Patents

Literature

94results about How to "Reduce production finished product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

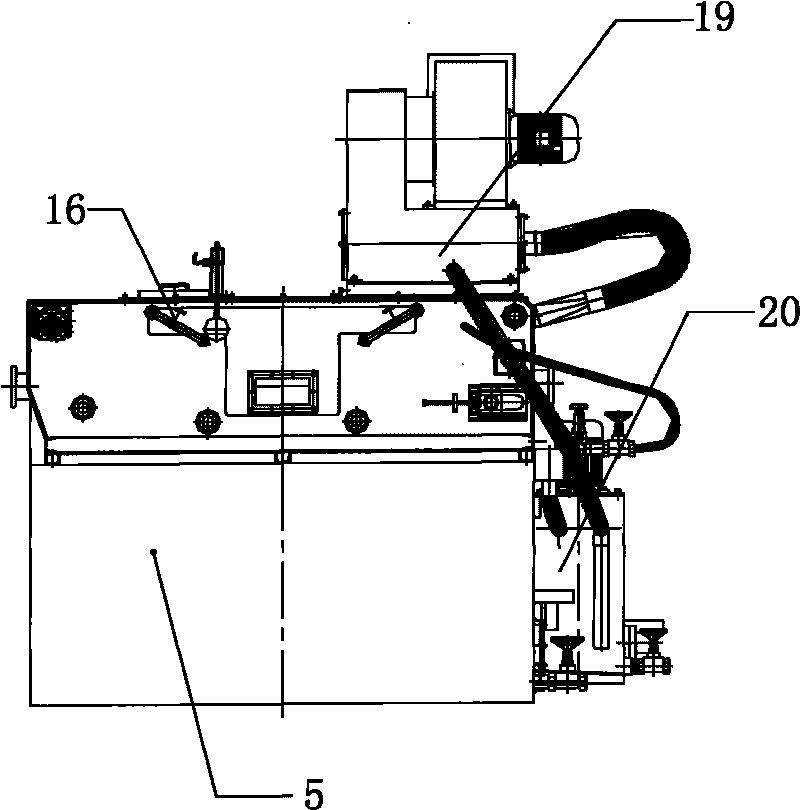

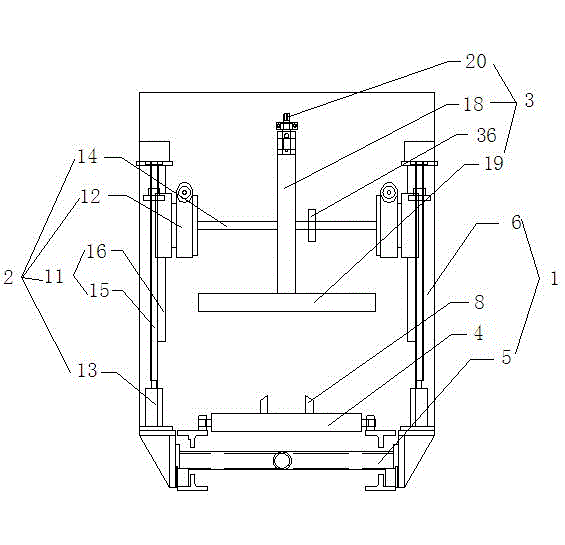

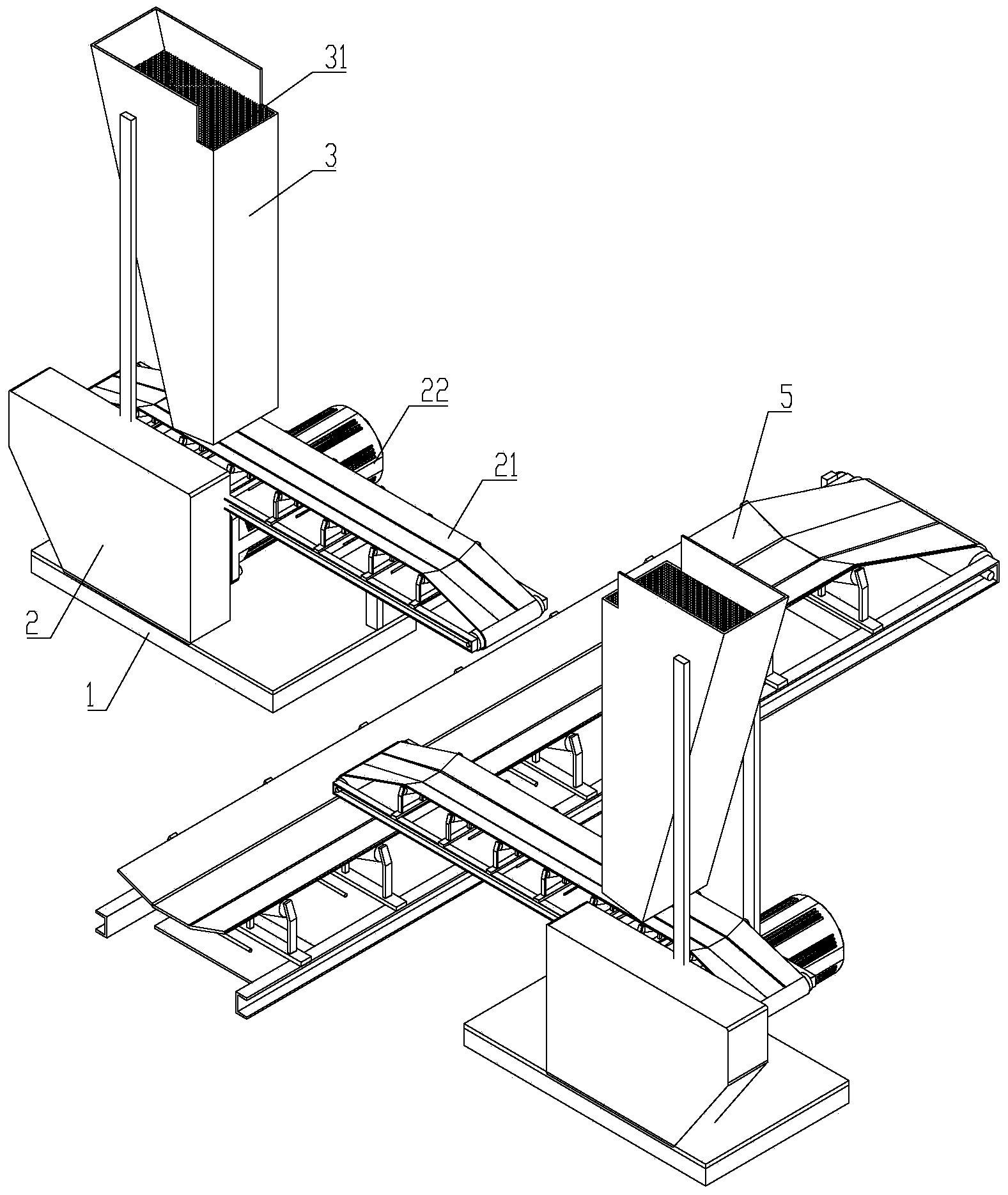

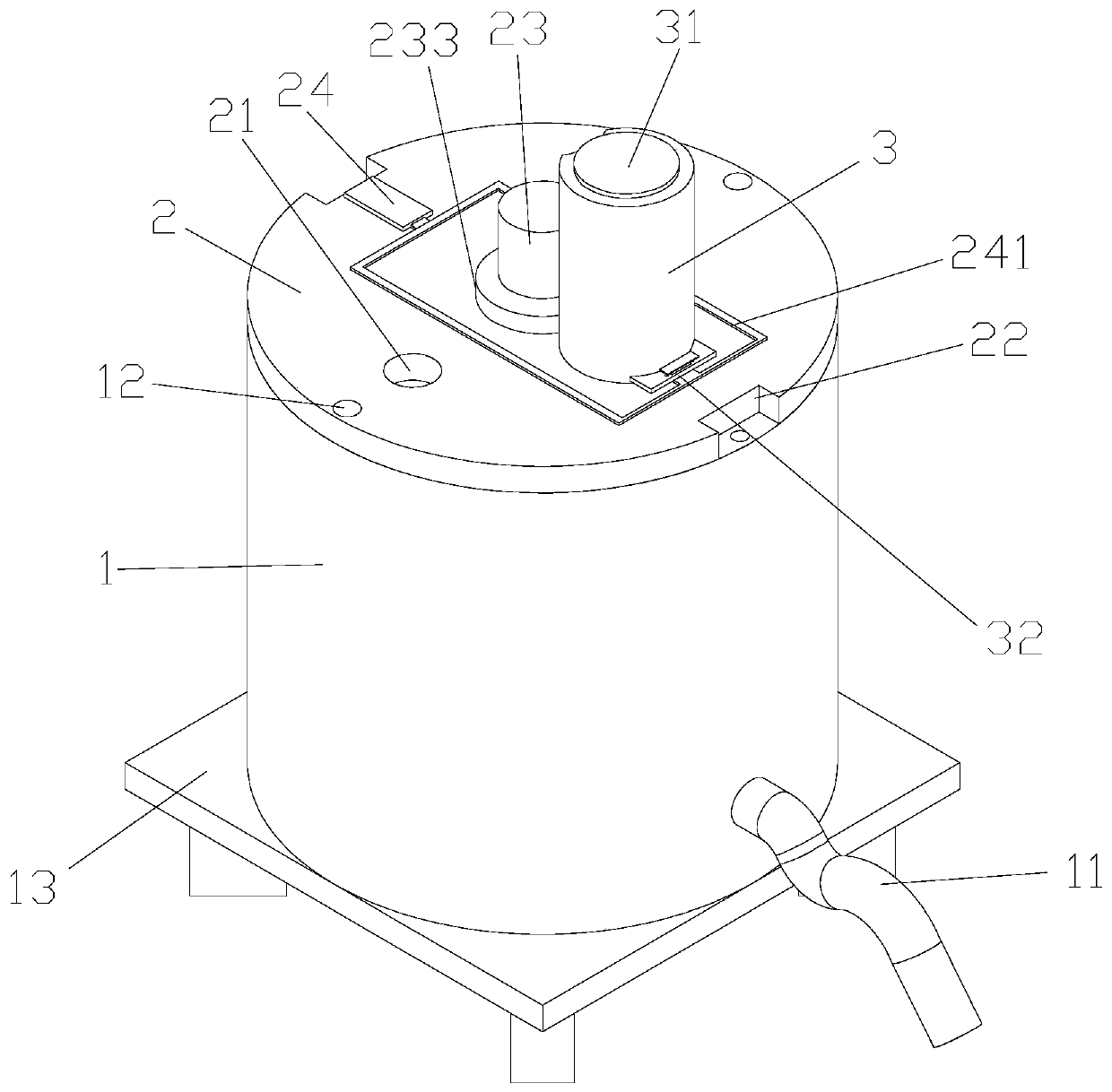

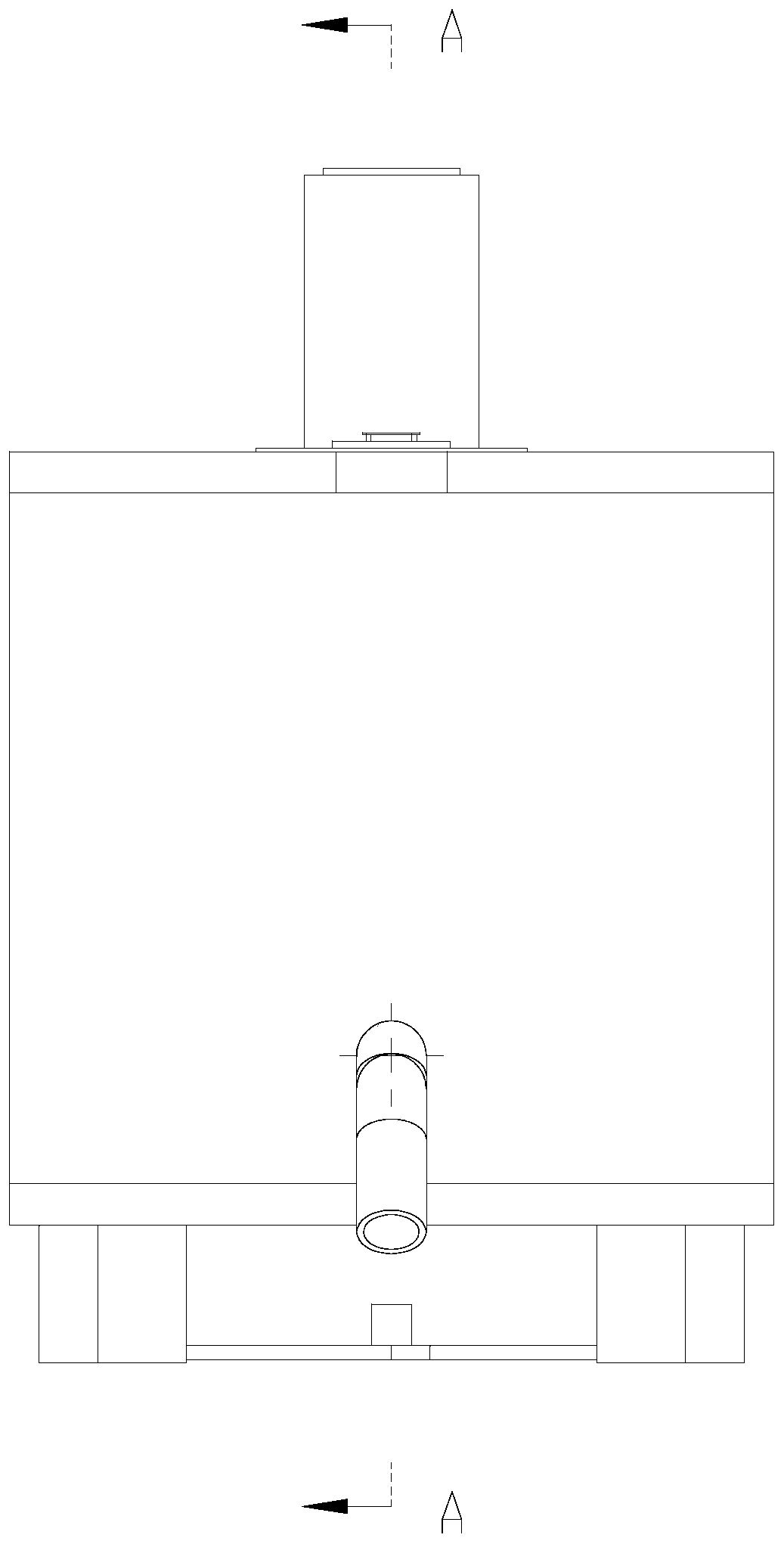

Flange assembly machine

ActiveCN104551496ASave manpower and material resourcesReduce production finished productWelding/cutting auxillary devicesAuxillary welding devicesAxis of symmetryPipeline transport

The invention relates to a flange assembly machine. The flange assembly machine comprises a pipeline transporting mechanism, and regulating mechanisms which are positioned at the two sides of the pipeline transporting mechanism and are symmetrically distributed left and right by taking the pipeline transporting mechanism as an axis of symmetry; when a pipeline transporting device transports a pipeline to an assembly position, the regulating mechanisms grip a flange and transport the flange to the two sides of the pipeline, so that the flange and the pipeline are aligned and fitted with each other and are finally welded into an integer; when the pipeline assembly is ended, the pipeline transporting device operates for transporting away the assembled pipeline. The flange assembly machine is convenient to operate, fully automatic and intelligent in operation in the whole process, and relatively safe and reliable, greatly saves manpower and material resources, and reduces production cost.

Owner:江苏振光电力设备制造有限公司

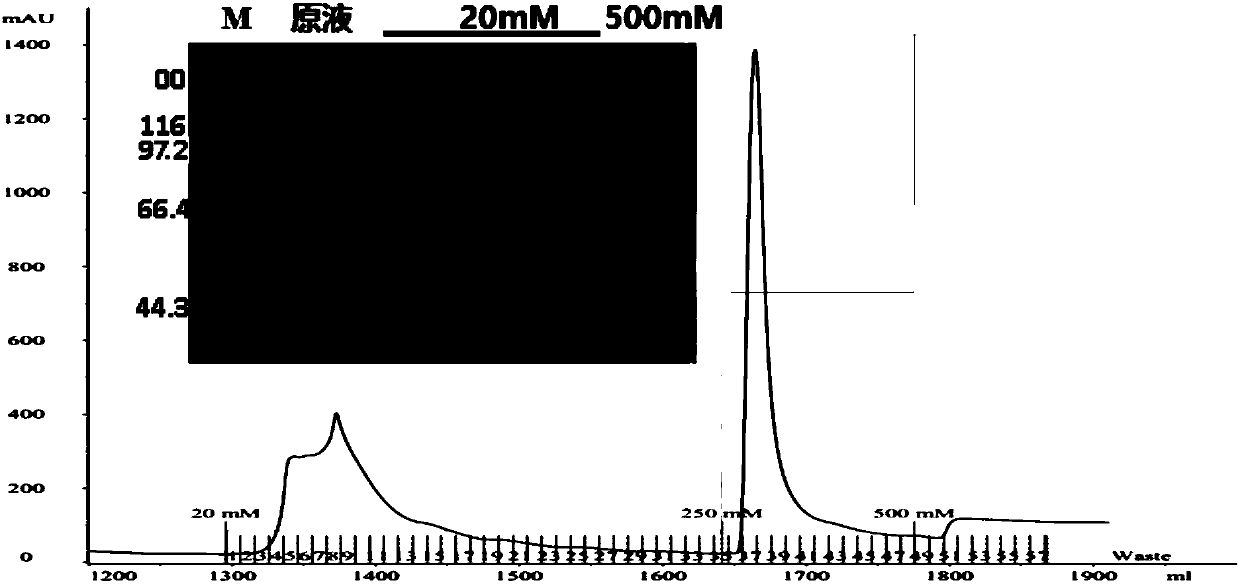

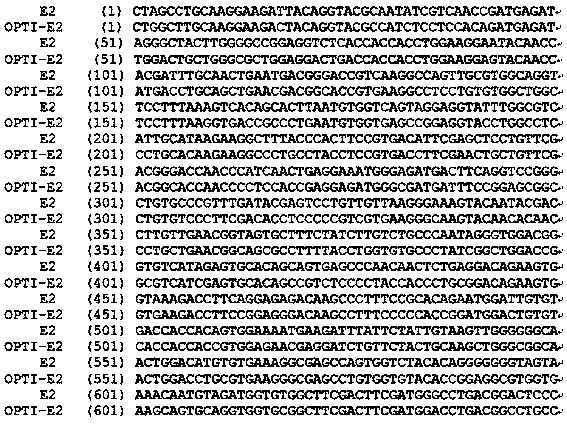

Preparation methods and application of recombinant swine fever E2 protein and subunit vaccine of recombinant swine fever E2 protein

PendingCN107674883AIncrease productionImprove securitySsRNA viruses positive-senseViral antigen ingredientsProtein targetVaccine Production

The invention discloses preparation methods and application of recombinant swine fever E2 protein and a subunit vaccine of the recombinant swine fever E2 protein. The preparation method of the recombinant swine fever E2 protein comprises the following steps that (1) a swine fever E2 protein coding gene is cloned into an eukaryotic expression vector to obtain recombinant plasmid containing the swine fever E2 protein coding gene; (2) then, the recombinant plasmid containing the swine fever E2 protein coding gene is transfected into a CHO cell strain; (3) the CHO cell strain obtained in the step(2) is cultured, screened and domesticated; and (4) the cell strain in the step (3) is fermented and cultured; and the recombinant swine fever E2 protein is obtained after purification. The methods provided by the invention have the advantages that the target protein can be obtained from cell culture supernatant; the yield reaches up to 1g / L; the protein purification time is shortened; the vaccineproduction steps are simplified; and the vaccine production cost is also greatly reduced.

Owner:NOVO BIOTECH CORP

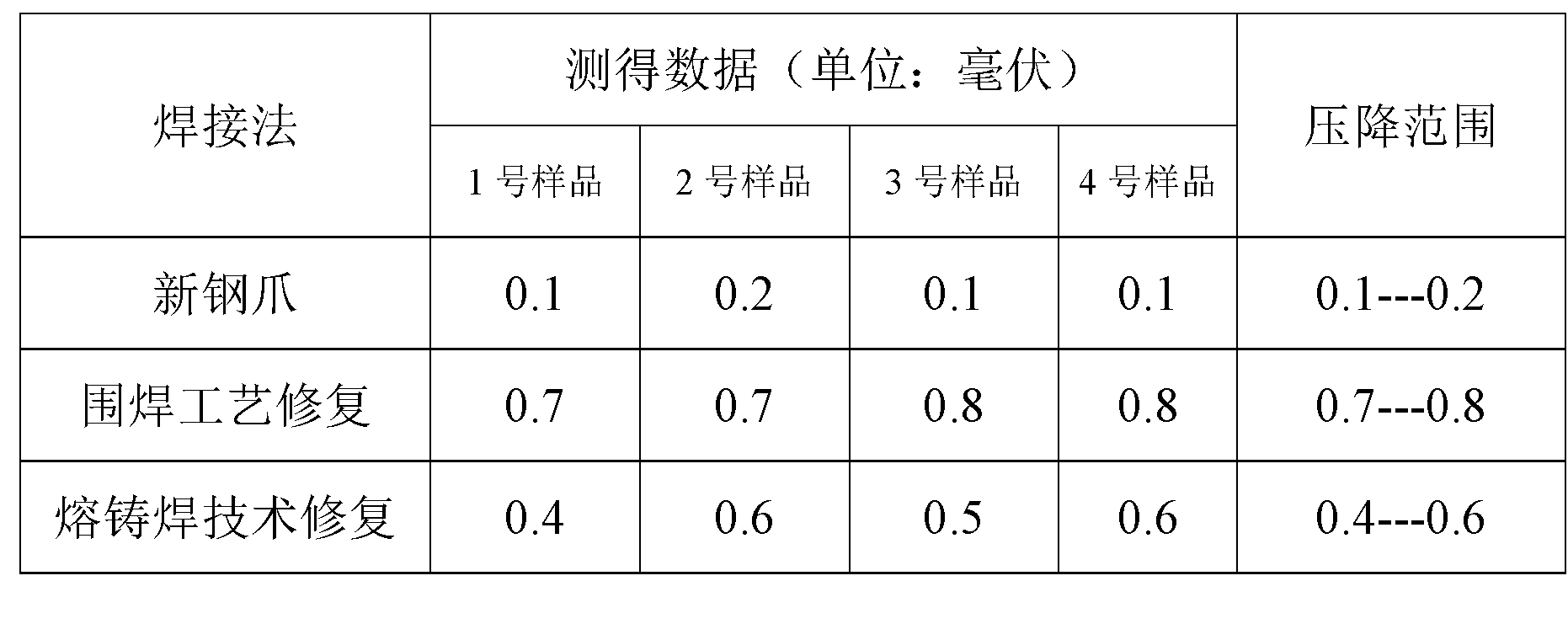

Method for repairing anode steel stud

The invention relates to a method for repairing an anode steel stud. The method for repairing the anode steel stud is characterized in that a burned steel stud head is cut by a section through gas welding, and with the design length of the steel stud head as a reference point, the cut section is longer than the burned section; a cylindrical steel bar with the same diameter as the steel stud head is prepared, one auxiliary connecting piece is arranged between the cutting face of the steel stud head and the cylindrical steel bar through vertical position welding so that the steel stud head and the cylindrical steel bar can be connected, and two same semi-circular bead weld supplement spaces are formed between the cylindrical steel bar and the cross section of the steel stud head; the two same semi-circular bead weld supplement spaces are filled with weld fillets in a bead weld mode, after the bead weld supplement space on one side is welded, the steel stud is turned over, the other bead weld supplement space is welded in a bead weld mode, and therefore repair of one steel stud is finished. The method for repairing the anode steel stud has the advantages that the anode steel stud repaired in the method is low in pressure drop, repeated repair on the anode steel stud can be achieved in the method, and production cost of electrolytic aluminum is reduced greatly.

