Automatic feeding and discharging device for sheet metal for numerical control punching machine

A technology of automatic loading and unloading and CNC punching machine, which is applied in the field of sheet metal processing, can solve the problems of difficult control of the position accuracy of the sheet metal, time-consuming and labor-intensive safety hazards, and hidden safety hazards of workers to achieve the elimination of safety hazards, high work efficiency, and strong reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

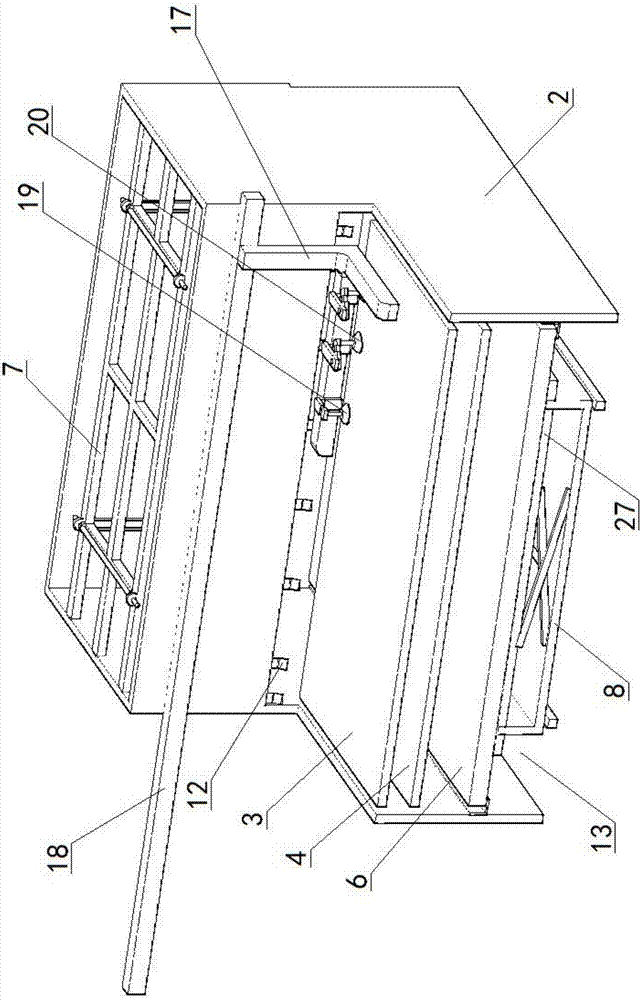

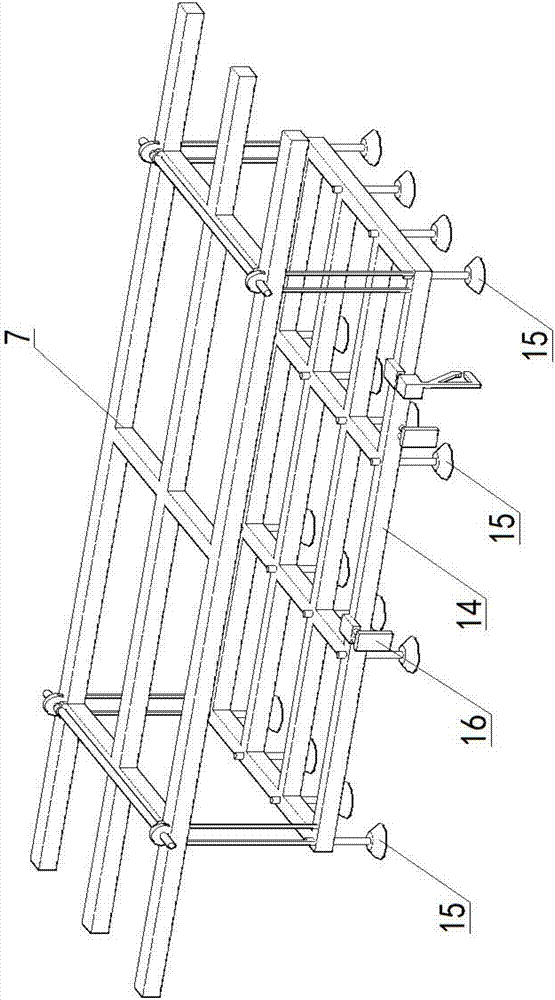

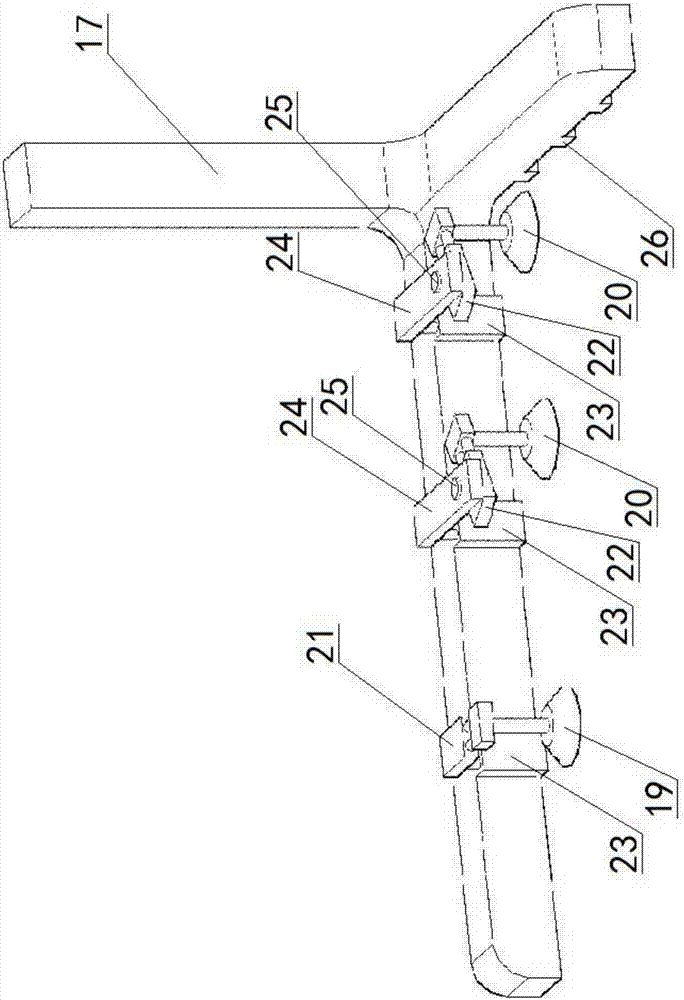

[0057] Example: see attached Figure 1-13 As shown, a sheet metal automatic loading and unloading device for a CNC punching machine is set in the X-axis direction corresponding to the loading and unloading sides (right side) of the processing table (not shown in the figure) of the CNC punching machine, and is set in the Y-axis direction It is arranged on the front side of the raw material rack (not shown in the figure), and several material boards 1 are stacked in the raw material rack; the automatic loading and unloading device includes a frame 2, and a feeding table arranged in the frame 1 3. Unloading table 4, raw material tray 5, waste tray 6, suction cup rack 7, handling manipulator and lifting trolley 8; among them:

[0058] The frame 2 includes a front space and a rear space arranged in the Y-axis direction, and the rear space includes an upper space and a lower space distributed in the Z-axis direction; as Figure 4 As shown, in the initial state of the device (that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com