Self-drilling differential grouting combined anchor rod and method for anchoring same

一种自钻式、注浆的技术,应用在安装锚杆、土方钻采、板桩墙等方向,能够解决增加施工工序、增加工程成本、钻孔工作量大等问题,达到提高支护效果、节约支护成本、节省施工时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

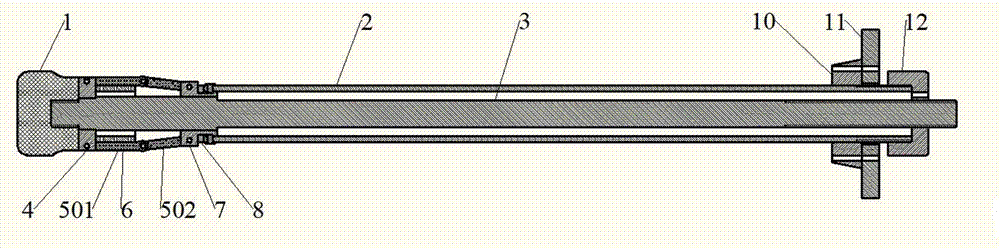

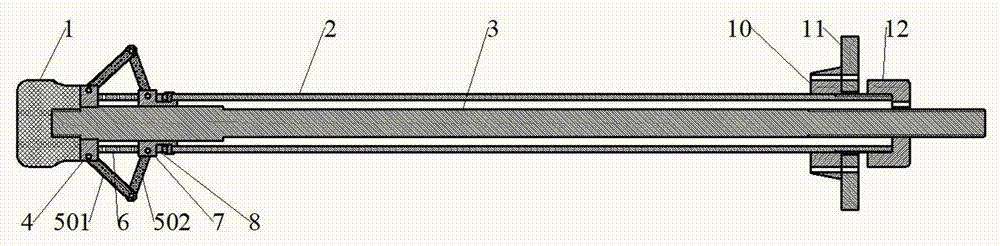

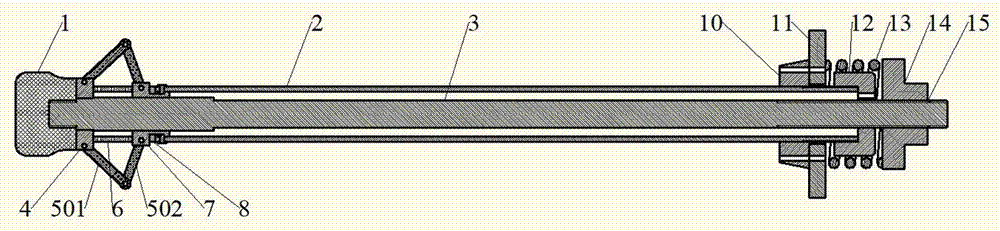

[0044] Such as Figure 1-3 As shown, the self-drilling differential grouting combination bolt proposed by the present invention is composed of a drill bit 1, a grouting pipe 2, a main shaft 3, an anchor head mechanism, an anchor tail mechanism and other components. The front end of the main shaft 3 is a threaded rod, the rear part of the drill bit 1 has a threaded hole, and the drill bit 1 and the front end of the main shaft 3 are threaded together. The anchor head mechanism includes a fixed ring 4 , six pairs of passive connecting rods 501 and active connecting rods 502 , a limiting tube 6 and a slip ring 7 . Six pairs of passive connecting rods 501 and active connecting rods 502 are evenly distributed along the circumference. The fixed ring 4 is fixed on the front end of the main shaft and is close to the rear part of the drill bit 1 . Bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com