Owner:BAOTOU ZHONGSHUO WELDING TECH

Method for preparing walnut protein beverage

ActiveCN103393190AImprove added value and market competitivenessReduce production finished productFood preparationChemistrySieve

The invention discloses a method for preparing a walnut protein beverage. The method comprises the following steps: 1, peeling walnut kernels, removing impurities, and washing to obtain walnut meat; 2, adding water having a mass 5-10 times the walnut meat, pulping, sieving by a 40-160 mesh sieve to obtain a pulp and sediments; and 3, adding white granulated sugar or xylitol having a mass being 4% of the pulp, a xanthan gum having a mass being 0.05-0.1% of the pulp and carboxymethylcellulose sodium having a mass being 0.05-0.1% of the pulp, carrying out complex formulation, adjusting the pH value to 7.0-7.5, and disinfecting at 105-121DEG C for 12-40min to obtain the walnut protein beverage. The method for preparing the beverage by mainly treating walnuts as a main raw materials aims at improving the added values and the market competitiveness of walnut products and saving the production cost. The method is especially suitable for walnut residues obtained after oil pressing, and can reduce the destroys of the discarding of wastes in the processing processes of the walnut products to the environment.

Owner:KUANDIAN CHENYANG SHAN ZHEN FOOD DEV +2

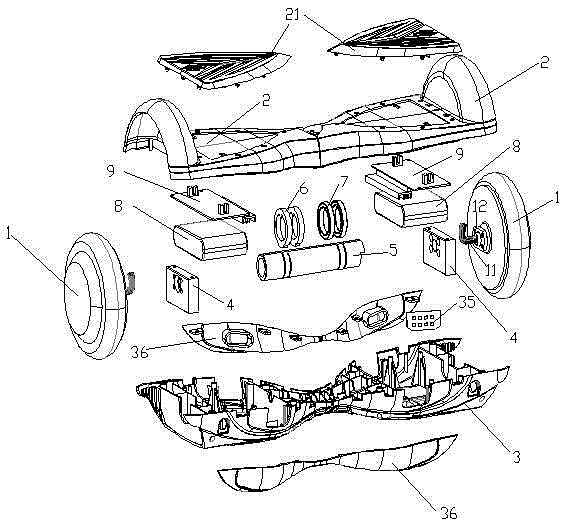

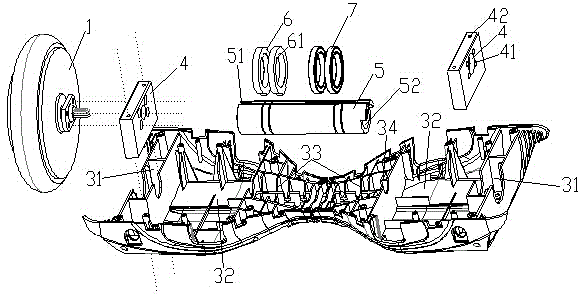

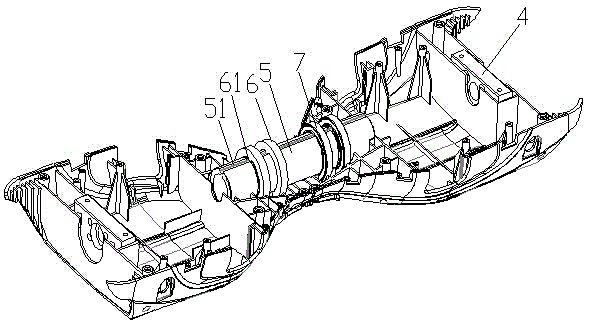

Light two-wheel balance vehicle for children

The invention provides a light two-wheel balance vehicle for children. The vehicle comprises a motor wheel, a left pedal, a right pedal, a battery and a controller. The left pedal and the right pedal each comprise an upper cover and a bearing lower cover. The motor wheels are connected with the bearing lower covers through fixing parts installed in fixing piece grooves. Reinforcing ribs which are crossed in a warp-weft mode are arranged in one end of each bearing lower cover. Shaft grooves are formed in the middles of the reinforcing ribs. The left pedal and the right pedal are connected through a connecting shaft installed in the shaft grooves and achieve relative rotation. According to the light two-wheel balance vehicle, no metal framework is needed; by reasonably arranging the reinforcing ribs and changing the connecting shaft structure, on the basis of ensuring the strength of the pedals, the vehicle body weight is reduced, and portability and user experience are improved. Due to the fact that no metal framework is needed, no mold manufacturing or frame casting technological process for a metal framework is needed, and the product production cost is reduced. The weight of the two-wheel balance vehicle is 3-4 kg, and the two-wheel balance vehicle is suitable for children with the weight smaller than 50 kg.

Owner:深圳维动智能科技有限公司

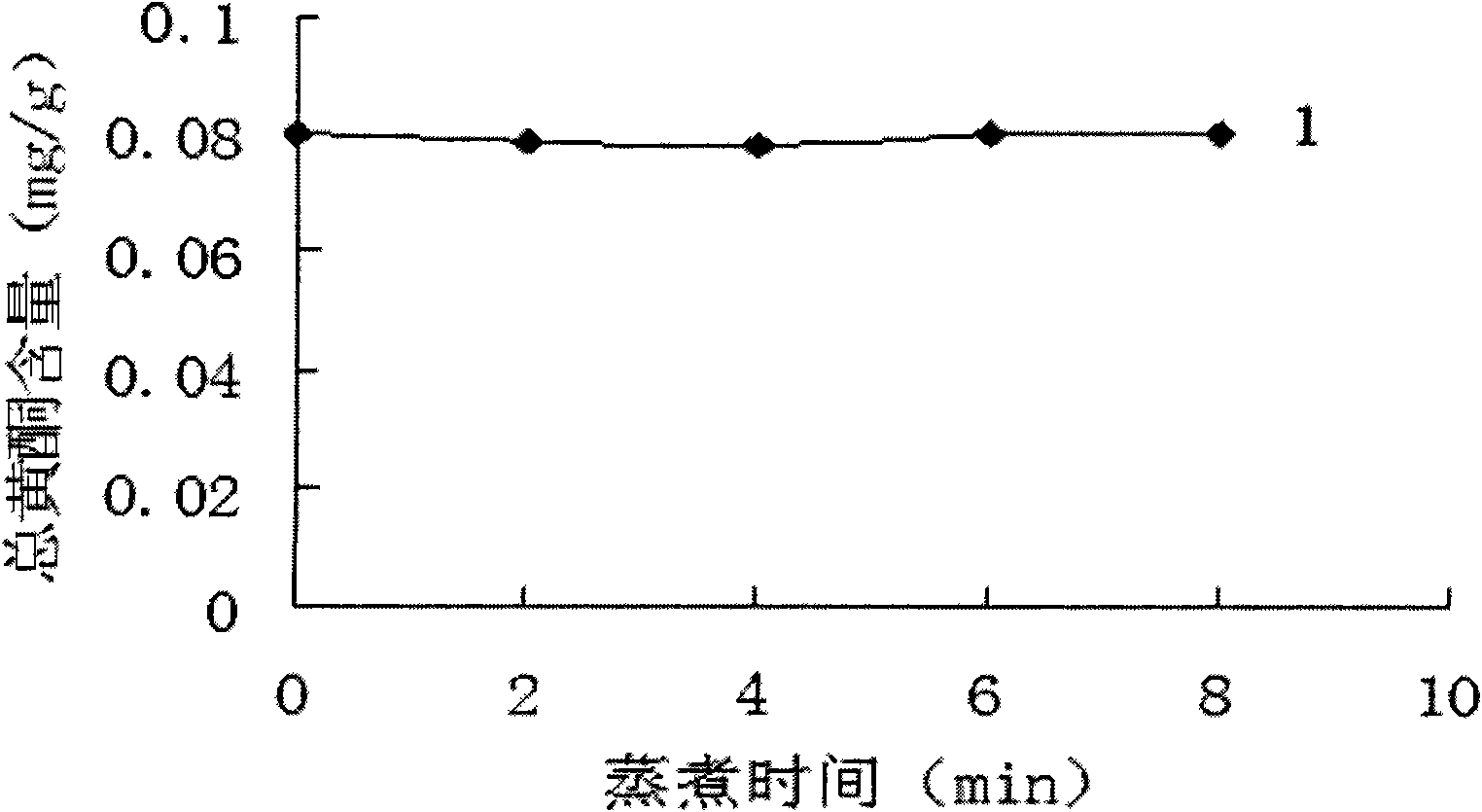

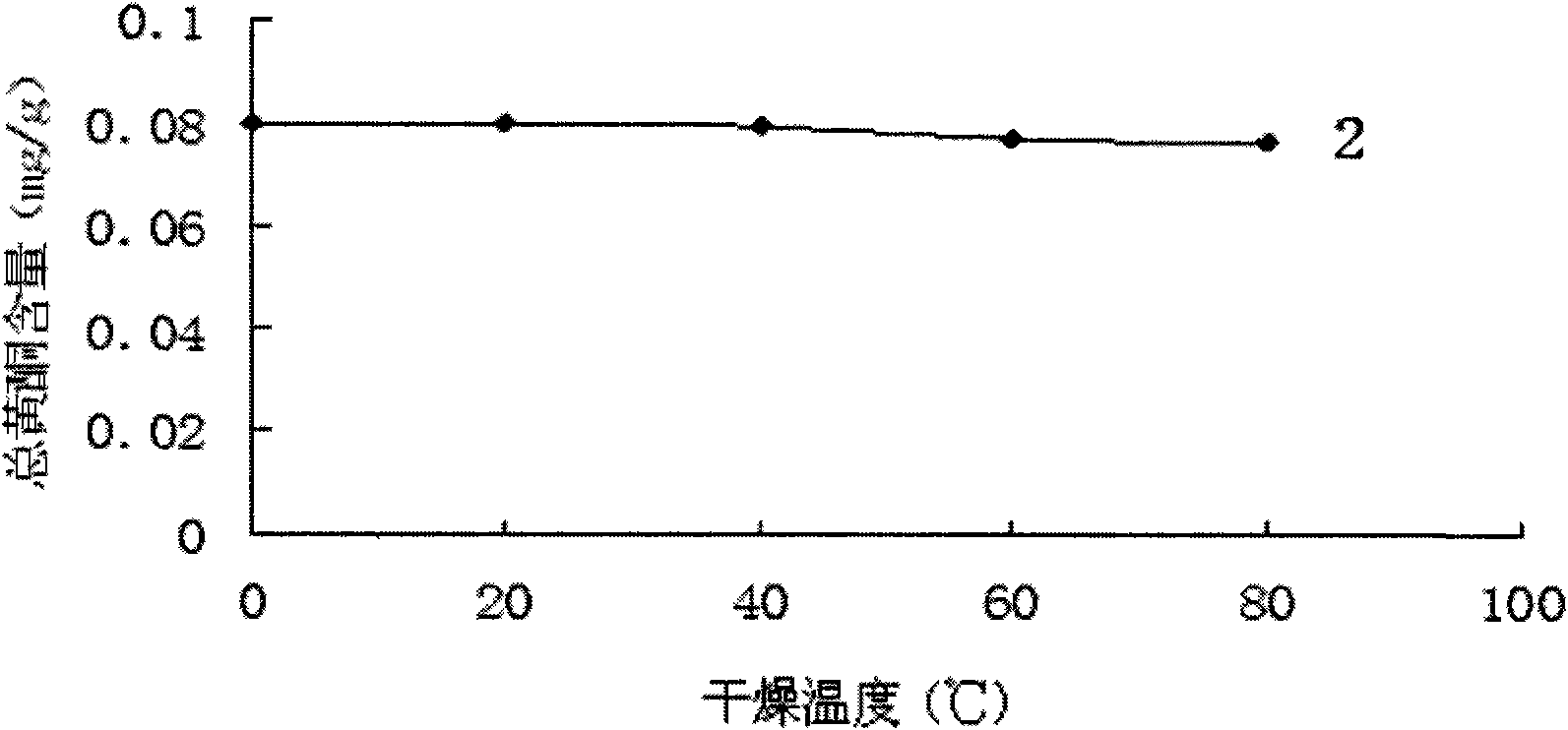

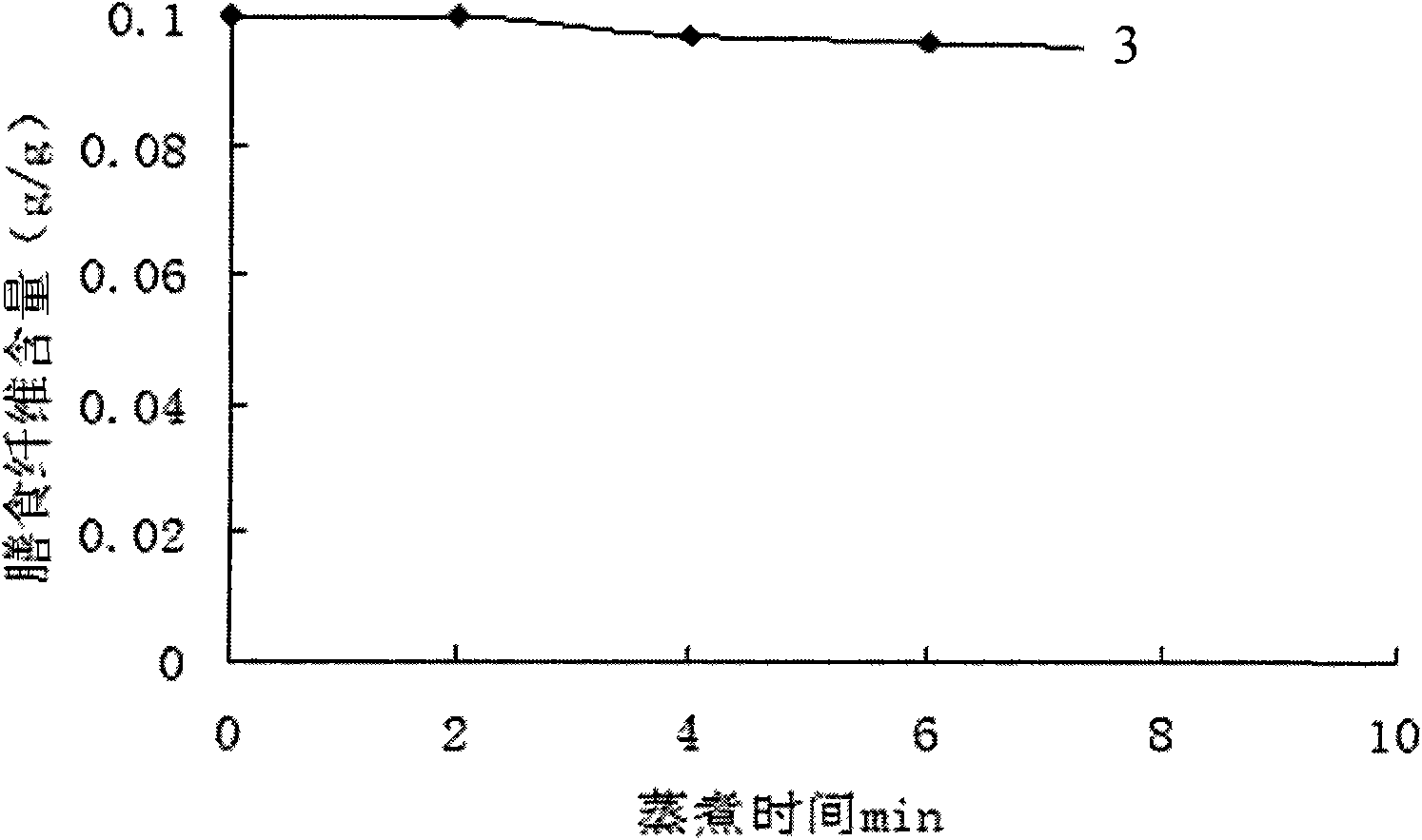

Method for producing water chestnut sheet jelly

The invention discloses a method for producing water chestnut sheet jelly, which comprises the following steps: adding flavone substances and dietary fiber separated and extracted from waste of water chestnut processing into water chestnut starch, corn starch, potato starch and sweet potato starch; stirring the mixture to obtain slurry; and preparing to obtain the water chestnut sheet jelly. The method extracts water chestnut flavones and the dietary fiber from mass processing waste caused by the current water chestnut production to realize waste utilization, and reduces the production cost of the water chestnut sheet jelly by adding accessories such as the corn starch, the potato starch and the sweet potato starch, does not influence the quality of the water chestnut sheet jelly, the content of functional ingredients of the sheet jelly is improved obviously, the stretching force of the water chestnut sheet jelly is increased by 11.5 percent, the boiling loss rate is increased by 25.0 percent, the swelling capacity is reduced by 8.0 percent, the content of flavone compounds is increased by 40mg / 500g, the dietary fiber is increased by 0.1g / g, and the water chestnut sheet jelly has high nutrition and health care values.

