Rapid grouting and arching reinforcement method before tunnel excavation in stratum with poor irrigability and difficult self-stabilization

A tunnel and self-stabilizing technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of inability to meet the anti-seepage and stability requirements of tunnel excavation, difficult self-stabilizing stratum tunnels, poor irrigability, etc., to ensure safety. The effect of fast penetration, increasing slurry diffusion distance and increasing grouting hole spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

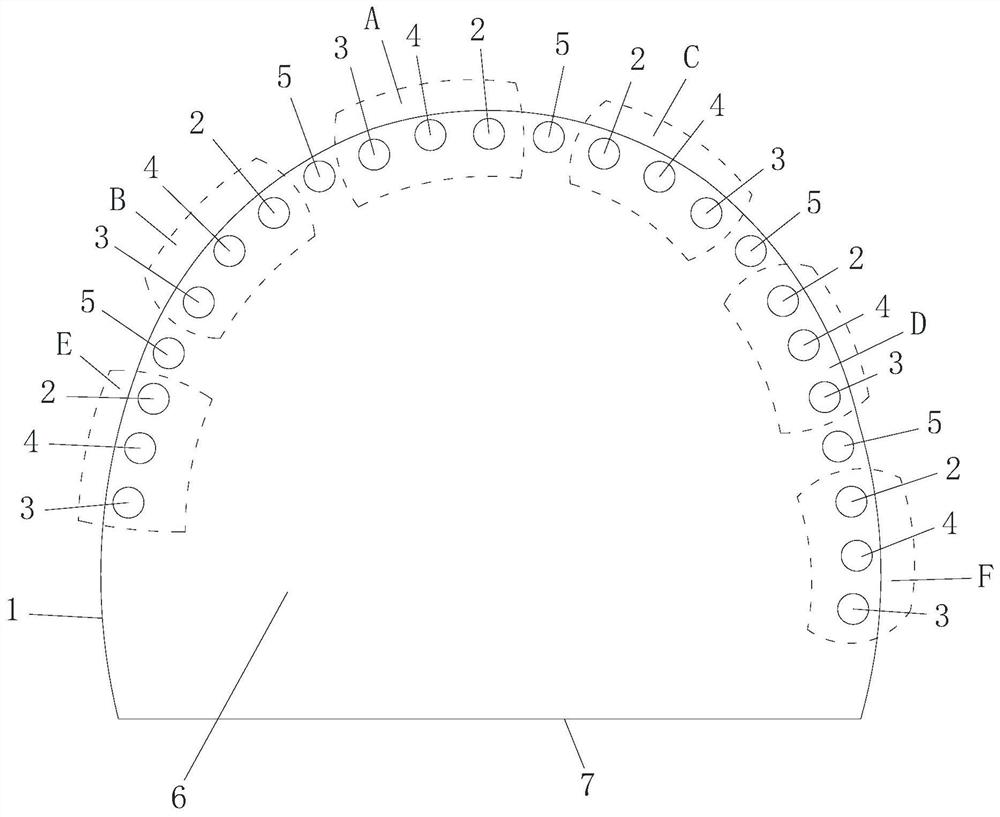

[0043] The tunnel to be excavated shall be reinforced before excavation, the tunnel excavation sideline 1, the tunnel face 6 and the tunnel bottom sideline 7 such as figure 1 shown.

[0044] A rapid grouting reinforcement method before excavation of a tunnel in a stratum with poor groutability and difficult self-stabilization, comprising the following steps:

[0045] (1) Divide into six reinforcement areas along the tunnel excavation sideline 1 on the inner side close to the tunnel excavation sideline 1;

[0046] The reinforced area includes the first reinforced area A, the second reinforced area B, the third reinforced area C, the fourth reinforced area D, the fifth reinforced area E and the sixth reinforced area F; Quantity can be divided according to need

[0047] (2) Reinforcement of the reinforcement area:

[0048] ① Drill the first group of flushing grouting holes 2 and drainage holes 3 in the first reinforcement area A on the inner side near the excavation sideline 1...

