Variable-dip-angle simulated fracture grouting model test platform

A technology of test platform and grouting model, which is used in fluid dynamics test, testing of machine/structural components, instruments, etc. It can solve the problems of neglecting the plugging range and achieve the effect of large adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

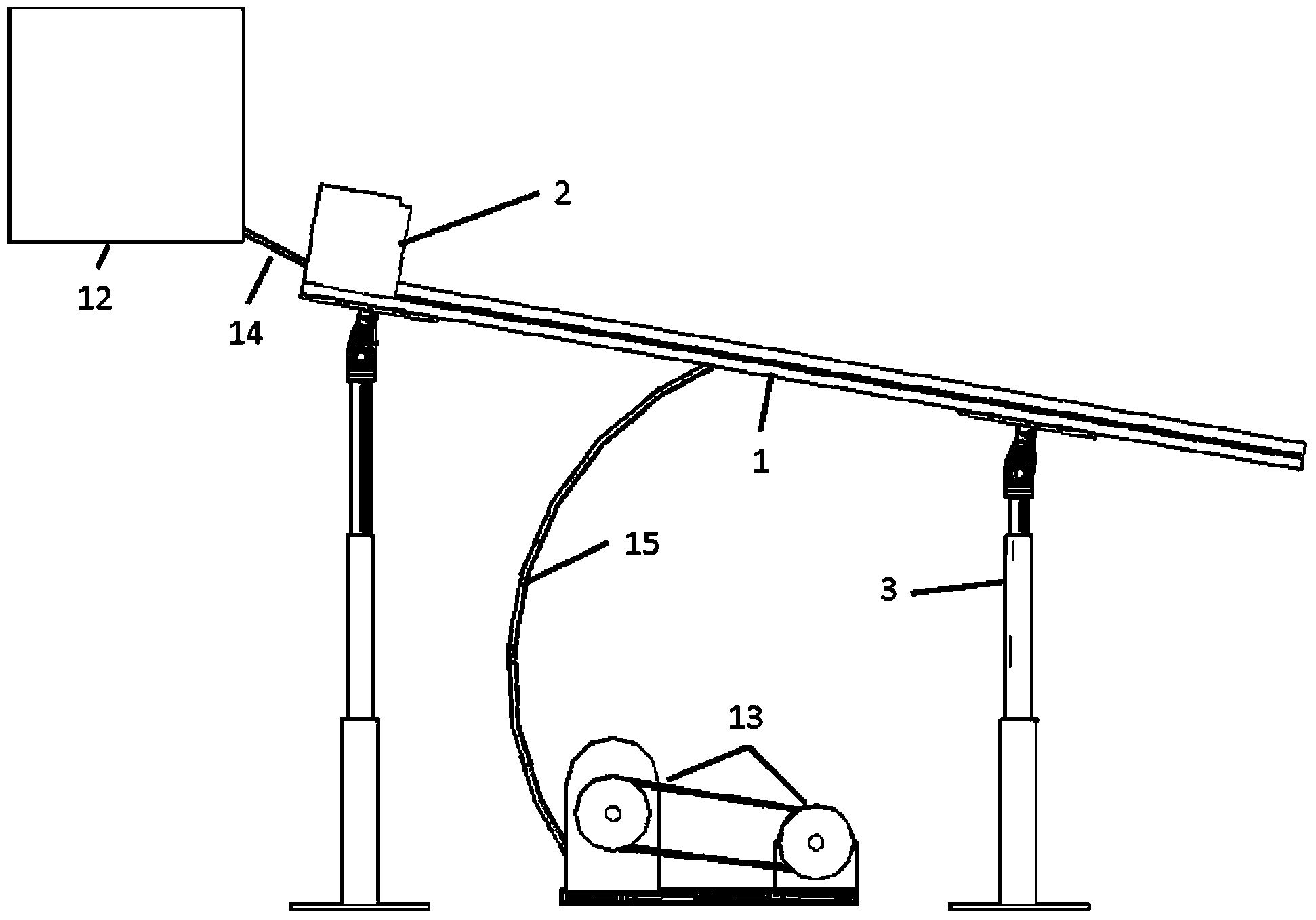

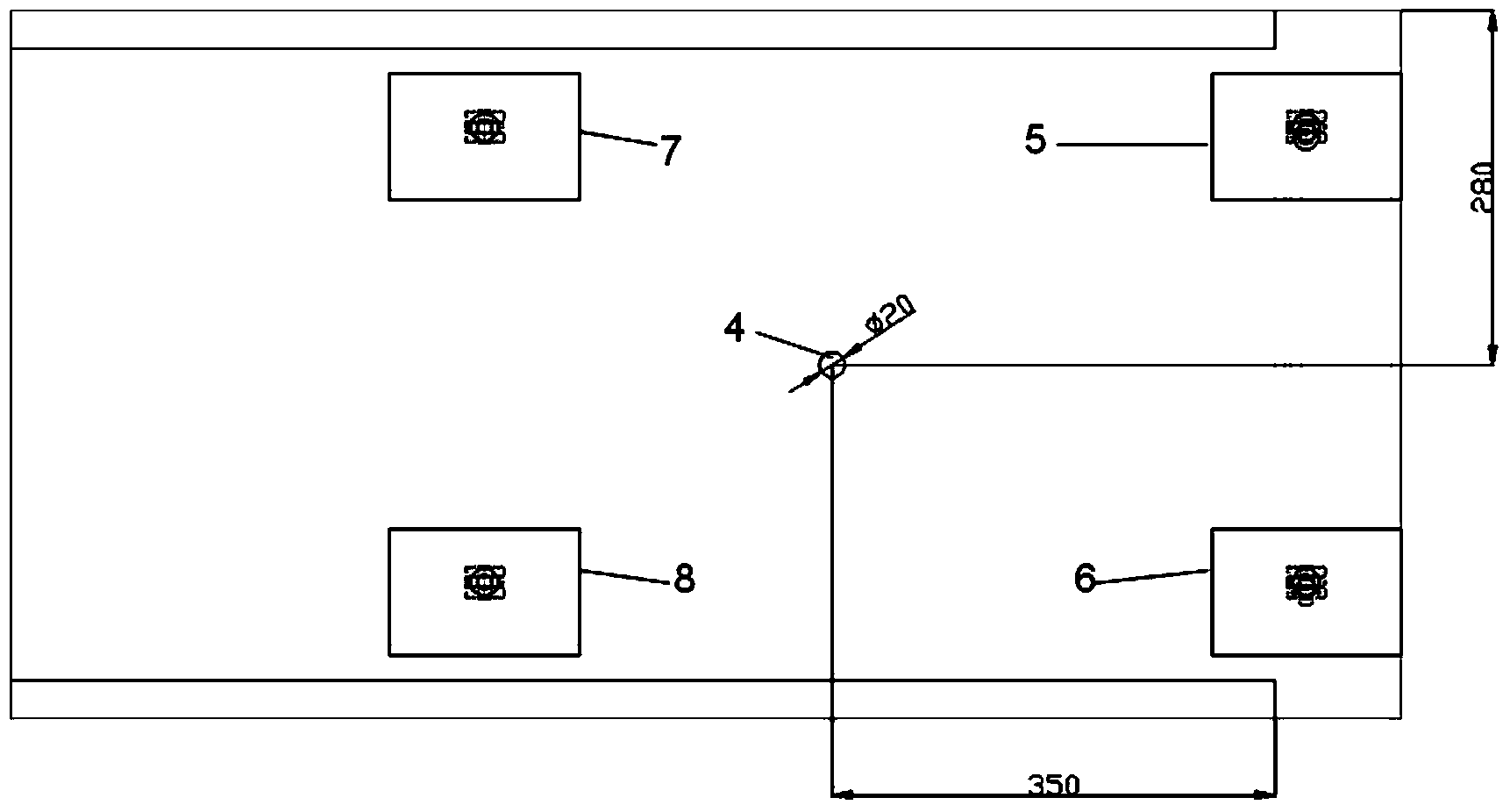