Owner:华农(潮州)食品研究院有限公司

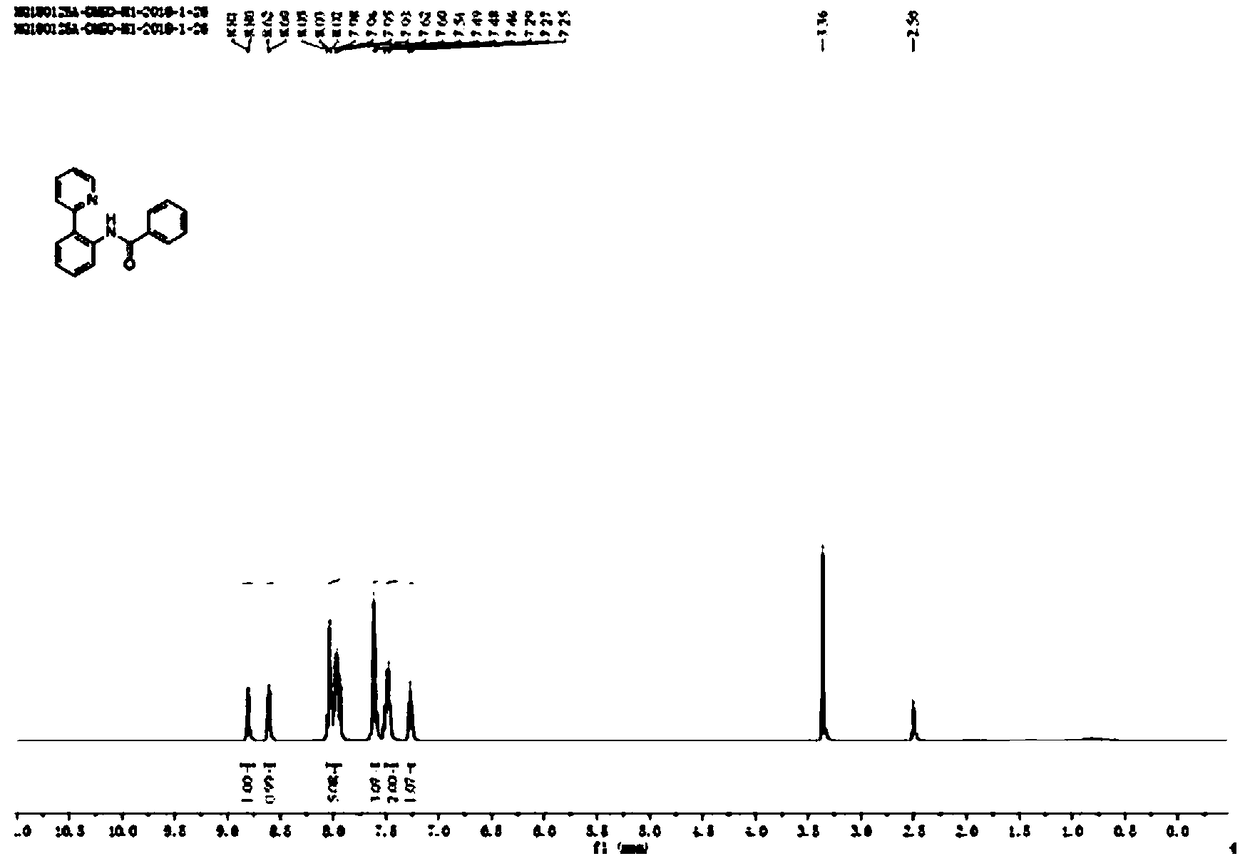

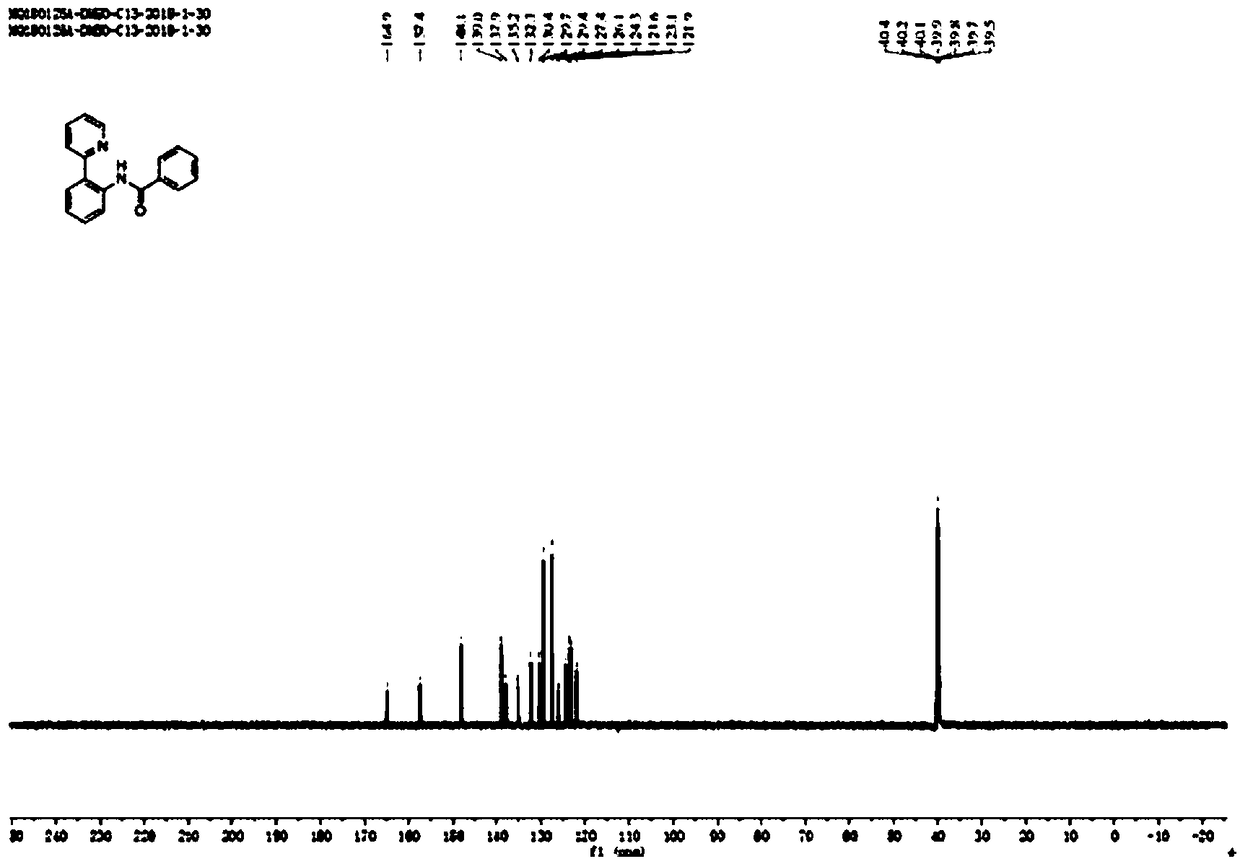

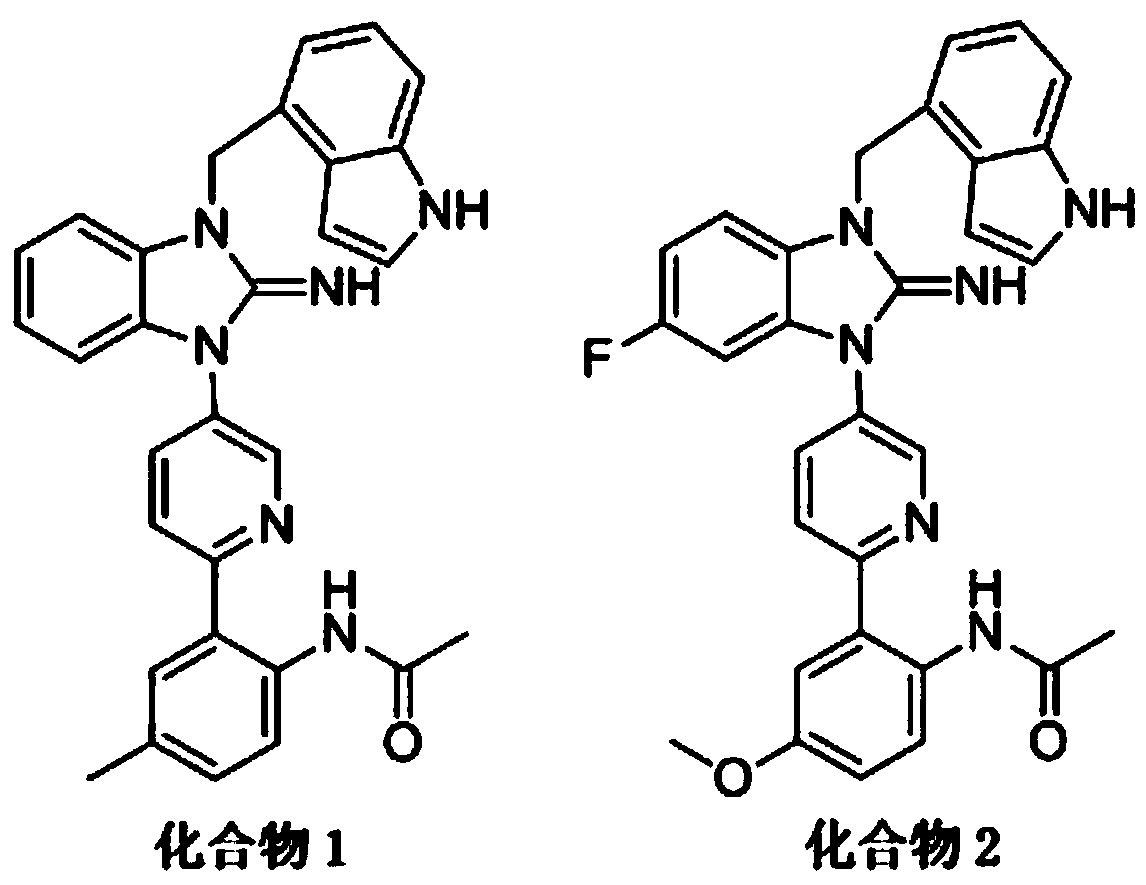

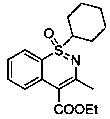

Efficient preparation of o-amidated aryl heterocyclic derivatives by transition metal catalyzed C-H coupling

InactiveCN108640869AAvoid pollutionAtom utilization is highOrganic chemistryChemical recyclingSynthesis methodsSolvent

The invention relates to a novel green synthesis method for preparing o-amidated aryl heterocyclic derivatives from an N1,N3-disubstituted imidazole ionic liquid as a solvent and dioxazolone compoundsas an amide source by transition metal catalyzed C-H coupling reaction. Compared with the traditional technology, the method is safer, simpler, more efficient and more environmentally friendly; a functional group has good tolerance and high yield; the solvent and a catalyst can be recycled, and the cost is greatly reduced; the by-product is merely carbon dioxide, a large amount of waste is avoided, and the atomic utilization rate is increased; pre-activation of a substrate is not needed, the reaction conditions are mild, and the operation difficulty is reduced. An o-amidated aryl heterocyclicderivative molecular library can be obtained efficiently and quickly, natural compounds can be modified later, and accordingly, new drug candidate molecules are synthesized.

Owner:SICHUAN UNIV

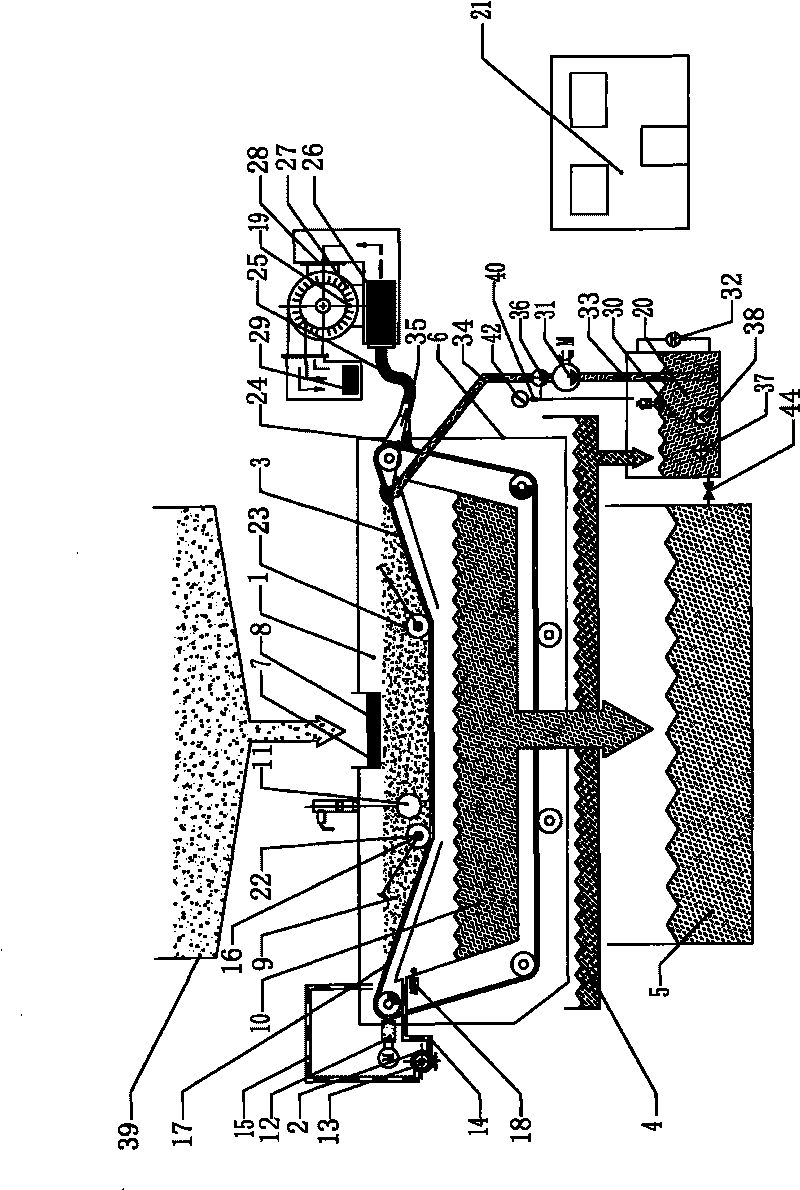

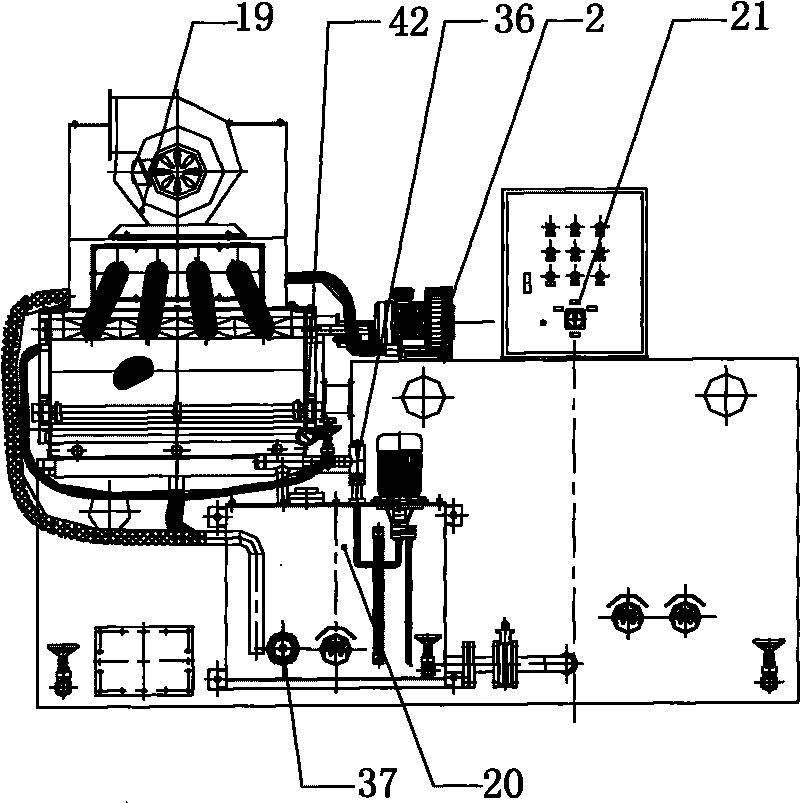

Net-belt type vacuum filter

ActiveCN101708397AReduce use costReduce production finished productMoving filtering element filtersElectrical controlLubrication

The invention discloses a net-belt type vacuum filter, comprising a vacuum filtering box, a vacuum negative pressure device, a conveying chain, an overflowing tray and a lubrication station fuel tank; the vacuum filtering box comprises a box body, the conveying chain is arranged in the box body and divides the inner part of the box body into a soiling solution cavity and a purification liquid cavity, a liquid level control device is arranged in the soiling solution cavity and the vacuum negative pressure device comprises a blower, an air suction pipe and an air exhaust pipe; the net-belt type vacuum filter is characterized in that: net pressing devices are respectively arranged at two sides in the soiling solution cavity, a stainless steel filter screen is paved on the conveying chain, a negative pressure sensor is arranged at the connecting position of the air suction pipe and purification liquid cavity, a soil adsorption device is arranged on the side wall at the other side of the box body, a sewage disposal pump device is arranged below the soil adsorption device, and the liquid level control device, a reduction box device, the blower, the negative pressure sensor, the soil adsorption device and the sewage disposal pump device are all connected with an electrical control box. The net-belt type vacuum filter has high working efficiency, low production cost, automatic cleaning, convenient operation and less pollution.

Owner:南通启重润滑设备有限公司

Self-help betel nut

InactiveCN102823826AReduce production finished productReduce manufacturing costFood preparationBetelNuciferine

The invention relates to a self-help betel nut. The betel nut comprises a betel nut semi-finished product prepared according to the traditional betel nut preparation technology and not coated with betel nut brine, and is characterized by also comprising a betel nut brine which is isolated from the betel nut semi-finished product and independently packaged. The invention also provides the betel nut brine, which is prepared by adding a lotus leaf product and / or lotus leaf extract instead of lime into a conventional betel nut semi-finished product. The betel nut semi-finished product and the betel nut brine are respectively packaged, thus the kinds and edible amount of the brine are chosen by the consumer; thus the ' halogenation ' phenomenon does not occur on the betel nut products, therefore the defects of the existing betel nut product and the brine preparation technology are made up. Moreover, nuciferine and lotus leaf flavone have obvious effects on weight reduction, fat reduction, virus resistance, bacteria inhibition, detoxification and oxidation resistance. The prepared betel nut brine not only extends the kinds of betel nut brine, but also increases the special function of the betel nut brine.

Owner:刘凌

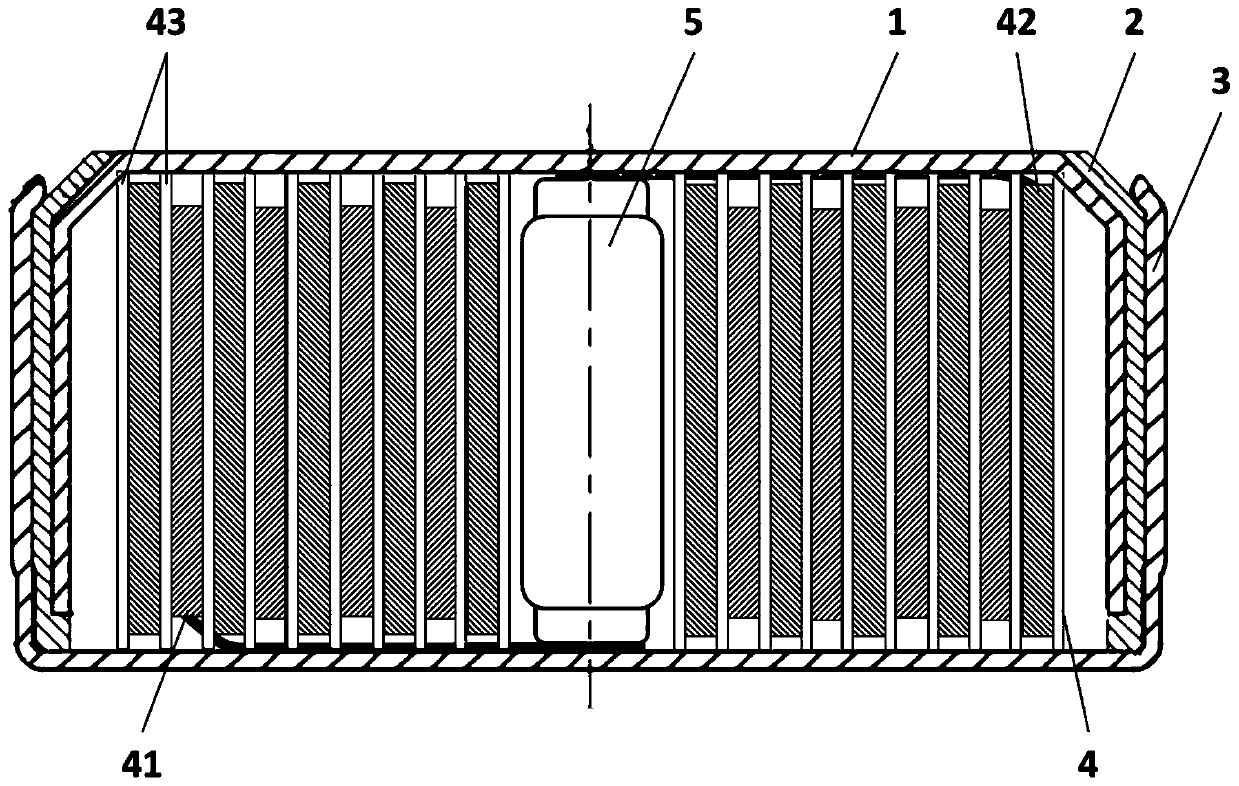

Button lithium secondary battery

PendingCN110364676AGood electrical performanceStable electrical connection requirementsFinal product manufactureCylindrical casing cells/batteryBiochemical engineeringBattery cell

The invention relates to the technical field of lithium batteries, in particular to a button lithium secondary battery and a manufacturing method thereof. The button lithium secondary battery comprises a shell, an insulating ring, a battery cell, a thimble and electrolyte, and is characterized in that the shell comprises an upper shell and a lower shell; the upper shell and the lower shell are both metal shells with openings in one side and hollow interiors; the end faces of the upper shell and the lower shell are two poles of the battery; the insulating ring is located between the upper shelland the lower shell; the battery cell is installed in the shell and comprises a first electrode, a second electrode and a diaphragm arranged between the first electrode and the second electrode; thefirst electrode, the diaphragm, the second electrode and the diaphragm are arranged in sequence; and the first electrode, the diaphragm and the second electrode form the battery cell in a winding mode. According to the invention, the thimble is adopted to achieve the effect of electrically connecting the electrode and the shell; the welding procedure of assembly is omitted; the efficiency is improved; the production cost is reduced; the battery performance can be improved; and the cycle life is prolonged.

