Experimental testing device for reinforcing fractured rock sample through high-pressure permeation grouting and grouting method

A rock sample and grouting reinforcement technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., to achieve the effect of controlling the air pressure, benefiting the air pressure, and optimizing the grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

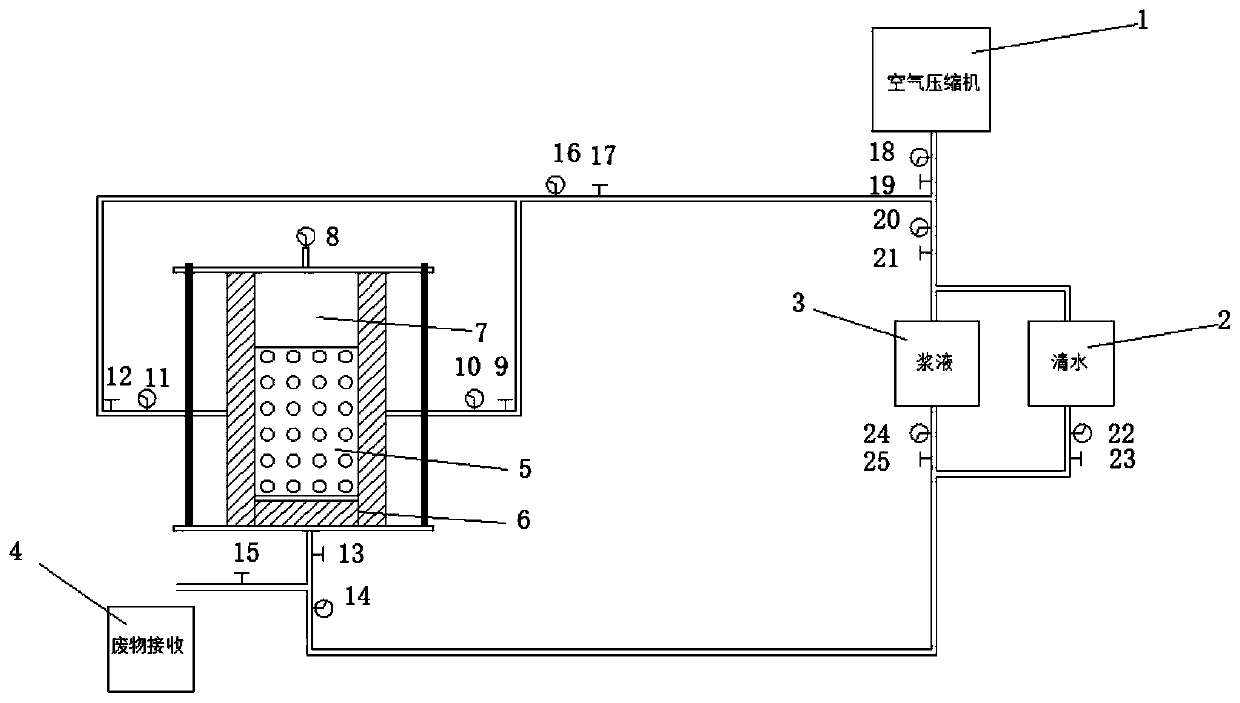

[0031] Such as figure 1 As shown, the present invention includes a grouting sample loading area, a grouting device and a cleaning device.

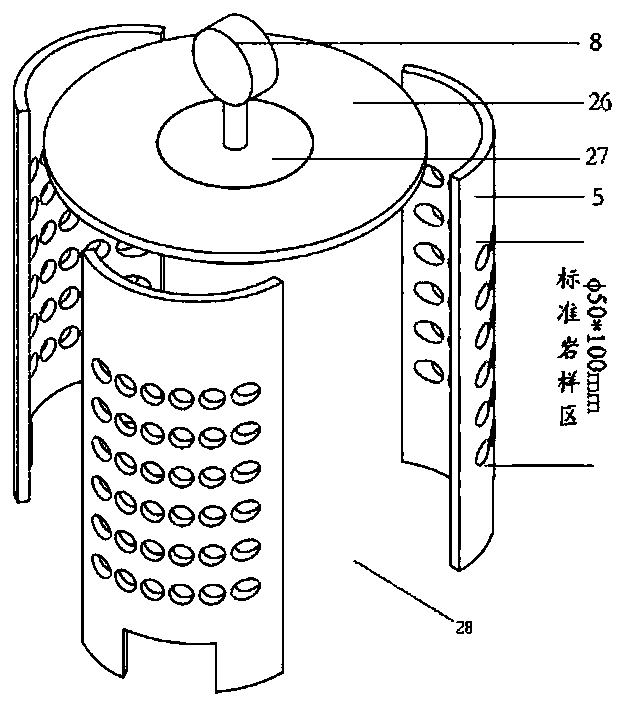

[0032] The grouting sample loading area includes a grouting filling area 6, a grouting area 7 and a metal hollow cylindrical fixture 5. The grouting sample loading area forms a closed system with excellent airtightness for the grouting rock sample to ensure the grouting effect. The grouting area 7 is located above the metal hollow cylinder fixture 5 , and a sealing cover 26 is provided on the top of the metal hollow cylinder fixture 5 . The center of the sealing cover is a transparent glass 27, and a barometer 8 is arranged above the transparent glass to observe the air pressure change in the grouting area 7, so the grouting area 7 can measure the pressure of the air.

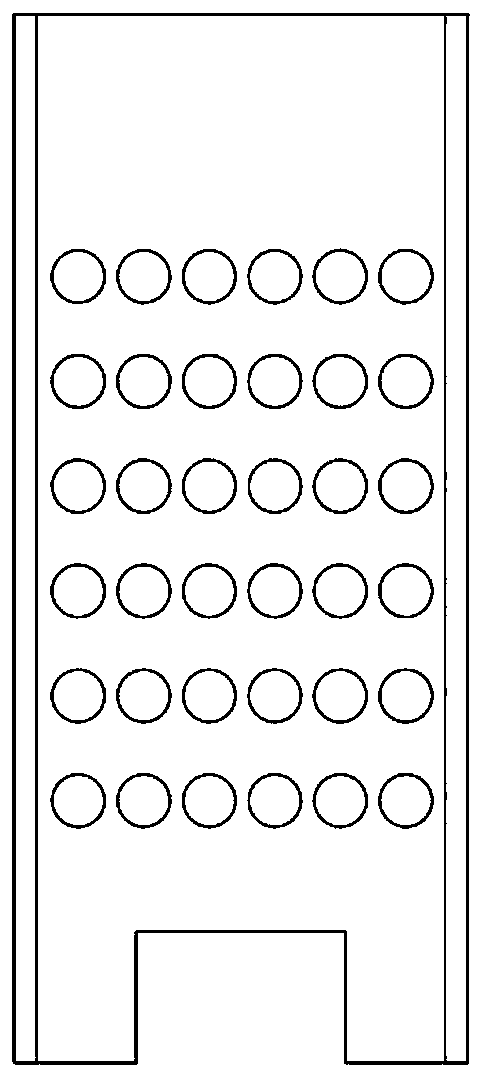

[0033] The metal hollow cylinder fixture 5 with holes is fixed by three fixture units with a central angle of 120°. The side and bottom of the metal hollow cylinder fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com