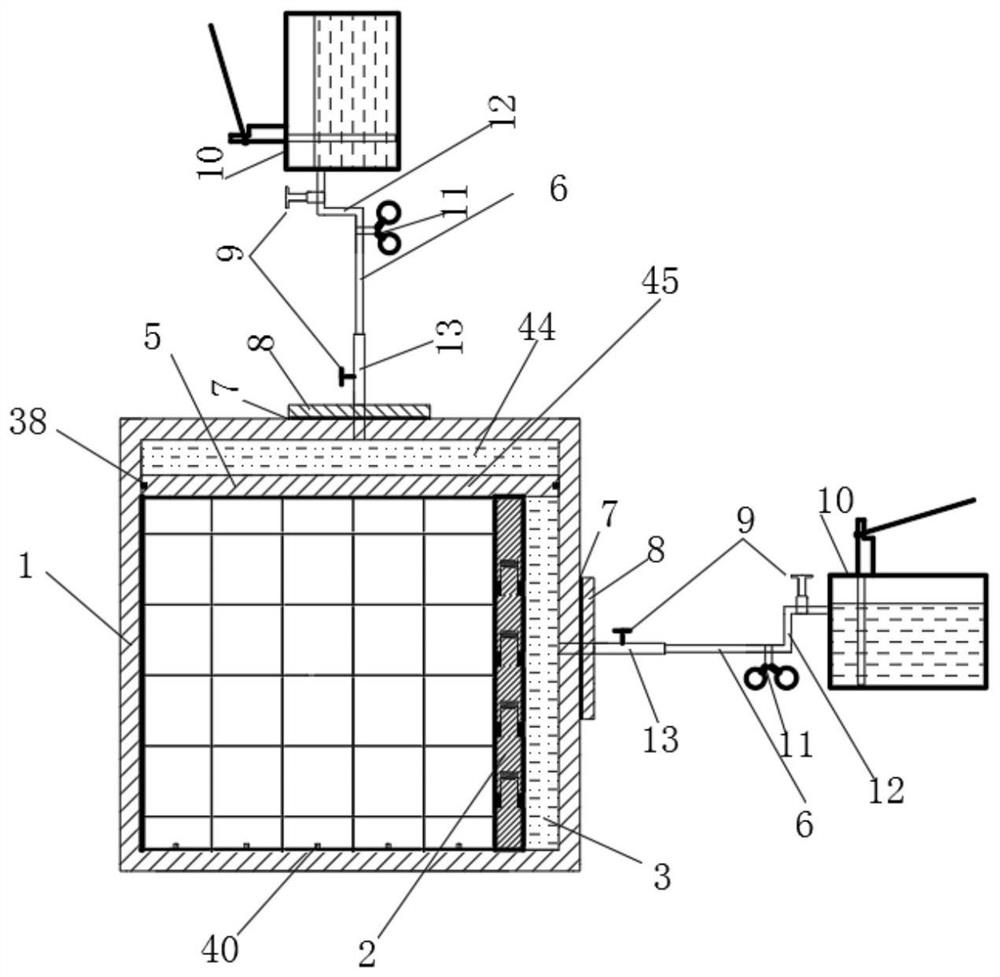

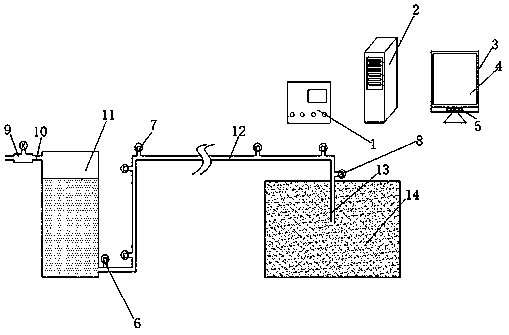

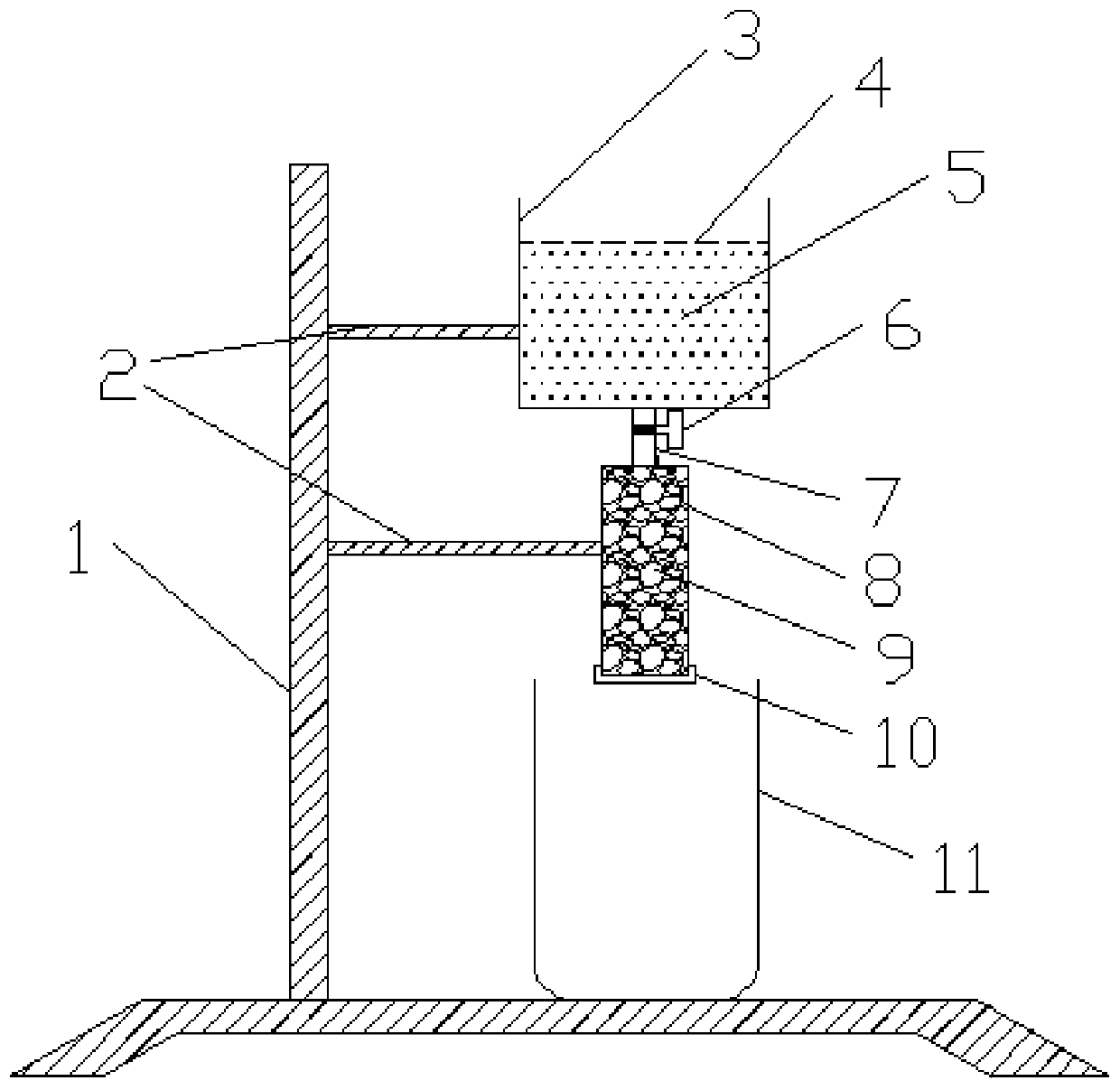

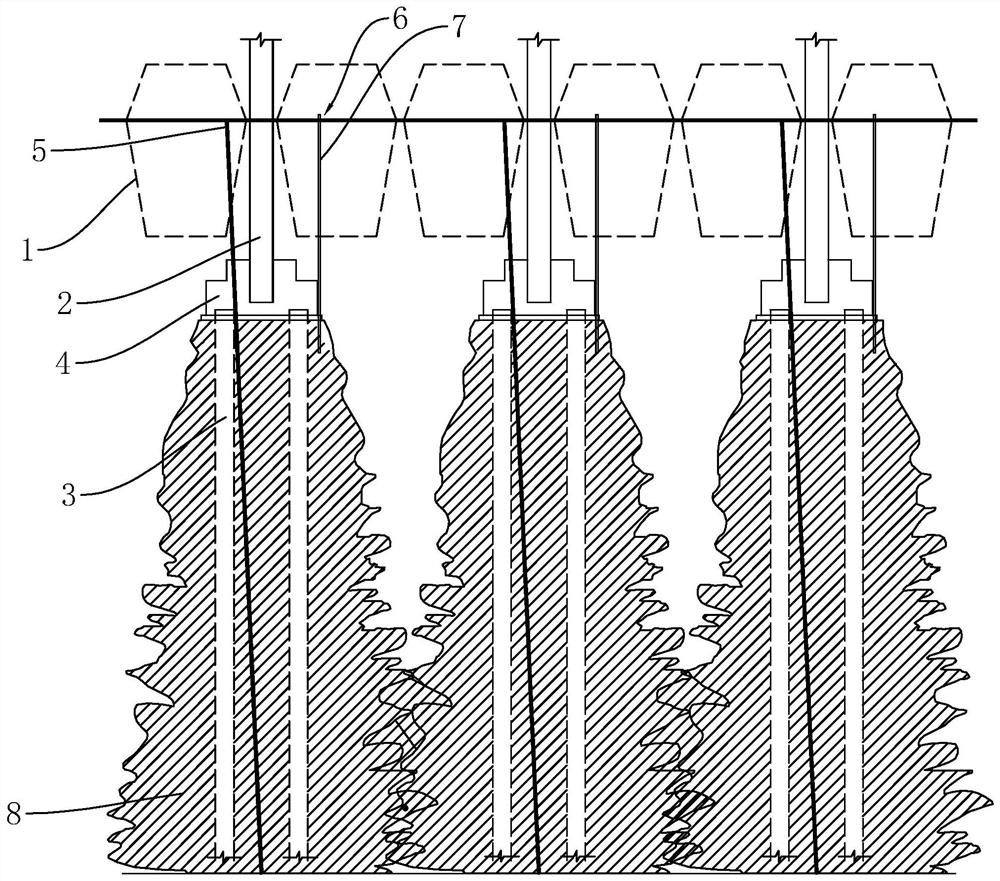

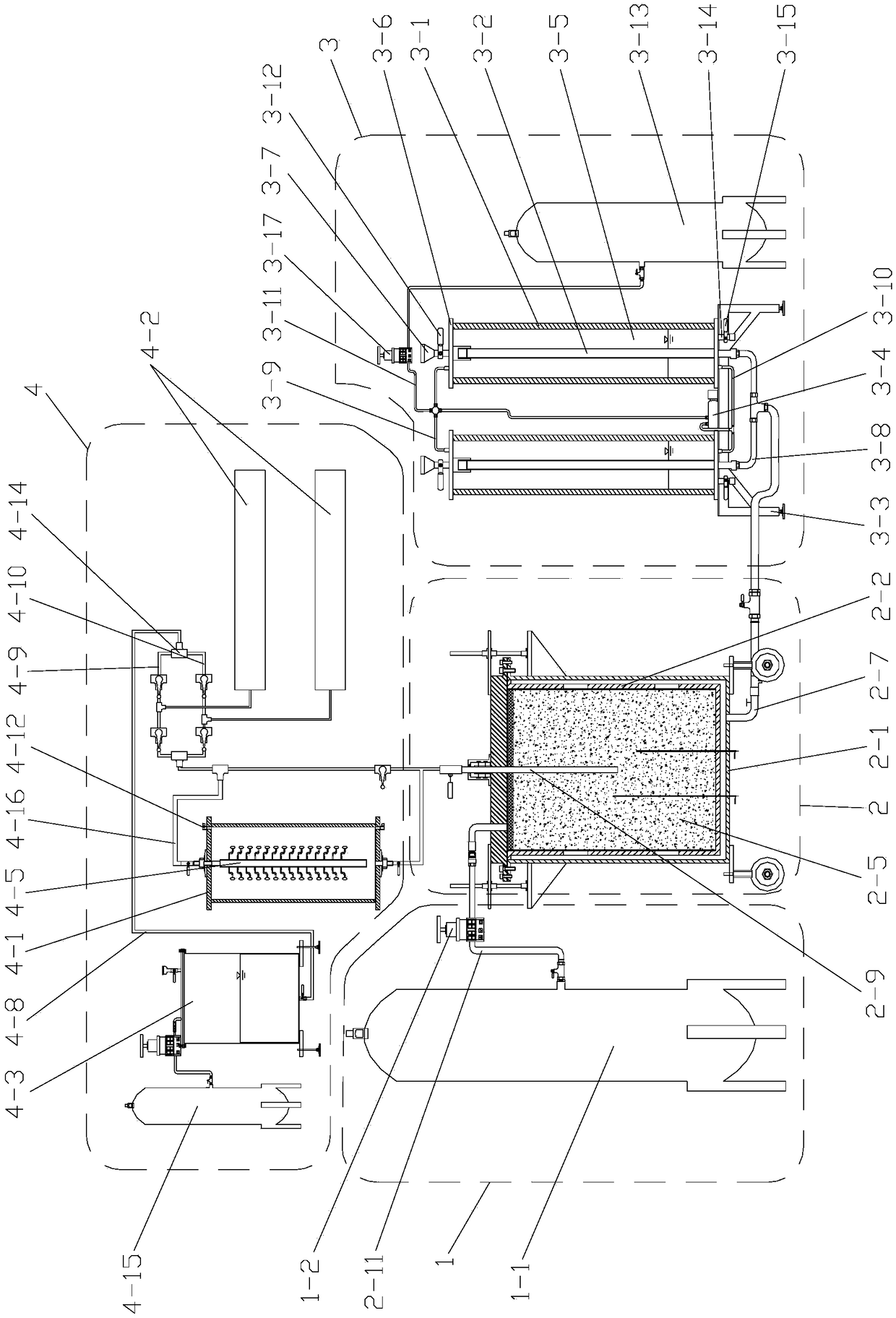

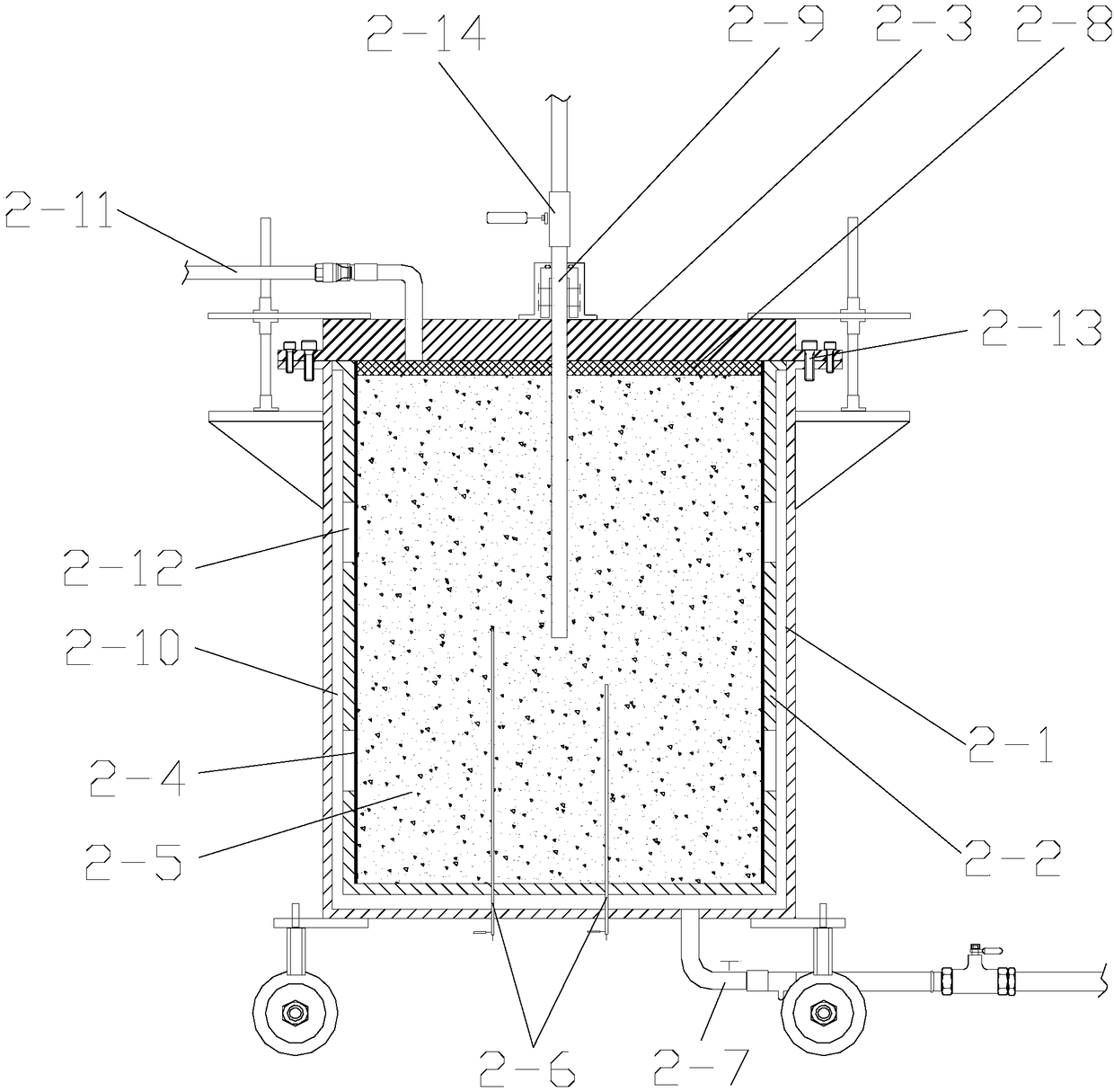

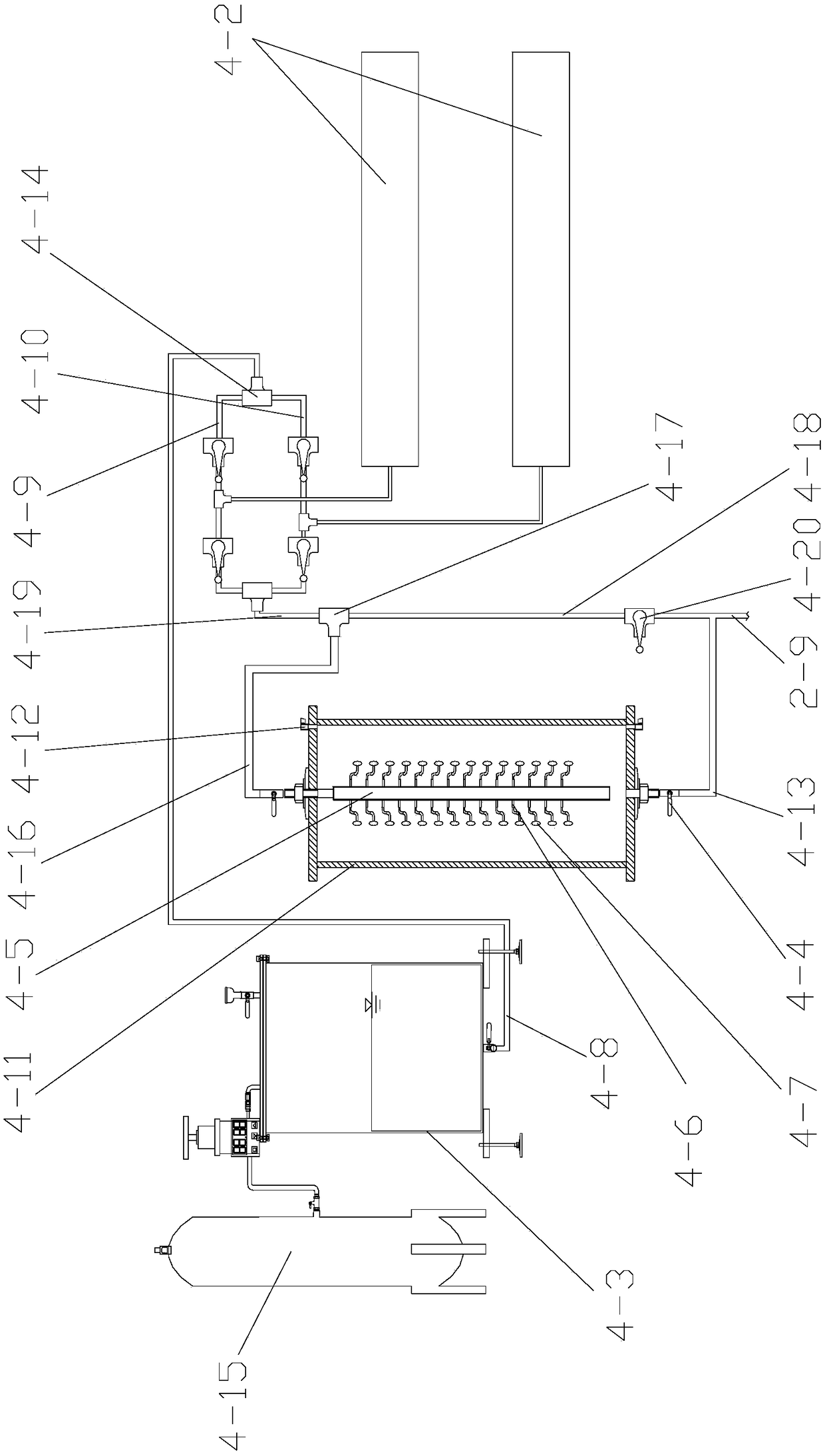

Laboratory simulation test system and method applicable to sand layer permeation grouting

ActiveCN107121371AShort test cycleImprove test efficiencyPermeability/surface area analysisSoil scienceSlurry

The invention discloses a laboratory simulation test system and a method applicable to sand layer permeation grouting. The system comprises a power device, a bearing grout storage bucket, a grouting pipeline and a grouting test device, wherein the power device applies pressure on the bearing grout storage bucket, so that grout in the bearing grout storage bucket is conveyed to the grouting test device by the grouting pipeline. The grouting test device comprises an experimental bench, the experimental bench is provided with a containing space for bearing a grouted medium, a grouting port is formed at the upper end of the containing space, and a grout discharge port is formed at the lower end of the containing space, so that a permeation process of pressed grout in the grouted medium is tested. The system adopts fabricated device design, so that a simulation test of sand layer permeation grouting performance can be performed by lower cost, less time and lower manpower input, and a relatively ideal effect can be obtained.