Owner:KUNSHAN SYNERGY SCIENTECH CO LTD

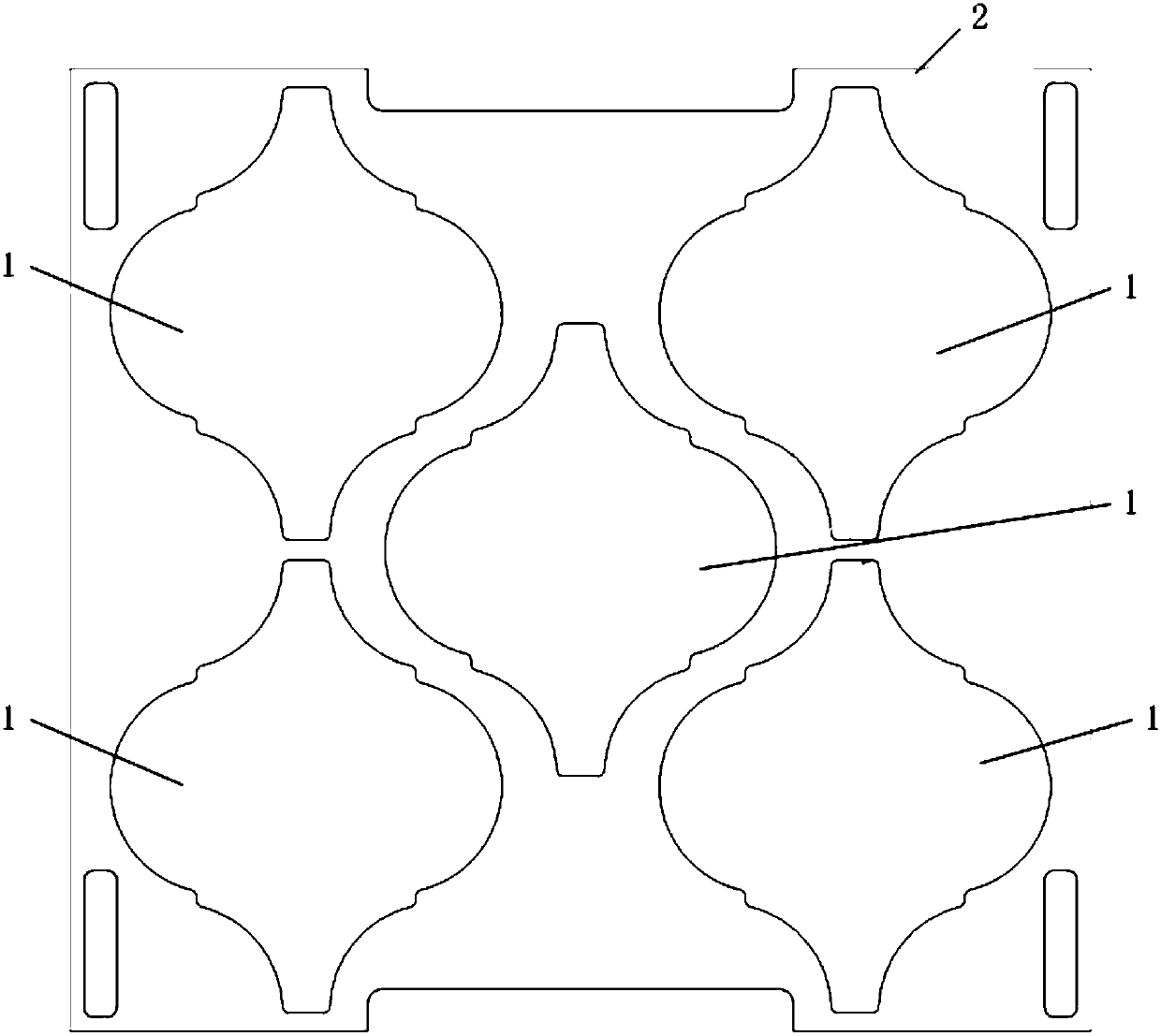

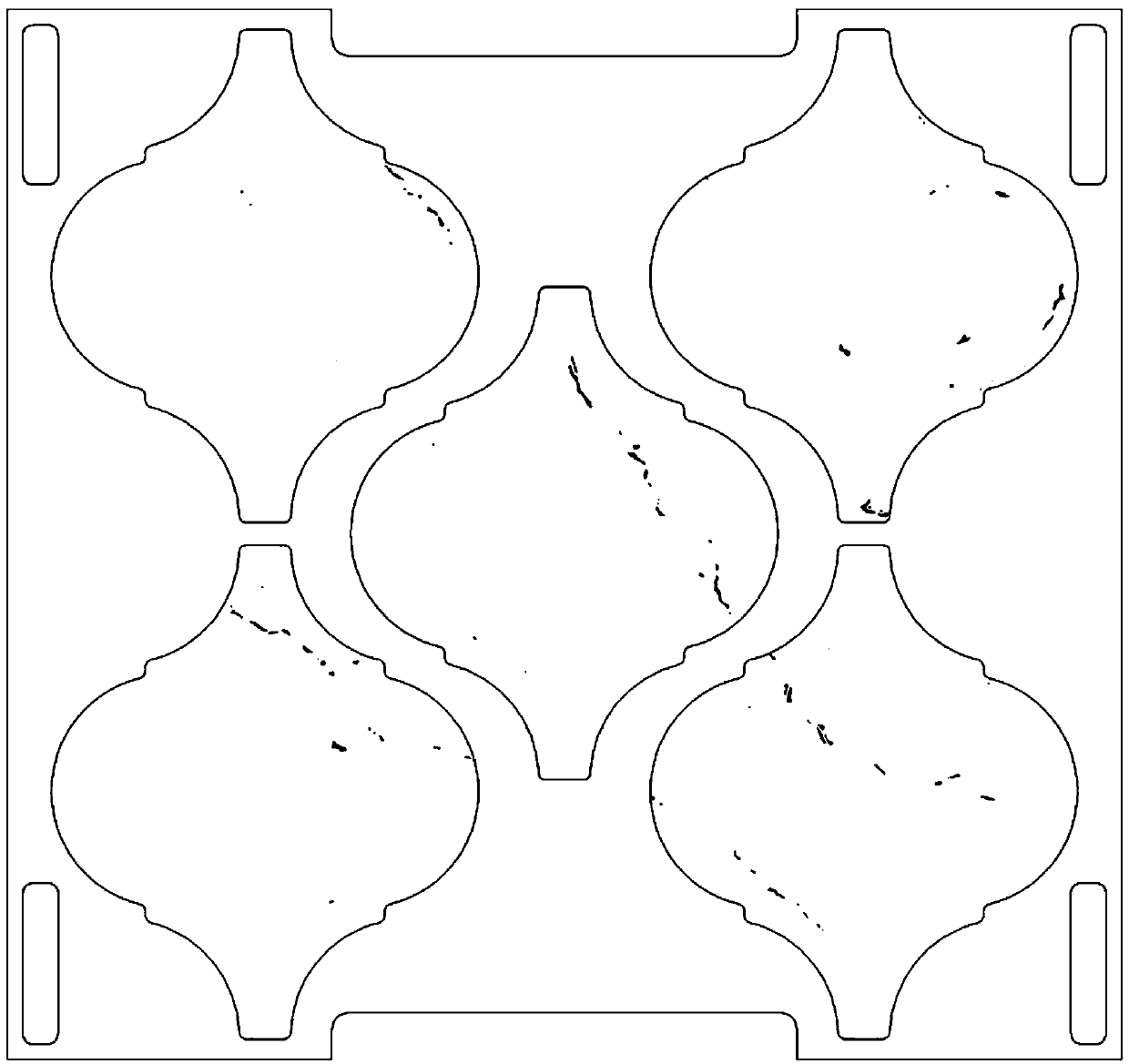

Preparation method of glass mosaic with marble patterns on the whole body

ActiveCN109553297AStrong sense of hierarchyClear structureOrnamental structuresGlass shaping apparatusWhole bodyMaterials science

The invention discloses a preparation method of glass mosaic with marble patterns on the whole body. The preparation method comprises: mixing glass powder and an additive to obtain a mixture; adding water to the mixture, mixing uniformly, granulating, and screening to obtain base billet powder; uniformly mixing a color material and a flux according to a certain ratio to obtain a powdery color material mixture; carrying out multi-layer cloth material treatment on the base billet powder and the color material mixture by a mold, and carrying out pressing molding to obtain a billet; and firing thebillet to obtain the glass mosaic with marble patterns on the whole body. Correspondingly the present invention further discloses the glass mosaic having the marble patterns on the whole body and prepared by the method. With the method of the present invention, the obtained glass mosaic has strong layering effect and clear structure, and can truly reproduce the texture and the pattern of naturalmarble.

