Construction method for treating cracks of semi-rigid base asphalt pavement

A semi-rigid base and asphalt pavement technology, applied in the field of construction engineering, can solve the problems of large traffic interference, long closed traffic time, incomplete treatment, etc., and achieve the goal of improving construction quality, shortening construction period, reducing investment and labor cooperation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

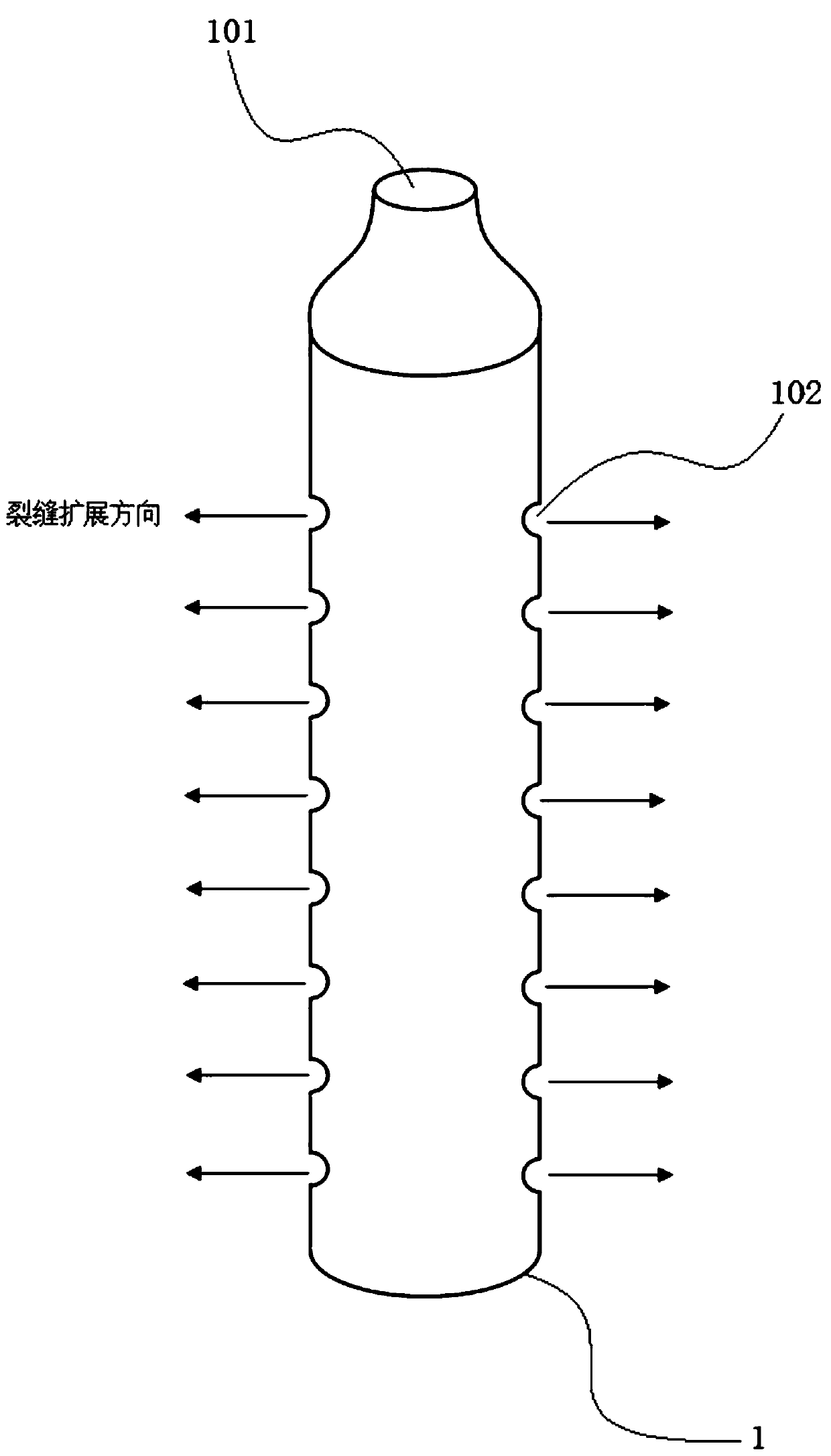

[0030] Conventional methods are mostly excavation-type maintenance, overlaying or pavement regeneration and other technologies, which require interruption of traffic, long construction period, and poor treatment effect. This embodiment provides a construction method for treating cracks in semi-rigid base asphalt pavement, comprising the following steps:

[0031] 1) Clean the cracks on the road surface, and use a high-power blower to clean the cracks and slots.

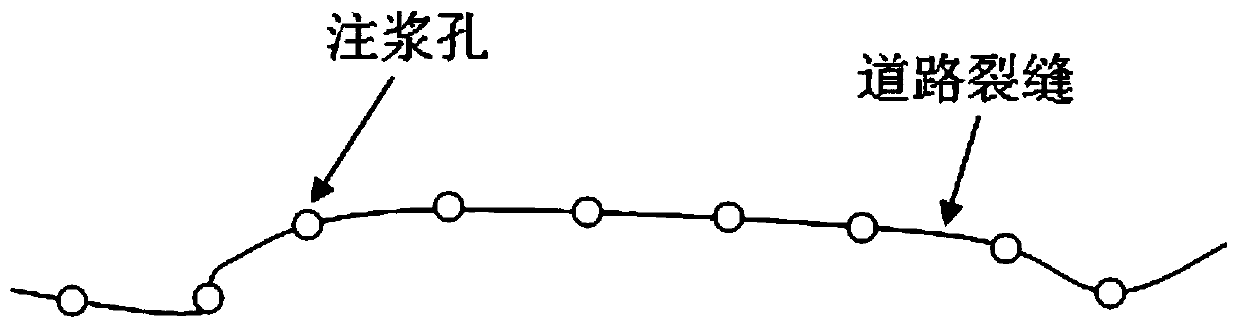

[0032] 2) Use 3D ground penetrating radar to detect the cracks on the pavement, and analyze the reflective cracks in detail combined with the detection results. Among them, the detection content of the three-dimensional ground penetrating radar is the position of the crack, the size of the crack and the disease condition of the parts below the base. The 3D ground penetrating radar grayscale image can display the transverse and vertical sections of the road surface and the radar images parallel to the road surface at d...

Embodiment 2

[0044] This embodiment provides a basic construction method for treating cracks in semi-rigid base asphalt pavement, including the following steps:

[0045] 1) Clean the cracks on the road surface.

[0046] 2) Use 3D ground penetrating radar to detect the cracks on the pavement, and analyze the reflective cracks in detail combined with the detection results.

[0047] 2.1) According to the design requirements, the three-dimensional ground penetrating radar is used to detect the road conditions within the detection range, and the gray-scale image of the radar parallel to the road surface and the gray-scale image of the horizontal and vertical sections are obtained.

[0048] 2.2) Determine the planar distribution of pavement cracks at different depths in the road structure layer based on the detected grayscale images parallel to the pavement.

[0049] 2.3) Determine the direction, opening and depth information of pavement cracks based on the detected grayscale image parallel to ...

Embodiment 3

[0058] The main steps of this embodiment are the same as in Example 2, wherein, in step 6), the permeable slurry is weighed according to the following raw materials in parts by weight: 100 parts of Portland cement, 25 parts of selected quartz sand, 35 parts of water, alkali 1 part of active agent and 10 parts of adhesive are mixed to obtain a penetrating slurry. The permeable slurry has low viscosity and good permeable type, and can permeate and diffuse well and cement road materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com