Owner:SHANDONG UNIV +1

Self-drilling differential grouting combined anchor rod and method for anchoring same

ActiveCN107387141AReduce the amount of drillingImprove the support effectBulkheads/pilesAnchoring boltsRock boltSmall range

The invention discloses a self-drilling differential grouting combined anchor rod and a method for anchoring the same. The self-drilling differential grouting combined anchor rod comprises a drill bit, a grouting pipe, a spindle, an anchor head mechanism and an anchor tail mechanism. The anchor head mechanism comprises a fixed ring, a slip ring, a limit pipe and a plurality of pairs of driven connecting rods and driving connecting rods. The anchor head mechanism can be matched with fracturing grouting, so that the stability of inner anchor ends of the self-drilling differential grouting combined anchor rod can be guaranteed. The anchor tail mechanism comprises an anchor disc, a connecting cap, a spring and a nut; the grouting pipe and the spindle can deform in a coordinated manner by the aid of the connecting cap, joint bearing effects can be realized by the grouting pipe and the spindle, and the self-drilling differential grouting combined anchor rod can be timely in driving support states by the aid of the spring and can be in the driving support states for a long term. The self-drilling differential grouting combined anchor rod has the advantages that drilling, inner anchor end reaming and fracturing grouting can be carried out on weak broken surrounding rock by the aid of the self-drilling differential grouting combined anchor rod, and permeation grouting can be carried out on remaining sections by the aid of the self-drilling differential grouting combined anchor rod; the surrounding rock in small ranges around the grouting pipe can be anchored by the grouting pipe in a full-length anchoring mode; squeezing reinforcing effects can be realized by the spindle for the surrounding rock in large ranges including anchoring regions of the grouting pipe, the anchoring regions of the grouting pipe and anchoring regions of the spindle act with one another, the synergistic bearing effects can be realized by the grouting pipe and the spindle, and accordingly support effects can be improved.

Owner:CHINA UNIV OF MINING & TECH

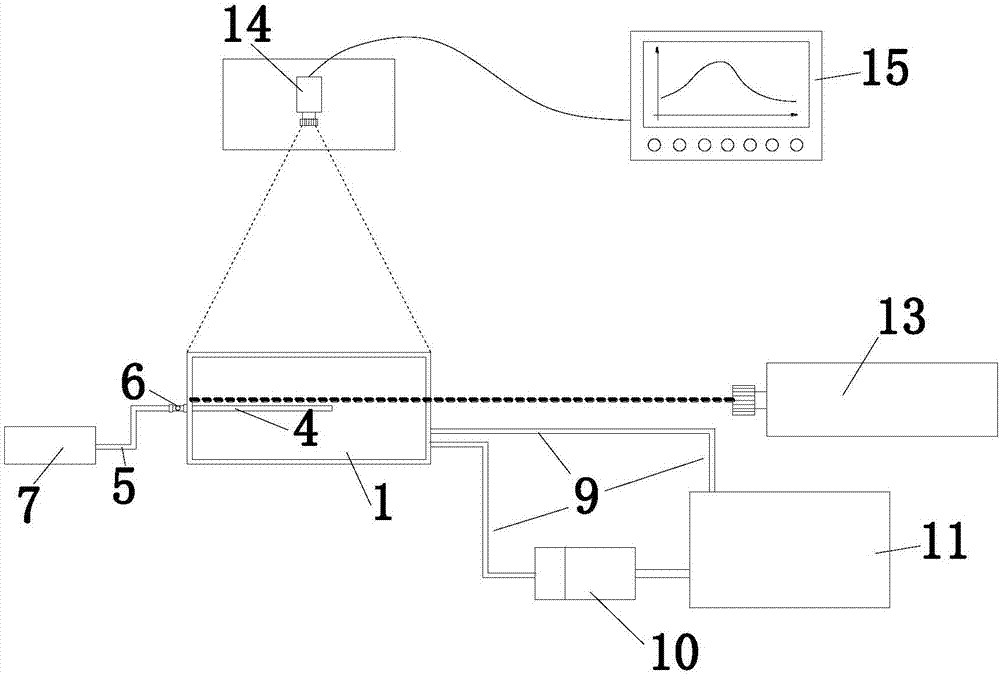

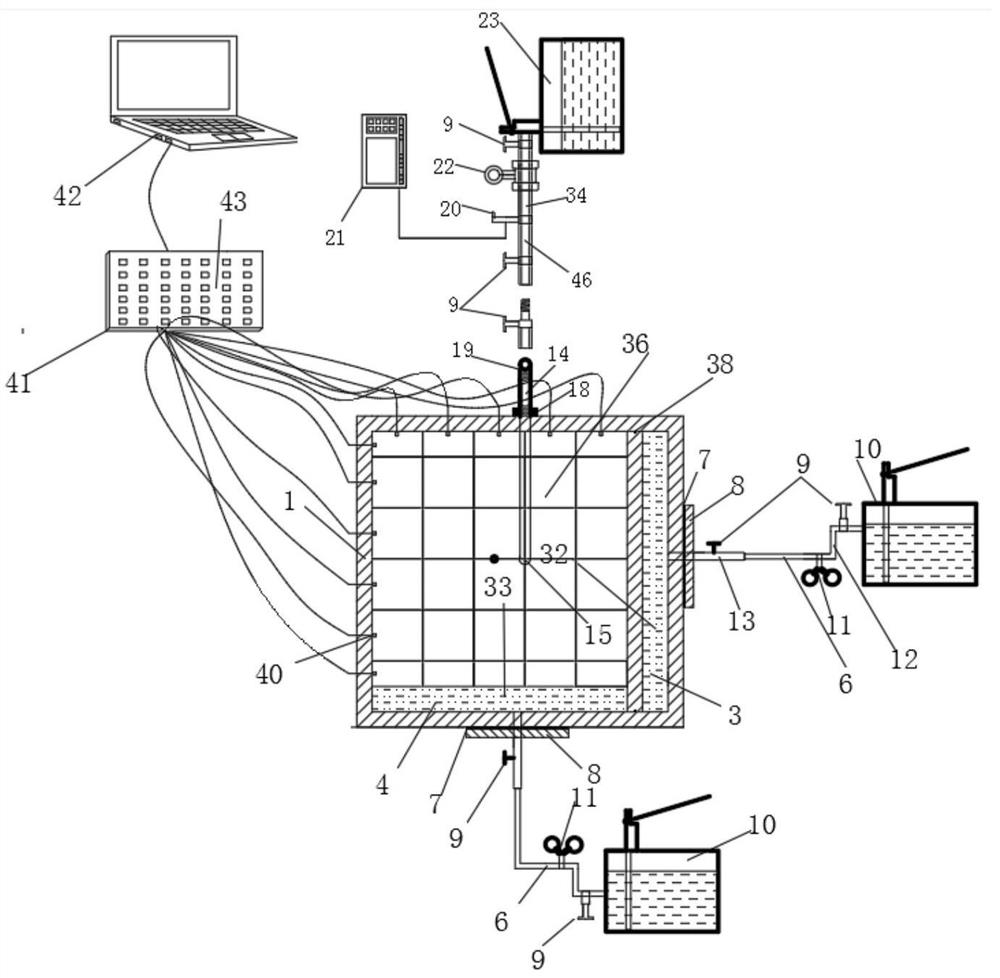

Visual saturated dynamic water-bearing sand bed permeation grouting test device and method

ActiveCN106885759ARealize visualizationReal-timeMaterial analysis by optical meansDiffusion analysisFuel tankVisualization model

The invention discloses a visual saturated dynamic water-bearing sand bed permeation grouting test device and method. The visual saturated dynamic water-bearing sand bed permeation grouting test device comprises a visual model box, a grouting pump, a sprinkling plate, an oil pump, a constant head water tank, a laser sheet source transmitter, an industrial camera and a data collection system, wherein slurry is injected into the visual model box by the grouting pump through a slurry delivery pipe; openings are uniformly formed in a bottom plate; a layer of filter net covers the bottom plate; an oil receiving tank is arranged at the bottom of the visual model box and connected with the oil pump through an oil delivery pipe; the oil pump is connected with the constant head water tank; a locating water tank is also connected with the sprinkling plate connected to the top of the visual model box through the oil delivery pipe; the laser sheet source transmitter is arranged at one side of the visual model box; laser light emitted from the laser sheet source transmitter penetrates through transparent soil through the visual model box to form a uniform speckle field; the shooting direction of the industrial camera is located in a normal direction of a laser plane; and the camera is connected with the data collection system and records the change of the speckle field in real time.

