Automatic aluminum oxide charging system for aluminum electrolysis based on linear drive circuit

A linear drive and automatic feeding technology, applied in the field of aluminum electrolysis, can solve problems such as inability to maintain stable alumina concentration, increase in power consumption and material consumption of aluminum electrolysis, and inability to feed on demand, so as to avoid adverse effects, drive stability, and The effect of reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

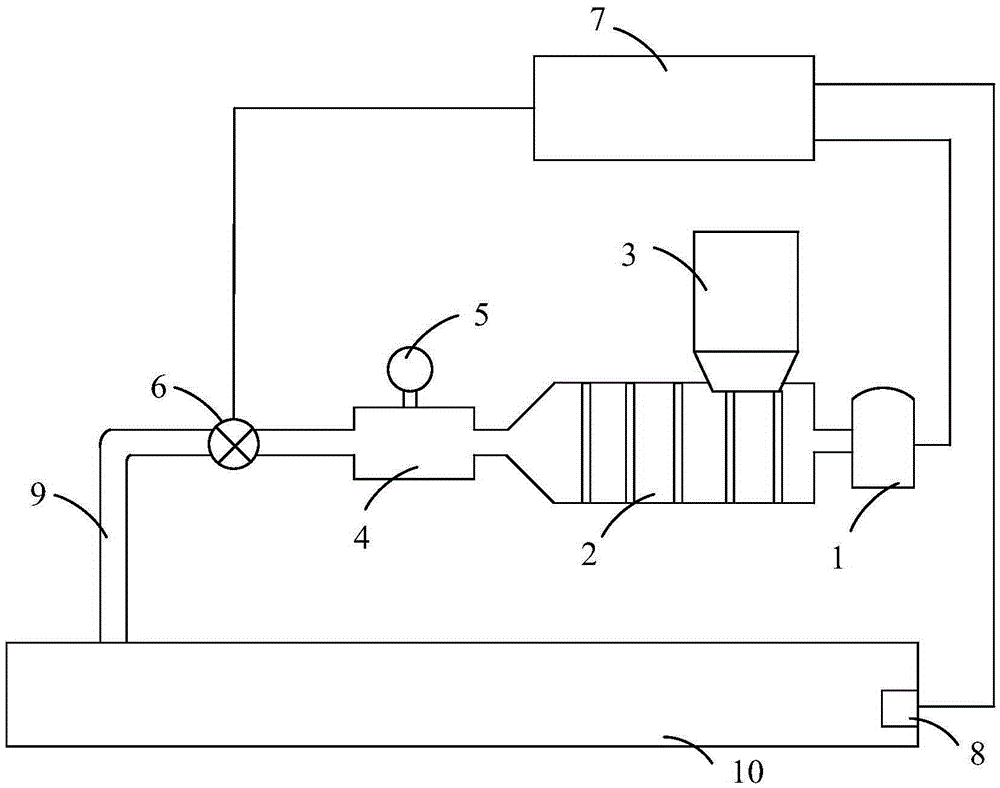

[0022] Such as figure 1 As shown, the alumina automatic feeding system for the aluminum electrolytic cell of the present invention consists of a concentration detection sensor 8 arranged in the aluminum electrolytic cell 10 for detecting the concentration of alumina in the aluminum electrolytic cell 10, a frequency conversion motor 1, and a frequency conversion motor 1 An alumina pressurized pump 2 connected to the power output shaft, a feed box 3 arranged at the feed port of the alumina pressurized pump 2, a buffer 4 connected between the feed port and the discharge port of the alumina pressurized pump 2 , the feeding pipe 9 connected to the discharge port of the buffer 4, the pressure gauge 5 arranged on the buffer 4, the solenoid valve 6 arranged on the feeding pipe 9, and the electromagnetic valve 6 and the frequency conversion motor 1 respectively It is composed of an automatic control system 7 connected with a concentration detection sensor 8.

[0023] When working, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com