Owner:FOSHAN PAMASE BUILDING MATERIAL CO LTD

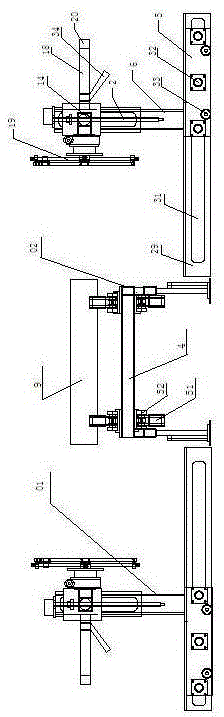

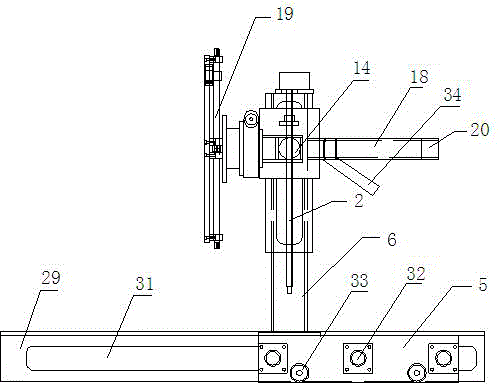

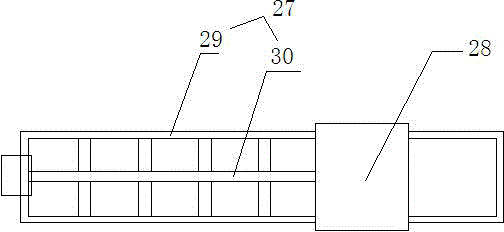

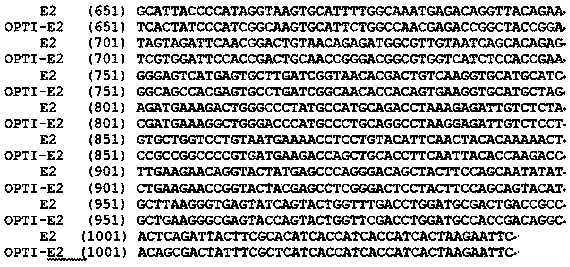

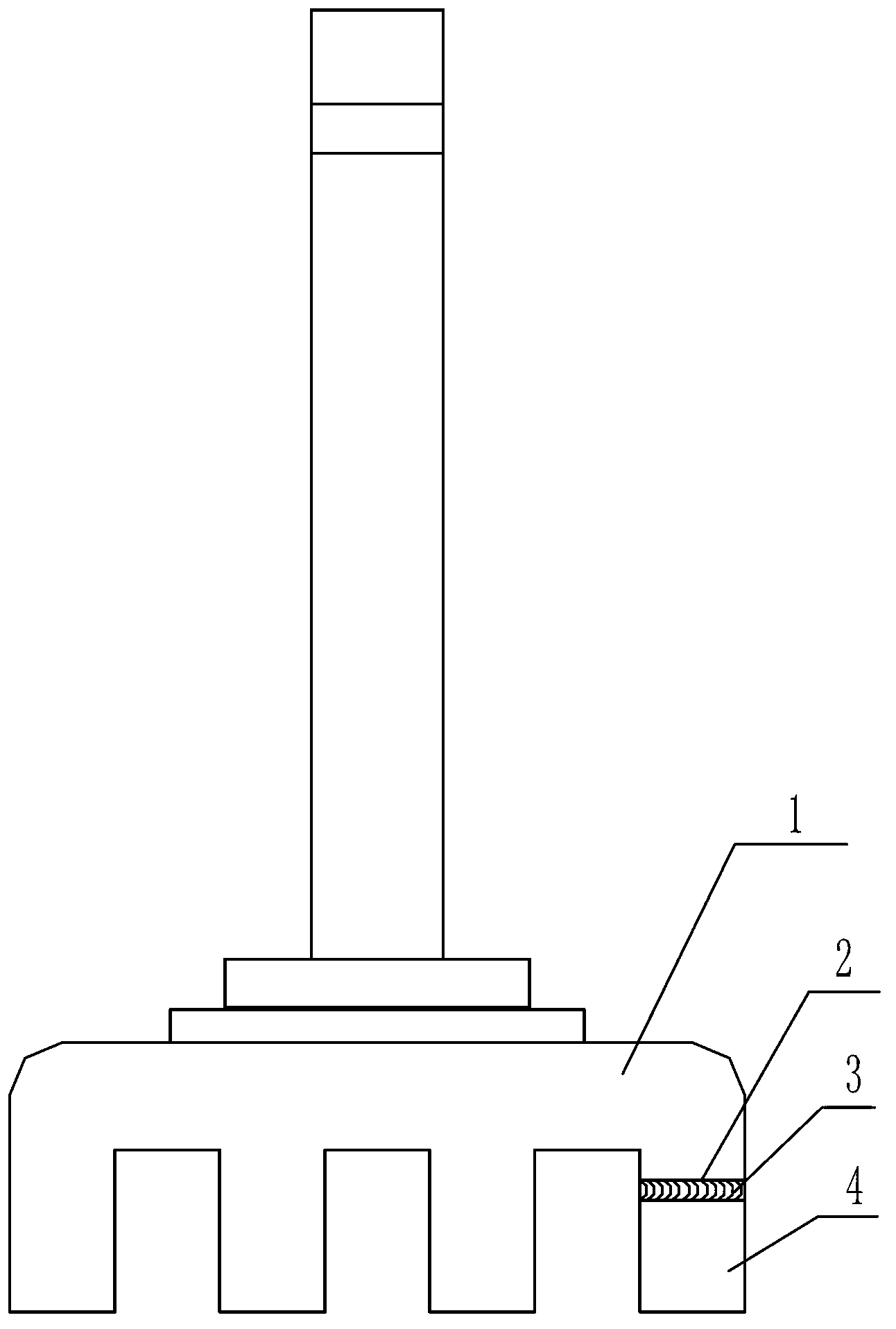

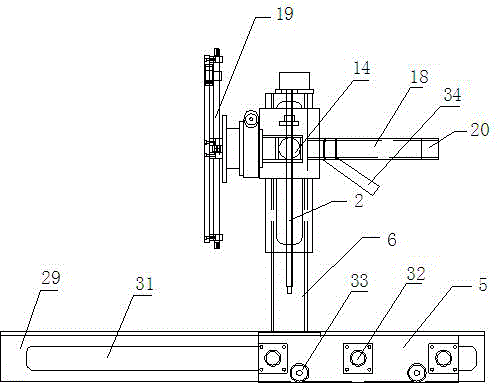

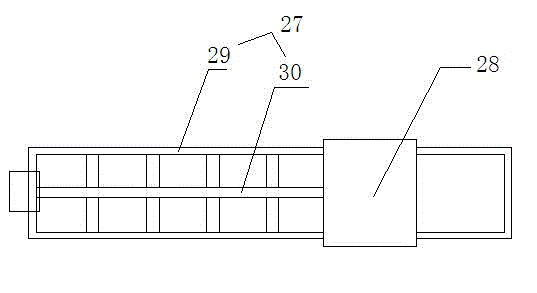

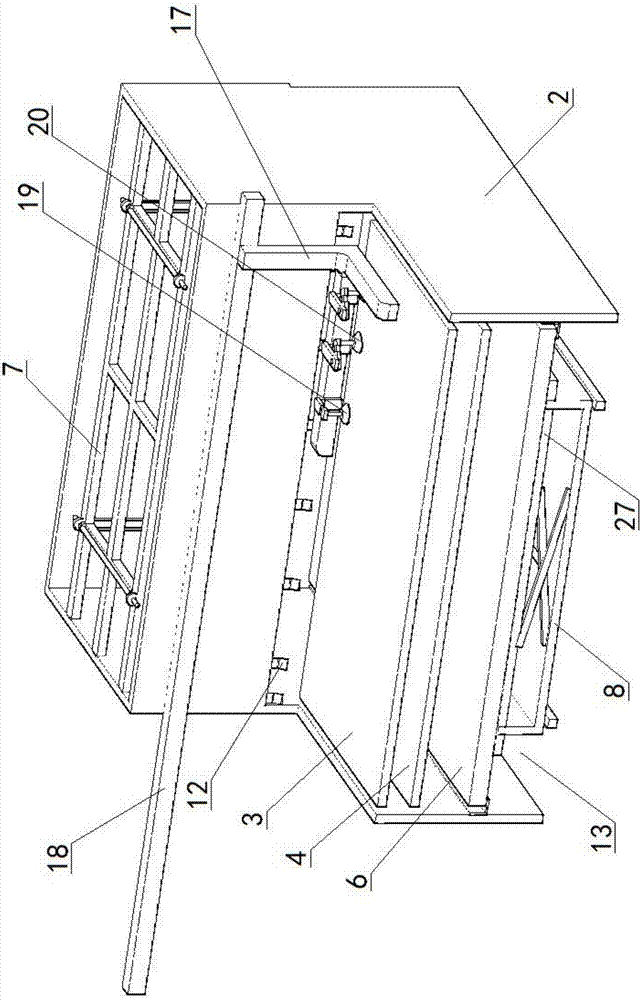

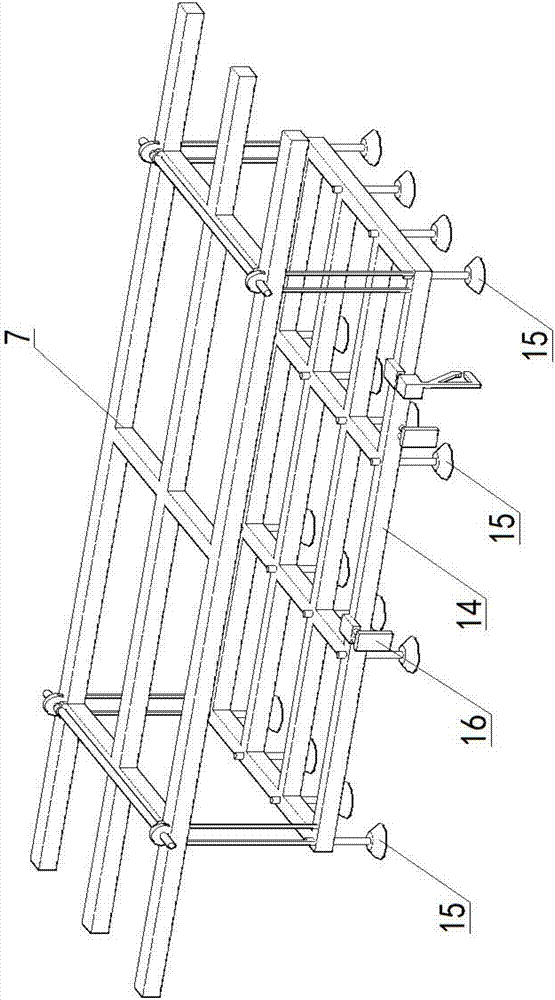

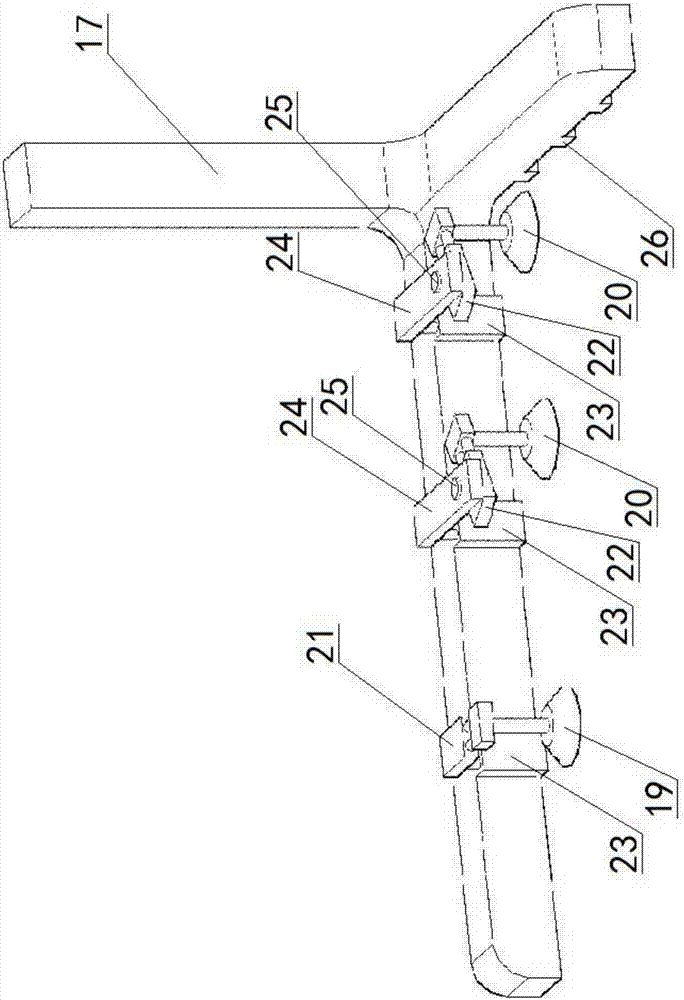

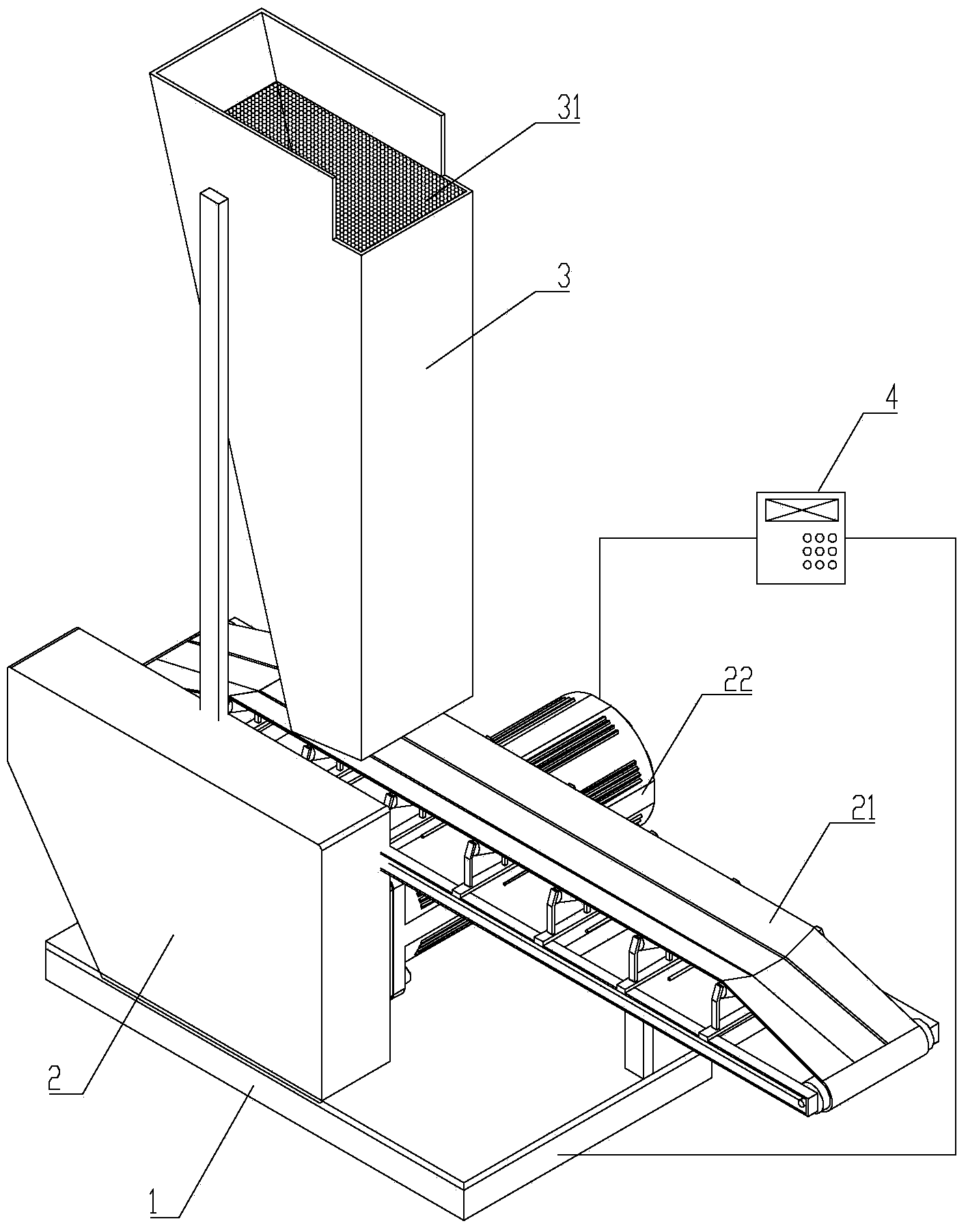

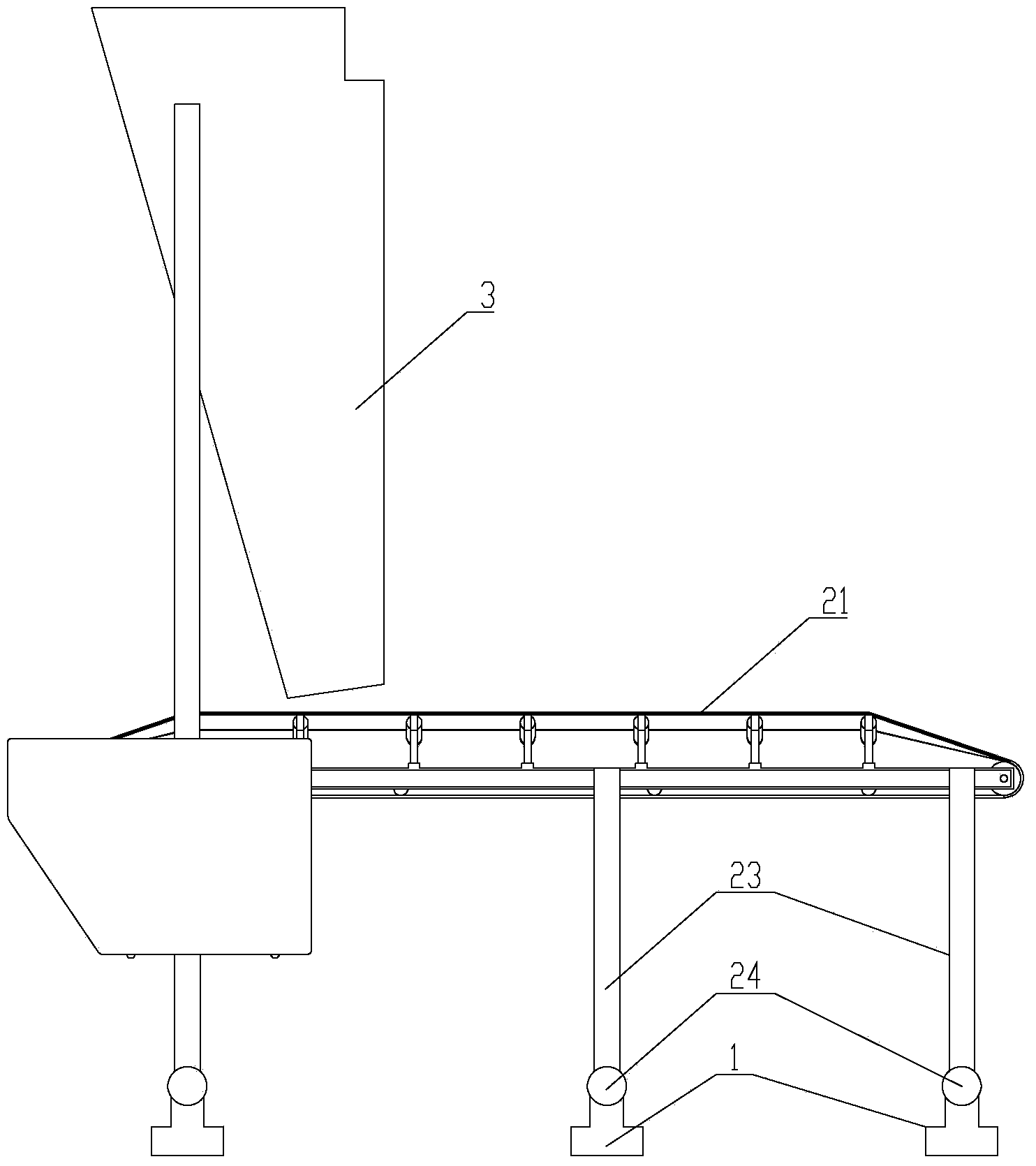

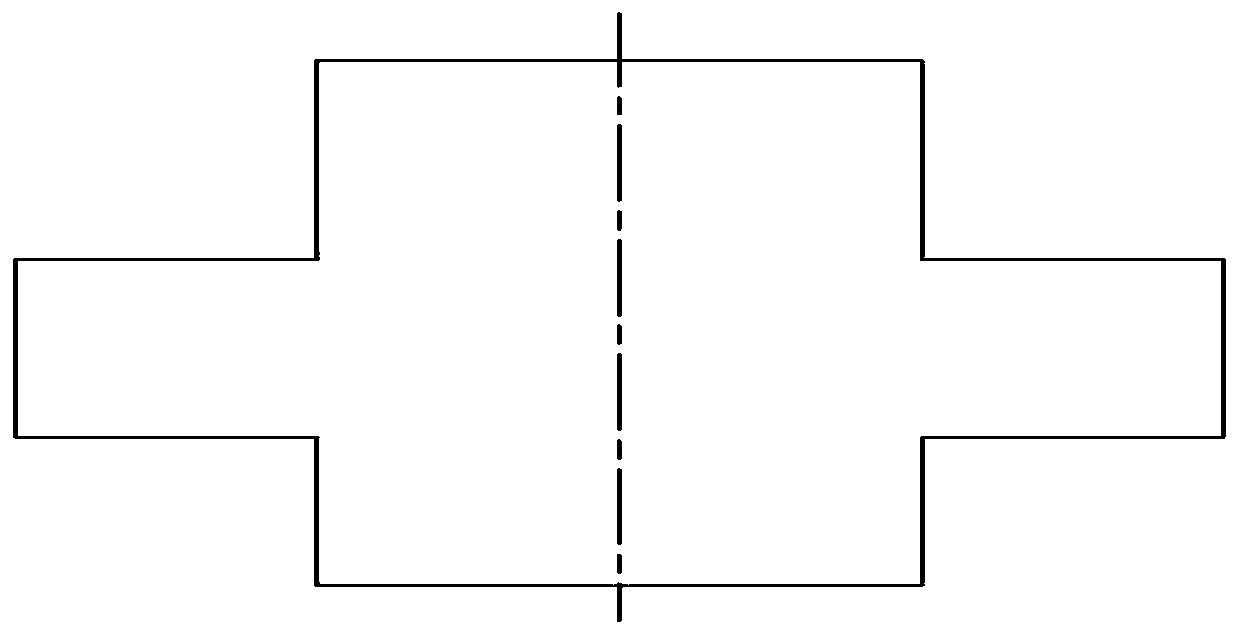

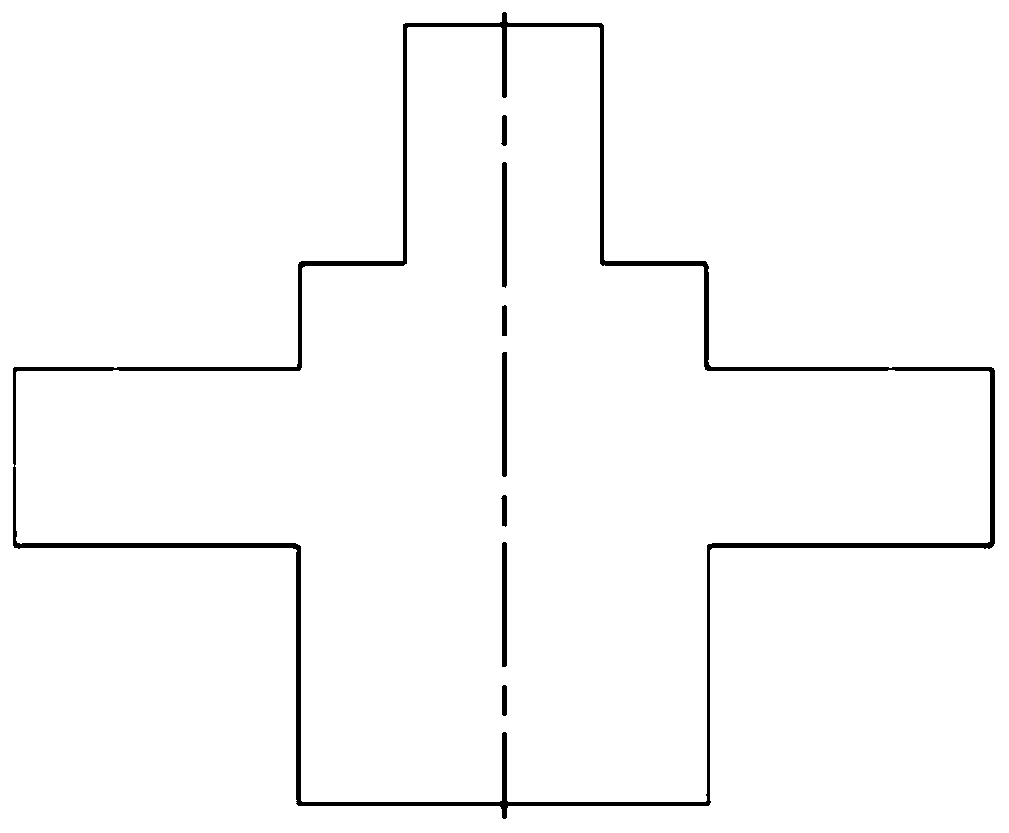

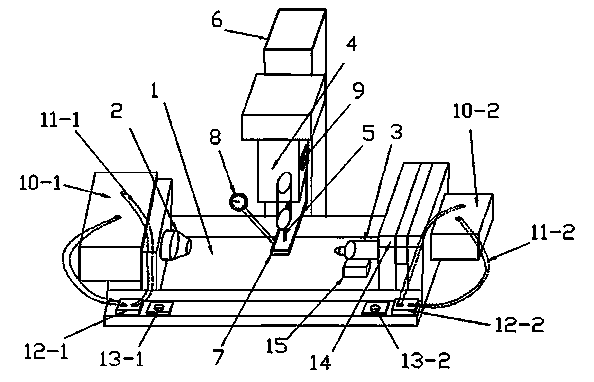

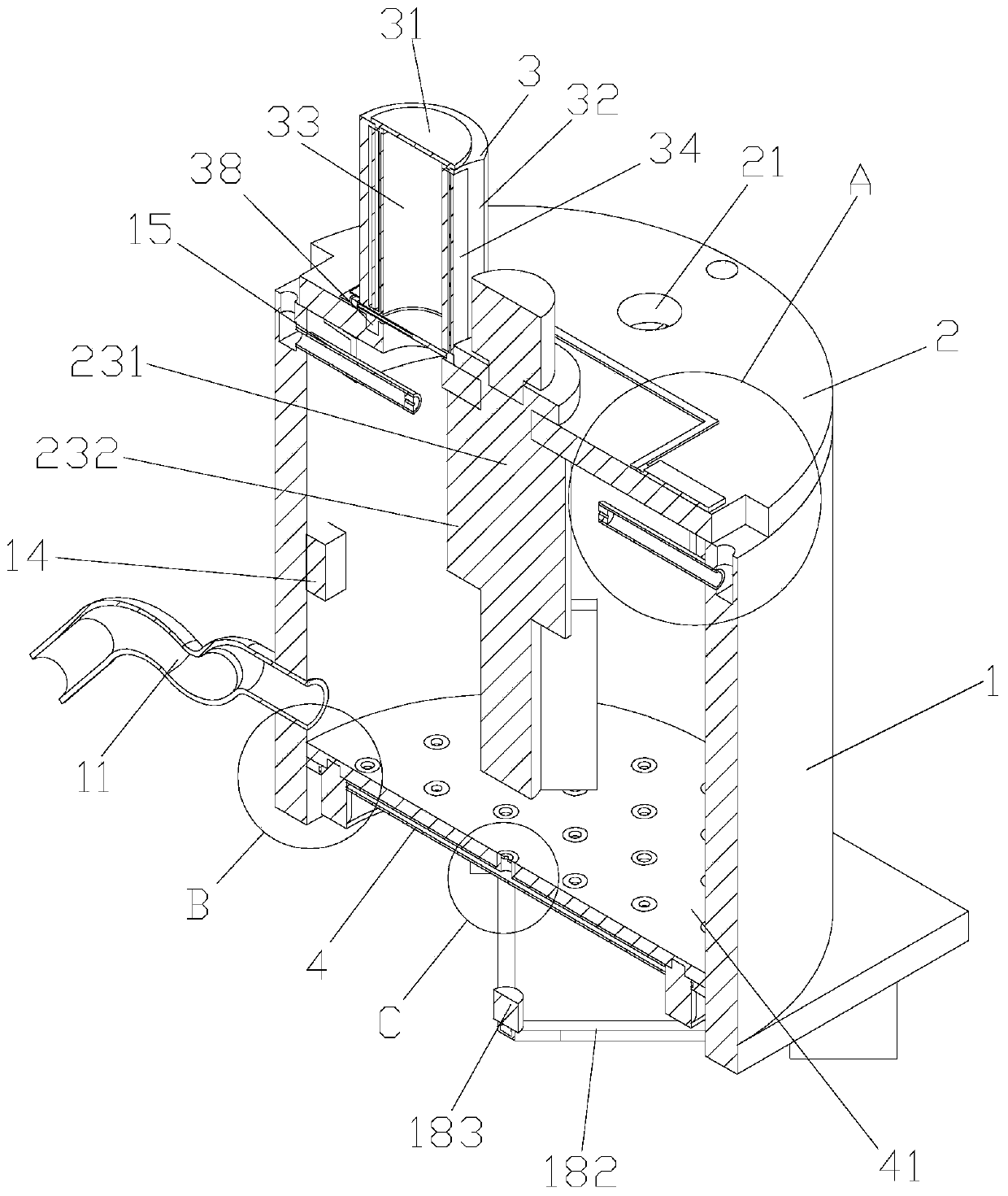

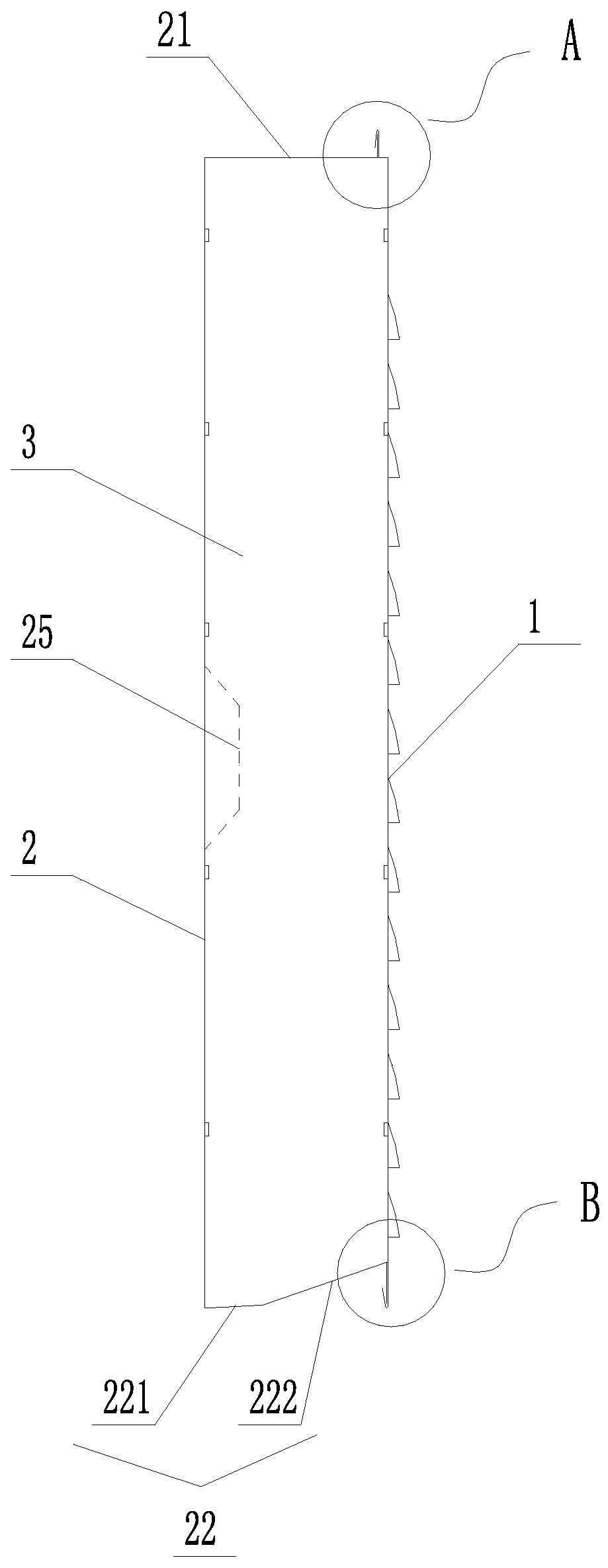

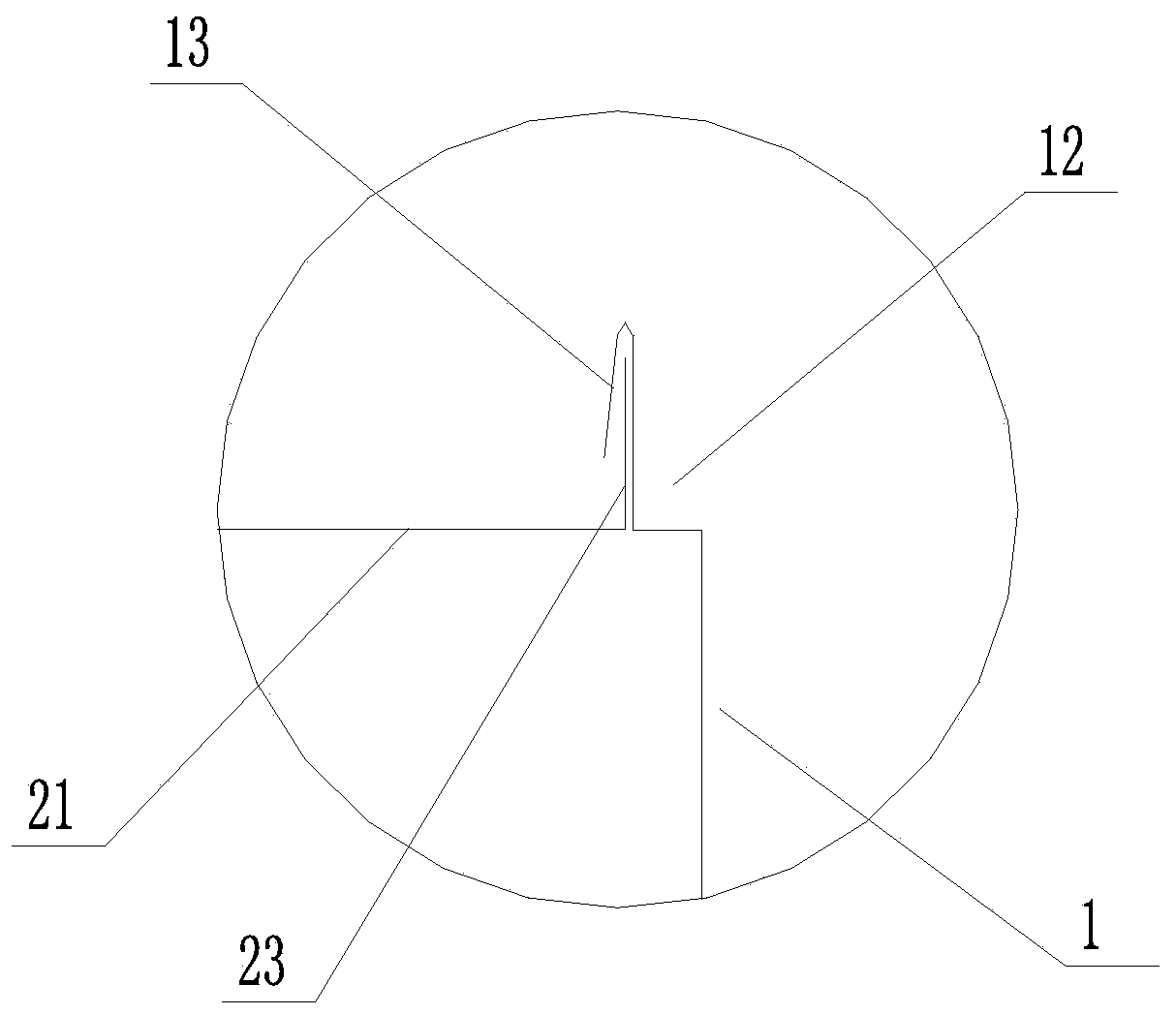

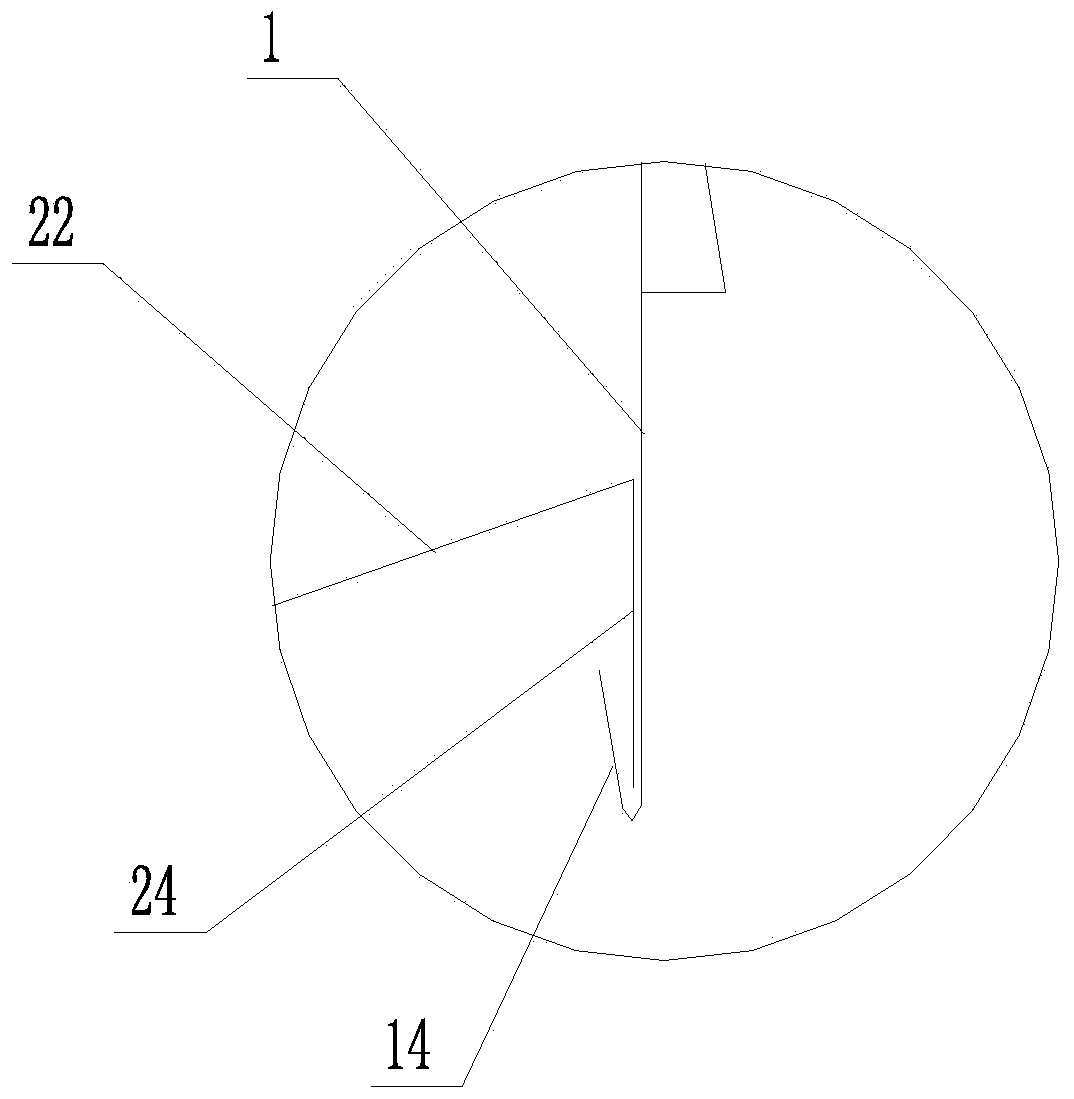

Regulating mechanism for flange assembly machine

ActiveCN104588933ASave manpower and material resourcesReduce production finished productWelding/cutting auxillary devicesAuxillary welding devicesMaterial resourcesEngineering

The invention relates to a regulating mechanism for a flange assembly machine. The regulating mechanism comprises a horizontal displacement mechanism and a grabbing mechanism. The horizontal displacement mechanism comprises a foundation and a telescopic pull rod. The foundation is of a cuboid frame structure. A sliding clamping channel is arranged on each of the two sides of the foundation. The telescopic end of the telescopic pull rod is fixed to the grabbing mechanism. The grabbing mechanism comprises a main frame, a lifting device, a grabbing device and a flange fixing disc. The main frame comprises a base and a frame body, the frame body is fixed on the upper portion of the base, and the flange fixing disc is fixed to the base. The lifting mechanism comprises a lifting sliding rail, a lifting sliding block, a cylinder and a fixed rotating shaft. The grabbing device comprises a supporting arm, a grabbing disc, a rotating motor and a turning motor, and is used for grabbing and conveying flanges to be assembled. The regulating mechanism for the flange assembly machine is convenient to operate, full automatic intelligent operation is adopted by the whole process, manpower and material resources are saved greatly, production cost is saved, and the regulating mechanism is safer and more reliable.