Owner:SHANDONG UNIV

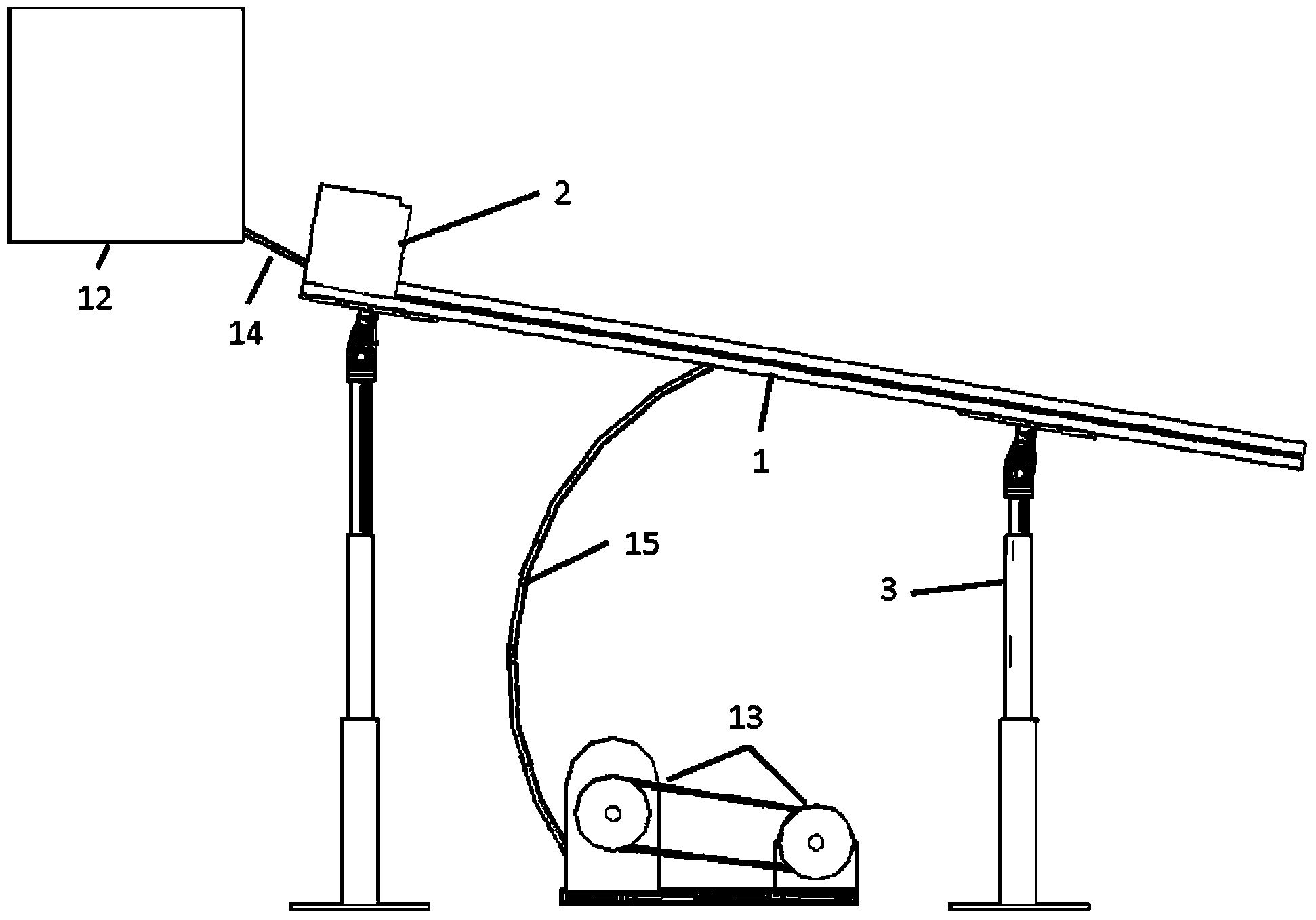

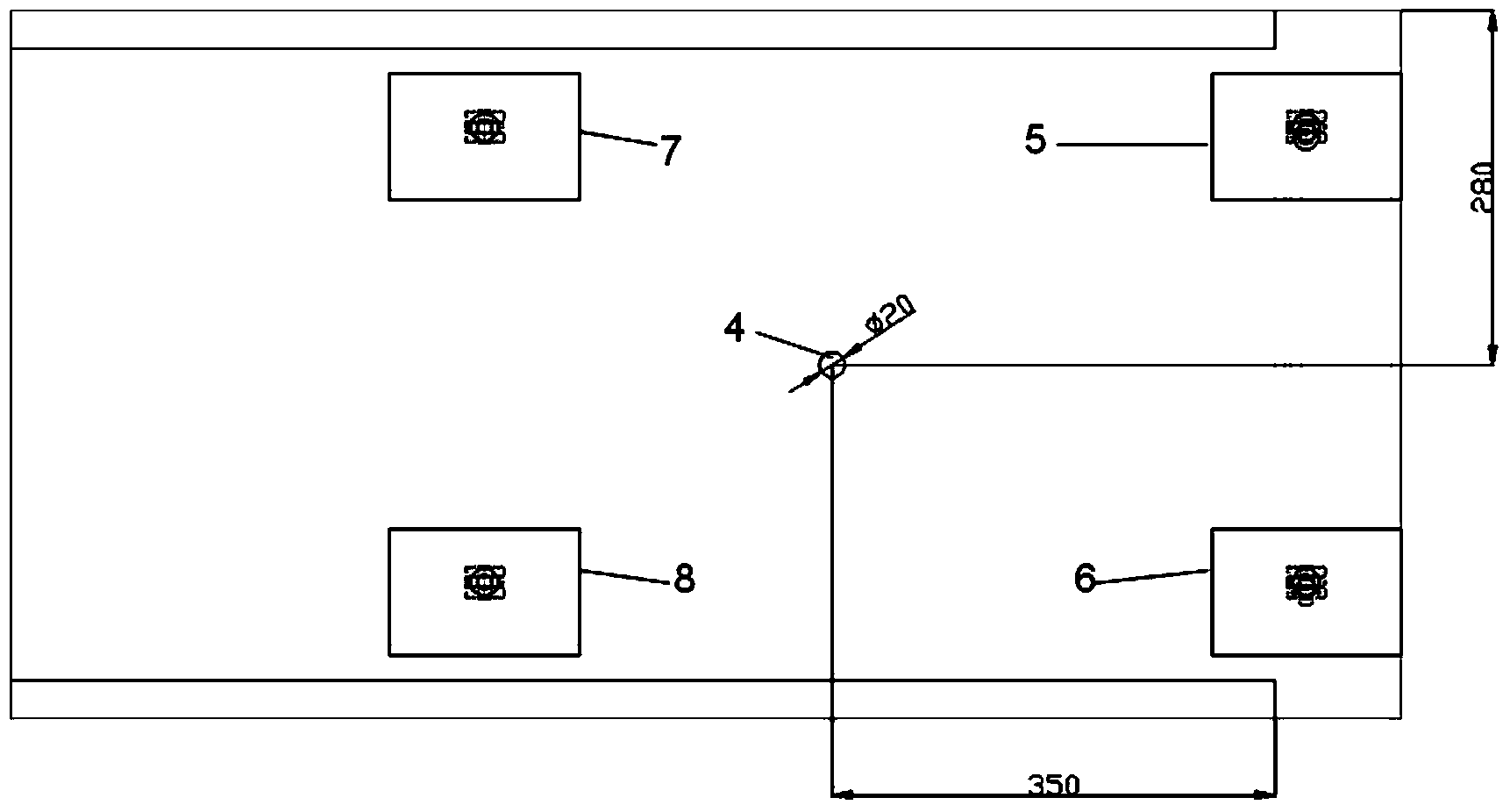

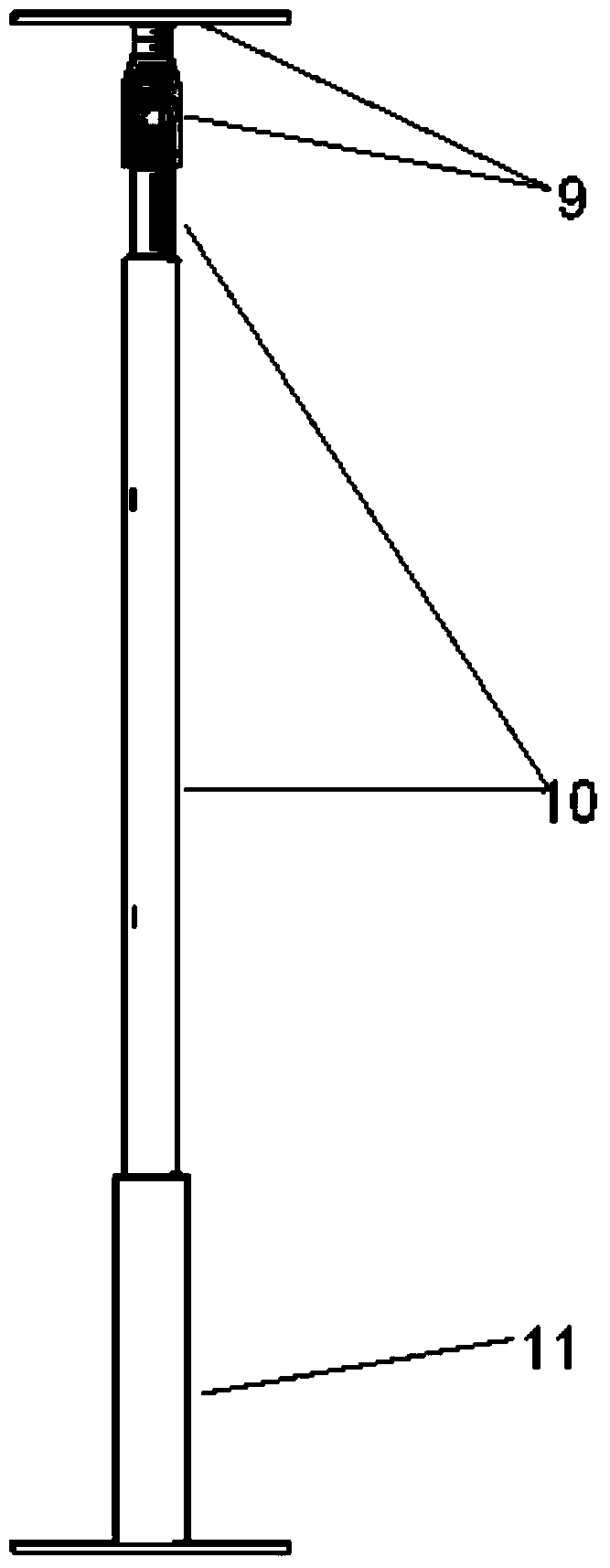

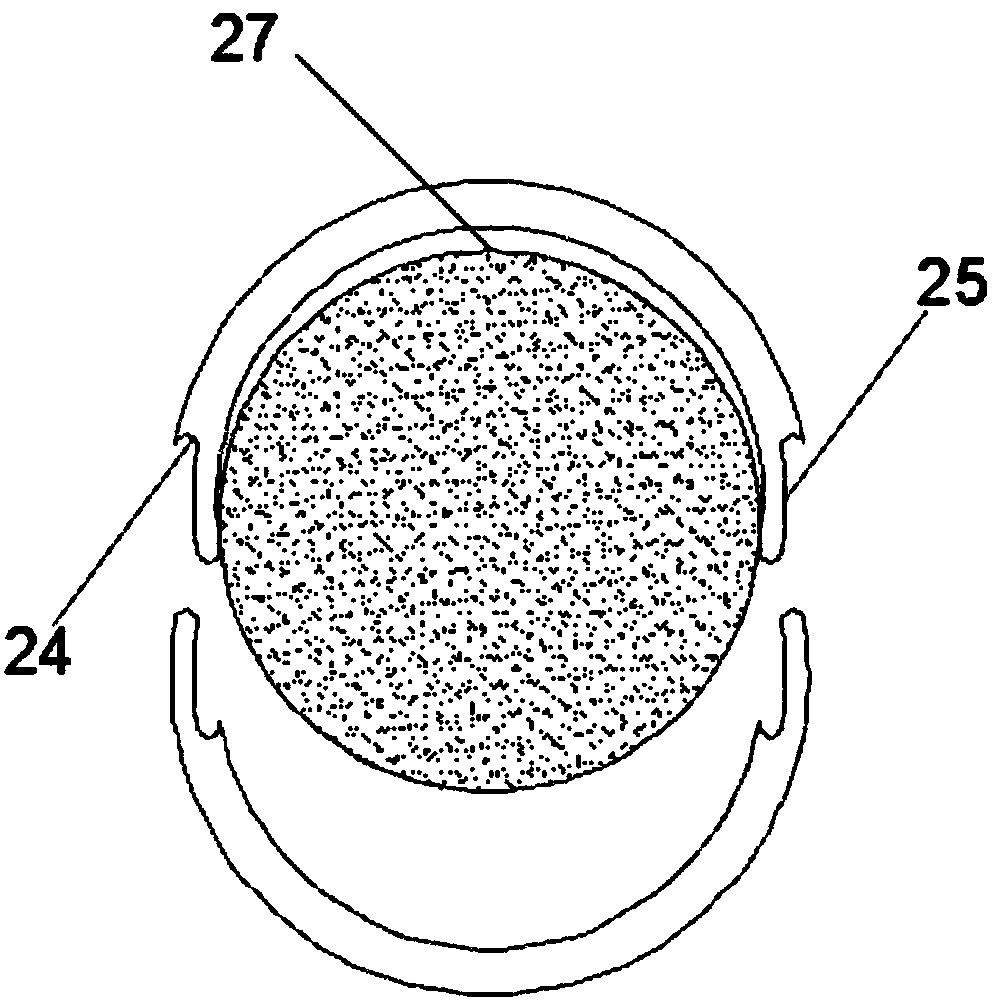

Variable-dip-angle simulated fracture grouting model test platform

The invention discloses a variable-dip-angle simulated fracture grouting model test platform. The variable-dip-angle simulated fracture grouting model test platform comprises a simulated fracture, a pressure stabilizing water tank and a liftable supporting base, wherein the simulated fracture comprises two glass panels, a grouting hole is formed in the lower side glass panel, and the space between the two glass panels is filled with porous media, the pressure stabilizing water tank is hinged to the upper side glass panel of the simulated fracture, the liftable supporting base is fixed to the lower end of the lower side glass panel of the simulated fracture and comprises a connecting disk, a lifting rod and a base, the connecting disk is fixed to the lower side glass panel of the simulated fracture, the lifting rod is fixed to the lower end of the connecting disk, and the other end of the lifting rod is fixed to the base. The simulated fracture can be assembled again as required, the width of the simulated fracture is adjusted, the simulated fracture can be filled with porous media, and permeation grouting under different medium conditions is simulated. The test platform is a model test device capable of being used for researching influences of fracture parameters, grout parameters and other parameters on grout diffusion in the fracture flowing water grouting simulating process.

Owner:SHANDONG UNIV

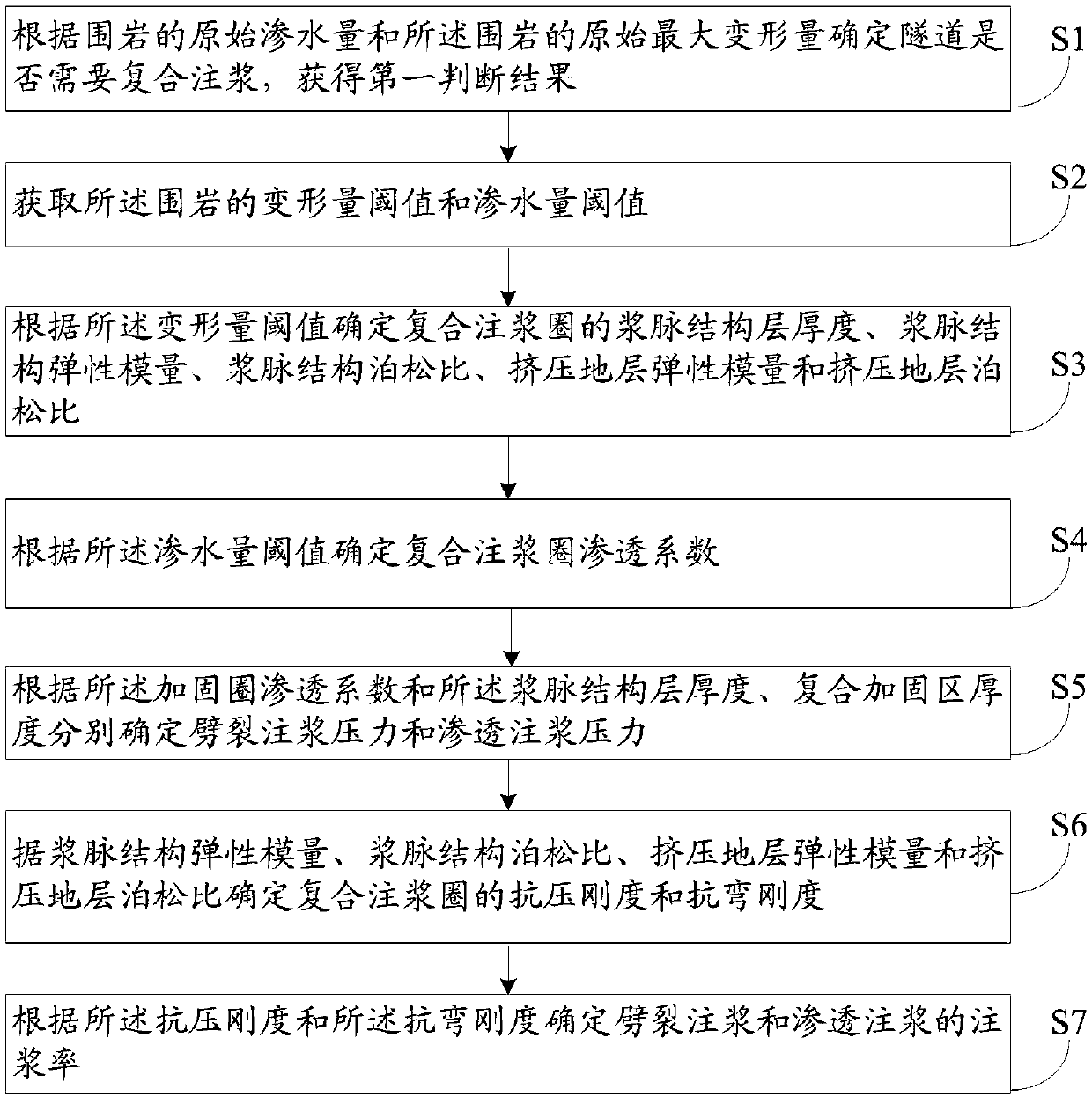

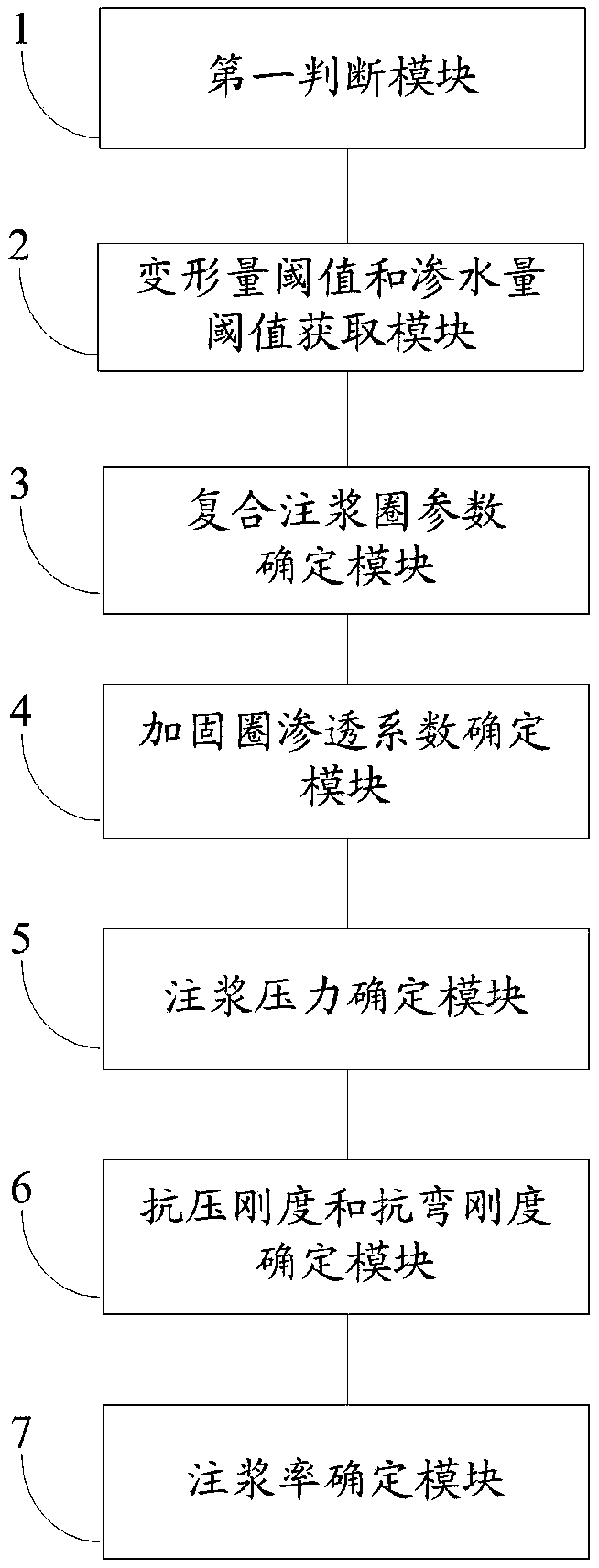

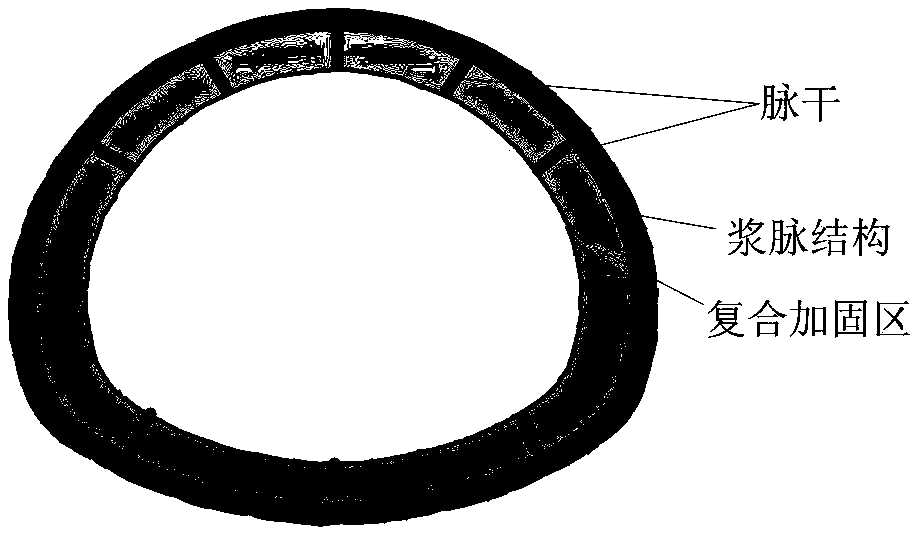

Subsea tunnel combined grouting parameter determining method and system

ActiveCN109577992AImprove securityReduce subjectivityTunnelsSoil preservationStructure of the EarthCompressive strength

The invention discloses a subsea tunnel combined grouting parameter determining method and system. The subsea tunnel combined grouting parameter determining method comprises, according to a surrounding rock deformation threshold, determining the vein structural layer thickness, the vein structural elastic modulus, the vein structural Poisson ratio, the squeezing stratum elastic modulus and the squeezing stratum Poison ratio of a combined grouting circle; according to a seepage threshold, determining the permeation coefficient of a reinforcing circle; according to the permeation coefficient ofthe reinforcing circle, the vein structural layer thickness and a combined reinforcing area thickness, determining splitting grouting pressure and permeation grouting pressure; according to the vein structural elastic modulus, the vein structural Poisson ratio, the squeezing stratum elastic modulus and the squeezing stratum Poison ratio, determining compressive strength and bending strength; according to the compressive strength and the bending strength, determining a grouting rate. The subsea tunnel combined grouting parameter determining method takes into overall consideration subsea tunnelreinforcement and water plugging, effectively subjectivity of subsea tunnel grouting design and can be applied to guiding technical implementation of subsea tunnel combined grouting to achieve scientific and precise grouting design and improve the safety performance of subsea tunnels.

Owner:BEIJING JIAOTONG UNIV

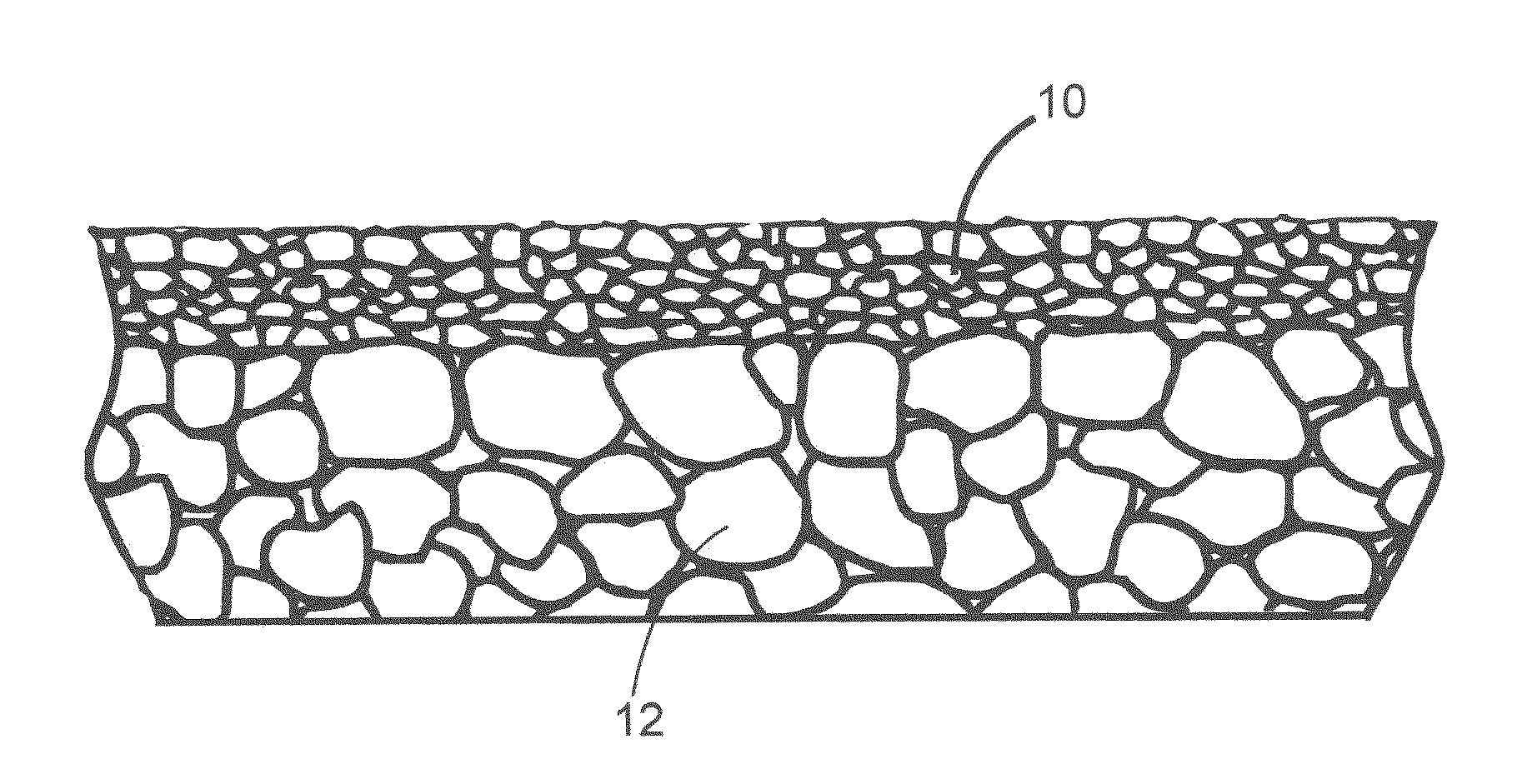

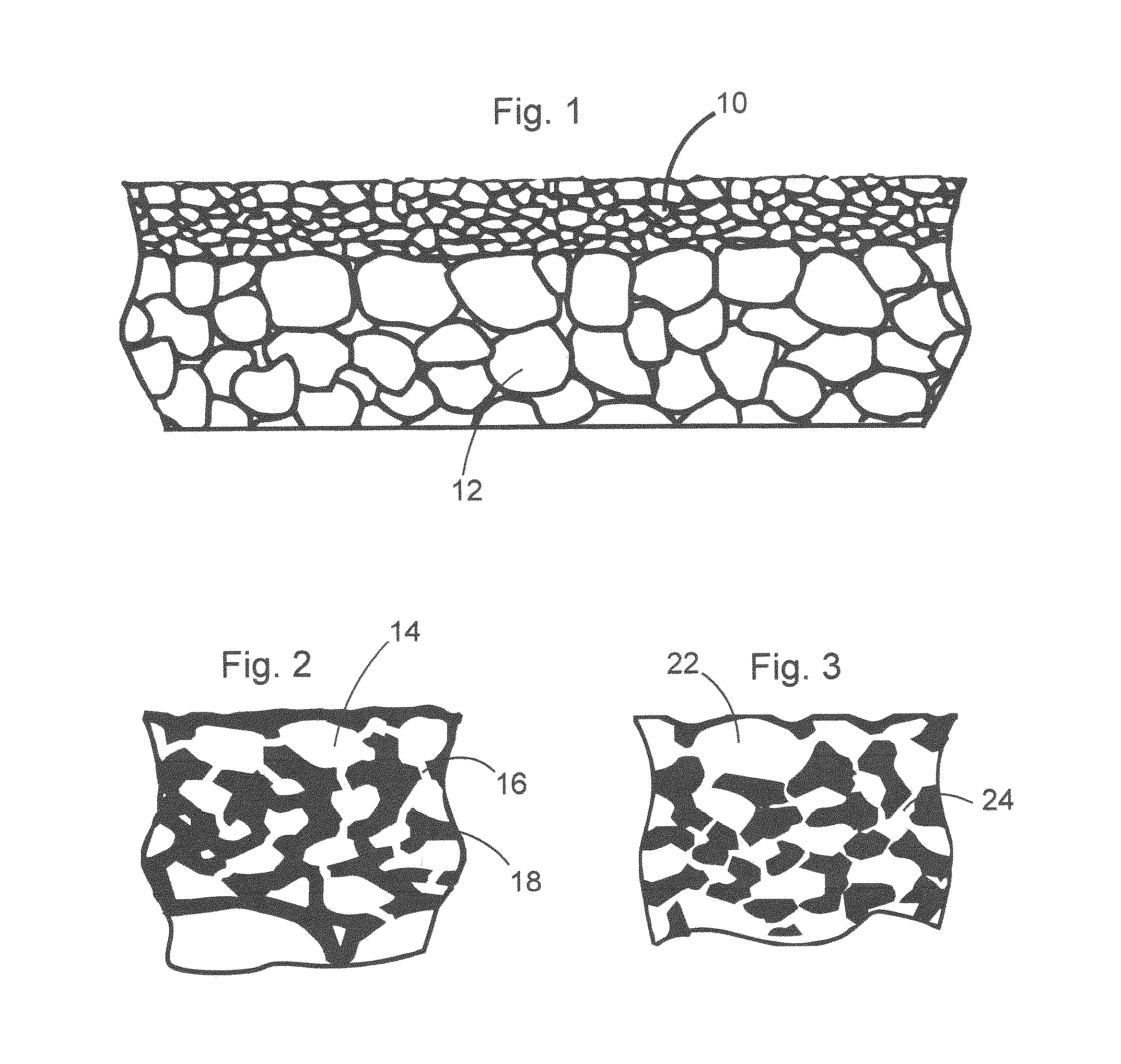

Pervious concrete permeable grout

InactiveUS20140272369A1Reduce penetrationSignificant accumulationSingle unit pavingsSynthetic resin layered productsEpoxyMaterials science

A water pervious concrete surface is described that is formed of a water pervious layer of concrete having interconnected voids, and a water permeable grout within the voids in the pervious layer. The permeable grout is formed of sand particles bonded in an open matrix with a two-part epoxy resin.

