Construction method for reinforcing pile-soil composite foundation

A composite foundation and construction method technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of deformation exceeding the allowable value and insufficient bearing capacity of composite foundation, and achieve excellent applicability, significant economy, and improved work performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] The invention discloses a construction method for reinforcing a pile-soil composite foundation, which consists of the following steps:

[0050] Calculate the centroid position of the soil between the minimum unit piles according to the pile arrangement form of the pile-soil composite foundation,

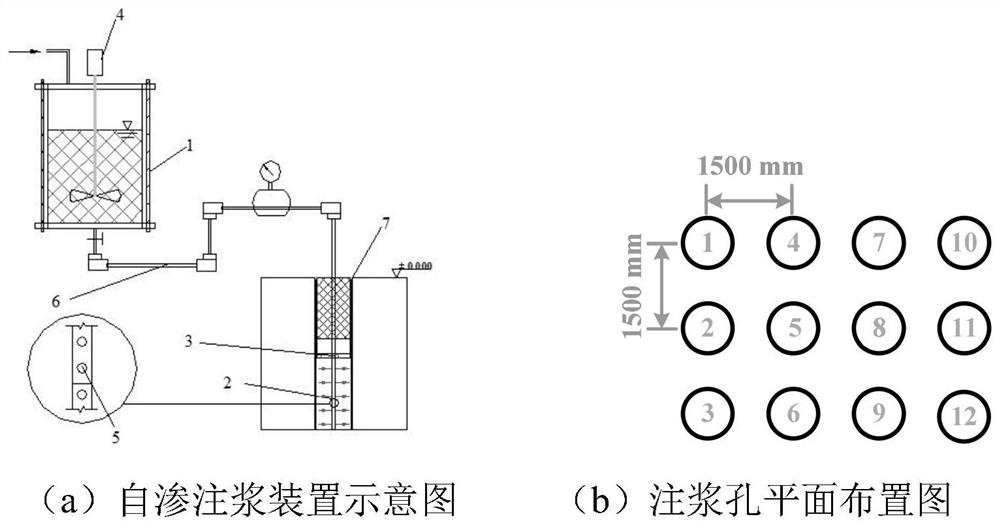

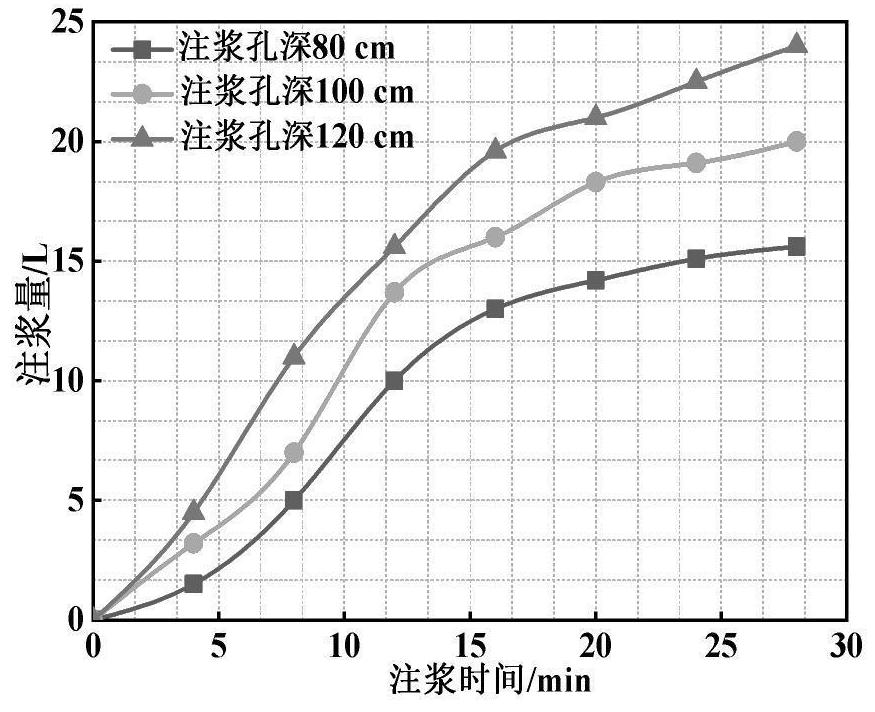

[0051] Utilize Luoyang shovel to dig out grouting hole 7 at the centroid position of soil body between piles, guarantee that grouting hole 7 is vertically offered, and the radius of grouting hole 7 is 10-15cm; The depth of grouting hole 7=(2 / 3 -1)*The length of the pile in the pile-soil composite foundation;

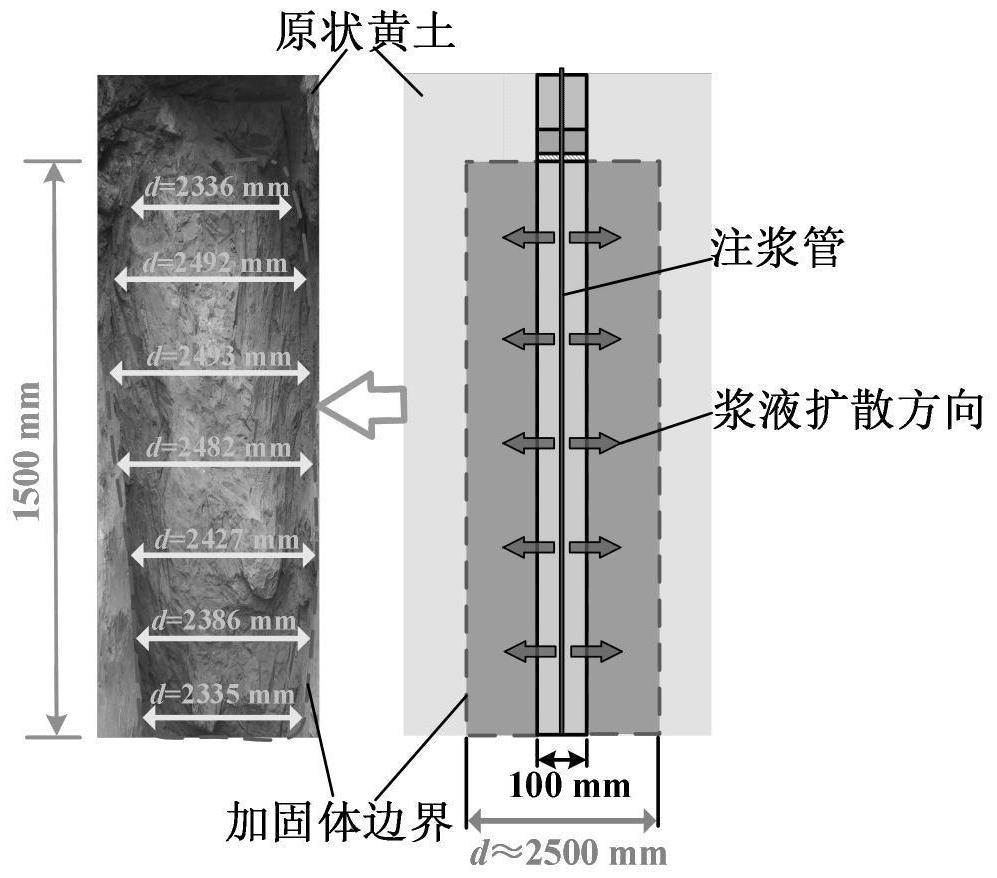

[0052] Put the grouting pipe 2 of the grouting system vertically into the center of the grouting hole 7, and reach the bottom of the grouting hole 7,

[0053] Put the packing 3 around the outer wall of the grouting pipe 2 in the grout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com