Owner:江苏振光电力设备制造有限公司

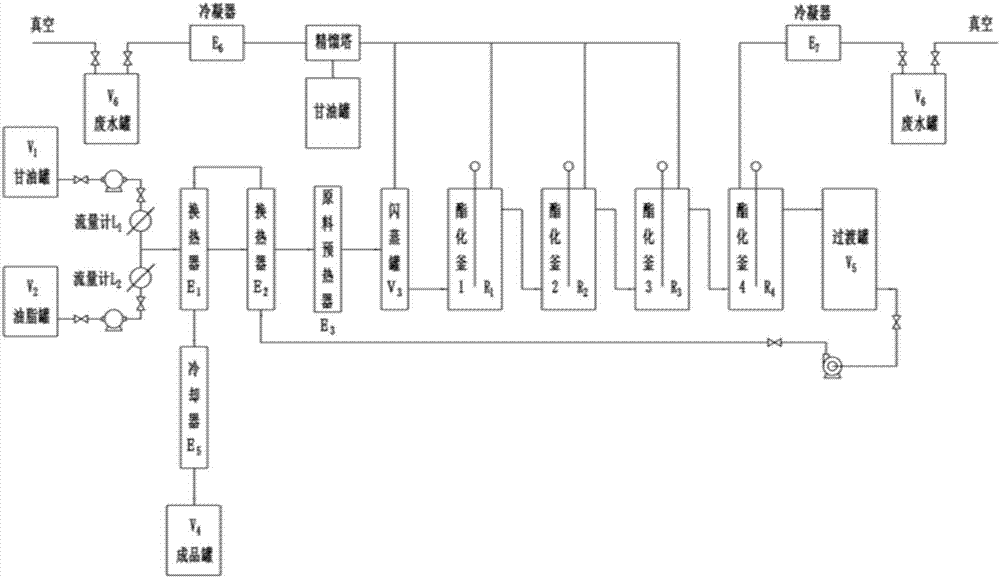

Catalytic-esterification-free acid-degrading process for continuous production of high-acid-value waste oil and fat glycerin

InactiveCN107459997ASolve the problem of meeting the requirements of transesterification for the preparation of biodieselHigh boiling pointBiofuelsLiquid hydrocarbon mixture productionReaction temperatureOil production

A catalytic-esterification-free acid-degrading process for continuous production of high-acid-value waste oil and fat glycerin comprises the steps of raw material mixing and delivery, mixed raw material and finished product heat exchange, mixed raw material preheating after heat exchange, flash evaporation and dehydration of mixed raw materials, continuous esterification reaction and separation of glycerin extracted in the esterification process. The problems of low esterification reaction speed and non-thorough esterification caused by untimely reaction moisture discharging due to low reaction temperature in the process of preparing biodiesel by using high-acid-value waste cooking oil and leftovers in oil production industry and using methyl alcohol as an esterifying agent for pre-esterification and acid decrease are effectively solved, and the problems of device corrosion and environmental pollution brought by a large amount of produced waste acid water due to the fact that sulfuric acid is added to serve as a catalyst in the esterification process is solved. A continuous production process is adopted for esterification reaction, heat exchange of raw materials and finished products is achieved in the continuous process, and the problems of frequent and complicated operation, high labor cost, high production energy consumption, small yield and low efficiency of an intermittent esterification process are solved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

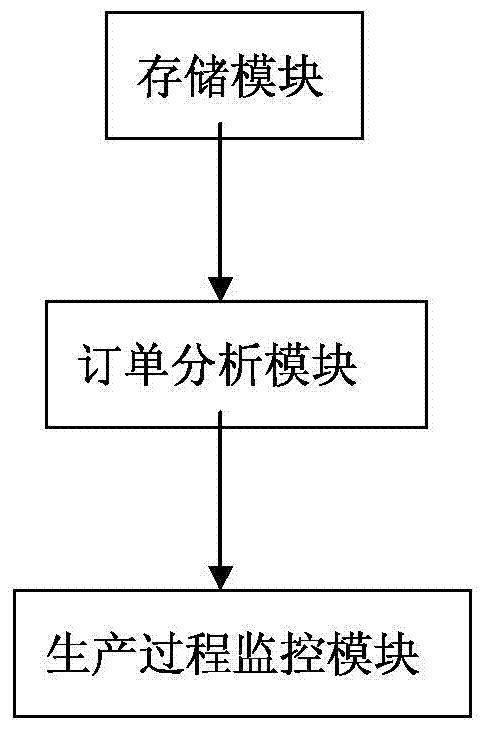

Full life cycle management system of internet of things in discrete manufacturing industry

ActiveCN104504539AImprove processing efficiencyPrecise deliverySensing record carriersResourcesFull life cycleOrder form

The invention provides a full life cycle management system of the internet of things in the discrete manufacturing industry. The full life cycle management system comprises a storage module stored with order information, an order analysis module for discomposing the order information into first order sub-information and second order sub-information and meanwhile storing the first order sub-information and the second order sub-information in the storage module, a first RFID card sender for writing the first order sub-information into corresponding first RFID cards, a card reader for reading the first order sub-information in each corresponding first RFID card and second order sub-information and second RFID card information in second RFID cards and uploading the information to the storage module, a controller for retrieving corresponding second order sub-information from the storage module, sending the second order sub-information to second RFID cards and writing the second order sub-information into the second RFID cards. The full life cycle management system establishes a perfect and integrated production quality monitoring and management system suitable for the discrete manufacturing industry.

Owner:GUANGXI UNIVERSITY OF FINANCE AND ECONOMICS +1

Centrifugal concrete pile die production process

The invention relates to a method for producing eccentric concrete post mould, wherein it comprises that: first, preparing needed elements as tube wall, longitudinal bar, annular bar, bolt, end plate, etc; then connecting and welding said elements; at least, finely processing half steel mould and whole mould, and turning integrity, to obtain the final product. The matched board and tube wall are cold drawn to fine size via cold drawer and mould, to save material and improve quality; the end plate and rolling wheel are made from plate bended by compressor to save steel.

Owner:JIANGSU HAI HENG BUILDING MATERIAL MACHINERY CO LTD

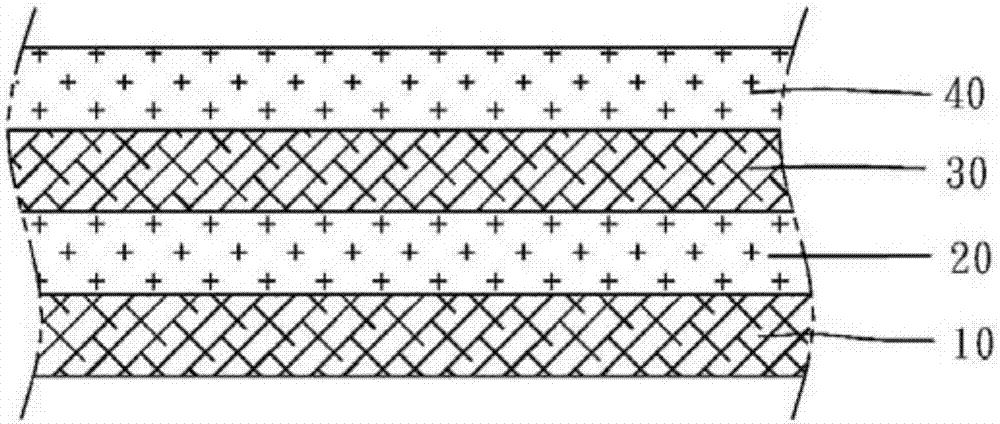

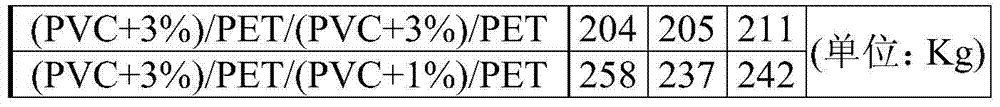

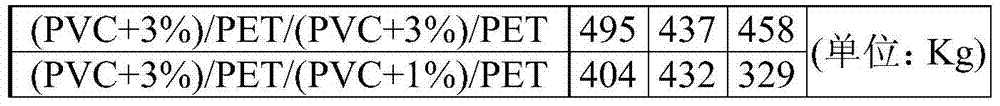

Running belt finished product or semi-finished product and manufacturing method thereof

InactiveCN106983987AInterface Strength ImprovementInterface strength solutionSynthetic resin layered productsClosed loop articlesPolyvinyl chloridePolyamide

The invention provides a finished or semi-finished running belt and its preparation method, which mainly uses sub-micron or nano-powders with high thermal diffusivity and low thermal conductivity, first disperses the surface active agent, and then adds it to the polymer in a gradually quantitative manner. Propylene (PP), polyethylene (PE), polyamide (PA), polyurethane (PU), polyvinyl chloride (PVC), artificial rubber or natural rubber or their solvents, using a mixing mixer Fully and uniformly mix high thermal diffusivity and low thermal conductivity sub-micron or nano-powders in the base material or solvent, and then after pasting, covering or impregnating pressure-absorbing woven fabrics, knitted fabrics or non-woven fabrics, and finally drying and curing, Manufactured into a running belt with multiple functions such as heat dissipation and prolonging service life.

Owner:乔山健身器材(上海)有限公司

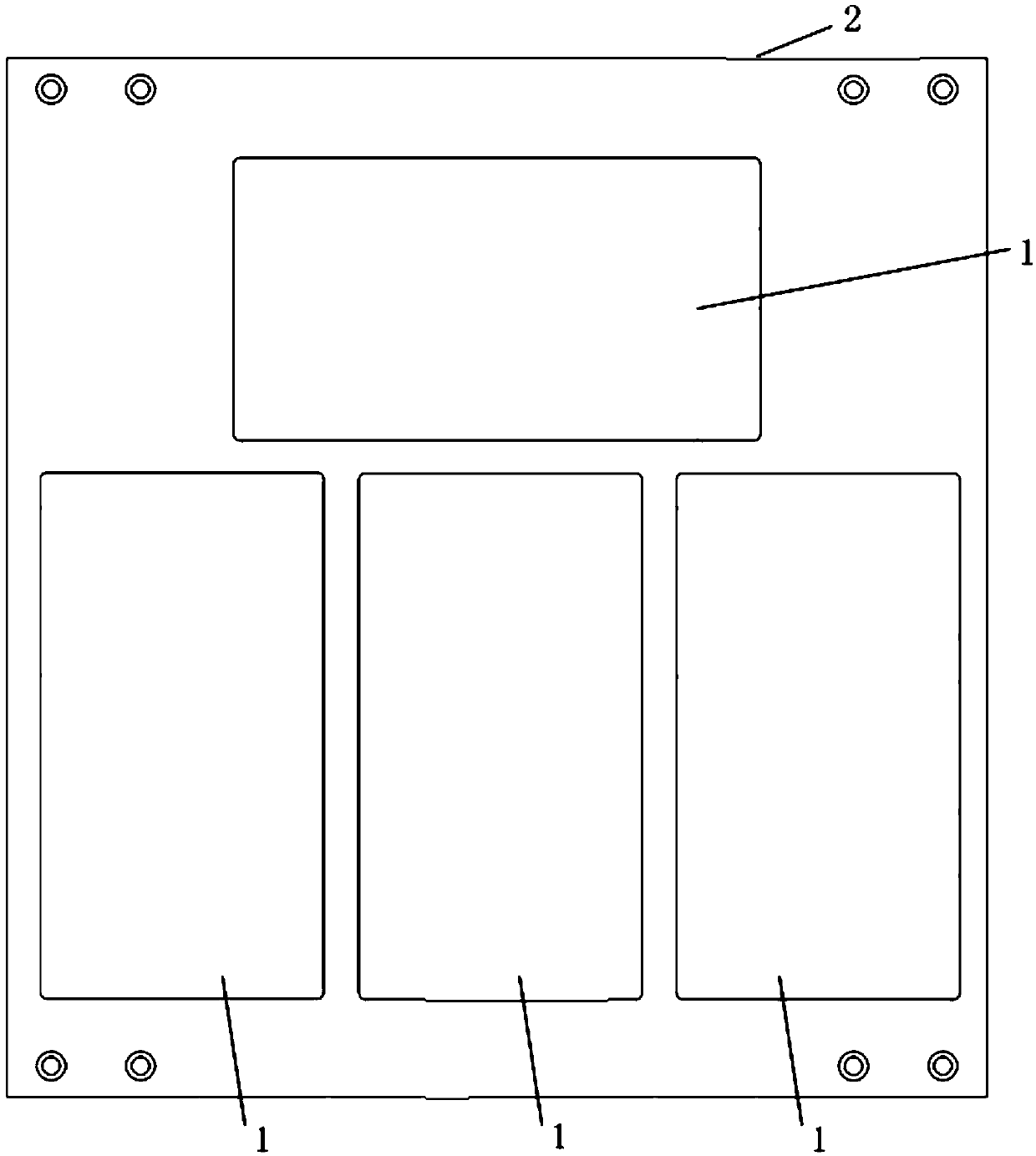

Automatic feeding and discharging device for sheet metal for numerical control punching machine

ActiveCN107052185AAvoid safety hazardsGuaranteed positioning accuracyMetal-working feeding devicesPositioning devicesNumerical controlPunching

The invention discloses an automatic feeding and discharging device for sheet metal for a numerical control punching machine. The automatic feeding and discharging device for the sheet metal for the numerical control punching machine is characterized by comprising a machine frame, a feeding table board, a discharging table board, a raw material tray, a waste material tray, a sucker frame, a carrying mechanical arm and a lifting and walking trolley; the feeding table board is arranged in the machine frame in a manner of sliding forwards and backwards and is used for loading material boards; the discharging table board is arranged in the machine frame in a manner of sliding forwards and backwards and is used for loading semi-finished boards, and the semi-finished boards become waste material boards after processed; the waste material tray is positioned below the discharging table board and is used for loading the waste material boards; the raw material tray is erected in a lower space and is used for stacking the multiple material boards; a frame body of the sucker frame is connected to the machine frame in a lifting mode, and a plurality of material sucking suckers are arranged at the bottom of the frame body of the sucker frame and are used for sucking the material boards on the raw material tray; the carrying mechanical arm is arranged above the feeding table board in a suspended mode and is used for feeding and discharging carrying and position precision adjusting of the material boards; and the lifting and walking trolley moves forwards and backwards at the bottom of the machine frame and is provided with a lifting platform, and the lifting platform is used for supporting the waste material tray or the raw material tray. The automatic feeding and discharging device for the sheet metal for the numerical control punching machine has the advantages that time and labor are saved, the working efficiency is high, and reliability is high.

Owner:金德精密配件(苏州)有限公司

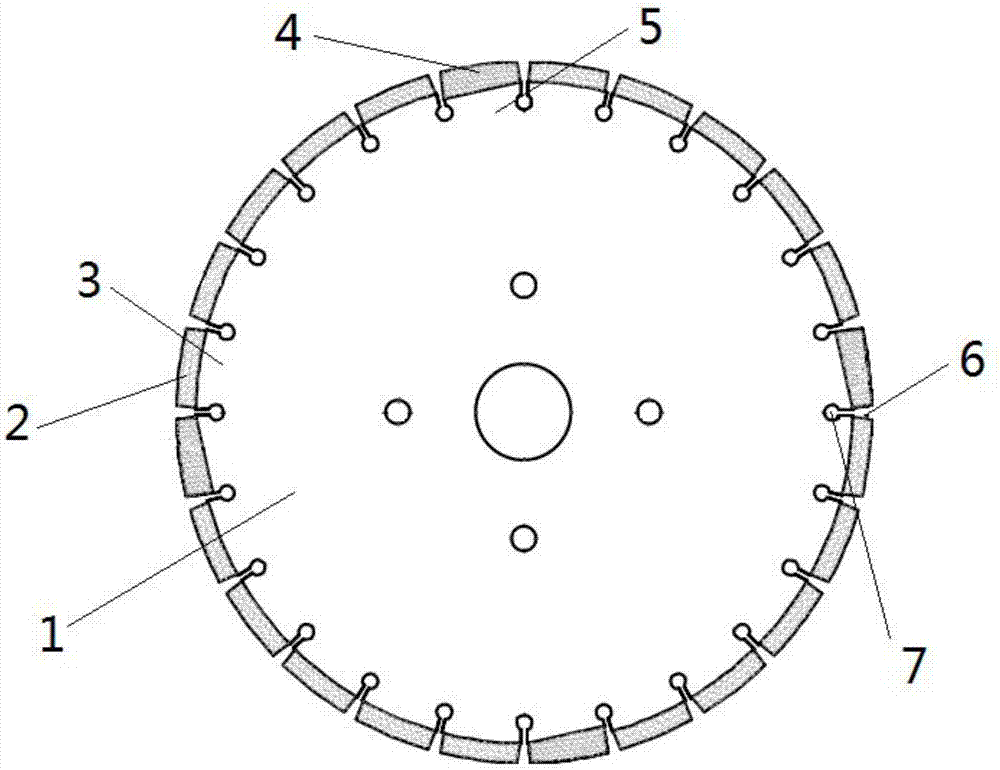

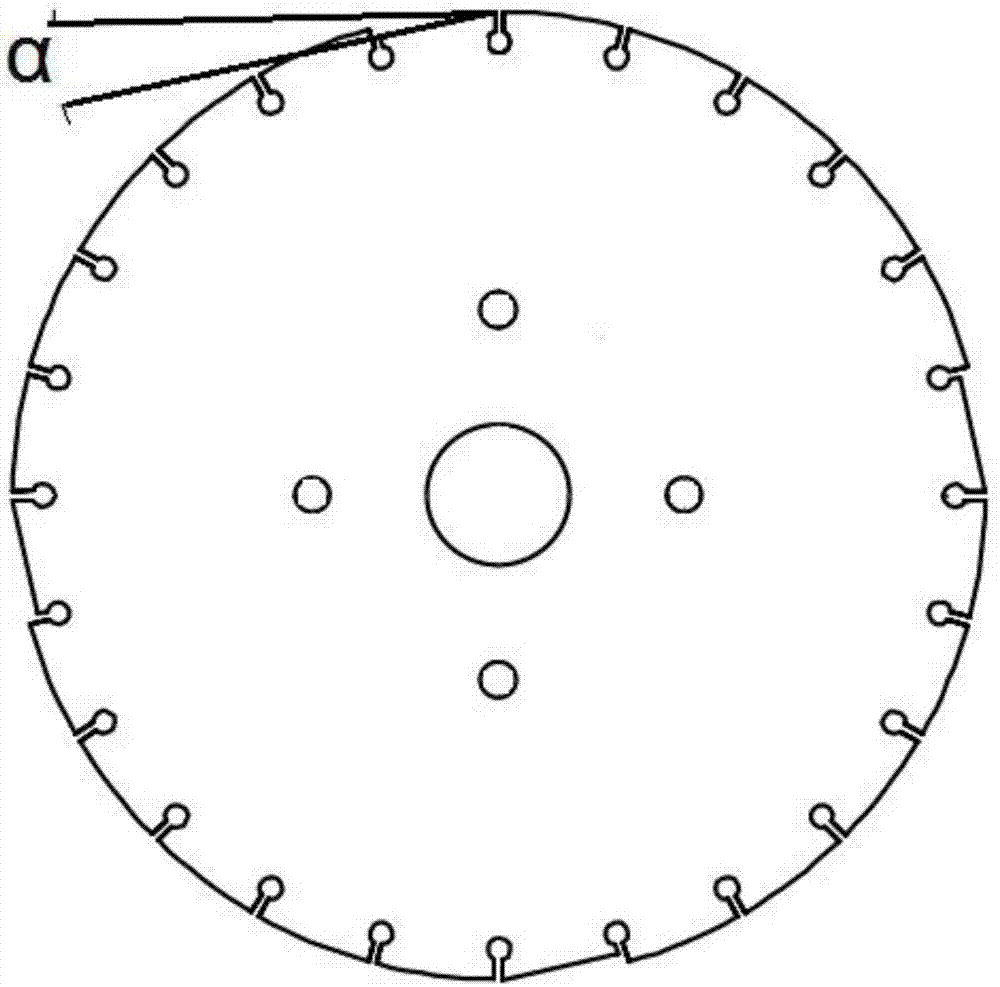

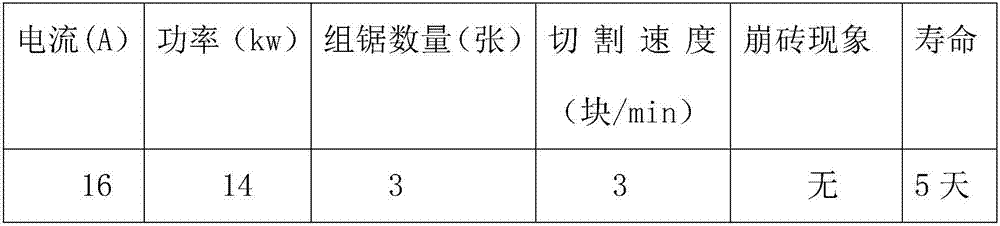

Formula for manufacturing of blank body of combined saw blade tip used for cutting black bricks and red bricks

InactiveCN107262709AImprove Chip EvacuationGuarantee personal safetyStone-like material working toolsBrickIron powder

The invention discloses a formula for manufacturing of a blank body of a combined saw blade tip used for cutting black bricks and red bricks and relates to the field of diamond saw blades. According to the formula, the blank body is formed by mixing diamond and metal powder and is characterized in that the concentration of the diamond is 20-35%, and the metal powder is prepared from the following components of, by weight, 25-50% of iron-copper-tin alloy powder, 15-30% of copper powder, 2-6% of tin powder, 5-15% of nickel powder, 2-10% of cobalt powder, 2-5% of 663 bronze powder and the balance iron powder in proportion. When the multiple saw blades manufactured according to the formula are used in a combined mode, the cutting speed is high, the cutting effect is good, and the problems that an existing saw blade is prone to breaking bricks during cutting, and the service life is short are solved.