Owner:KING JONATHAN TODD

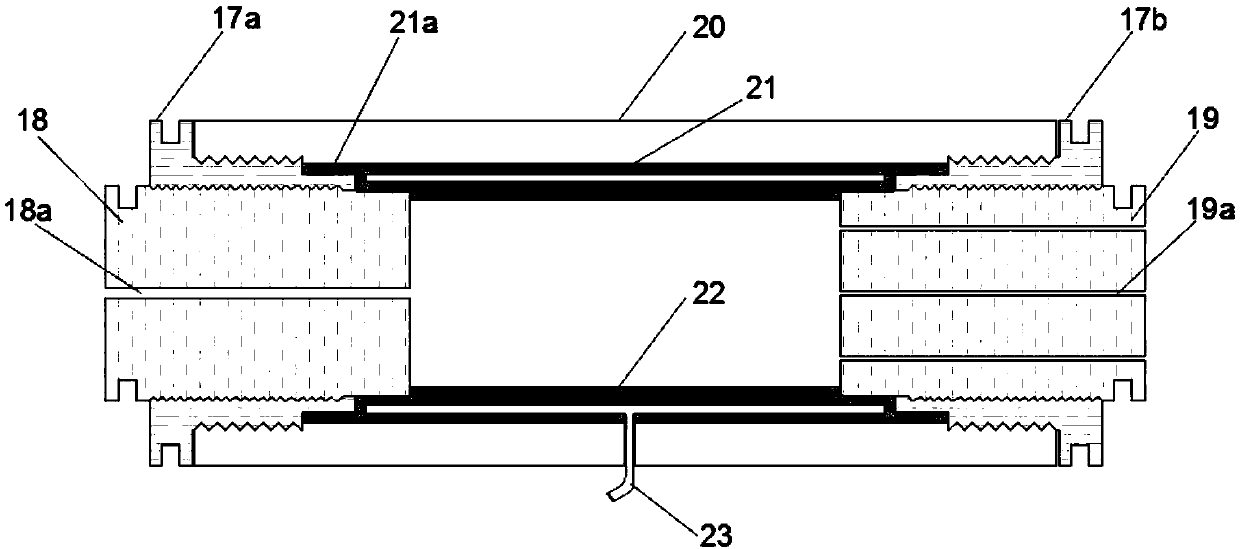

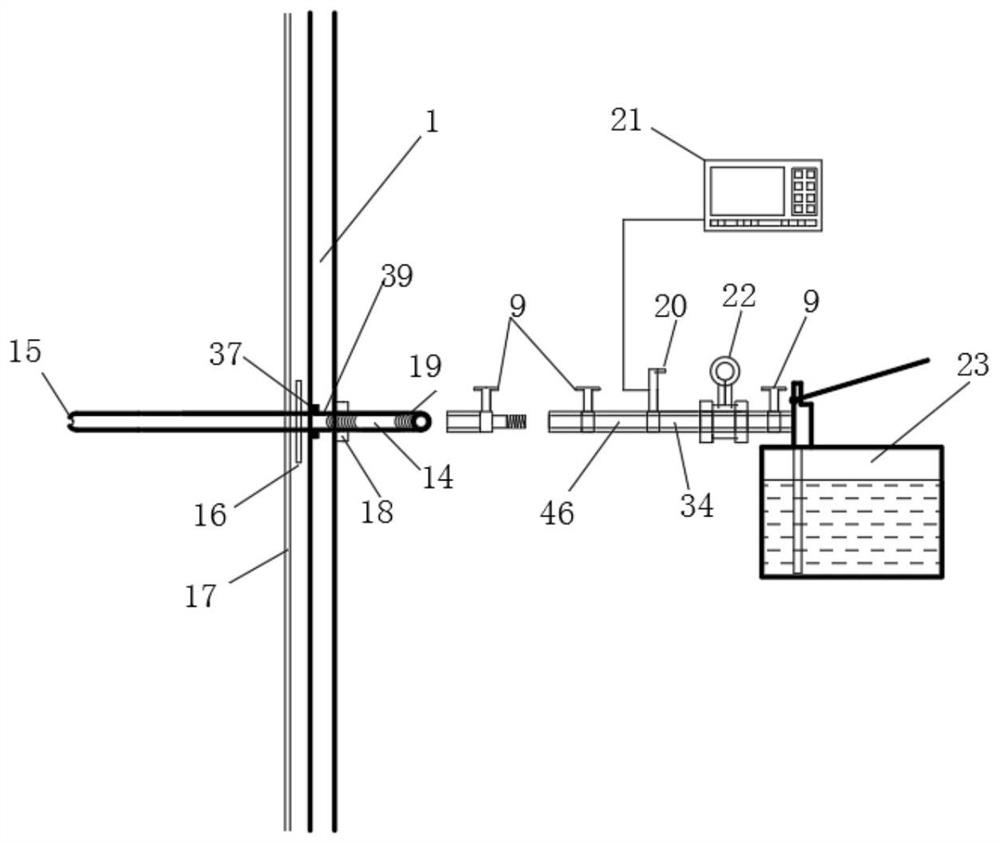

Loose body permeation grouting simulating testing device

The invention discloses a loose body permeation grouting simulating testing device. A grouting system comprises a grouting pump, a grout storing tank and a grouting pipeline, wherein the grouting pumpis used for conveying grout in the grout storing tank to a peripheral pressure loading system; the peripheral pressure loading system comprises a double-rubber-sleeve peripheral pressure loader and amanual peripheral pressure pump; an outer water bag rubber sleeve is connected to the peripheral pressure pump, so that a peripheral pressure environment is created; an inner flap membrane rubber sleeve wraps a loose medium; a monitoring system comprises a monitoring host, a pressure pump sensor, a grouting port pressure sensor, a peripheral pressure sensor and a resistivity sensing element. According to the loose body permeation grouting simulating testing device, the flap membrane rubber sleeve wraps a loose body, and the water bag rubber sleeve is used for pressurizing the loose body so asto simulate a ground stress environment; the pressure of a constant-pressure peripheral pressure pump and the grouting pump is adjusted until the peripheral pressure is beyond the grouting pressure,and thus the loose body permeation grouting process can be simulated; after the grouting is finished, the solidified loose body wrapped with the flap membrane rubber sleeve can be completely removed for study. The method is convenient to operate; and the obtained test result has directive significance on actual engineering design.

Owner:CHINA UNIV OF MINING & TECH

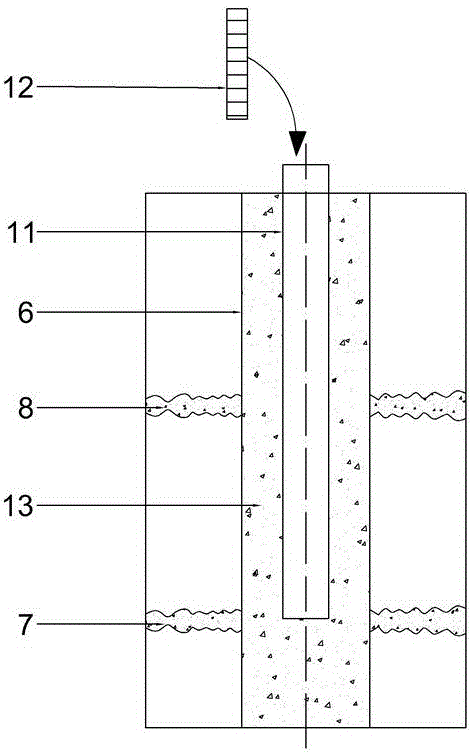

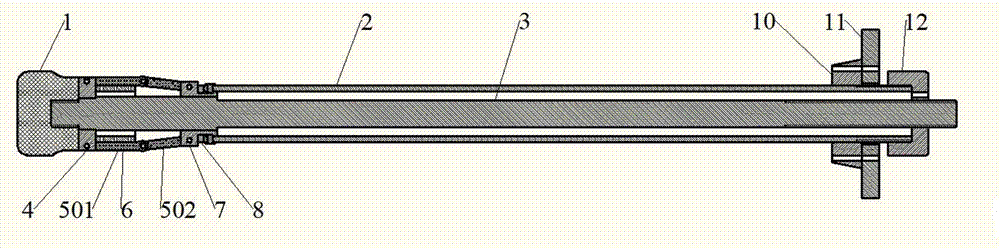

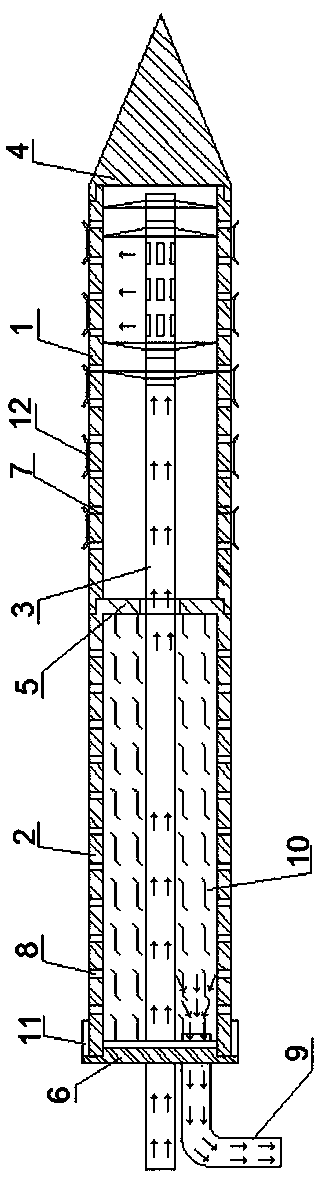

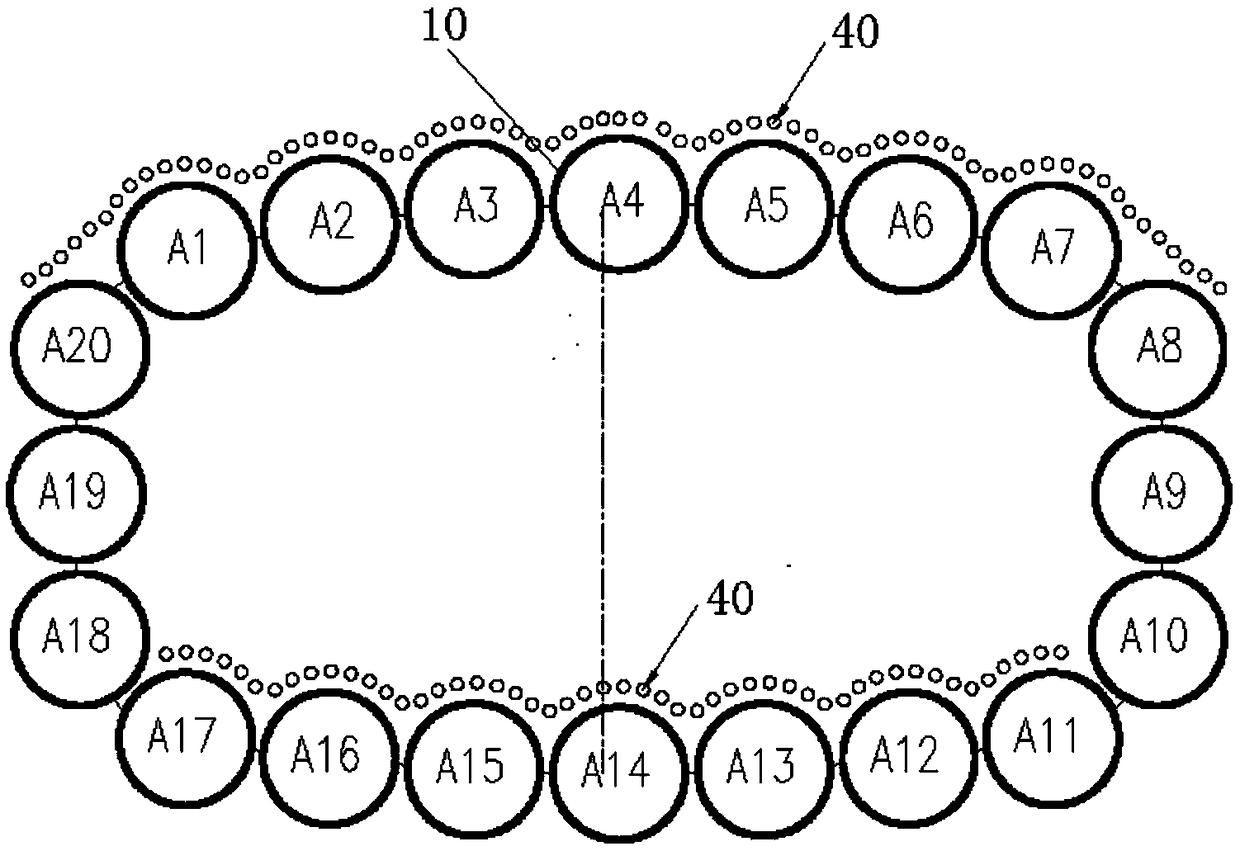

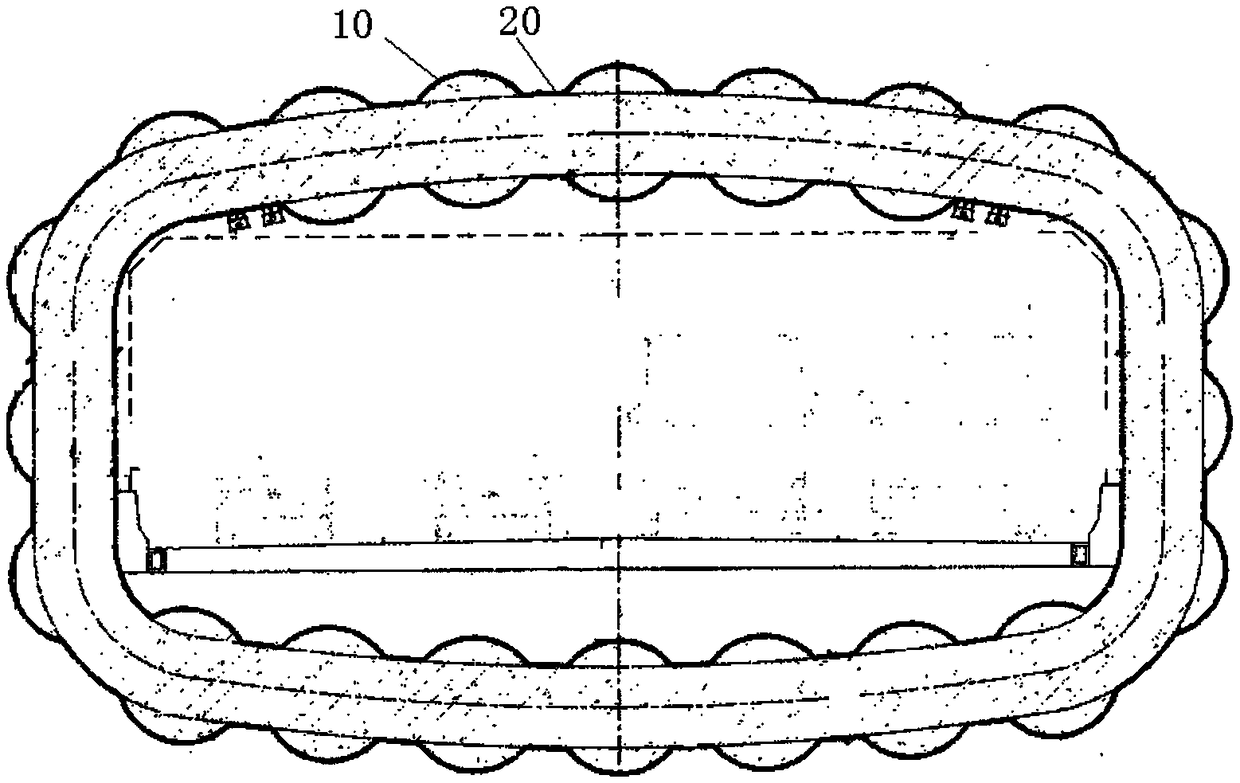

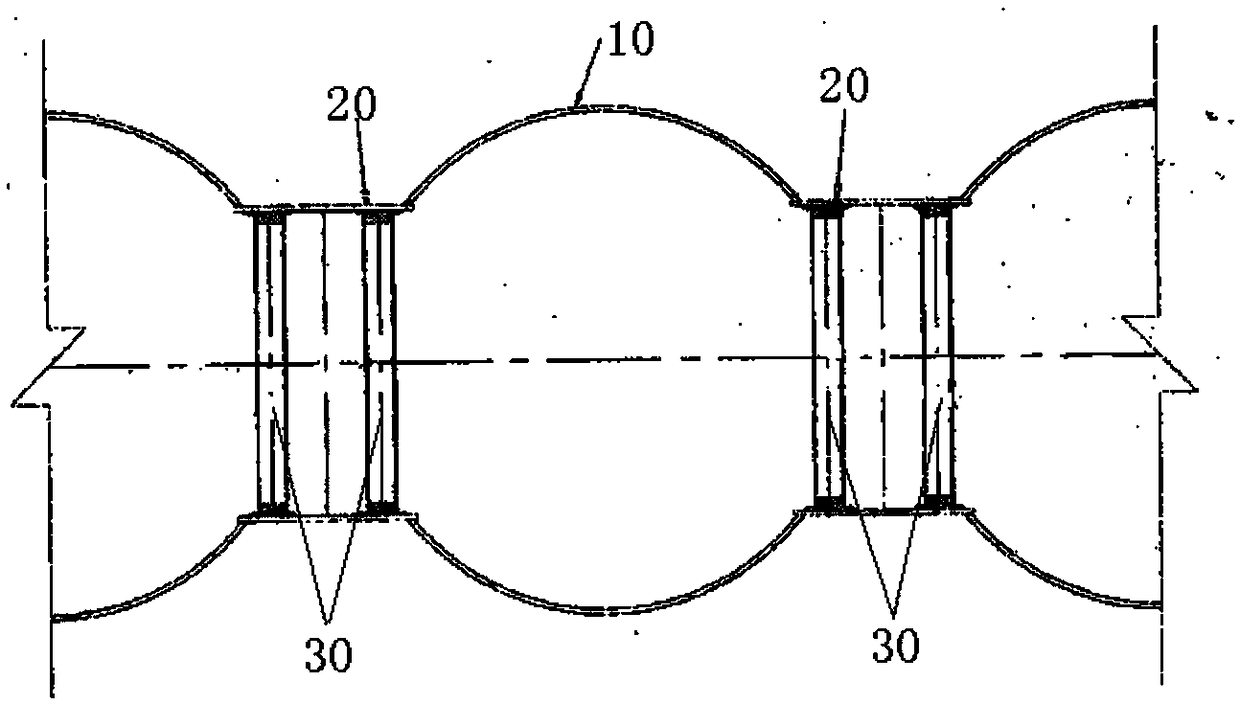

Permeation grouting integrated rod suitable for shield tunnel, and construction method

PendingCN109139059AEffective stress increaseDissipate excess pore water pressureUnderground chambersDrainageSoil massPore water pressure

The invention relates to a permeation grouting integrated rod suitable for a shield tunnel, and a construction method of the permeation grouting integrated rod. The permeation grouting integrated rodcomprises a tubular grouting rod, a tubular permeation rod and a grouting tube, wherein a plug is fixed to the head end of the grouting rod, the tail end of the grouting rod is sealed and fixedly connected with the head end of the permeation rod, a partition plate is fixed to the head end of the permeation rod, an end plate is fixed to the tail end of the permeation rod, slurry outlets are evenlyformed in the peripheral wall of the grouting rod, water penetration holes are evenly formed in the peripheral wall of the permeation rod, the grouting rod sequentially passes through the end plate and the partition plate and then extends into the grouting rod, a water outlet pipe is fixed on the end plate, and the water outlet pipe is communicated with the permeation rod after passing through theend plate. The permeation grouting integrated rod has the functions of grouting and drainage, thus can quickly and effectively dissipate excessive pore water pressure caused by shield tunneling, quickly improve the effective stress of a formation soil mass, improving the secondary grouting and grouting reinforcement effect during operation, integrates the permeation rod and the grouting rod, is convenient for installation and convenient to use, and is applicable to the fields of tunnel engineering, underground engineering seepage reinforcement and the like.

