Vertical shaft foundation thermal drainage consolidation test device

A technology of consolidation test and hot drainage, which is applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc. The effect of large pressure load, good reliability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

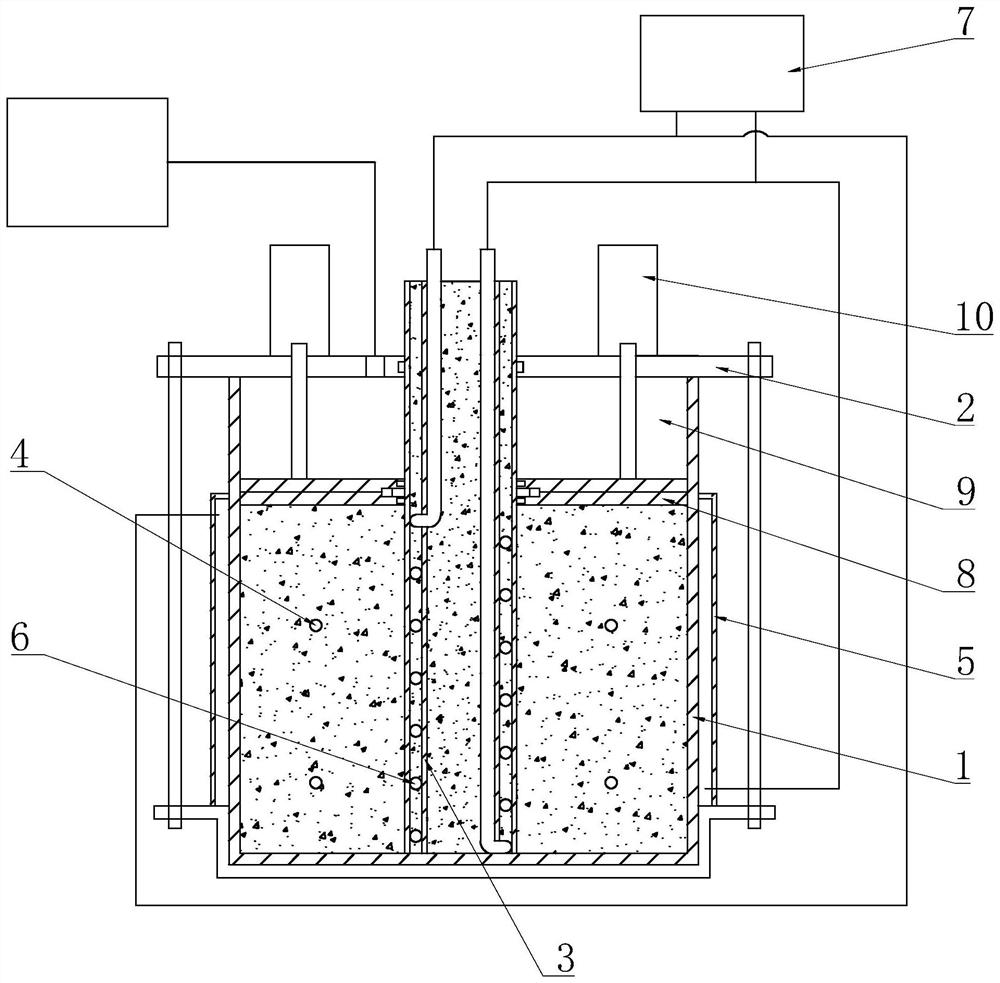

[0063] A shaft foundation thermal drainage consolidation test device is characterized in that it includes:

[0064] A test box 1, the top of the test box 1 is provided with a box cover 2, and soil samples are filled in the test box 1;

[0065] A pressurizing mechanism for loading and compacting the soil sample;

[0066] Drainage mechanism, including the vertical shaft 3 arranged in the test chamber 1;

[0067] A heating mechanism for heating the soil sample;

[0068] Wherein, the pore water pressure sensor 4 is pre-buried in the soil sample; the heating mechanism includes a first heating assembly arranged on the outer wall of the test chamber 1 and a second heating assembly arranged on the outer wall of the shaft 3 .

[0069] The box cover 2 and the test box 1 can be fixedly connected by a plurality of screws, and the outside and the center of the test box 1 are jointly heated, so that the heating uniformity is good, and the detection accuracy of the test can be improved.

Embodiment 2

[0071] In this embodiment, in addition to the structural features of the preceding embodiments, the further first heating assembly includes a jacket 5 arranged on the outer wall of the test chamber 1, and an insulation layer is provided outside the jacket 5;

[0072] The second heating assembly includes a heating coil 6;

[0073] The heating mechanism also includes a heating unit 7 for heating the jacket 5 and the heating coil 6;

[0074] The heat supply unit 7 is used to provide the heat medium at the required temperature. The heat supply unit 7 can be an external water tank or heat transfer oil tank with heating function, and the circulating hot water or heat conduction is delivered through the circulating pump box jacket 5 and the heating coil 6 Oil.