Owner:河北小蜜蜂工具集团有限公司

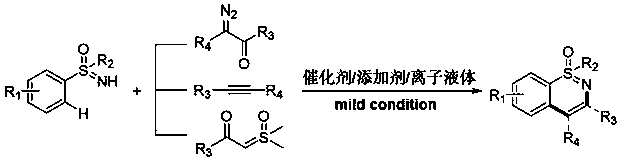

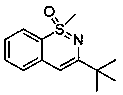

Novel green synthetic method for 1,2-benzothiazine derivative through transition metal catalyzed C-H activation/cyclization

ActiveCN110105305AAvoid pollutionReduce production finished productOrganic chemistryChemical recyclingPtru catalystAlkyne

The invention relates to a novel green synthetic method. According to the method, N1,N3-disubstituted imidazole type ionic liquid is taken as a solvent, NH-sulfoximine is taken as a raw material, a diazo compound, alkyne and sulfur ylide are taken as coupling reagents, and a 1,2-benzothiazine derivative is mildly and efficiently synthesized through a transition metal catalyzed C-H activation / cyclization reaction. Compared with other technologies, the condition is milder, the operation is simple, the method is safe, and the environmental friendliness is achieved; the catalytic activity is high,the reaction yield is high, and the application range of substrates is wide; the solvent and catalysts can be recycled, so that the reaction cost is reduced.

Owner:SICHUAN UNIV

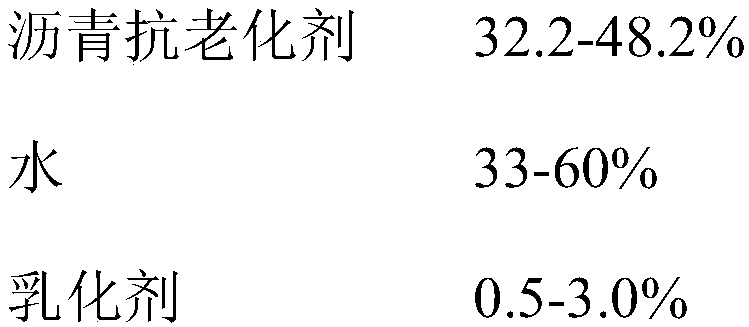

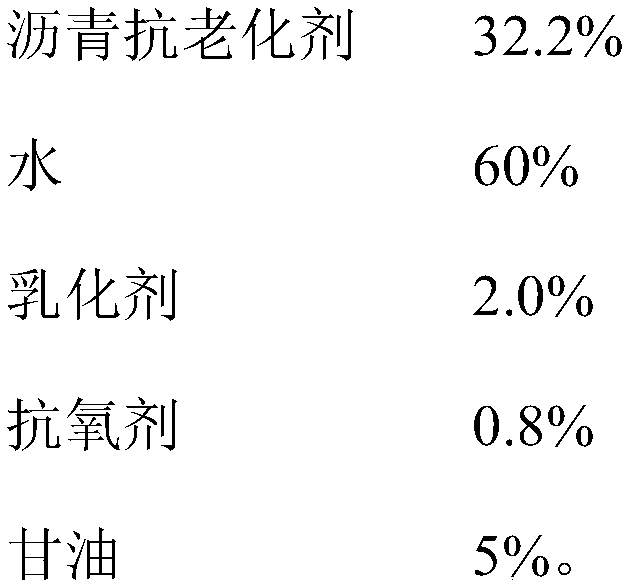

Asphalt pavement roller isolating agent as well as preparation method and test method thereof

The invention relates to an asphalt pavement roller isolating agent as well as a preparation method and a test method thereof. The asphalt pavement roller isolating agent comprises the following components in percentage by weight: 32.2-48.2% of an asphalt anti-aging agent, 33-60% of water, 0.5-3.0% of an emulsifier, 0.3-0.8% of an antioxidant and 5-15% of glycerin. The preparation method of the asphalt pavement roller isolating agent is used for preparing the asphalt pavement roller isolating agent, and comprises the following steps: S1, heating water, and mixing with the emulsifier, the antioxidant and glycerin according to a ratio so as to obtain emulsified liquid A for later use; S2, heating the asphalt anti-aging agent, conveying the emulsified liquid A and the heated asphalt anti-aging agent into a colloid mill emulsifying machine, fully shearing and blending until clustering is avoided or no flocculent mass exists so as to obtain a blend B; S3, pouring out the blend B, and cooling to obtain the asphalt pavement roller isolating agent, and storing or filling the prepared asphalt pavement roller isolating agent. The invention further provides a test method of the asphalt pavement roller isolating agent.

Owner:GUANGZHOU HONGJIN SYNTHETIC MATERIAL CO LTD

Accurate-metering charging device

InactiveCN103640907AThere is no problem with weighing valuesReduce labor intensityLoading/unloadingControl theoryBelt conveyor

The invention discloses an accurate-metering charging device. The accurate-metering charging device comprises a weighing device, a belt conveyor and a charging box arranged above a belt at one end of the belt conveyor, the charging box is fixedly arranged on the belt conveyor, the belt conveyor is arranged on the weighing device, and the overall weight of the belt conveyor, the charging box, the belt and materials in the charging box can be weighed by the weighing device. Due to the fact that the belt conveyor is arranged on the weighing device, the overall weight of the belt conveyor, the charging box, the belt and the materials in the charging box can be weighed by the weighing device. Compared with the mode that the weighing device is only arranged below a carrier roller of the belt conveyor, the weighing mode has the advantages that the problems that tension of the belt influences a weighed value of a gravity sensor in the weighing device, and the materials in the charging box can not be weighed are avoided, and meanwhile the automatic-metering charging system is simple in equipment, high in work efficiency and the like.

Owner:重庆市酉阳县酉好化肥有限公司

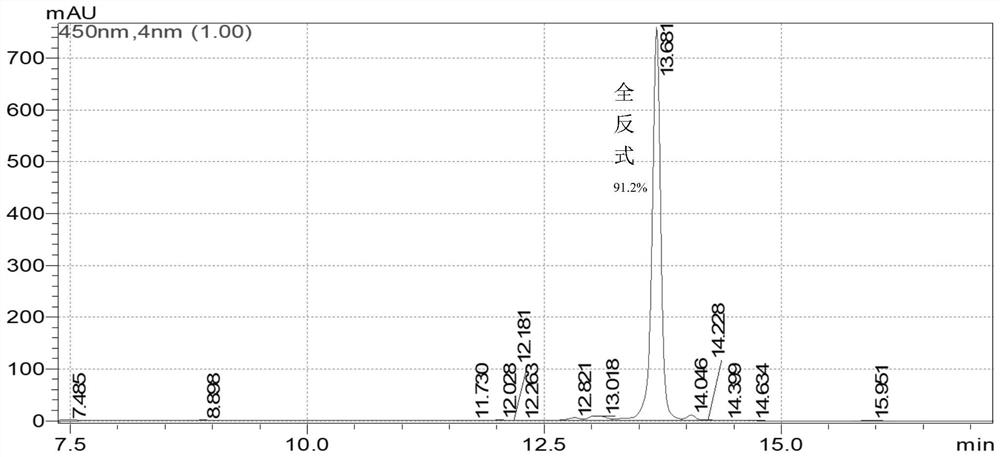

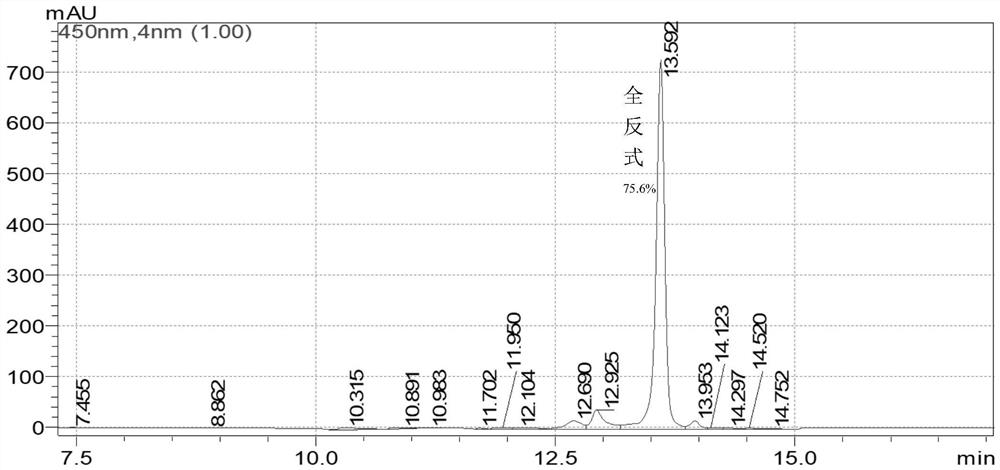

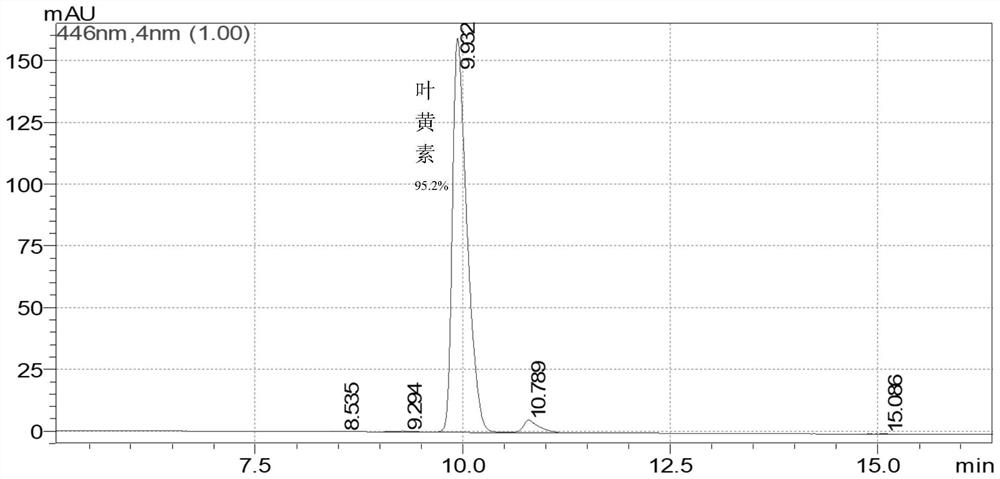

Preparation method of carotenoid

PendingCN113598304AReduce loss rateWell mixedPowder deliveryCosmetic preparationsEmulsionProcess engineering

The invention provides a preparation method of carotenoid, and belongs to the technical field of carotenoid processing. The preparation method comprises the following specific steps of: performing vacuum inert gas filling positive pressure emulsification stirring blending on carotenoid and / or a diluent and / or a dispersing agent and / or a filling agent, automatically controlling ultrahigh-temperature instantaneous melting, performing inert gas positive pressure protection, directly conveying to an emulsification shearing surface, performing vacuum emulsification, performing rapid cooling and / or performing spray drying, and obtaining a carotenoid emulsion or powder product by preparation. By optimizing the technological process and various limiting conditions of carotenoid preparation, the loss rate of carotenoid can be effectively reduced; the stability and bioavailability of carotenoid are improved; and the carotenoid prepared by the invention has the advantages of small particle size, high all-trans component content and low loss rate.

Owner:HENAN ZHONGDA HENGYUAN BIOTECH CO LTD

Room-temperature composite soft sheathing method for high-temperature alloy forge piece hot die forging and forging method of high-temperature alloy forge piece

The invention relates to a room-temperature composite soft sheathing method for high-temperature alloy forge piece hot die forging and a forging method of a high-temperature alloy forge piece. The sheathing method comprises the following steps that the surface of a blank is cleaned; a coating matched with the blank in shape and size is cut; one surface of the coating is coated with a high-temperature binder; the surface of the blank is covered with the surface, coated with the high-temperature binder, of the coating, and glass fiber cloth is used for winding to obtain the sheathed blank; and the coating is an aluminum silicate fiber blanket or an aluminum silicate felt. According to the room-temperature composite soft sheathing method for the high-temperature alloy forge piece hot die forging, after repeated tests of the inventor, it is found that the glass fiber cloth can replace a previous stainless steel sleeve and / or a metal fixing strip, so that the whole sheathing and forging process is more convenient in operation, the cost is lower, and the product quality and the machining efficiency are improved.

Owner:CENT IRON & STEEL RES INST +1

Autoclaved aerated lime brick and preparation method thereof

The invention relates to an autoclaved aerated lime brick. Calculated in percentage by weight, the raw material formula of the autoclaved aerated lime brick comprises, 70-90% of fly ash, 0.5-5% of cement, 5-15% of lime, 1-10% of gypsum, and 0.01-0.2% of aluminium powder. By improving the formula and optimizing concrete technological parameters in the preparation method, fatty acid soap and gleditsia sinensis powder are not needed, also the usage amount of cement and aluminium powder is further reduced, environmental pollution is reduced, and the raw material cost is reduced. Additionally, fly ash and gypsum do not need mixed grinding, the preparation step is reduced, and the production cost is further reduced. Additionally, the performance indexes of the prepared autoclaved aerated lime brick are all qualified.

Owner:吴江市范氏新型建材制品有限公司

Drilling machine device for CV outer rings

ActiveCN103737057AFully automatedImprove machining accuracyMeasurement/indication equipmentsPositioning apparatusPneumatic valveEngineering

The invention provides a drilling machine device for CV outer rings. The drilling machine device comprises a base, a first clamp, a second clamp, a main shaft rotating device and a drill bit. The first clamp is arranged at one end of the base, and the second clamp is arranged at the other end of the clamp. The main shaft rotating device is fixed to a support, the drill bit is arranged under the main shaft rotating device, and a drill jig seat plate is arranged under the drill bit and connected with the support together. The main shaft rotating device is provided with a drill bit bounce detection meter and an adjusting switch. Pneumatic devices are arranged on the clamps and connected with pneumatic valves through gas conveying pipes, and the pneumatic valves are arranged on the base. According to the drilling machine device, the arranged pneumatic devices can control a pneumatic switch to rotate the first clamp, and automatic machining on multiple-position and multiple-face of the CV outer rings can be achieved; the arranged drill bit bounce detection meter can monitor bounce situations of the drill bit; the drill jig seat plate is arranged under the drill bit, so the CV outer rings can be fixed, and machining accuracy of the drill bit can be improved.

