Permeation grouting process simulation method and system based on near-field dynamics

A process simulation and dynamics technology, applied in the field of geotechnical engineering, which can solve the problems of few applications in the field of geotechnical engineering, difficulty in accurately describing the temporal and spatial evolution characteristics of grout, and lack of theoretical methods and calculation strategies for grouting reinforcement simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

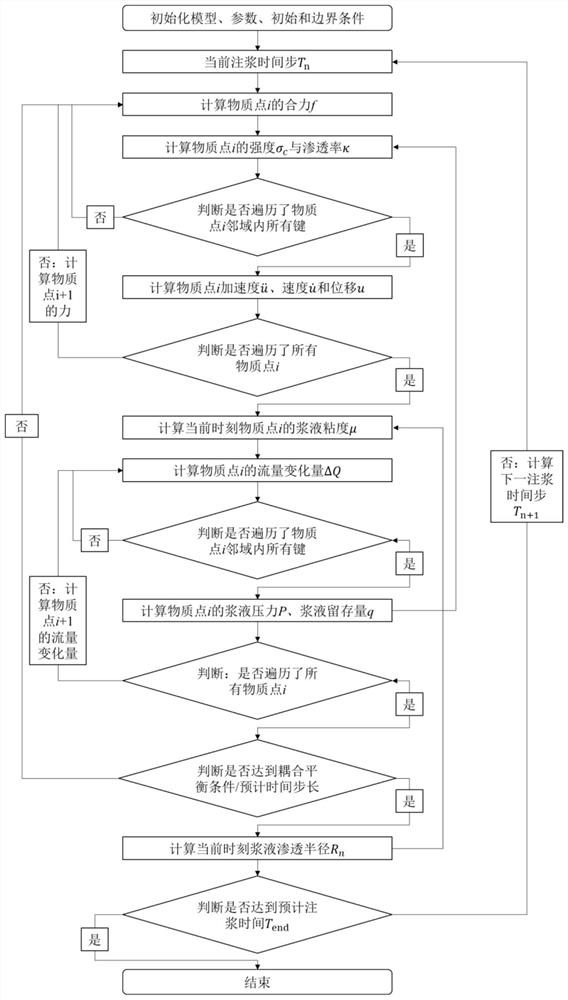

[0034] Such as figure 1 As shown, this embodiment provides a peridynamics-based simulation method for seepage grouting reinforcement process, which specifically includes:

[0035] S1: Initialize the relevant parameters of the infiltration grouting simulation model based on peridynamics;

[0036] Specifically, the infiltration grouting simulation model is discretized into a certain number of material points with rock mass material properties and rock mass volume information, and an appropriate neighborhood range δ is selected to construct the neighborhood matrix, coordinate matrix and material parameters of all material points Matrix; according to the model boundary conditions, initial conditions and constraints, initialize the model load matrix, pressure matrix and displacement matrix.

