System closing method used for oil shale underground in-situ exploitation

A technology of in-situ mining and oil shale, which is applied in the direction of mining fluid, underground mining, earth drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

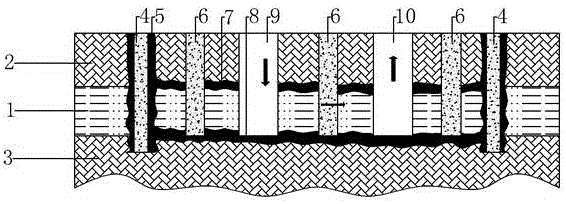

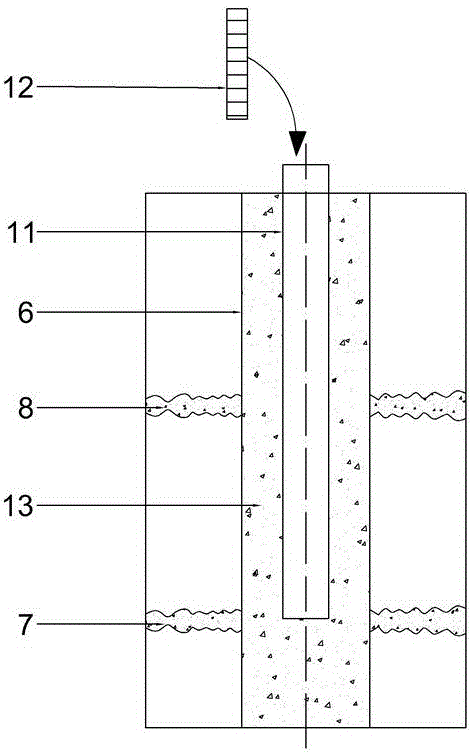

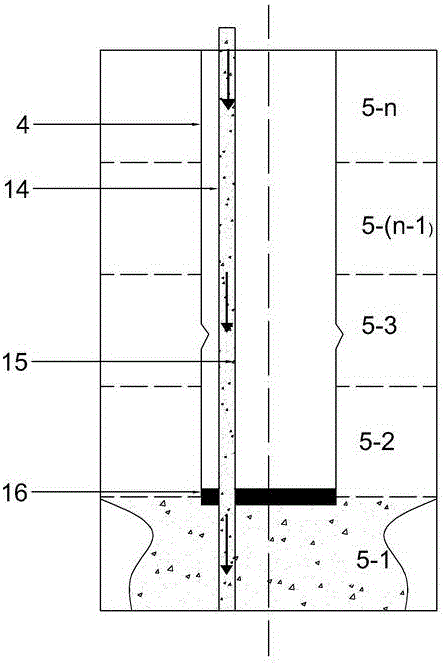

[0029] see figure 1 , figure 2 , image 3 and Figure 4 As shown, it is the first embodiment of the present invention. The sealing system involved in this embodiment is composed of a roof insulation sealing layer, a floor insulation sealing layer and a horizontal mining area sealing curtain.

[0030] Vertically, groundwater entry and heat loss need to be blocked; horizontally, groundwater entry and oil gas and by-products must be blocked.

[0031] According to geological data, the burial depth of the oil shale layer is 64-72m, and most of the formations are impermeable formations. The delineated oil shale mining area is a 30m×30m square area.

[0032] According to the weak water permeability of the stratum, the construction of the roof insulation sealing layer and the bottom insulation sealing layer shall be carried out first. The split grouting method is used for construction, the diameter of the grouting hole is 80mm, and the hole depth is 75m, passing through the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com