Owner:NEXTEER LINGYUN DRIVELINE WUHU

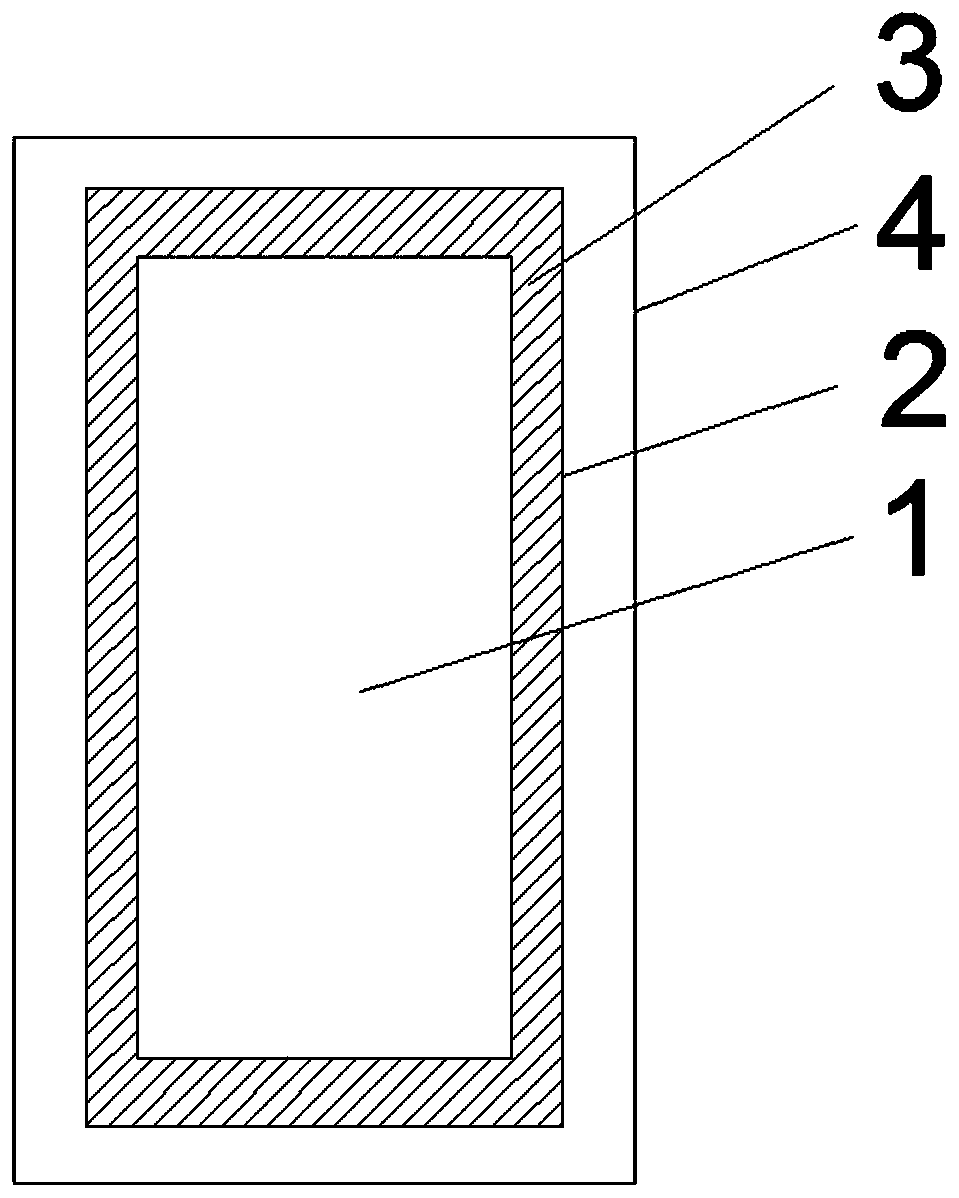

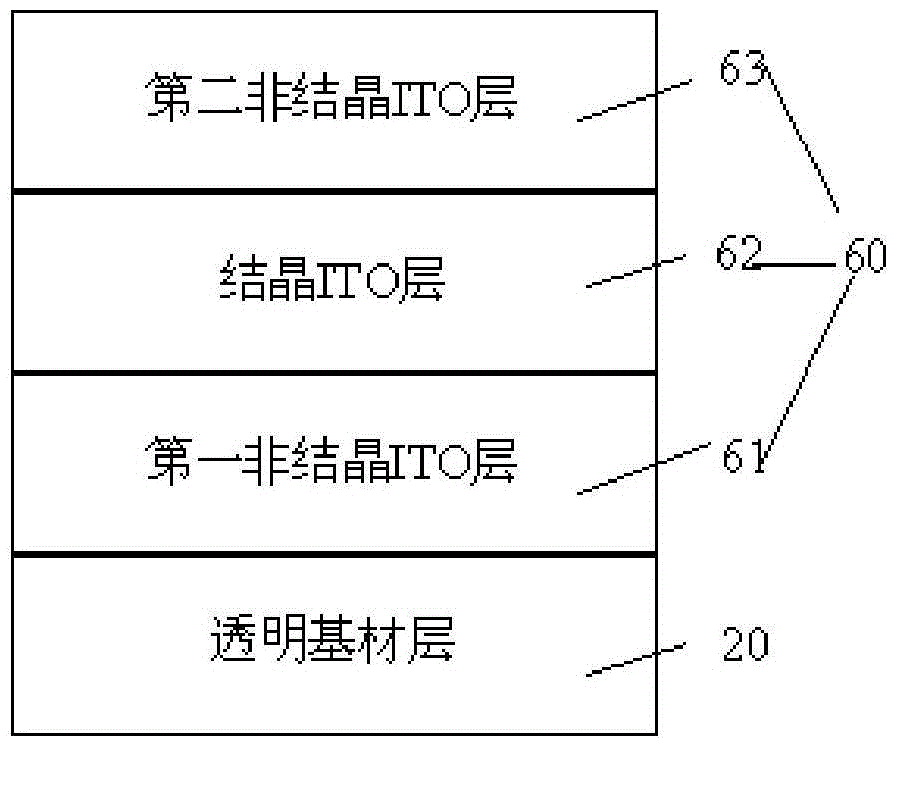

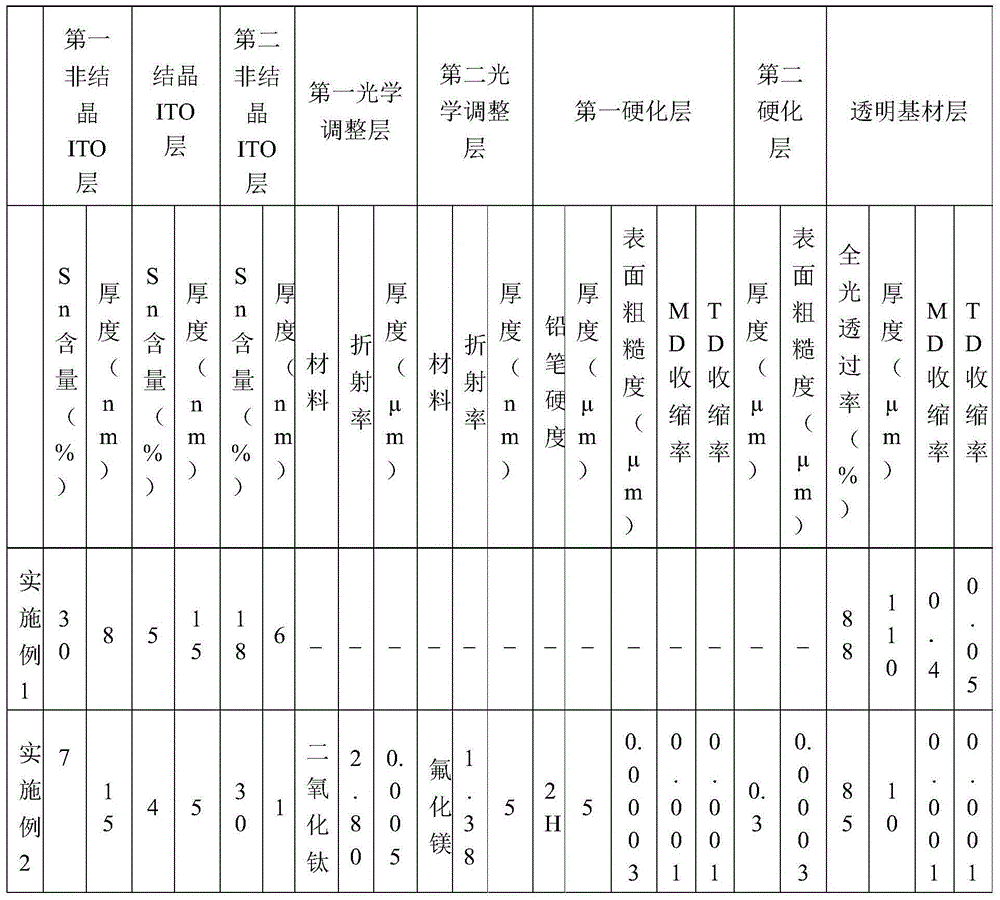

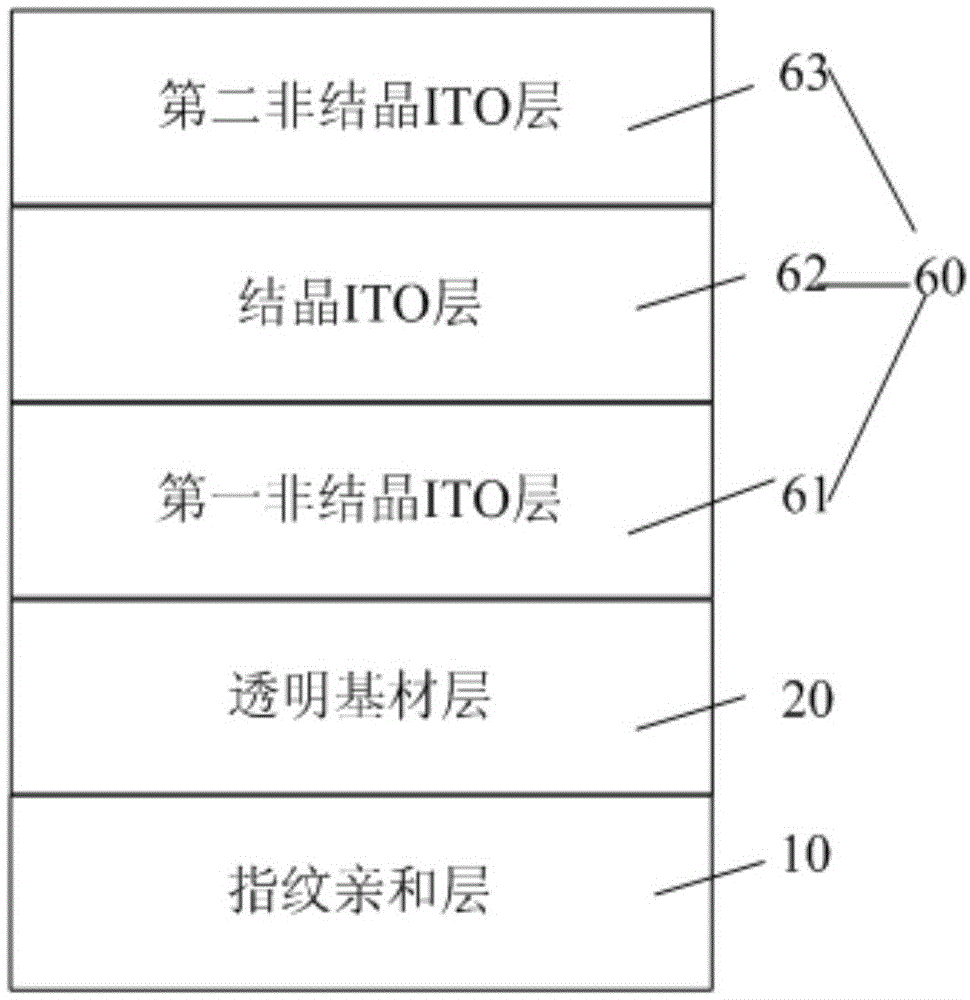

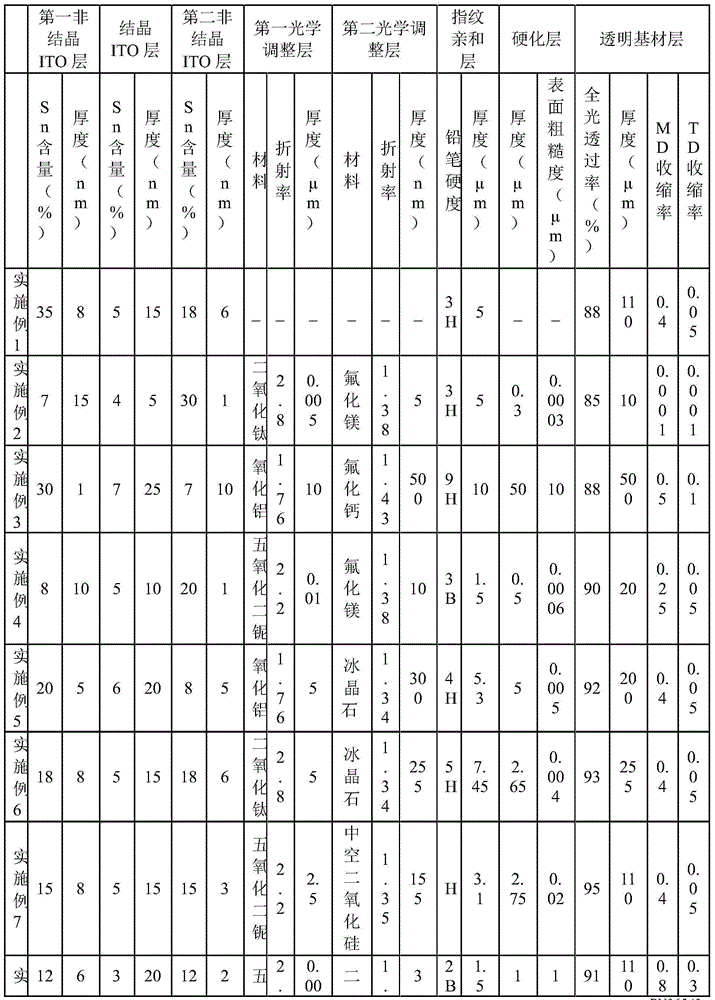

Transparent conductive film and capacitive touch screen comprising same

ActiveCN104951166AAlleviate the serious problem of three-dimensional linesImprove performanceInput/output processes for data processingIndium tin oxideTransparent conducting film

The invention provides a transparent conductive film and a capacitive touch screen comprising the same. The transparent conductive film comprises a transparent substrate layer and ITO (indium tin oxide) layers arranged on the surface of the transparent substrate layer, wherein the ITO layers comprise a first amorphous ITO layer, a crystalline ITO layer and a second amorphous ITO layer; the first amorphous ITO layer is arranged on the surface of the transparent substrate layer; the crystalline ITO layer is arranged on the surface, far from the transparent substrate layer, of the first amorphous ITO layer; the second amorphous ITO layer is arranged on the surface, far from the first amorphous ITO layer, of the crystalline ITO layer. The transparent conductive film has the characteristics of unapparent solid lines, lower impedance, lower cost and simpler production process; meanwhile, the ITO layers have good adherence with the transparent substrate layer and a silver or copper conductive printing layer in a follow-up process, so that good performance of the transparent conductive film is guaranteed, and the continuity of processes for production is improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

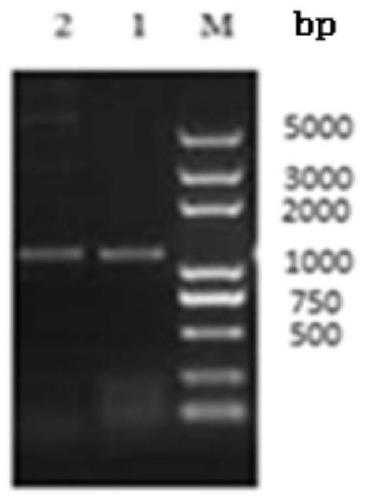

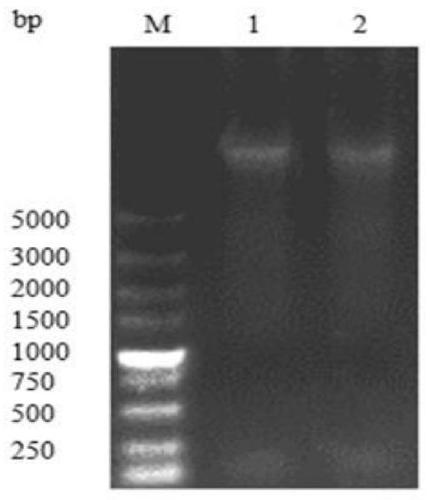

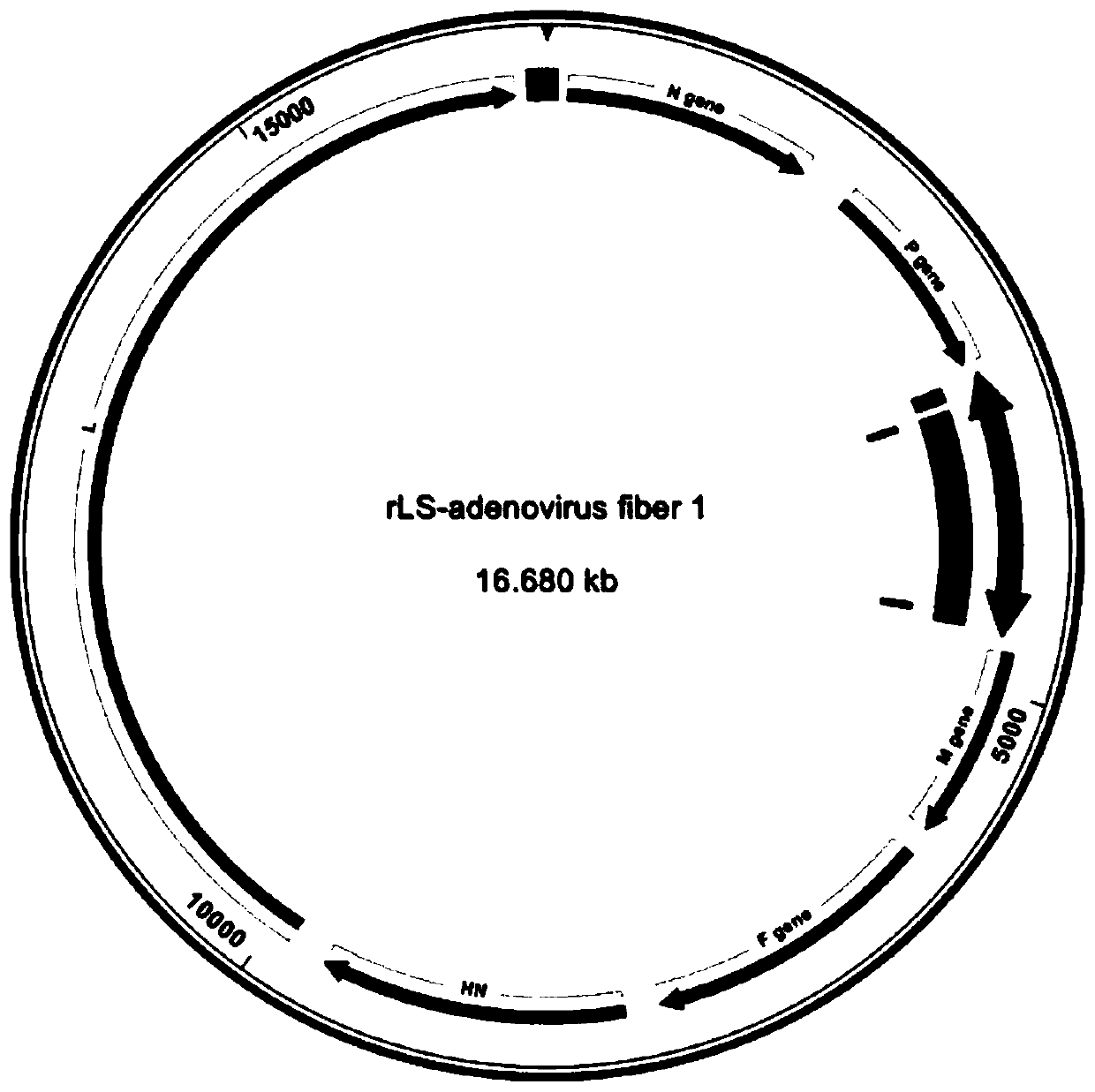

Vaccine vector preventing FAdV-4 and NDV and preparation method and application of vaccine vector

ActiveCN110484515ASimplified immunization programGood immune protectionSsRNA viruses negative-senseViral antigen ingredientsFiberProtective antigen

The invention relates to a vaccine vector preventing the FAdV-4 and the NDV and a preparation method and application of the vaccine vector, and belongs to the technical field of prevention for the FAdV-4 and the NDV. According to vaccine vector and the preparation method and application of the vaccine vector, based on the structure characteristic of the FAdV-4, an FAdV-4 protective antigen Fiber 1protein is selected as a research and development object, and by constructing a recombinant Newcastle disease virus expressing the Fiber 1, a novel genetic engineering vaccine capable of preventing the FAdV-4 and the NDV is obtained through research and development; through research and development of the vaccine, not only is an important tool provided for prevention and control over the FAdV-4,but also a LaSota toxic strain of the Newcastle disease virus is selected as the vaccine vector, the toxic strain is a common vaccine toxic strain in production, an effect can be achieved that one strain prevents the two viruses, and therefore the vaccine immunization process is simplified.

Owner:HENAN UNIV OF SCI & TECH

Deep extraction process for matcha-derived bioactive component

InactiveCN111528315AIncrease profitIncrease contentTea extractionSolid solvent extractionInstant teaFluid phase

The invention discloses a deep extraction process for a matcha-derived bioactive component. The process comprises the following steps: a, weighing tea leaves, and drying, crushing and screening the tea leaves successively to obtain tea leaf powder; b, putting pure water accounting for 8-15 times of the weight of the tea leaf powder and the tea leaf powder into a treatment barrel, carrying out mixing, then conducting heating to 80-90 DEG C, carrying out stirring for 30-60 minutes, and performing solid-liquid separation to obtain a first solid-phase isolate and a first liquid-phase isolate; c, filtering, evaporating, concentrating and drying the first liquid-phase isolate to obtain concentrated instant tea; d, performing primary enzymolysis, alkaline extraction and secondary enzymolysis on the solid-phase isolate generated in the step b to obtain an enzymolysis product; and e, carrying out solid-liquid separation on the enzymolysis product obtained in the step d to obtain solid residuesand a second liquid-phase isolate, and filtering, evaporating, concentrating and drying the second liquid-phase isolate to obtain the bioactive component.

Owner:ZHEJIANG CAMEL JIUYU ORGANIC FOOD CO LTD

Sound screen board and sound barrier using same

PendingCN110042773ANo connection requiredThe strength of large expansionNoise reduction constructionRear quarterLap joint

The invention discloses a sound screen board and a sound barrier using the same. A sound screen board comprises a rectangular outer shell body and a sound absorbing body, wherein the rectangular outershell is composed of a panel, a back board, and a side board, and the sound absorbing bodyfillsthe interior of the outer shell body;in the assembly process of the sound screen board, the use of rivets is omitted, the appearance is more aesthetic, automatic continuous production can be realized, using of manpower is reduced, production efficiency is greatly improved, and finished products are decreased;in terms of using performance, the corrosion of riveting joints can be avoided, and the overall fixing strength can be ensured. In the assembly structure of the sound screen board, the top of the outer shell body is in the structural form of an upper flanging groove covering an upper clamping part, and an overlap joint slit is vertically formed, and a vertical upper clamping part is arrangedon the inner side of the lap joint slit for protection, so that rainwater does not enter into the outer shell body, thus the problemsof corrosion of the sound screen board and uneven filling caused by sinking of the sound absorbing body are avoided, the service life of the sound screen board is prolonged, and the sound absorption and noise reduction effects are further improved.A sound barrier has the using and producing advantages of the sound screen board.

Owner:HEBEI JINBIAO CONSTR MATERIALS TECH CORP LTD

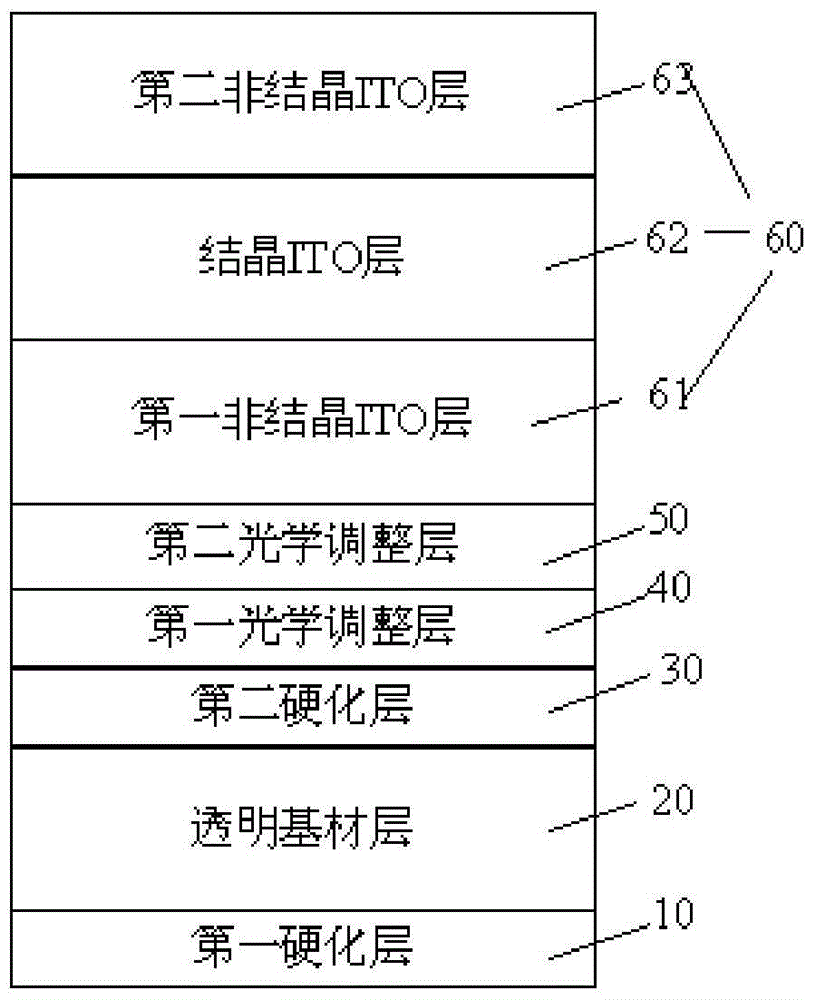

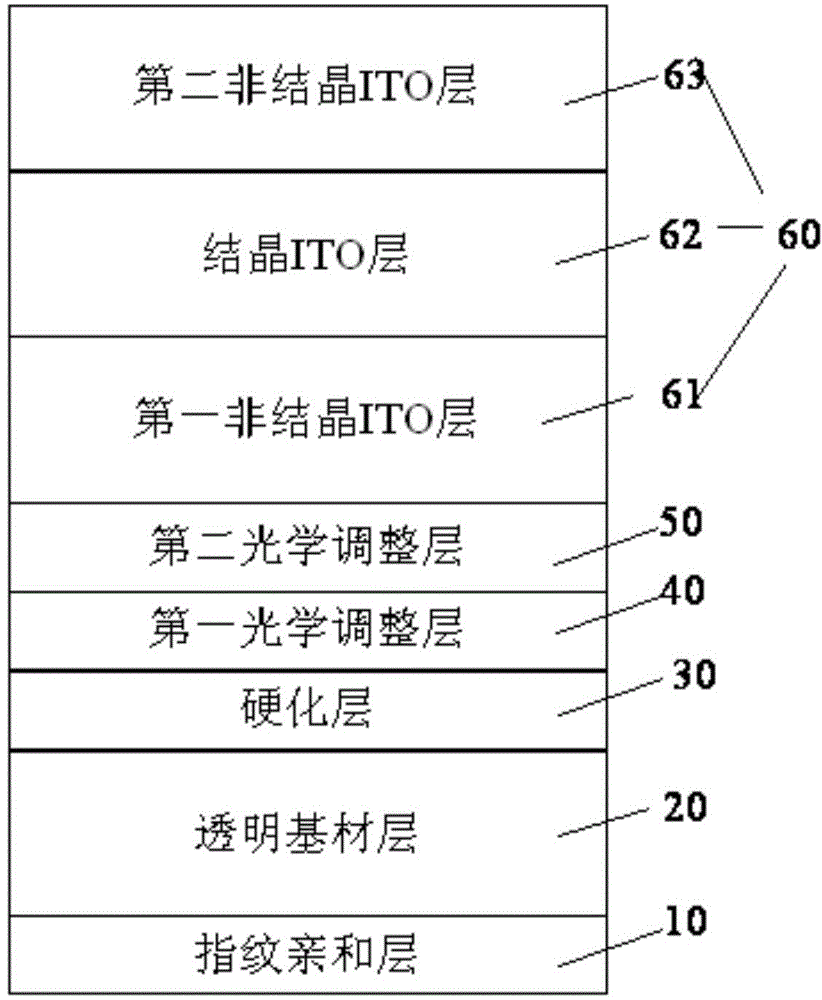

Transparent conductive film and capacitive touch screen comprising same

ActiveCN104951165AAlleviate the serious problem of three-dimensional linesImprove performanceInput/output processes for data processingIndium tin oxideTransparent conducting film

The invention provides a transparent conductive film and a capacitive touch screen comprising the same. The transparent conductive film comprises a fingerprint affinity layer, a transparent substrate layer and ITO (indium tin oxide) layers, wherein the transparent substrate layer is arranged on the surface of the fingerprint affinity layer; the ITO layers comprise a first amorphous ITO layer, a crystalline ITO layer and a second amorphous ITO layer; the first amorphous ITO layer is arranged on the surface, far from the fingerprint affinity layer, of the transparent substrate layer; the crystalline ITO layer is arranged on the surface, far from the transparent substrate layer, of the first amorphous ITO layer; the second amorphous ITO layer is arranged on the surface, far from the first amorphous ITO layer, of the crystalline ITO layer. The transparent conductive film has the characteristics of better adherence, better anti-pollution performance and slip resistance, lower impedance, unapparent solid lines, lower cost and simple production process.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com