PVC pipe hole bottom grouting device and its installation and grouting method

A technology of PVC pipe and grouting device, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve the problems of low grouting pressure, poor water shutoff effect, and small slurry diffusion range, and achieve good reinforcement and water shutoff , Improve the uniformity and reduce the amount of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

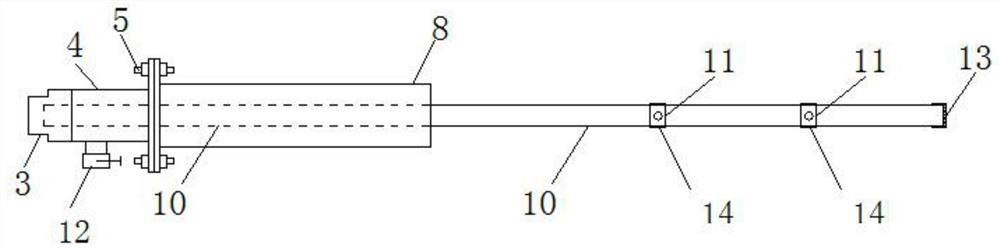

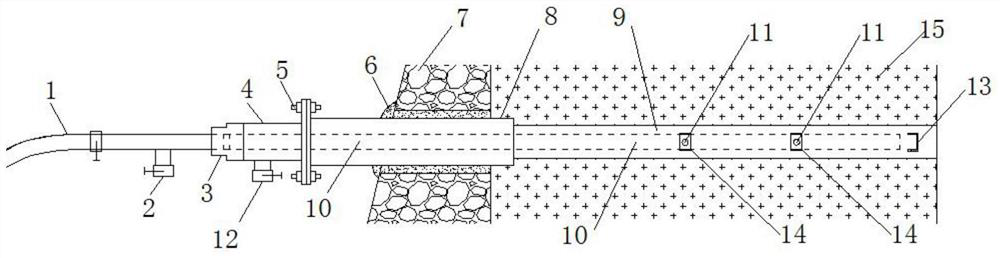

[0041] The PVC pipe hole bottom grouting device mainly includes an orifice pipe 8, an orifice connector 3 and a PVC pipe 10, a slag discharge and exhaust device 4, a slurry inlet pipe 1, and a grouting pump 2. Among them, one end of the orifice tube 8 is located in the orifice of the grouting hole 9 and fixed on the orifice wall, and the other end of the orifice tube 8 is located outside the grouting hole 9 and is connected to the slag discharge exhaust device 4 through the flange 5, wherein the slag discharge The exhaust device 4 is a commercially available product that is relatively common in existing applications. The other end of the slag discharge and exhaust device 4 is connected to the orifice connector 3 and connects the PVC pipe 10 with the slurry inlet pipe 1 through the orifice connector; the front end of the orifice connector 3 is glued with PVC glue at the rear end of the PVC pipe 10, and its front end The external thread is connected with the slag discharge and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com