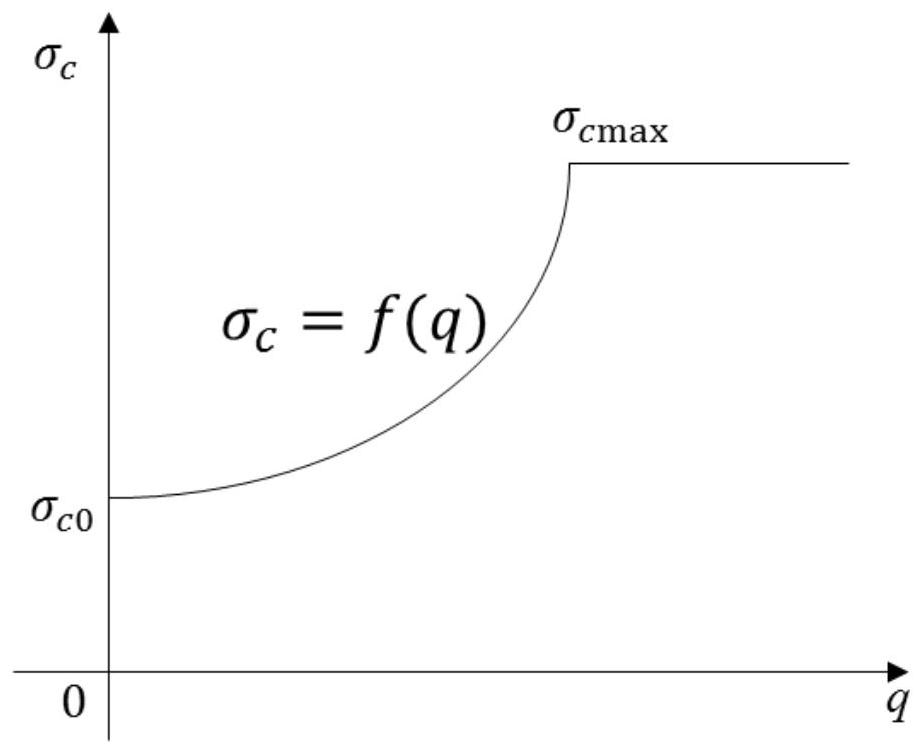

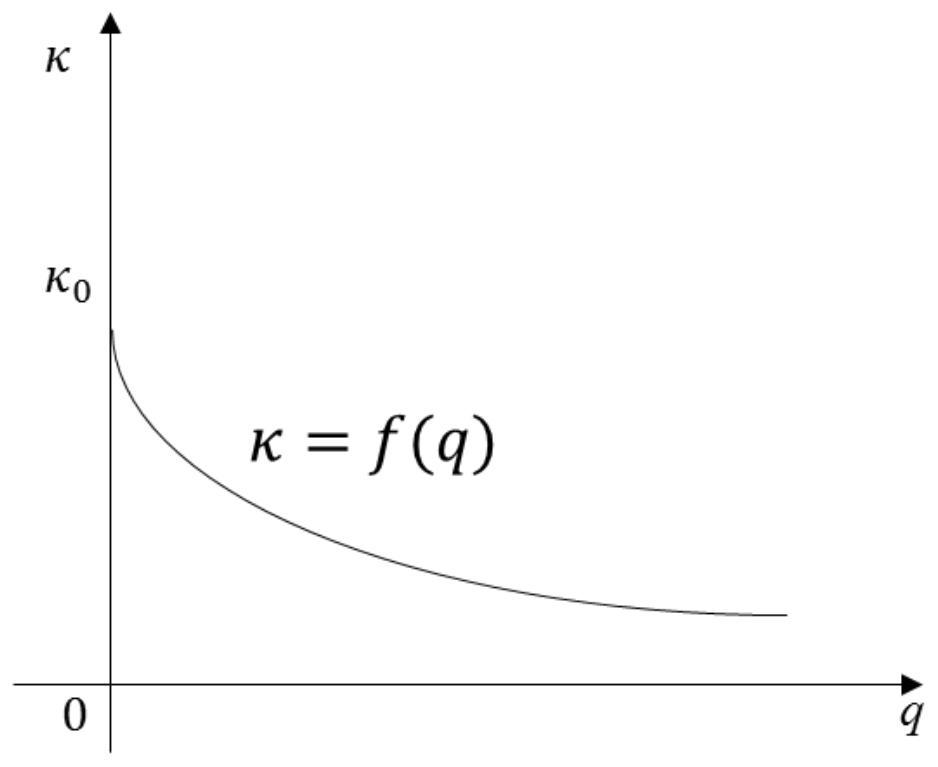

[0037] Preferably, the material point refers to a node representing the material volume and quality of rock mass within a certain spatial range; the node itself does not occupy a spatial volu...

Embodiment 2

[0073] This embodiment provides a permeation grouting process simulation system based on peridynamics, including:

[0074] The discretization module is used to discretize the seepage grouting simulation model into multiple material points according to the rock mass material and rock mass volume, and divide the seepage grouting process into multiple grouting time steps;

[0075] The solution module is used to construct a fluid-solid coupling cyclic model based on peridynamics. In the grouting time step, the displacement of the material point and the grout pressure are obtained by using a cyclic iterative solution method until the solution results meet the fluid-solid coupling equilibrium condition;

[0076] The cycle module is used to use the grout penetration radius of the current grouting time step as the initial condition of the next grouting time step, and add the material point strength and material point permeability obtained according to the grout remaining amount to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com