Owner:ZHENGZHOU UNIV

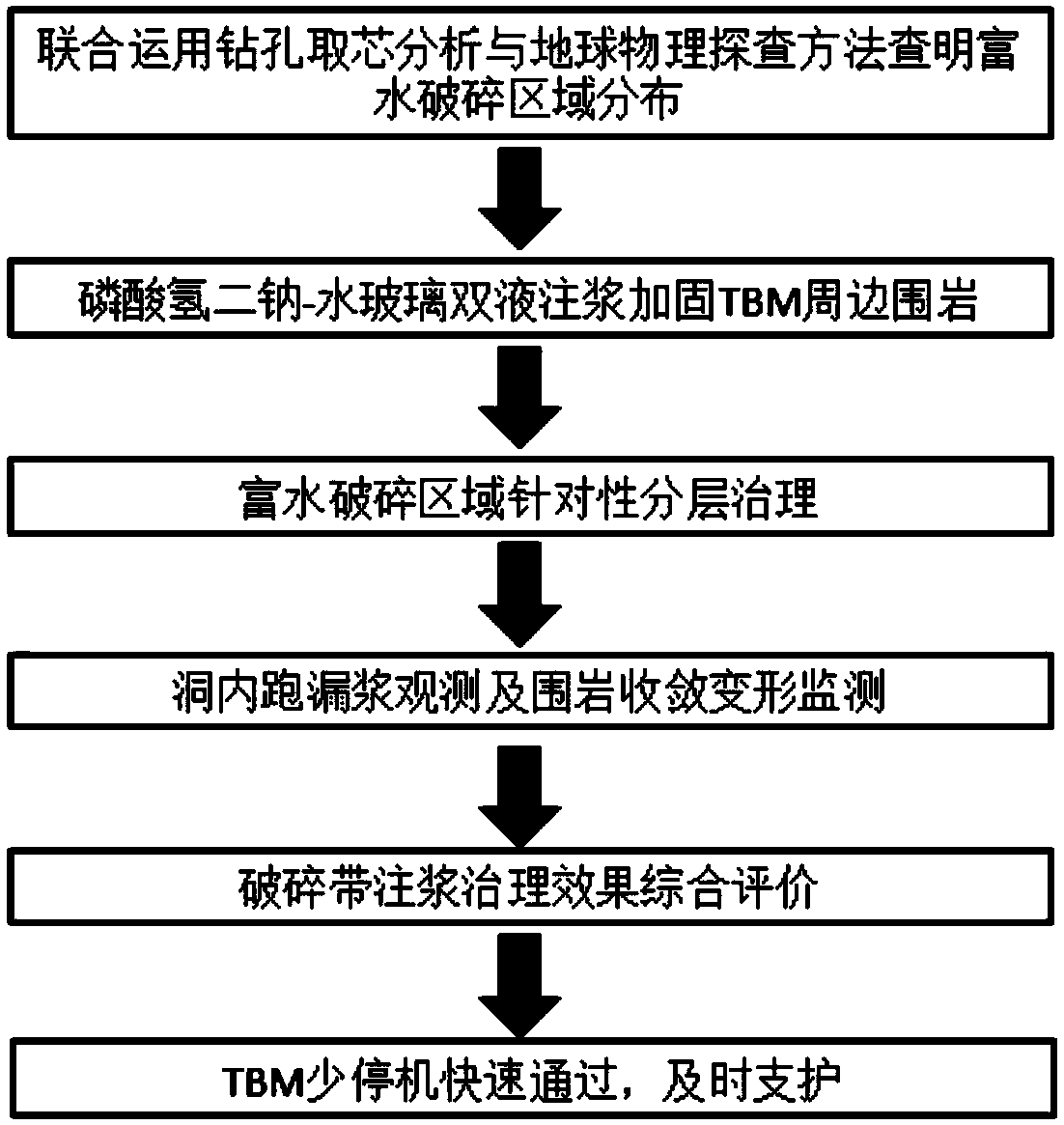

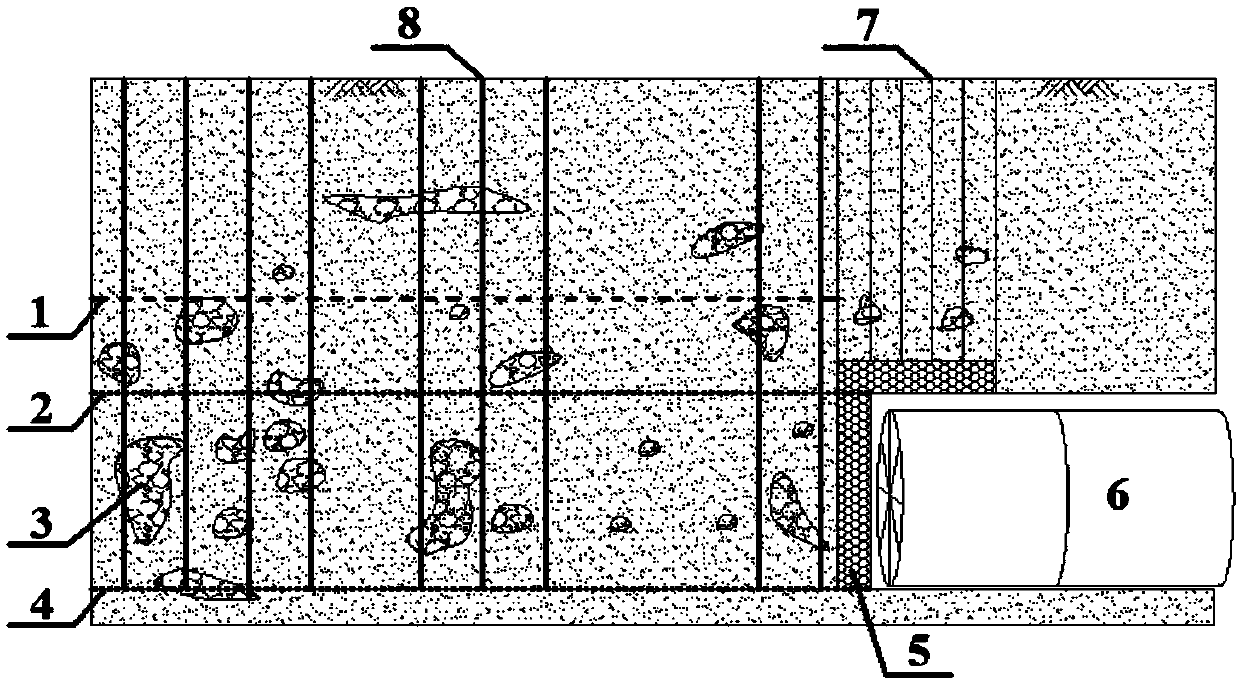

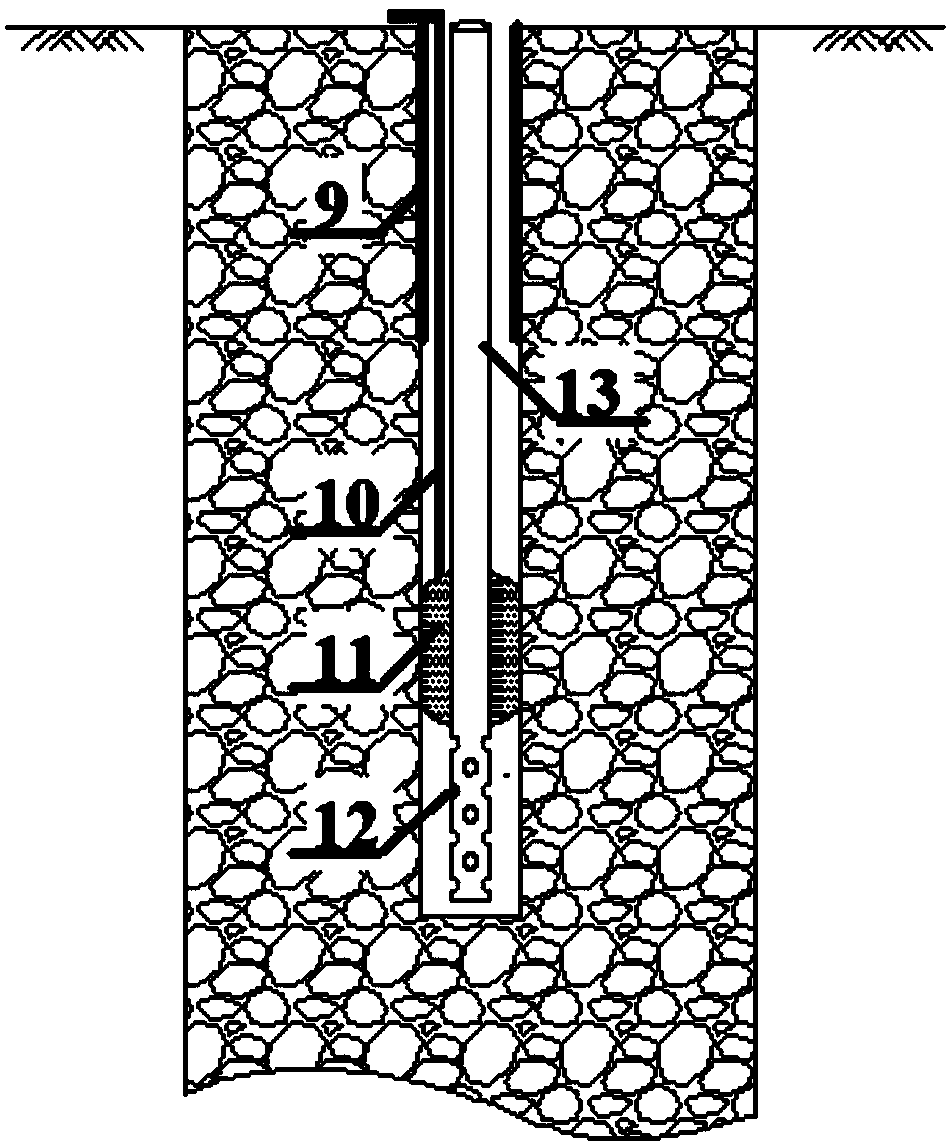

TBM construction over-crushed zone disaster source advanced control method and system

ActiveCN109611109AAccurate judgmentSolve the blind delineation of governance areasUnderground chambersTunnel liningTreatment effectCrushed stone

The invention provides a TBM construction over-crushed zone disaster source advanced control method and system. The method comprises the steps of using drilling and geophysical exploration to performcoring on the ground layer in the distribution range of a crushed zone on the ground surface by adopting an advanced drilling method, adjusting the distribution range of a weak crushed area accordingto a coring result, and determining the occurrence position and characteristics of a disaster source at front of a TBM tunneling place; forming a vertical drill hole in the ground surface, conductinglow-pressure permeation grouting reinforcement on the stratum around the TBM, and conducting ground surface grouting treatment on a water-rich weak stratum of the crushed zone; and comprehensively employing geophysical exploration and an inspection hole method to inspect the reinforcement treatment effect of a water-rich crushing disaster source, judging the grouting reinforcement effect until thegrouting treatment effect meets an expected requirement, and then starting TBM tunneling again to guarantee safe and smooth construction.

Owner:QINGDAO METRO LINE 1 CO LTD +1

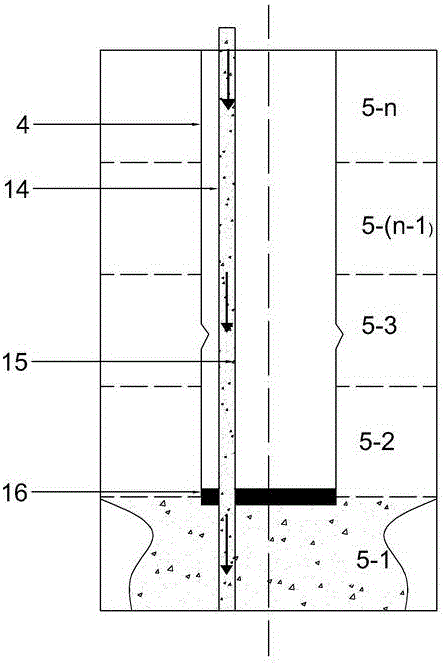

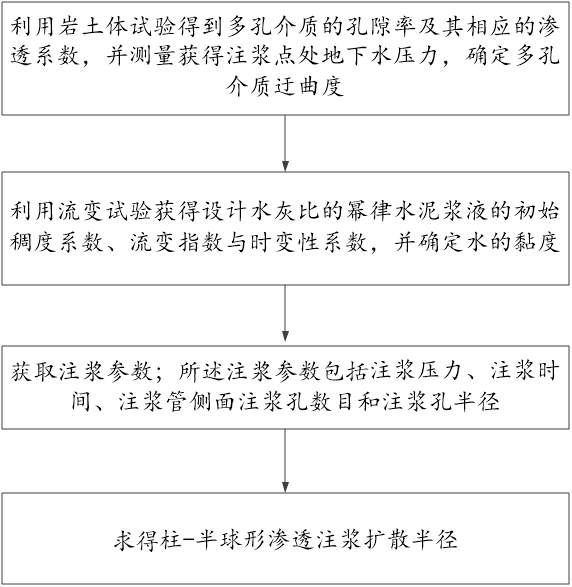

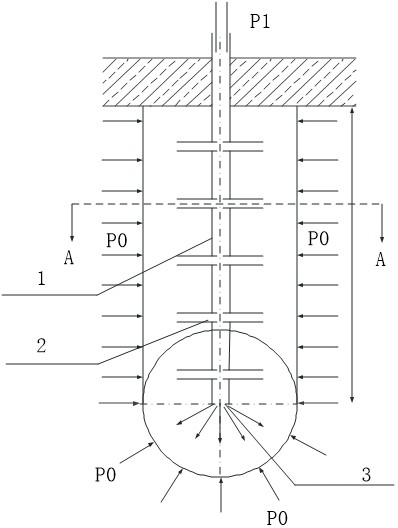

Method for determining permeability radius of column hemisphere of rock-soil body tortuosity power law slurry time-varying property

ActiveCN114720331AGrouting engineering practice complies withImproving the Technical Level of Strengthening Porous MediaPermeability/surface area analysisDirect flow property measurementSoil sciencePorous medium

The invention discloses a rock-soil body tortuosity power-law slurry time-varying cylindrical hemisphere permeability radius determination method, which comprises the following steps: obtaining the porosity of a porous medium and a corresponding permeability coefficient by utilizing a rock-soil body test, measuring to obtain underground water pressure at a grouting point, and determining the tortuosity of the porous medium; obtaining an initial consistency coefficient, a rheological index and a time-varying coefficient of the power-law cement slurry with the designed water-cement ratio by using a rheological test, and determining the viscosity of water; grouting parameters are obtained, wherein the grouting parameters comprise grouting pressure, grouting time, the number of grouting holes in the side face of a grouting pipe and the radius of the grouting holes; and solving the diffusion radius of the column-hemisphere permeation grouting considering the tortuosity of the porous medium and the time-varying coupling effect of the power-law cement grout. Through the scheme, the method has the advantages of simple logic, accuracy, reliability and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

Three-dimensional stress loading fractured rock mass splitting-permeation grouting test device and method

ActiveCN111638171AEliminate the problem of unstressed cornersEliminates the difficult problem of corner effectsMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesPrincipal stressClassical mechanics

The invention discloses a three-dimensional stress loading fractured rock mass splitting-permeation grouting test device and method, and is suitable for physical simulation experiment research in theaspect of geotechnical engineering. The device comprises a three-dimensional loading frame, a side pressure isolation telescopic plate, a first main stress pressurizing device, a second main stress pressurizing device, a third main stress pressurizing device, a grouting device and a stress monitoring system. First main stress, second main stress and third main stress are applied to the combined fractured rock mass; two pressurizing liquid bags applying pressure through side pressure are separated through the side pressure isolation telescopic plate, the scalability of the pressurizing liquid bags is combined with the characteristic that the rigidity of an iron isolation plate is small, and the corner effect of the loaded fractured rock mass is perfectly eliminated; the pressurizing liquidbags areadopted to apply side pressure, and therefore the sealing performance of the fractured rock mass is greatly improved; the problems of corner effect and sealing performance in a three-dimensional stress loading rock mass experiment are solved, and the large fractured rock mass formed by splicing the small rock samples has important significance in carrying out the experiment in the presenceor absence of the fractured filling body.

Owner:CHINA UNIV OF MINING & TECH

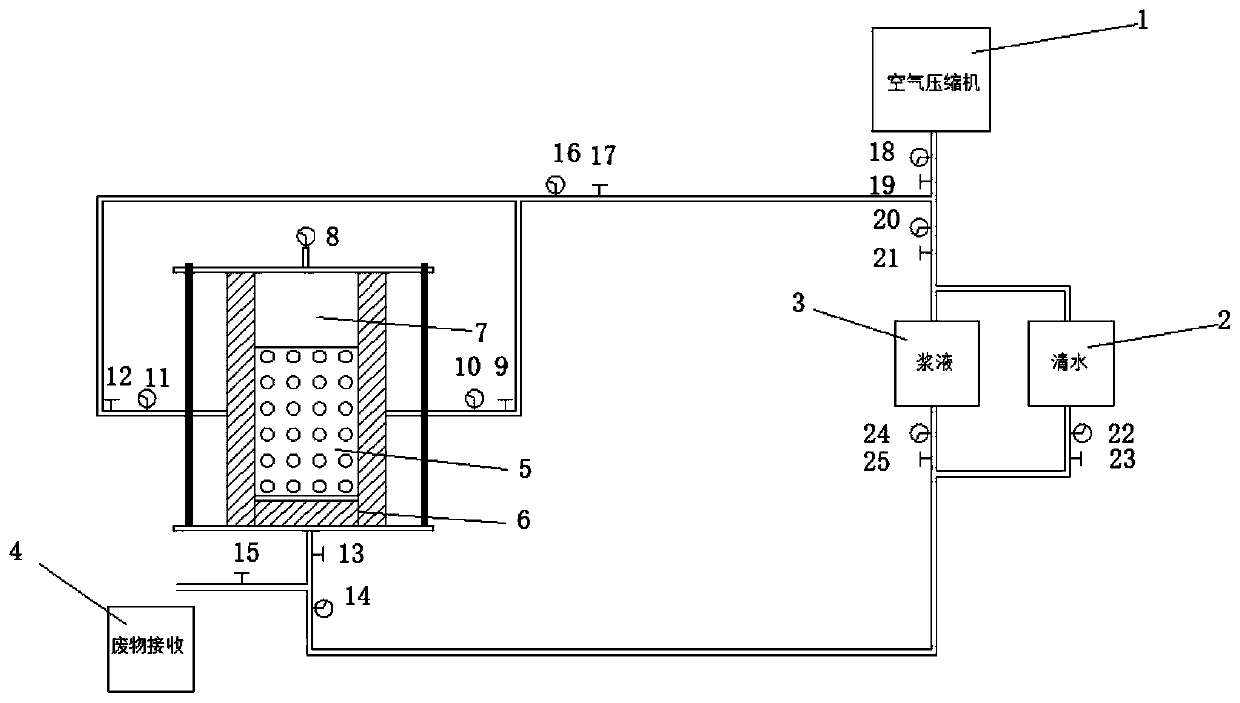

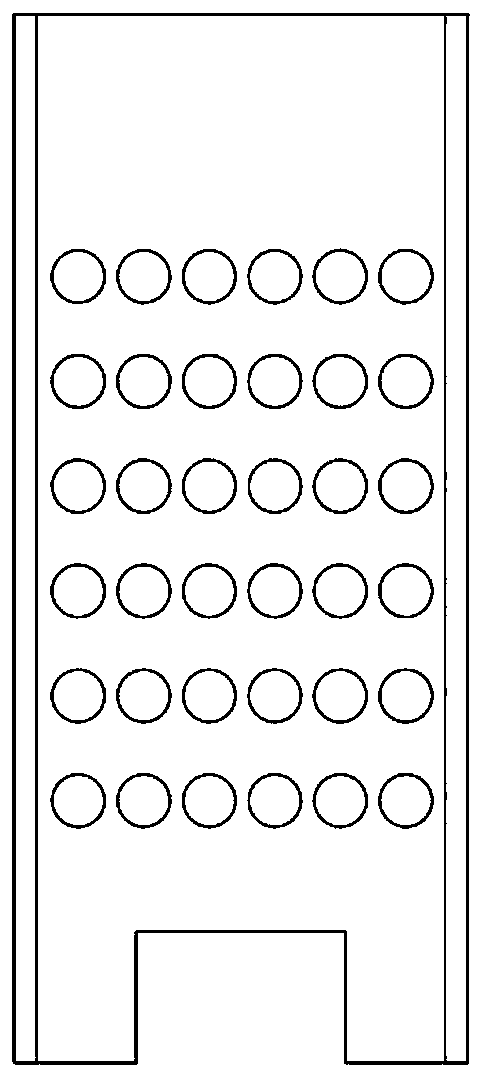

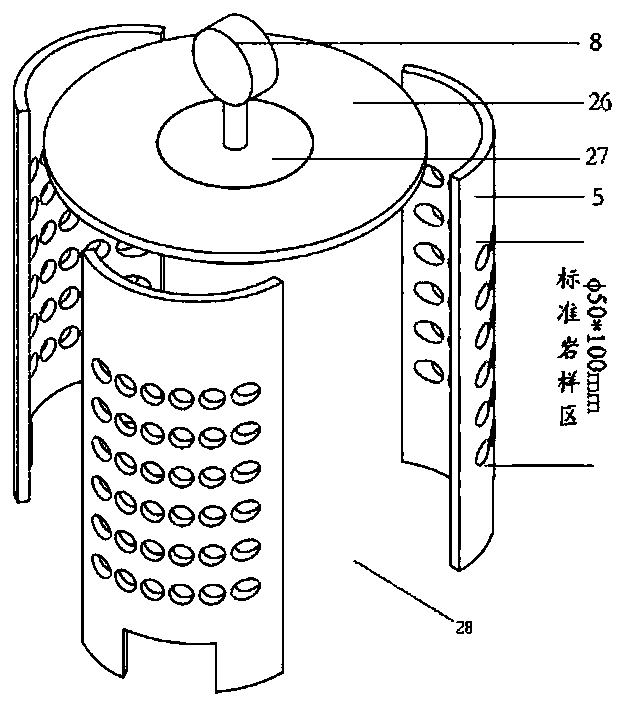

Experimental testing device for reinforcing fractured rock sample through high-pressure permeation grouting and grouting method

