Preparation method of carotenoid

A technology of carotene and species, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve trans content degradation, high loss rate, agglomeration, floating surface, attachment tank wall and other problems to achieve the effect of reducing loss rate, preventing oxidation deformation and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

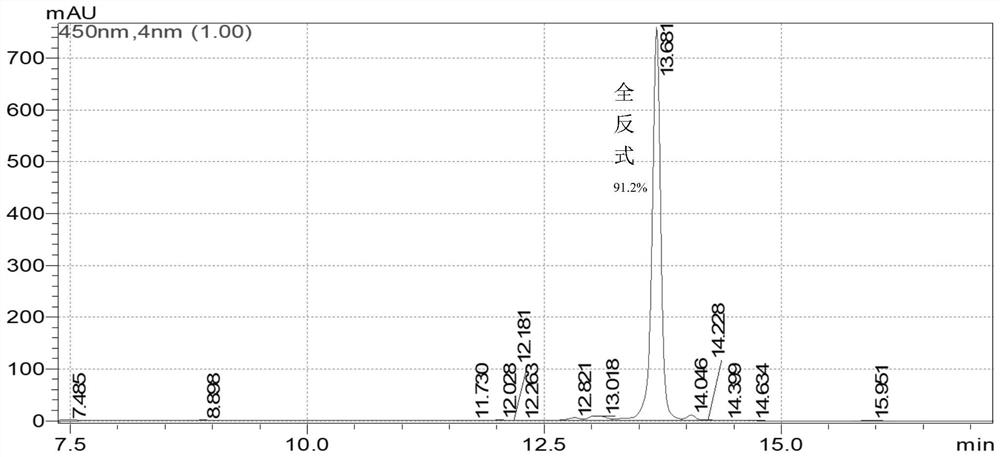

[0058] Add 6kg of β-carotene crystals (content: 98.2%, trans content: 95.1%), tocopherol: 1.0kg, deodorant rosemary extract: 1.0kg, sunflower oil: 52Kg, add low-temperature vacuum, inert gas and positive pressure emulsification In the stirring batching tank, the temperature is 20°C, vacuum degree: -0.08Mpa, stirring: 15HZ, stirring for 25min, emulsification: 35HZ, emulsification for 30min, emulsifying and dispersing the oil phase solution evenly. Open the nitrogen valve, pressurize and fill with nitrogen, replace the vacuum state, fill the preparation tank with nitrogen gas pressure: 0.3Mpa, β-carotene is protected by positive pressure of inert gas, positive pressure is conducive to material fusion;

[0059] Emulsify and dissolve 360Kg of modified starch, 80Kg of maltodextrin, reverse osmosis membrane water: 660Kg in a vacuum emulsification tank, first stir counterclockwise at 10HZ at a constant speed for 15min, then emulsify clockwise at 25HZ for 15min, stirring temperature: 3...