Embodiment 2

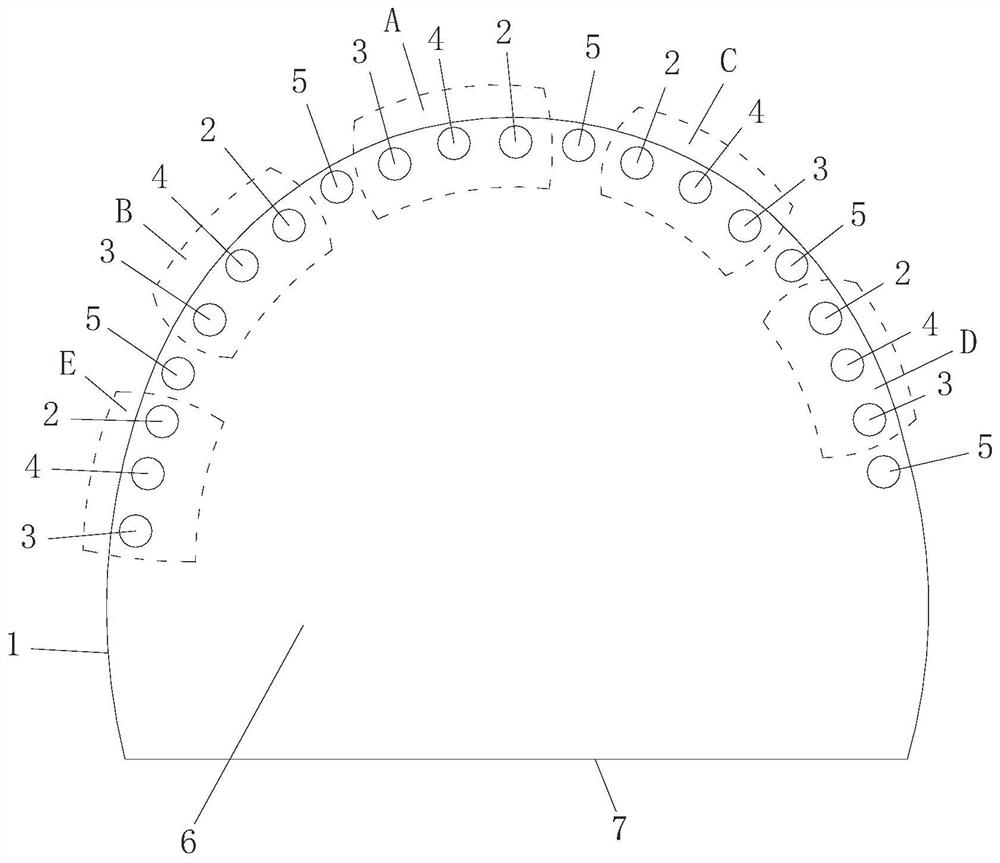

[0061] The tunnel to be excavated shall be reinforced before excavation, the tunnel excavation sideline 1, the tunnel face 6 and the tunnel bottom sideline 7 such as figure 2 shown.

[0062] A rapid grouting reinforcement method before excavation of a tunnel in a stratum with poor groutability and difficult self-stabilization, comprising the following steps:

[0063] (1) Divide five reinforcement areas along the tunnel excavation sideline 1 on the inner side close to the tunnel excavation sideline 1;

[0064] The reinforced area includes a first reinforced area A, a second reinforced area B, a third reinforced area C, a fourth reinforced area D and a fifth reinforced area E;

[0065] (2) Reinforcement of the reinforcement area:

[0066] ① Drill the first group of flushing grouting holes 2 and drainage holes 3 in the first reinforcement area A on the inner side near the excavation sideline 1 of the tunnel. The flushing grouting holes 2 and the drainage holes 3 are drilled ad...

Embodiment 3

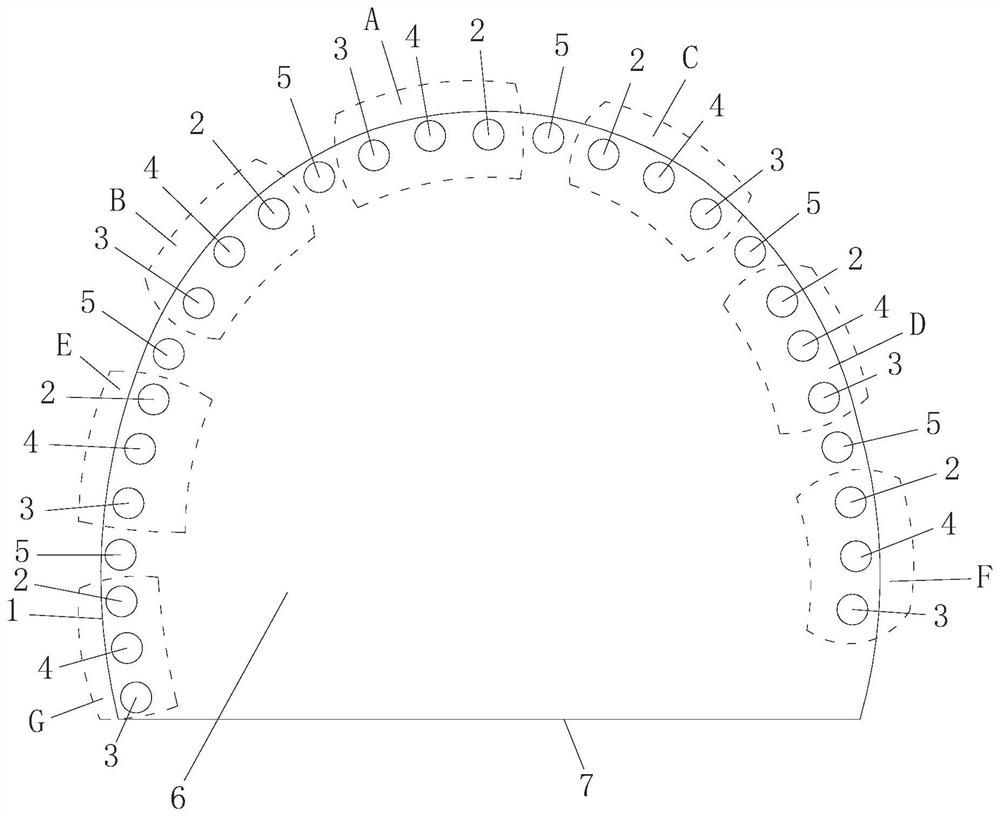

[0079] The tunnel to be excavated shall be reinforced before excavation, the tunnel excavation sideline 1, the tunnel face 6 and the tunnel bottom sideline 7 such as figure 2 shown.

[0080] A rapid grouting reinforcement method before excavation of a tunnel in a stratum with poor groutability and difficult self-stabilization, comprising the following steps:

[0081] (1) Divide into seven reinforcement areas along the tunnel excavation sideline 1 on the inner side close to the tunnel excavation sideline 1;

[0082] The reinforcement area includes the first reinforcement area A, the second reinforcement area B, the third reinforcement area C, the fourth reinforcement area D, the fifth reinforcement area E, the sixth reinforcement area F and the seventh reinforcement area Reinforced area G;

[0083] (2) Reinforcement of the reinforcement area:

[0084] ① Drill the first group of flushing grouting holes 2 and drainage holes 3 in the first reinforcement area A on the inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com