PendingCN111006952AGood effectRealize all-round groutingSurface/boundary effectMaterial strength using tensile/compressive forcesMicrofine cementAir compressor

The invention discloses an experimental testing device for reinforcing a fractured rock sample through high-pressure permeation grouting and a grouting method. The experimental testing device comprises a grouting sample loading area, a grouting device and a cleaning device, wherein the grouting device comprises an air compressor and a slurry barrel. High-pressure air drives superfine cement slurryin the slurry barrel to enter the bottom of the grouting sample loading area; the high-pressure air passes through a plurality of valves and then enters the two sides in the grouting area; the grouting sample loading area is of a sealed structure and comprises a slurry loading area, a grouting area and a metal hollow cylinder clamp; during grouting, a fractured rock sample is placed in a center hole of the clamp; high-pressure slurry flowing out of the slurry barrel permeates from the bottom end of a slurry filling area at the lower portion of the clamp and the periphery of the clamp and fills the rock sample at the same time; and clear water is pumped out by the high-pressure air to clean residual slurry in the pipeline into a waste receiving barrel. The rock sample grouting effect is observed through low-position grouting and high-position slurry turning, cleaning is conducted in time while grouting is completed to avoid slurry deposition, operation is convenient, grouting control is accurate, and the grouting effect is good.

Owner:HOHAI UNIV

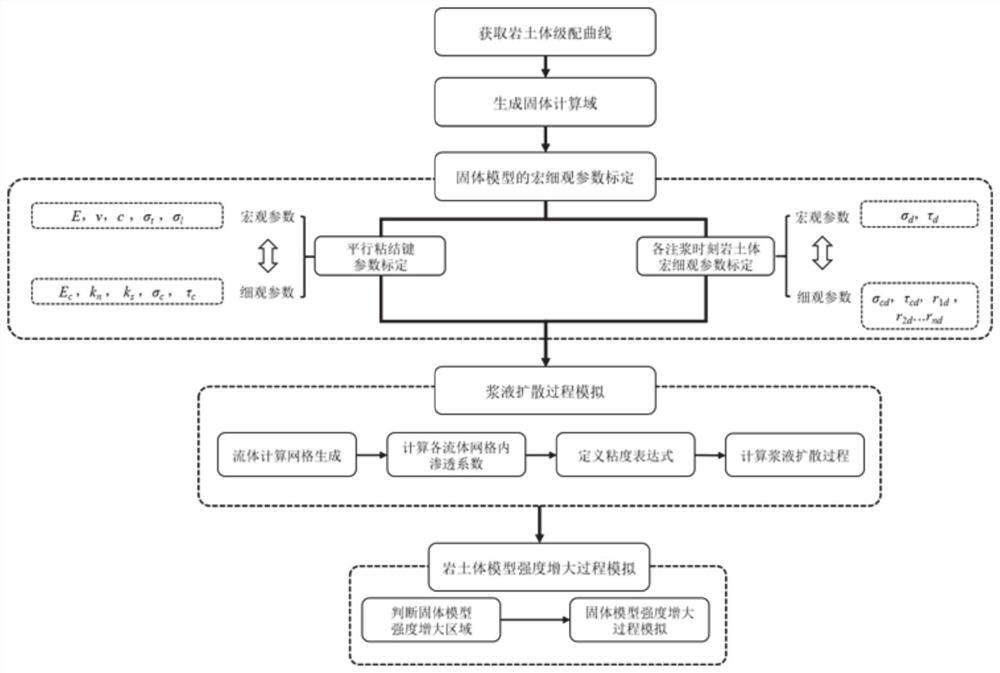

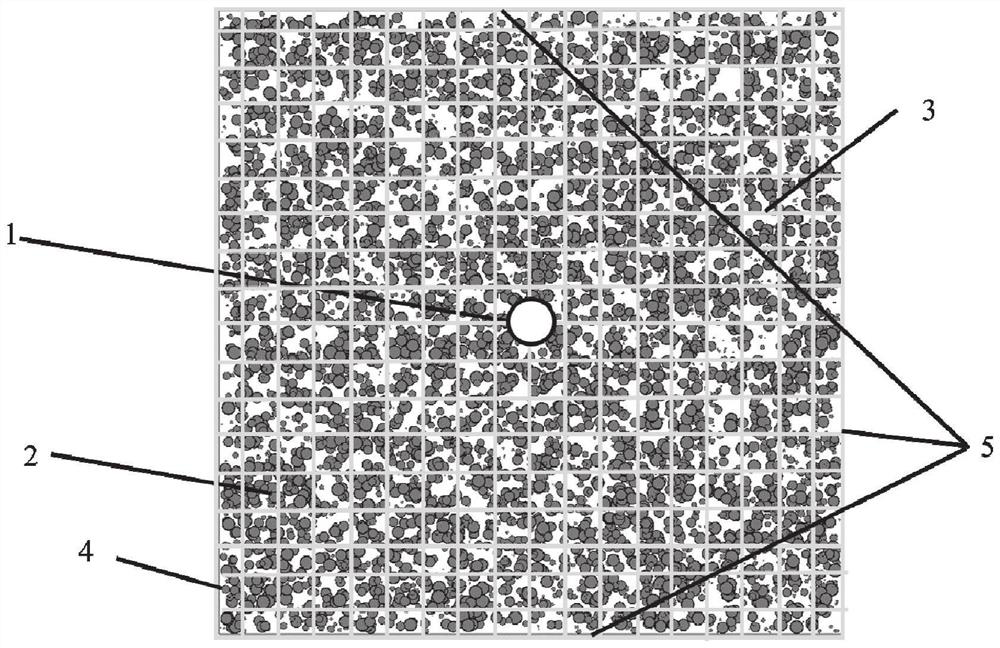

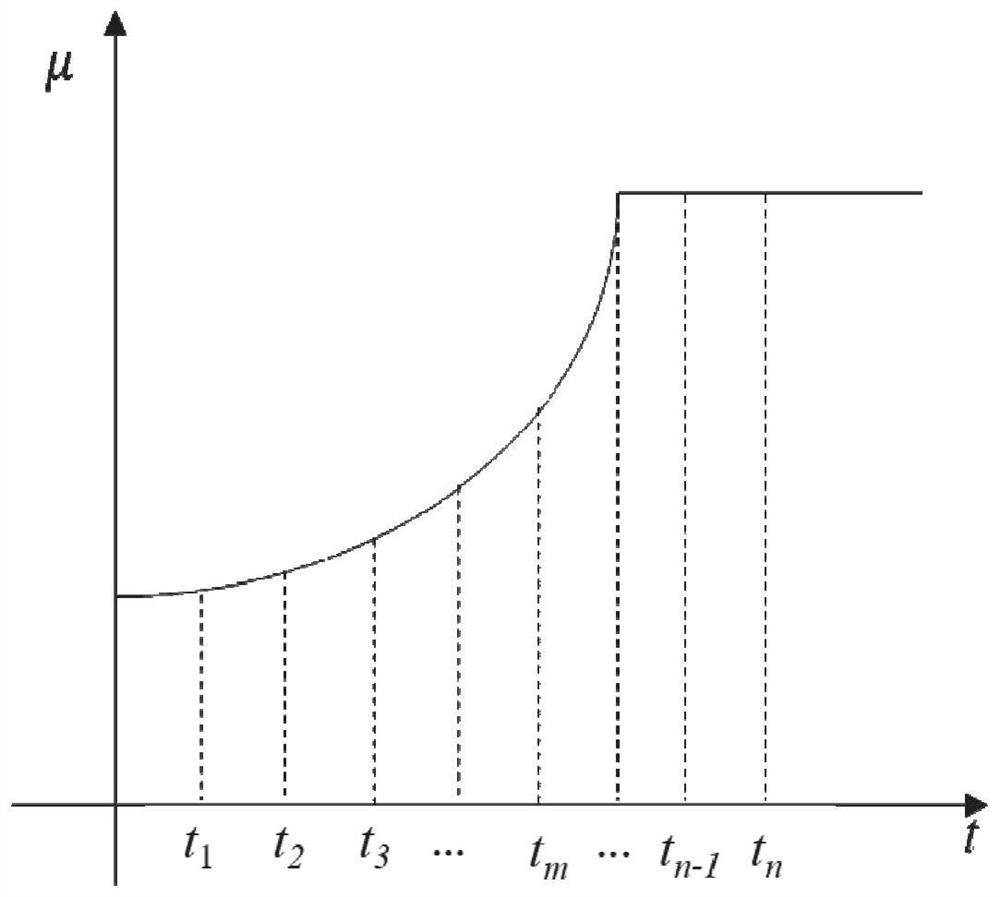

Permeation grouting process simulation method and system based on DEM-CFD coupling

ActiveCN112347709ARealize simulationHigh strengthClimate change adaptationDesign optimisation/simulationFluid viscosityComputational model

The invention provides a permeation grouting process simulation method and system based on DEM-CFD coupling. The method comprises the steps: obtaining a rock-soil body grain composition curve; generating a rock-soil body calculation model according to the grain composition curve; obtaining parallel bond initial parameters, and initializing the strength of the rock-soil body calculation model; dividing the rock-soil body calculation model information into grids to generate fluid calculation grids; and simulating the slurry diffusion process according to the permeability coefficient of the fluidcalculation grid and the space-time characteristic of the fluid viscosity. According to the invention, the interaction between the rock-soil body and the slurry can be considered, and the real simulation of the permeation grouting process is achieved.

Owner:SHANDONG UNIV

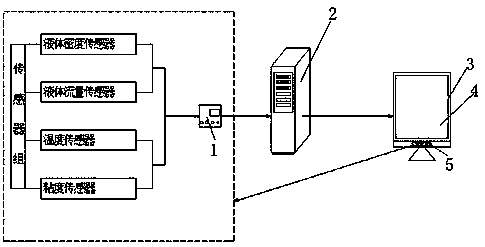

Intelligent monitoring control system and monitoring control method of grouting fluid parameters in permeation grouting process

InactiveCN108592988AReal-time density monitoringMonitor traffic in real timeMeasurement devicesData displayAutomatic control

The invention relates to an intelligent monitoring and control system and monitoring and control method of grouting fluid parameters in a permeation grouting process and belongs to the rock engineering technical field. The system includes a data monitoring and acquisition system, a data analysis and processing system and a data display and control system; the data monitoring and acquisition systemincludes a pressure automatic control regulator, a sensor group and a data acquisition device, wherein the sensor group includes a liquid density sensor, a liquid flow sensor, a temperature sensor and a viscosity sensor; the data analysis and processing system includes a high-performance computer, wherein the high-performance computer is internally equipped with data acquisition and analysis software; and the data display and control system includes a processor, an LED liquid crystal display and an adjustment control knob. The system and method of the invention can be used for permeation grouting test and on-site grouting engineering practice, automatically monitor and acquire grouting fluid parameters in real time, and automatically adjust and control grouting pressure and a grouting rate in the permeation grouting process according to monitoring results in real time.

Owner:KUNMING UNIV OF SCI & TECH

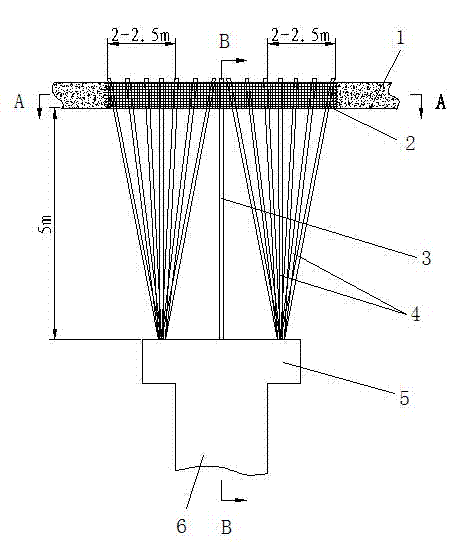

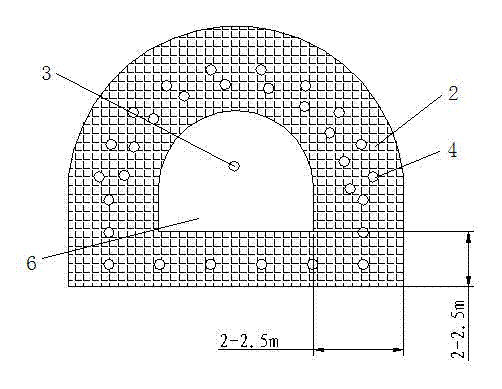

Pipe roof construction method

PendingCN109488314ASpeed up constructionSolve the problem of large settlementTunnelsUnderground tunnelGround track

The invention provides a pipe roof construction method. The pipe roof construction method is applied to construction of an underground channel passing through a station and is characterized by comprising permeation-grouting the ground; setting the initial position and the final position of a channel, and digging a working well respectively in the initial position and the final position, wherein the working well of the initial position is a starting well, and the working well of the final position is a receiving well; driving a plurality of steel pipes from the starting well into a preset tunnel route until out of the receiving well; sequentially from bottom to top, driving in all the steel pipes of a pipe roof structure; sequentially from top to bottom, cutting and supporting the steel pipes of the pipe roof structure; excavating earth enclosed by the pipe roof structure simultaneously from the starting well and the receiving well towards the middle of the tunnel until the entire tunnel is broken through. The pipe roof construction method solves the problem of large ground track subsidence caused by tunnel pipe roof construction in the prior art.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

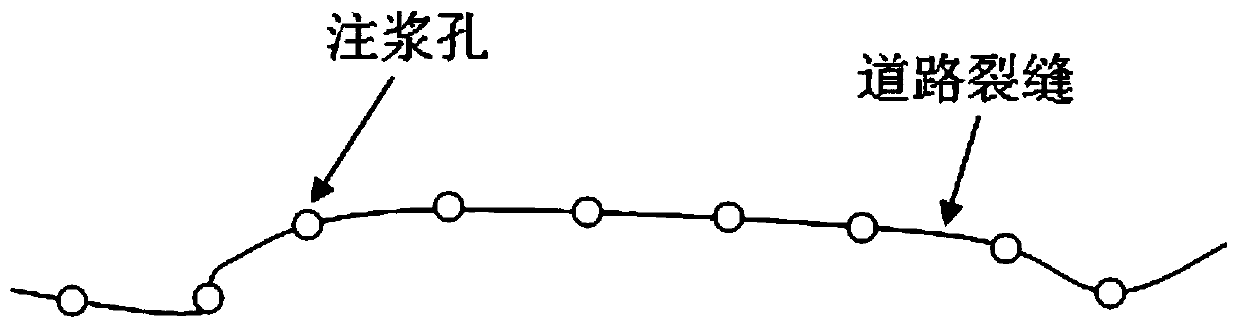

Construction method for treating cracks of semi-rigid base asphalt pavement

ActiveCN110453581AReduce the impactReduce investmentRoads maintainenceRoad surfaceGround-penetrating radar

The invention provides a construction method for treating cracks of a semi-rigid base asphalt pavement. According to the construction method, firstly a three-dimensional ground penetrating radar is used for accurately detecting the cracks, according to the results of the three-dimensional ground penetrating radar, a special grouting pipe is arranged in a targeted mode, then the surfaces of the cracks are sealed, and finally, permeation grouting is implemented, so that the functions of improving construction process, shortening construction period and reducing construction machinery and personnel input are achieved.