Embodiment 2

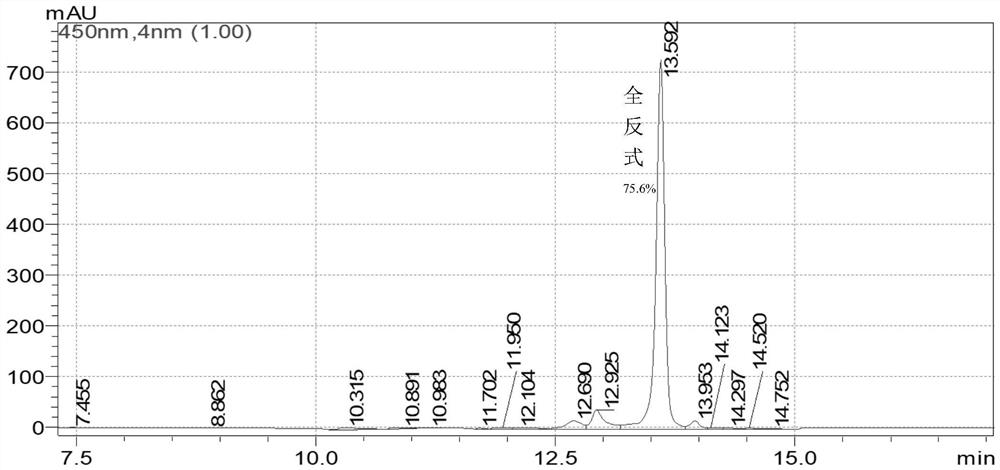

[0065] Add 6.8kg of β-carotene crystals (content: 97.2%, trans content: 94.5%), deodorant rosemary extract: 3.0kg, Span: 8Kg, MCT oil: 18Kg, add inert gas, positive pressure, emulsification and stirring at low temperature and vacuum In the batching tank, the temperature is 35°C, vacuum degree: -0.09Mpa, stirring: 25HZ, stirring for 40min, emulsification: 40HZ, emulsifying for 45min, emulsifying and dispersing the oil phase solution evenly. Open the nitrogen valve, pressurize and fill with nitrogen, replace the vacuum state, fill the preparation tank with nitrogen gas pressure: 3.0Mpa, β-carotene is protected by positive pressure of inert gas, positive pressure is conducive to material fusion;

[0066] Emulsify and dissolve 105Kg glycerin, 27.2Kg polyglycerol fatty acid ester, 12Kg sucrose fatty acid ester, reverse osmosis membrane water: 20Kg in a vacuum emulsification tank, first stir counterclockwise at 8HZ at a constant speed for 10min, and then emulsify clockwise at 10HZ 1...

Embodiment 3

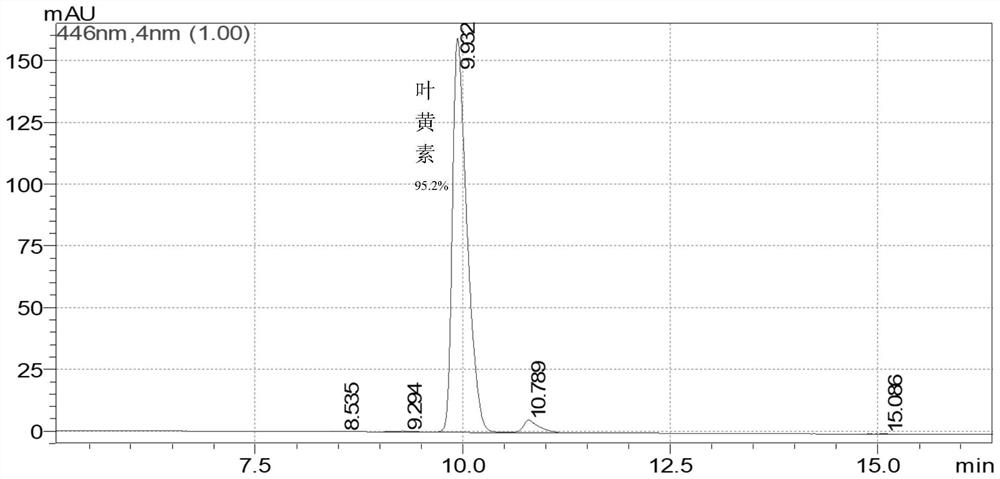

[0072] With 12.0kg lutein crystals (content 84.6%, trans content 98.5%), deodorized rosemary extract: 3.0kg, tocopherol: 3.0Kg, mono- and diglyceride fatty acid ester: 3.0Kg, MCT oil: 29.0Kg is added to the low-temperature vacuum filled inert gas positive pressure emulsification stirring batching tank at a temperature of 35 ° C, the vacuum degree:

[0073] -0.09Mpa, stirring: 25HZ, stirring for 40min, emulsification: 40HZ, emulsifying for 45min, emulsifying and evenly dispersed oil phase solution. Open the nitrogen valve, pressurize and fill with nitrogen, replace the vacuum state, fill the preparation tank with nitrogen gas pressure: 2.5Mpa, lutein is protected by positive pressure of inert gas, positive pressure is conducive to material fusion;

[0074] Emulsify and dissolve 170Kg glycerin and 80Kg polyglycerin fatty acid ester in a vacuum emulsification tank, first stir counterclockwise at a constant speed of 15HZ for 15min, then emulsify clockwise at 10HZ for 10min, stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com