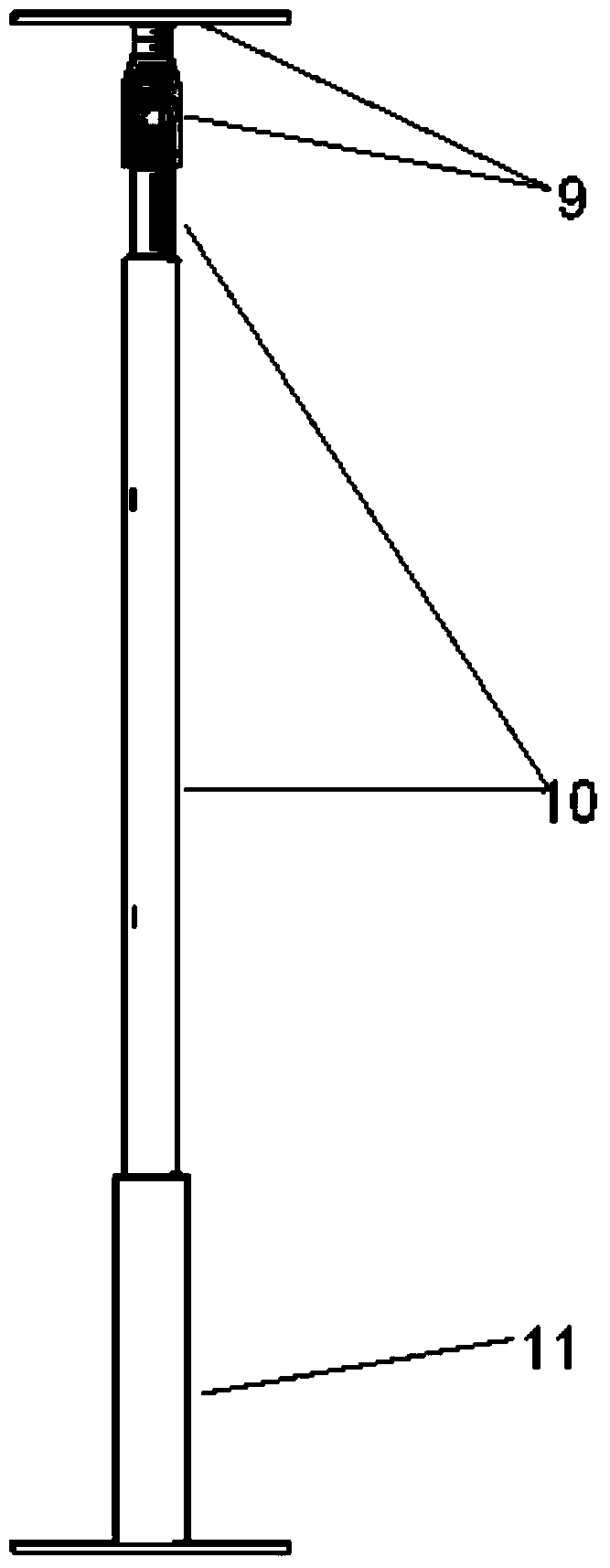

[0029] Such as Figure 1-Figure 4 , a simulated crack grouting model test platform with a variable inclination angle, including a simulated crack 1, a pressurized water tank 2 and a liftable support 3. The simulated crack is composed of two tempered glass plates parallel to each other, 3mm apart, and 1000×560mm in size. A 20mm grouting hole 4 is reserved at the center of the lower glass plate at a distance of 350mm from one short side. During the test, the simulated crack 1 can be reassembled as needed, the width of the simulated crack 1 can be adjusted, and porous media can be filled in the simulated crack 1 to simulate seepage grouting under different media conditions. The stabilized pressure water tank 2 is hinged with the short side of the simulated crack 1 that is closer to the grouting hole 4. There is a water inlet hole on the outside of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com