Owner:CHONGQING UNIV IND TECH RES INST

Compact sandy-pebble layer dynamic grouting curing construction method

The invention discloses a compact sandy-pebble layer dynamic grouting curing construction method and an application layer structure. The method includes the following steps that (1) a drill machine is put in place and performs hole drilling and forming to form a grouting hole; (2) a grouting pipe is prepared and buried in the grouting hole; (3) grouting and hole sealing are performed, specifically, a permeating grouting mode is adopted for grouting, and the grouting hole is sealed; (4) curtain grouting is conducted, that is, all grouting holes in a curtain are grouted to form a finally curtain; (5) a pump-in test is performed, and the anti-permeability of the cured final curtain is detected. The compact sandy-pebble layer dynamic grouting curing construction method is applicable to foundation ditch waterproof curtain construction under the hydrogeological condition with a compact sandy-pebble layer rich in flowing underground water; high strength of the compact sandy-pebble layer is avoided by means of permeating grouting; grout is good in anti-permeability after being cured after a certain time; accordingly, hydraulic connection of inside and outside of a foundation ditch is reduced, and a manual waterproof barrier is formed.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

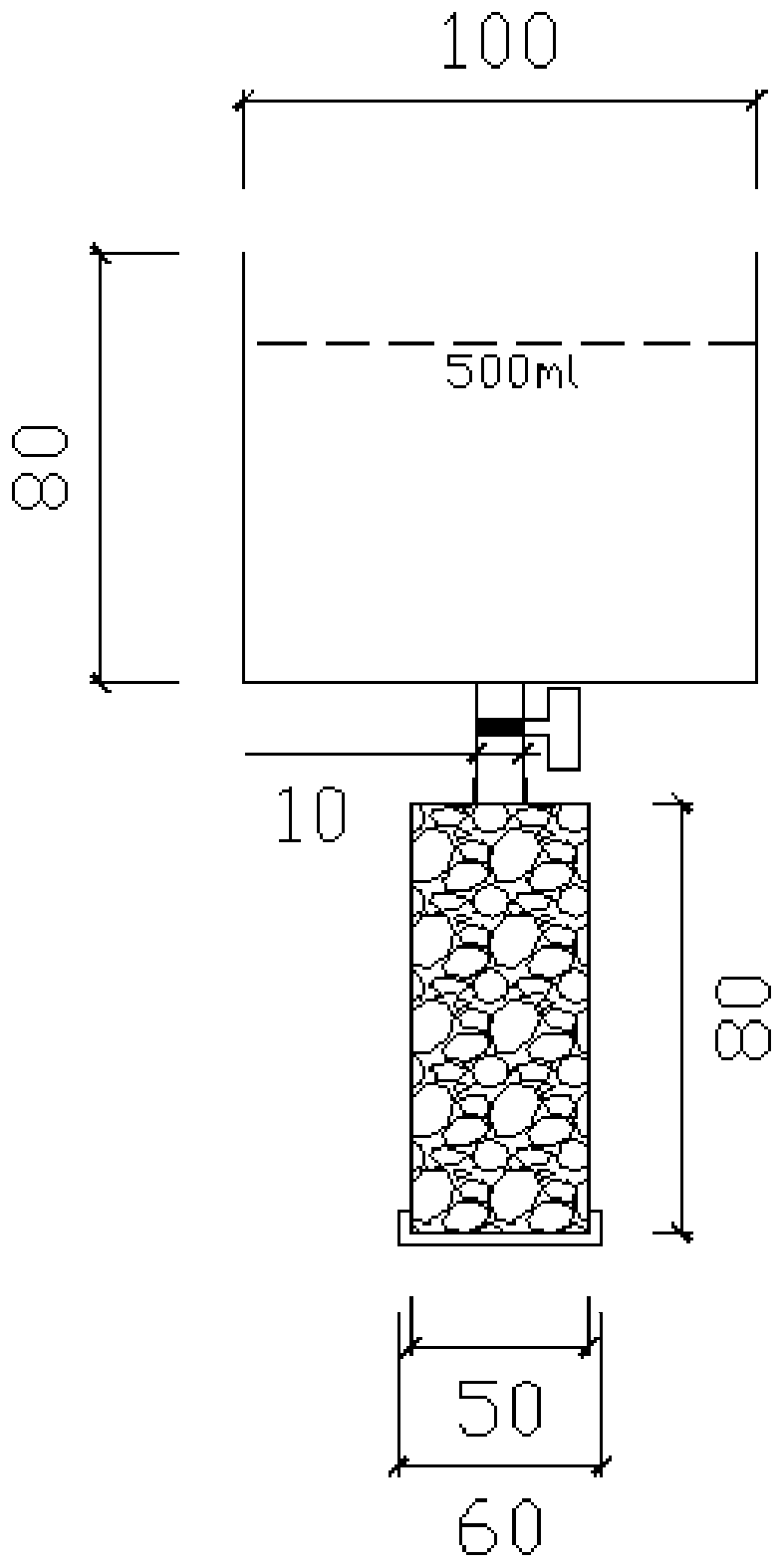

Device and method for testing permeation flowing property of geopolymer slurry

ActiveCN110031364ASimple structureEasy to operateWeighing by removing componentPermeability/surface area analysisMetallurgyGeopolymer

The invention discloses a device and method for testing the permeation flowing property of geopolymer slurry. The testing device is composed of a slurry storage pipe, a seepage pipe and a measuring cup, the geopolymer slurry seeps through the seepage pipe from the slurry storage pipe, the original volume of the geopolymer slurry is ensured through the slurry storage pipe, the seepage pipe is filled with a filler to simulate a seepage environment of the geopolymer slurry, the slurry storage pipe communicates with the seepage pipe through a connecting pipe, and the geopolymer slurry flowing property difference caused by different materials, mating ratios, admixtures and the like can be tested through the slurry storage pipe and the seepage pipe. By adopting the mass loss ratio r and the seepage speed v obtained through the device and the method, the permeation flowing property of the geopolymer slurry in the gravel filler can be accurately evaluated, the testing device is simple and easyto operate and suitable for being widely applied to determination and evaluation of the permeation flowing property of the geopolymer slurry, and the geopolymer slurry is applied and promoted in permeation grouting engineering advantageously.

Owner:CHANGAN UNIV

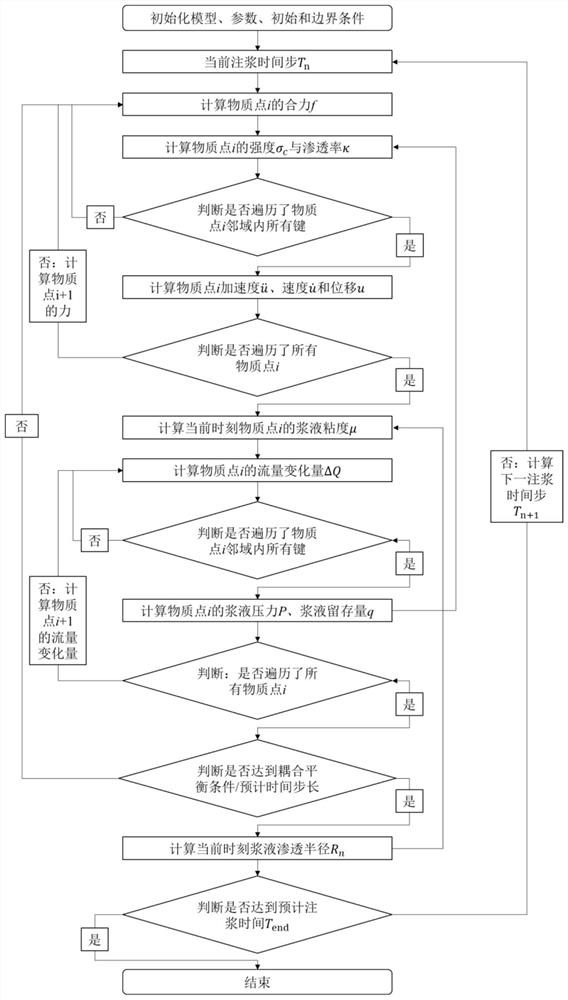

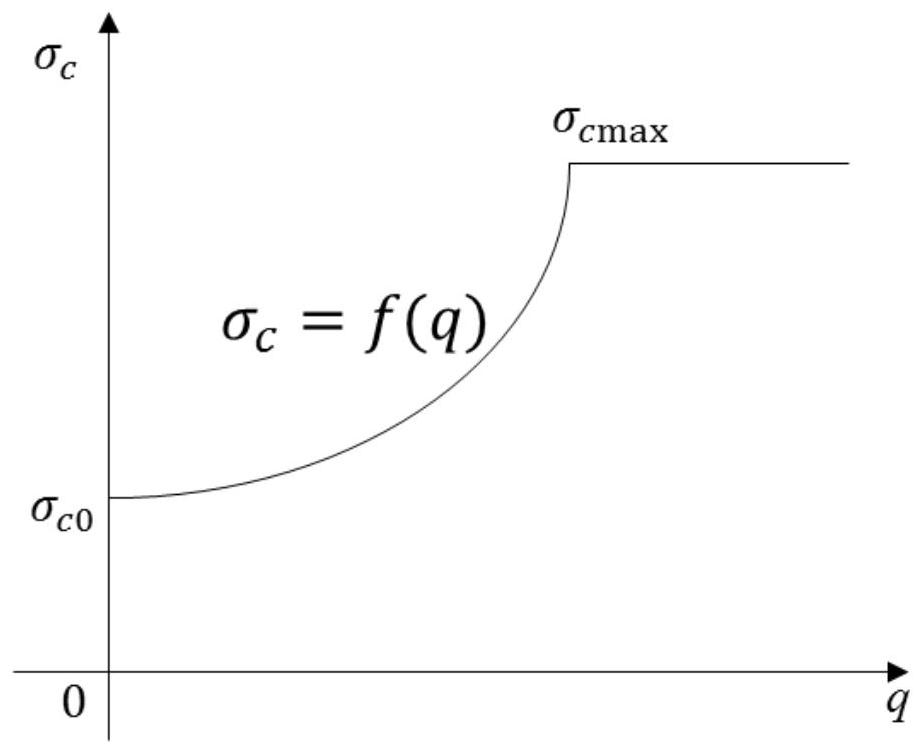

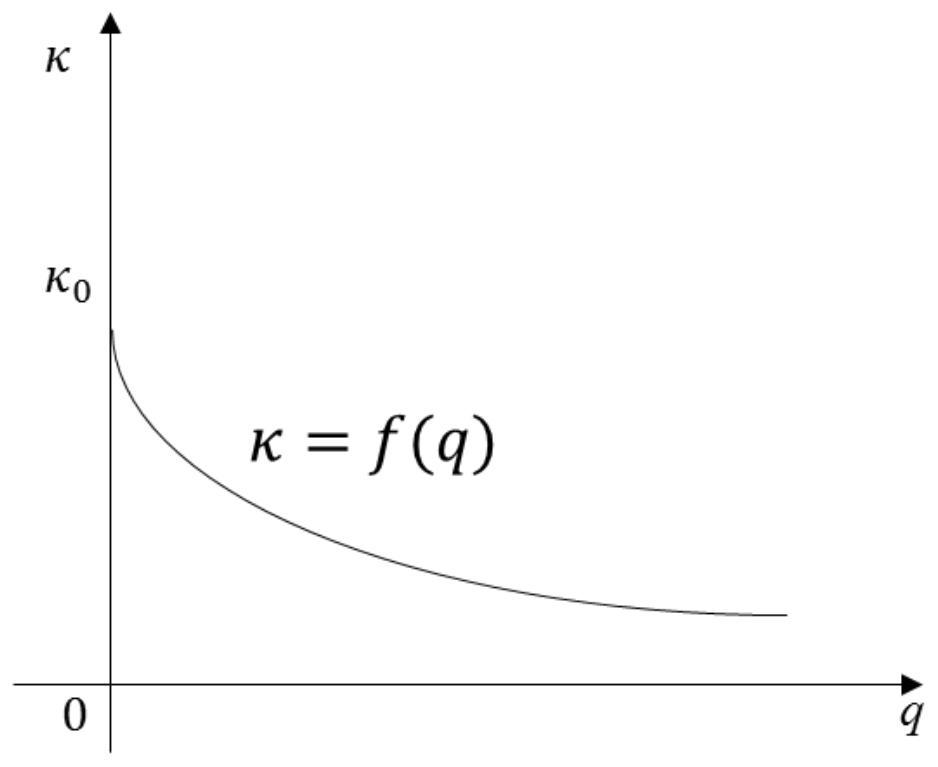

Permeation grouting process simulation method and system based on near-field dynamics

ActiveCN112098273AEffective simulationLow costSurface/boundary effectPermeability/surface area analysisClassical mechanicsSlurry

The invention discloses a permeation grouting process simulation method and system based on near-field dynamics; and the method comprises the steps: discretizing a permeation grouting simulation modelinto a plurality of material points according to a rock mass material and a rock mass volume, and dividing a permeation grouting process into a plurality of grouting time steps; constructing a fluid-solid coupling circulation model based on near-field dynamics, and obtaining the displacement of a material point and the slurry pressure by adopting a loop iteration solving method in a grouting timestep until a solving result meets a fluid-solid coupling balance condition; and taking the slurry permeation radius of the current grouting time step as an initial condition of the next grouting timestep, adding the material point strength and the material point permeability obtained according to the slurry retention amount into the permeation grouting simulation process of the next grouting time step until the permeation grouting process is completed, and outputting the whole-process simulated permeation grouting. The time-space double-variation characteristic and the rock mass reinforcement effect are considered, and effective simulation of the rock mass permeation grouting reinforcement process is achieved.

Owner:SHANDONG UNIV

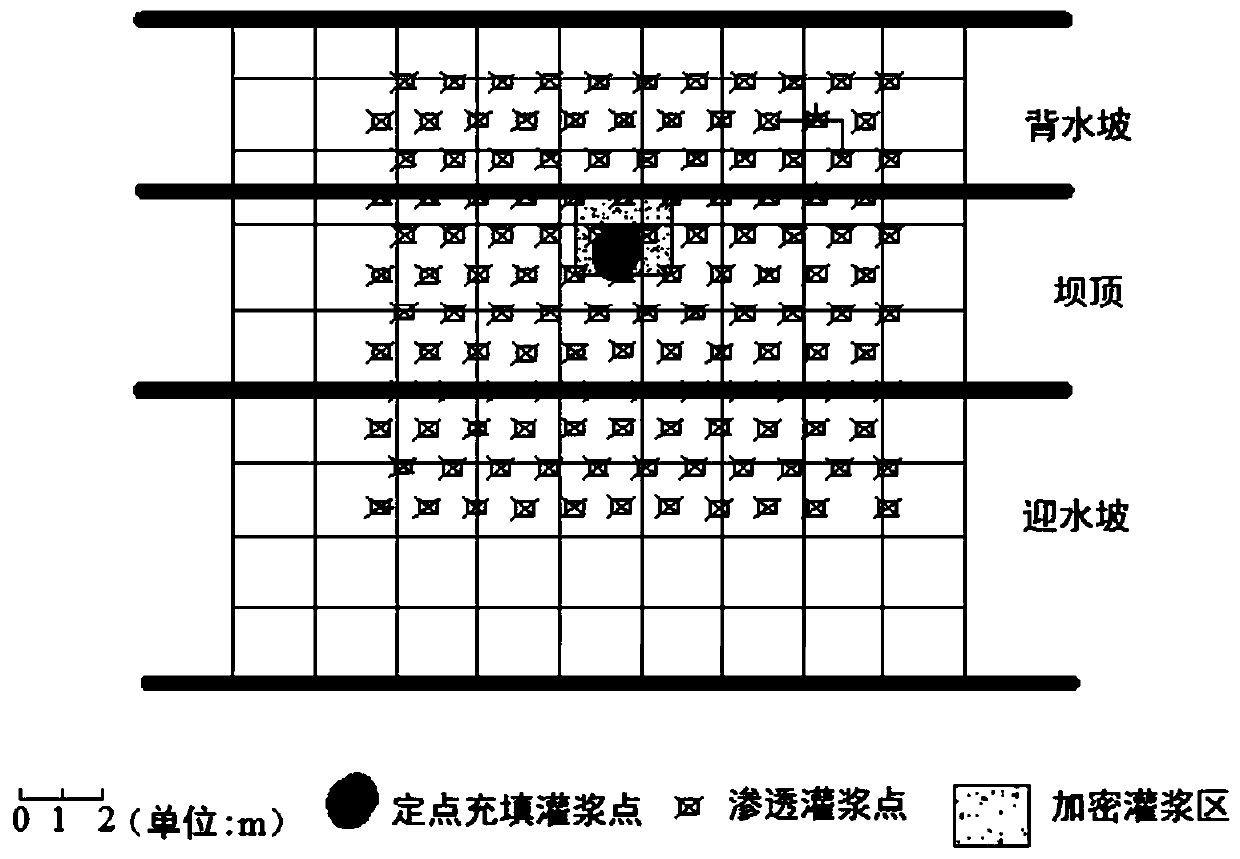

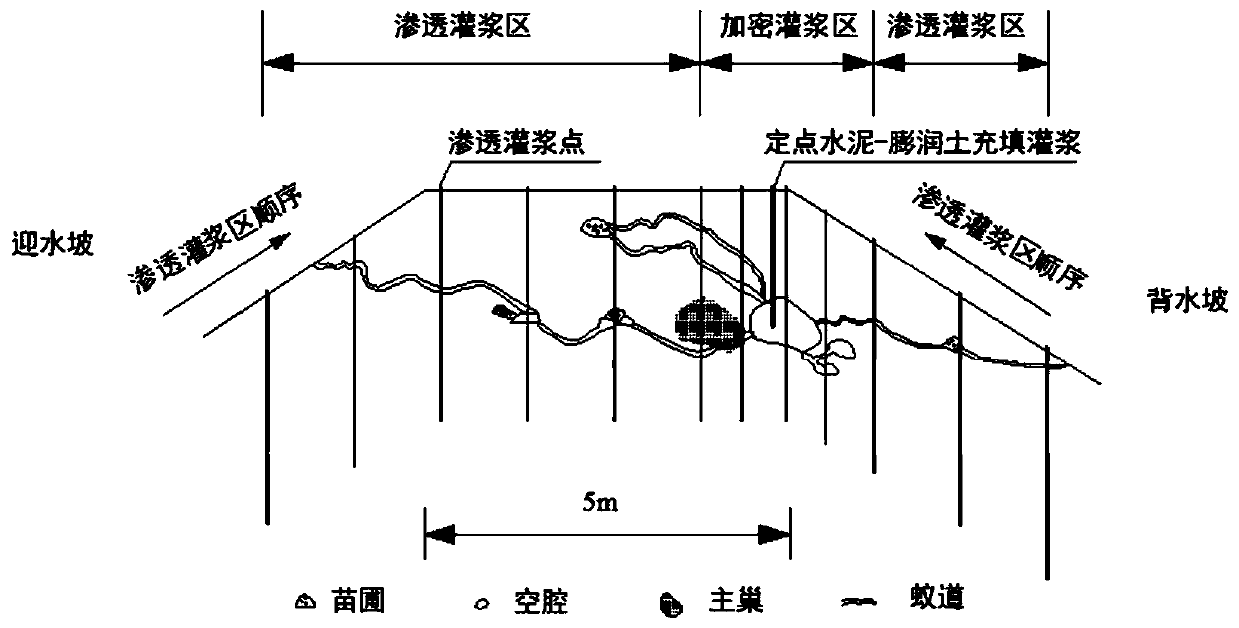

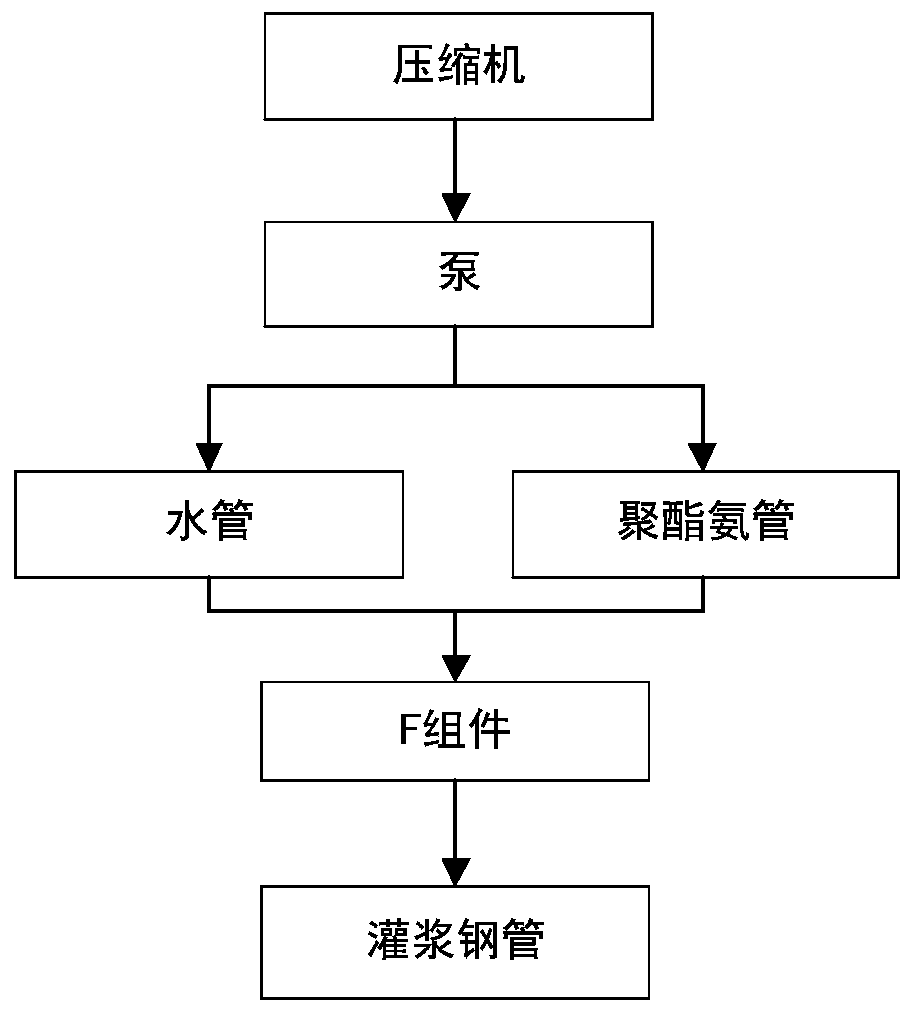

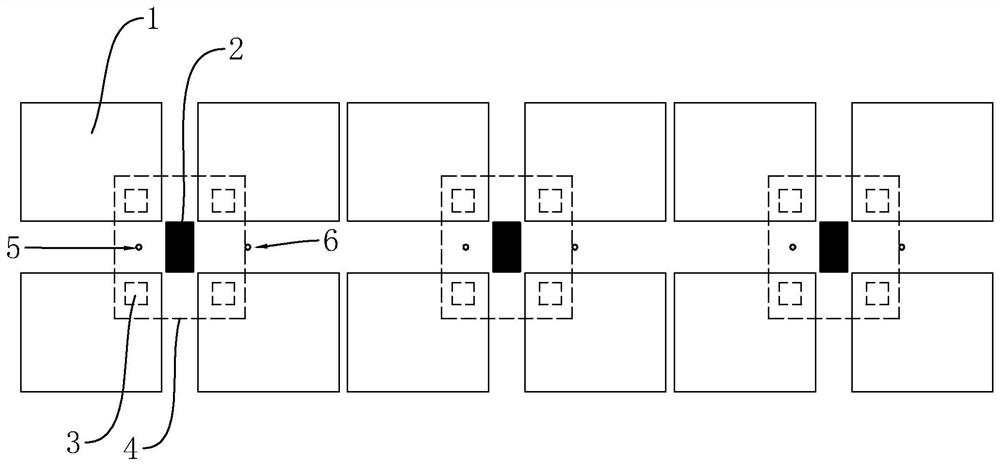

Dam termite filling and permeating combined type grouting treatment method

ActiveCN110278936AImprove integrityEnsure the effect of killing termitesMarine site engineeringInsect catchers and killersSlurrySystem identification

The invention discloses a dam termite filling and permeating combined type grouting treatment method. The method includes the steps of recognizing a termite nest group system, locating a main nest, and conducting first-order filling grouting and second-order permeating grouting. Slurry for the first-order filling grouting is a cement-bentonite mixture, and a portable grouting device is used for dry-method pore forming; slurry for the second-order permeating grouting is polyurethane-medicine mixed liquid, a grouting pouring pipe and a permeating grouting gun are adopted for the plum-blossom-shaped point distributing. By means of the filling and permeating combined type grouting technology, the grouting technology is created, the termite nest system is filled, the nest system and the surrounding combination part of the nest system are compacted, the structural integrity of a dam is improved, the leakage accident risk is reduced, termite is killed, and the reoccurrence of termite is prevented.

