Loose body permeation grouting simulating testing device

A simulation test and loose body technology, applied in the direction of measuring devices, diffusion analysis, instruments, etc., can solve the problems of difficulty in the analysis process of loose body consolidation form, difficulty in monitoring the slurry diffusion process, and the inability to reproduce the stress environment, etc., to achieve dynamic Tracing, eliminating boundary effects, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with embodiment.

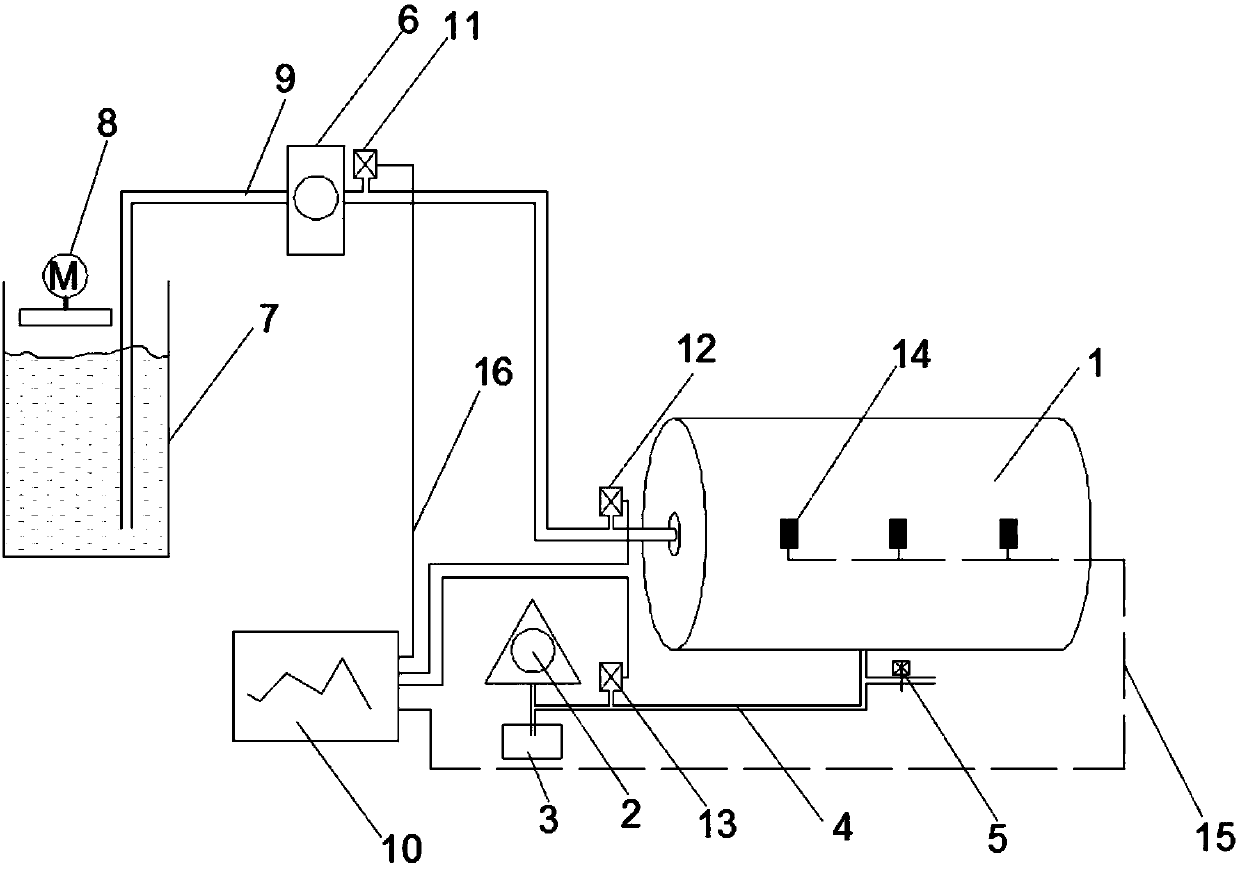

[0029] As shown in the figure, a loose body seepage grouting simulation test device includes a grouting system, a confining pressure loading system and a monitoring system,

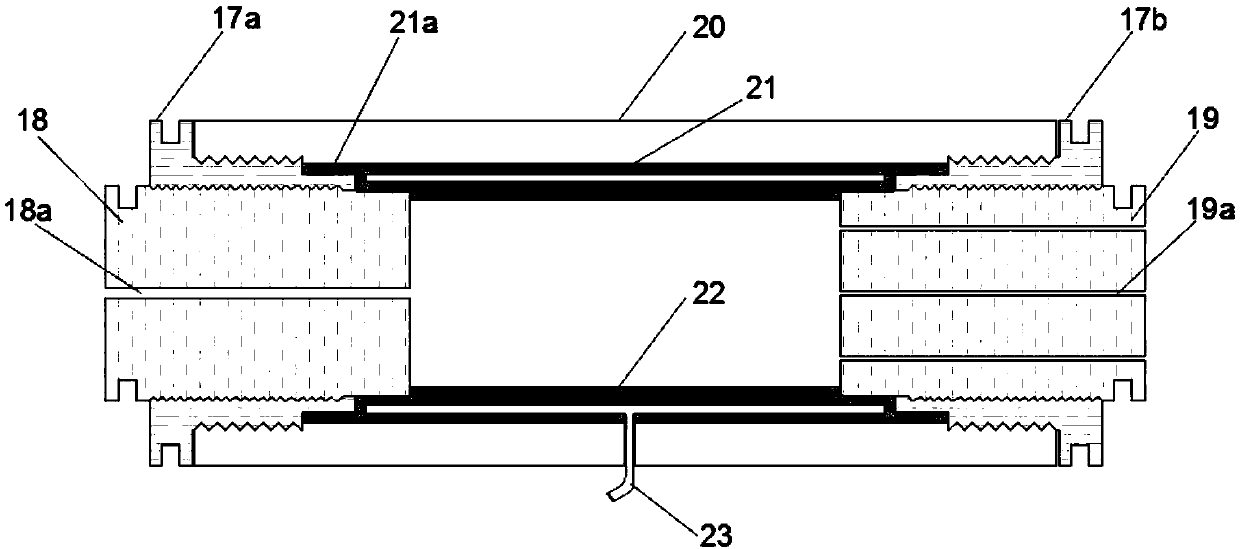

[0030] The confining pressure loading system includes a constant pressure confining pressure pump 2 and a double rubber sleeve confining pressure loader 1, and the double rubber sleeve confining pressure loader 1 includes a cylinder 20, a fastening device arranged at one end of the grouting port of the cylinder 20 Nut I17a, fastening nut II17b set at one end of the slurry outlet of the cylinder 20, the cylinder 20 is provided with a valve rubber sleeve 22, and a water capsule sleeve is provided around the outer wall of the valve rubber sleeve 22 and the inner wall of the cylinder 20 21. The tightening nut I17a and the tightening nut II17b are screwed into the cylinder 20 from both ends, and the ends respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com