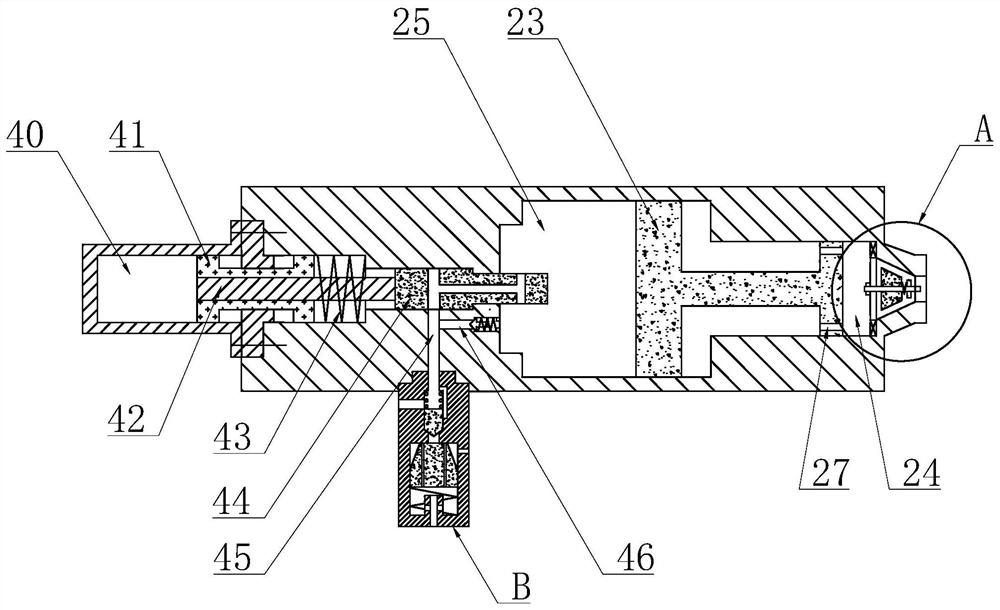

[0075] The shaft 3 is an inner and outer double-layer cylinder, and the heating coil 6 is arranged between the two layers of cylinders, and the water inlet end of the heating coil 6 radially penetrates the inner cylinder and...

Embodiment 3

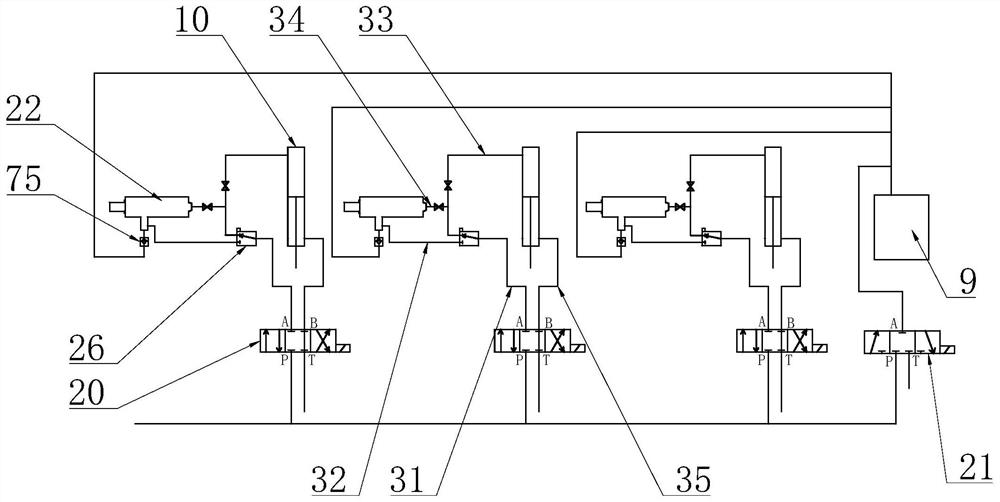

[0078] In this embodiment, in addition to the structural features of the preceding embodiments, the pressurizing mechanism further includes:

[0079] Pressure plate 8, the pressure plate 8 is located in the test box 1, and the main pressure chamber 9 is formed between the pressure plate 8 and the box cover 2;

[0080] Auxiliary cylinder 10, the number of auxiliary cylinders 10 is evenly installed on the top of the box cover 2, and the cylinder rod of the auxiliary cylinder 10 is installed through the box cover 2 and connected with the pressure plate 8, and the cylinder rods are mounted on the pressure plate in a circular equidistant manner 8 on the perimeter;

[0081] The air control unit is used to control the intake and exhaust of the main pressure chamber 9 and the auxiliary cylinder 10;

[0082] Wherein, the box cover 2 is provided with air holes communicated with the main pressure chamber 9, the pressure plate 8 is an upper and lower double-layer structure, and the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com