Owner:NANJING HYDRAULIC RES INST

Settlement reinforcement method for independent foundation of building brewing workshop

InactiveCN112081159AAvoid disturbanceAvoid destructionFoundation repairSoil preservationArchitectural engineeringStructural engineering

The invention relates to a settlement reinforcement method for an independent foundation of a building brewing workshop. The settlement reinforcement method comprises the following steps that S1, grouting holes are formed, wherein one grouting hole is formed in one side of each stand column, and the depths of the grouting holes are determined according to the geological condition; S2, observationholes are formed, wherein the observation holes are formed in one sides, away from the grouting holes, of the stand columns, the observation holes are drilled to the position below a bearing platform,the observation holes are located in the outer edges of contour lines of pile foundations, on the sides, away from the grouting holes, of the stand columns, guide pipes are inserted into the observation holes, and monitoring devices used for detecting the grouting heights and diameters are arranged at the top ends of the guide pipes; and S3, grouting reinforcement is conducted, wherein grouting is conducted in the grouting holes to reinforce the independent foundation, during grouting, pressure grouting is conducted firstly, then permeation grouting is conducted, and whether grouting is completed or not is judged according to the monitoring devices. The method has the advantages of being suitable for construction in a narrow area, simple in process and small in stratum disturbance.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

Horizontal grouting and static breaking construction method for tunnel shield originating portal with high water pressure

InactiveCN108915706AReduce construction dustReduce noiseUnderground chambersTunnel liningHydration reactionBlind zone

The invention discloses a horizontal grouting and static breaking construction method for a tunnel shield originating portal with high water pressure. The construction method includes the steps that reinforced blind areas are determined according to the law of groundwater pressure and the size of permeability in different positions; controlled circulation permeation grouting is carried out by drilling holes in the reinforced blind areas, through compaction, permeation and splitting, so that net shaped slurry vein is formed between multiple reinforced blind areas in a communication mode; a soundless cracking agent is injected in drilling holes and hydration reaction is sent to expand to make concrete appear three processes of crack appearing, crack propagation and crack expansion, and finally, the concrete is broken in the expected direction. The horizontal grouting and static breaking construction method for the tunnel shield originating portal with the high water pressure has the beneficial effects that the construction cost is low, the reinforcement effect is good, and the construction safety, environmental protection and efficiency are effectively guaranteed.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

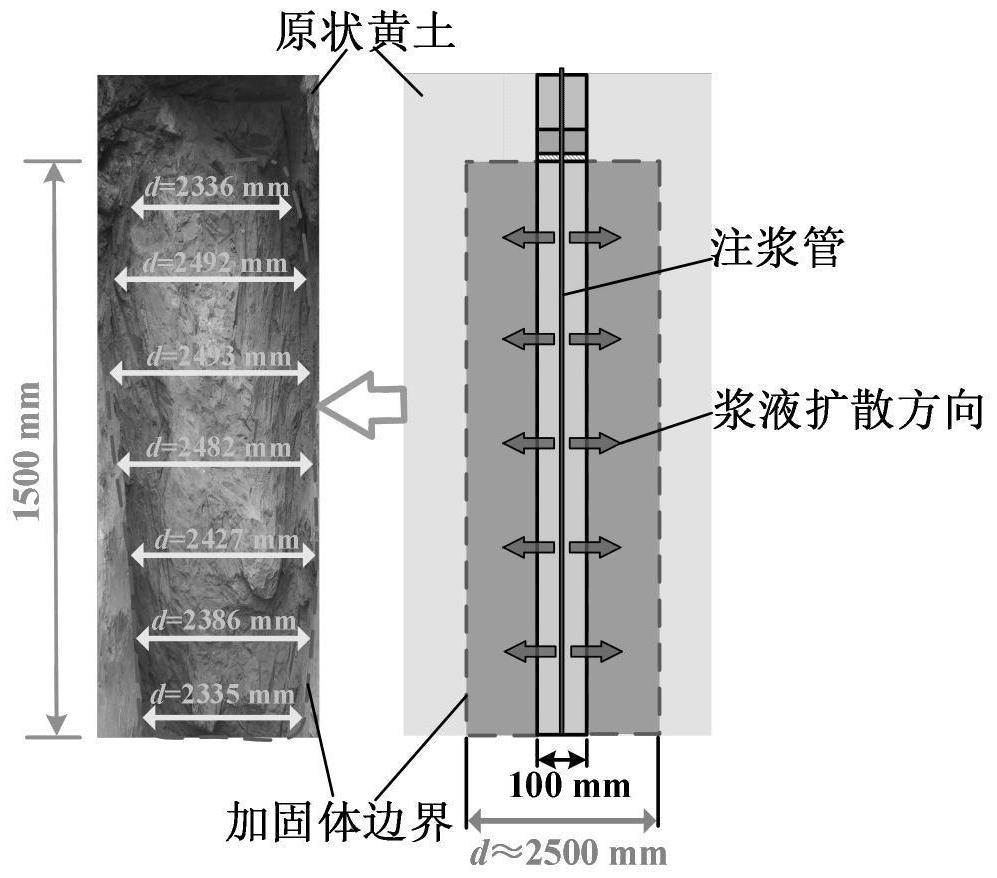

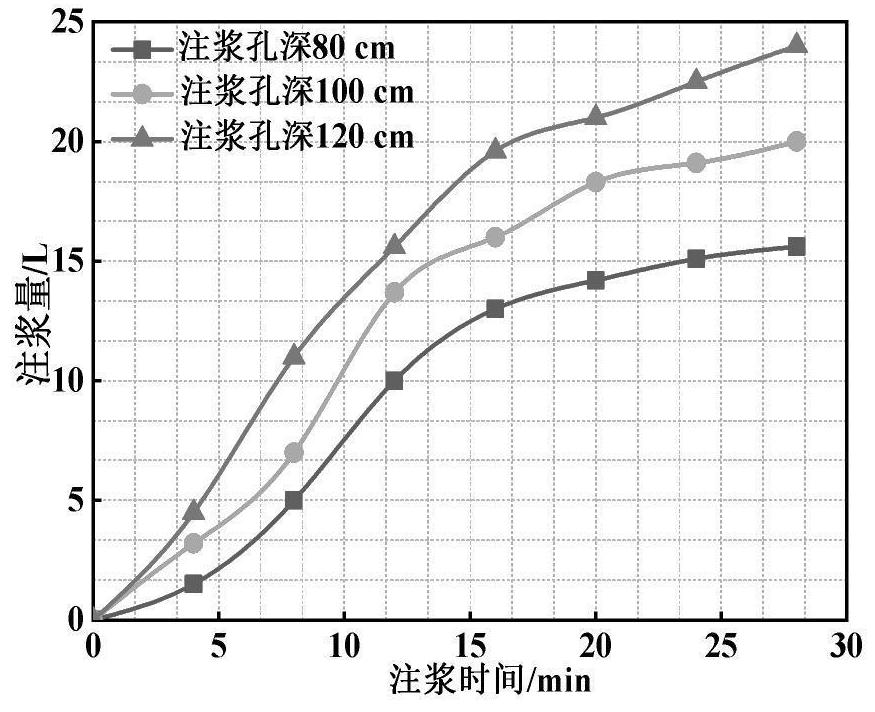

Method for determining reinforcing parameters during soil body permeation grouting and reinforcing method using method

ActiveCN112144507AEliminate collapsibilitySmall space constraintsGeometric CADIndirect flow property measurementSoil scienceStructural engineering

The invention discloses a method for determining reinforcing parameters during soil body permeation grouting and a reinforcing method using the method. The method for determining the reinforcing parameters is composed of the following steps that under different grouting pressures, grouting is conducted on a soil body, a relational expression between effective grouting time and the grouting pressure, a relation between effective grouting amount and the grouting pressure and the grouting pressure, namely splitting grouting pressure Pp when splitting is generated are respectively obtained, in combination with pore pressure initial conditions, boundary conditions and permeation speed continuous conditions and through Boltzmann transformation and order reduction treatment, an equation between the grouting pressure and the grouting radius is obtained, and the grouting radius is obtained through calculation according to the equation of the grouting pressure and the grouting radius and the grouting pressure p lower than the splitting grouting pressure Pp. According to the method, by the directly controlled and observed grouting amount, grouting time and grouting pressure in the grouting process, a diffusion rule of grout can be accurately predicted, and the geometrical characteristics of a reinforcing body can be specifically described.

Owner:XIAN TECHNOLOGICAL UNIV

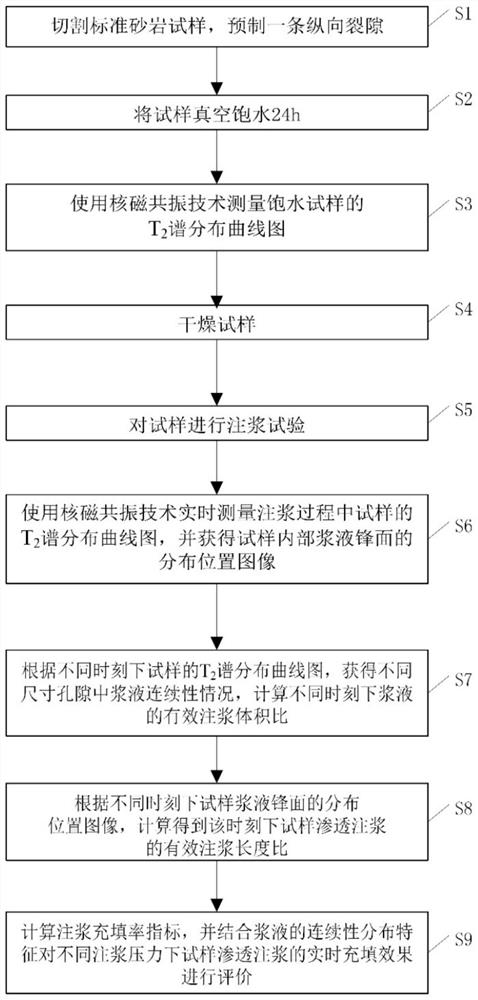

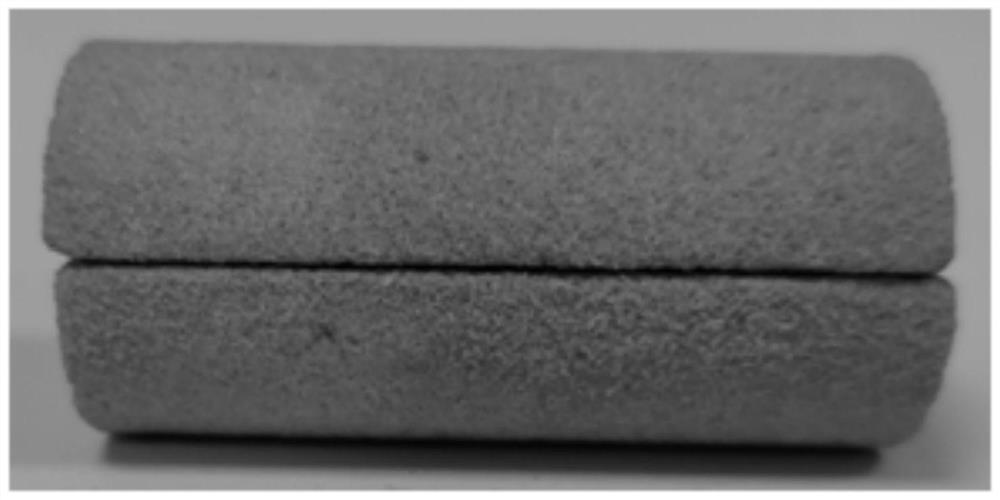

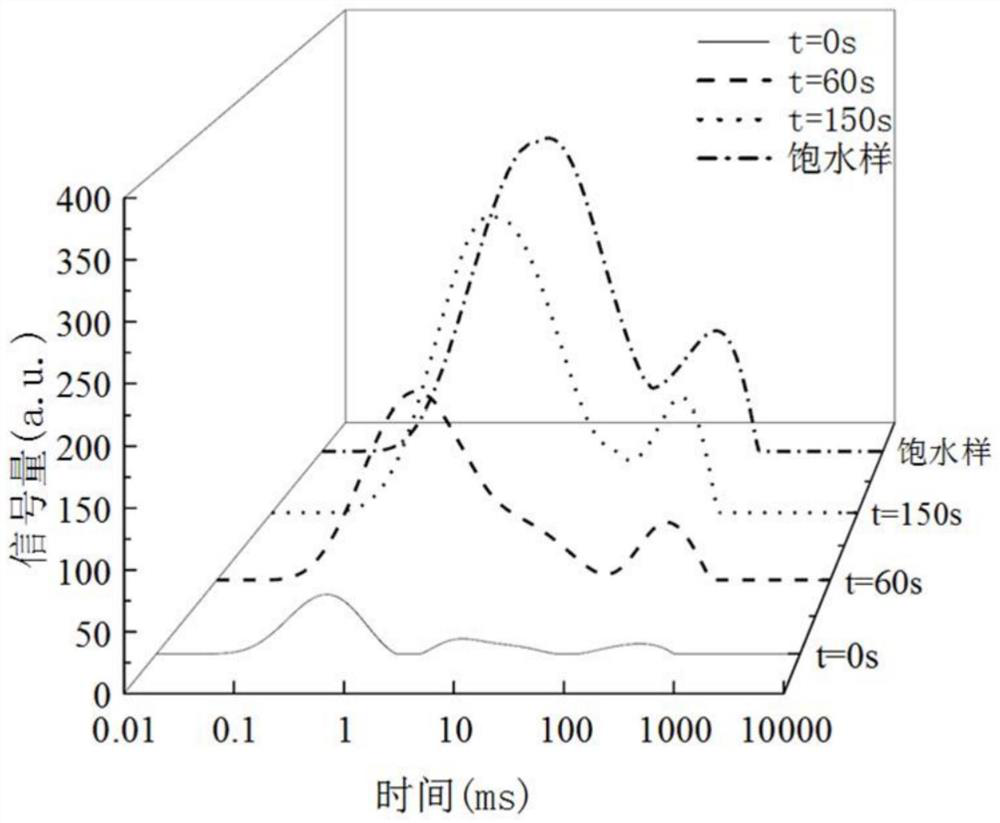

Method and system for detecting permeation grouting filling effect of fractured rock core

ActiveCN112946006AGood grouting filling effectConstruction safetyAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceRock core

The invention provides a method and system for detecting the permeation grouting filling effect of a fractured rock core. The method comprises the steps of obtaining a columnar rock core sample of a rock mass to be detected for cutting; carrying out vacuumizing water saturation treatment on the sample to obtain a water-saturated sample; wiping off water on the surface of the water-saturated sample, then carrying out nuclear magnetic resonance sampling, measuring a T2 spectrum distribution curve graph of the water-saturated sample, and calculating to obtain a nuclear magnetic semaphore of the water-saturated sample; performing drying treatment on the sample; performing a grouting test on the dried sample; performing nuclear magnetic sampling on the sample to obtain a T2 spectrum distribution curve graph of the sample at different moments in the grouting process and a distribution position image of a slurry frontal surface in the sample; according to the T2 spectrum distribution curve graph, obtaining the effective grouting volume ratio of the grout at different moments; according to the distribution position image of the slurry frontal surface in the sample, obtaining the distance between the slurry frontal surface and the grouting end surface, and calculating the effective grouting length ratio of permeation grouting of the sample at each moment; and calculating to obtain the grouting filling rate.

Owner:WUHAN UNIV

Critical experiment simulation equipment for permeation and separation grouting

ActiveCN108717039AAvoid Split Grouting SituationsShorten the timePermeability/surface area analysisEngineeringHigh pressure

The invention discloses critical experiment simulation equipment for permeation and separation grouting. The critical experiment simulation equipment comprises an overbarden pressure simulation unit,a grouting experiment tank unit and a confining pressure simulation unit. The grouting experiment tank unit comprises a steel outer barrel, a steel inner barrel and a soil sample. The soil sample is arranged in the steel inner barrel. A first cover is arranged on the steel outer barrel. A cavity is formed between the steel outer barrel and the steel inner barrel. A hole communicated with the cavity is formed in the side wall of the steel inner barrel. A geotechnical cloth is arranged on the inner wall of the steel inner barrel. A pore pressure meter and a first water drain pipe are mounted atthe bottom of the grouting experiment tank unit. A pressure bearing plate is arranged above the soil sample and located below the first cover. A grouting pipe is arranged on the first cover. A gas pipeline for injecting high-pressure air into a gap between the first cover and the pressure bearing plate is arranged on the first cover. The critical experiment simulation equipment has the advantagesthat time and cost for on-site experimental grouting are omitted, and the effect of on-site permeation grouting is improved effectively.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

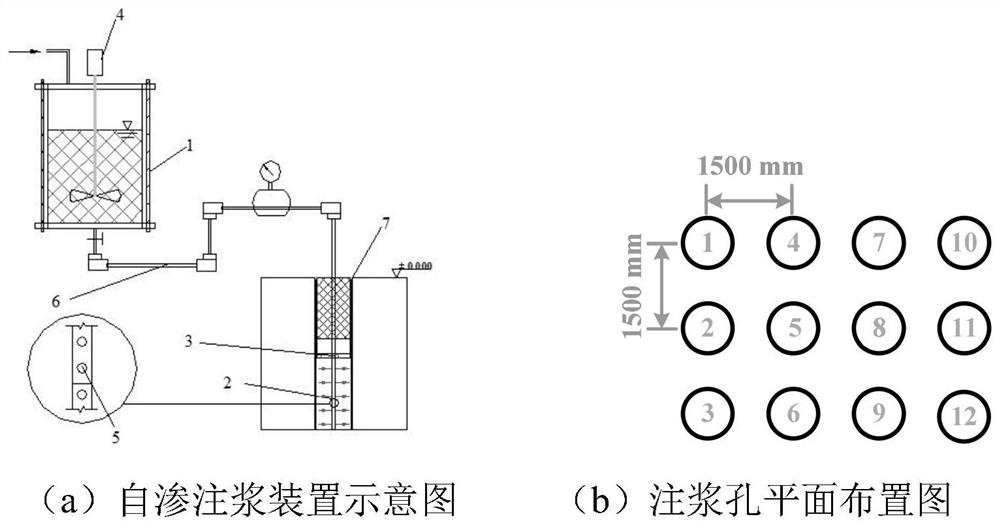

Construction method for reinforcing pile-soil composite foundation

The invention discloses a construction method for reinforcing a pile-soil composite foundation. The method includes the steps that a centroid position of a soil body between minimum unit piles is calculated according to a pile arrangement form of the pile-soil composite foundation, a grouting hole is dug in the centroid position of the soil body between the piles by utilizing a Luoyang shovel, and the situation that the grouting hole is vertically formed is ensured; a grouting pipe of a grouting system is vertically placed in the center of the grouting hole and directly reaches the bottom of the grouting hole, packing is placed in the grouting hole around the outer wall of the grouting pipe for sealing, and the grouting hole is divided into an upper half portion and a lower half portion through the packing; and the upper half portion of the grouting hole is backfilled, the grouting system is started to conduct self-permeation grouting of water glass or alkali liquor into the grouting hole, and a small pile reinforcing body is formed, so that the pile-soil composite foundation is reinforced by the small pile reinforcing body. According to the construction method for reinforcing the pile-soil composite foundation, on the premise that loess collapsibility is not eliminated, the pile spacing of existing plain concrete piles is kept unchanged, and the small pile reinforcing body is formed at the center of the soil body between the piles by adopting the simple, convenient and low-cost method, so that the working performance of the composite foundation is effectively improved.

Owner:XIAN TECHNOLOGICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com