Method for producing water chestnut sheet jelly

A production method and technology of water chestnut powder, applied in the field of production of water chestnut powder skin, can solve the problems of not exerting the health care function of water chestnut skin, high production of water chestnut powder skin, single component function, etc., and achieve unique water chestnut flavor, remarkable comprehensive utilization effect, and flexible taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 water chestnut vermicelli

[0040] The water chestnut powder skin of the present embodiment, its production method comprises the steps:

[0041] (1) Extraction of flavonoids from water chestnut processing waste

[0042] Take the processing waste from the water chestnut powder skin factory, dry it at 60°C to a solid flake shape, then crush it with a pulverizer, add water 40 times the weight of the crushed material, extract it in warm water at 75°C for 2 hours, and then extract it with microwave for 4 minutes , and the filtrate obtained by filtering is the flavonoids solution;

[0043] (2) Extraction of dietary fiber from water chestnut processing waste

[0044] Dry the above-mentioned flavonoid-extracted waste at 80°C to constant weight, then pulverize it with a pulverizer, and use a high-temperature-resistant α-amylase solution for enzymolysis. The dosage of the enzyme solution is 0.3mL / g. The temperature of hydrolysis is 65°C, and the time of enzymolysi...

Embodiment 2

[0052] Embodiment 2 water chestnut vermicelli

[0053] The water chestnut powder skin of the present embodiment, its production method comprises the steps:

[0054] (1) Extraction of flavonoids from water chestnut processing waste

[0055] Take the processing waste from the water chestnut powder skin factory, dry it at 60°C to a solid flake, then crush it with a pulverizer, add 70% ethanol that accounts for 10 times the mass of the crushed material, extract it in warm water at 75°C for 2 hours, and then microwave it in mid-range Extract for 4 minutes, and filter the obtained filtrate to be the flavonoids solution;

[0056] (2) Extraction of dietary fiber from water chestnut processing waste

[0057] Dry the above-mentioned flavonoid-extracted waste at 80°C to constant weight, then pulverize it with a pulverizer, and use a high-temperature-resistant α-amylase solution for enzymolysis. The dosage of the enzyme solution is 0.3mL / g. The temperature of hydrolysis is 65°C, and th...

Embodiment 3

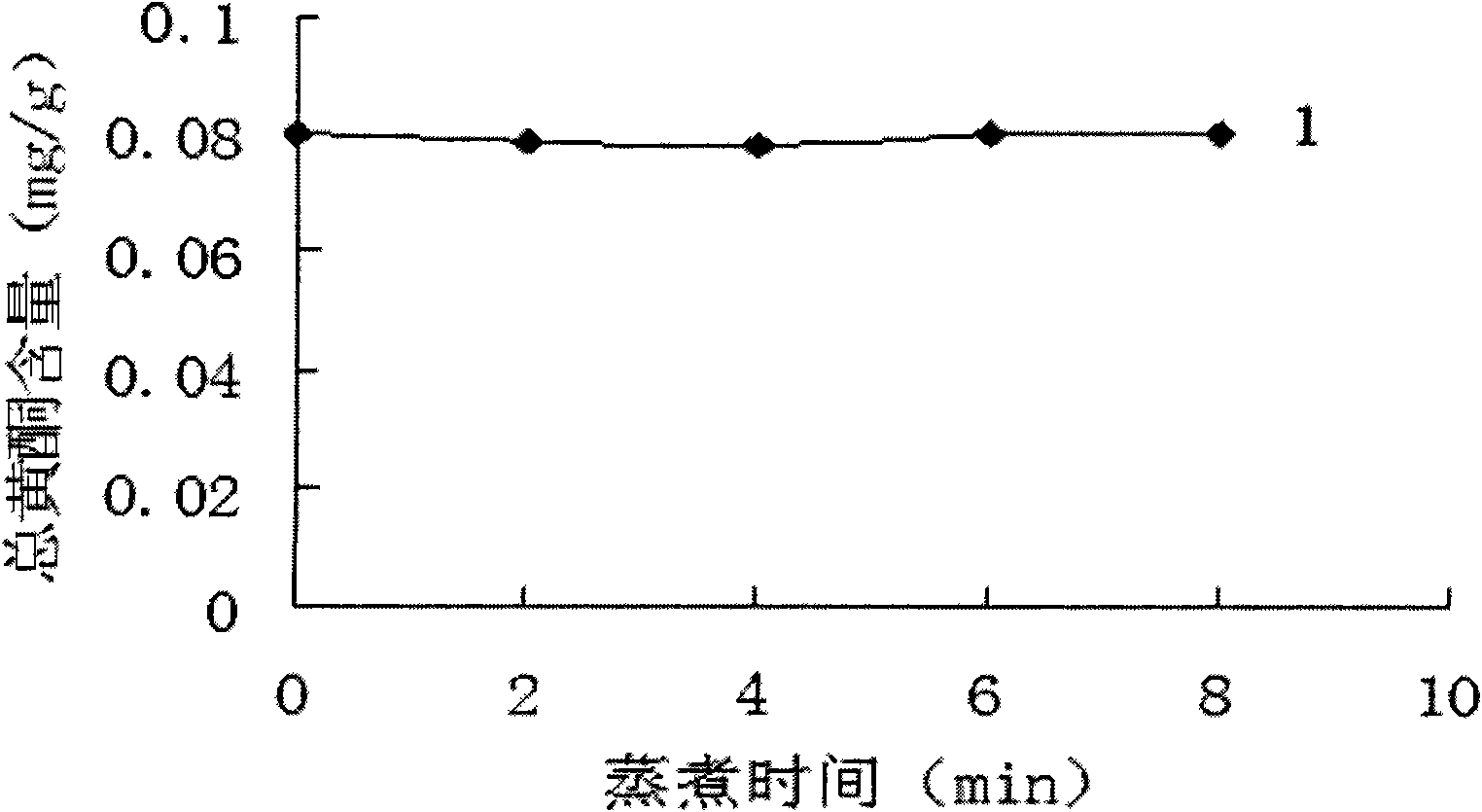

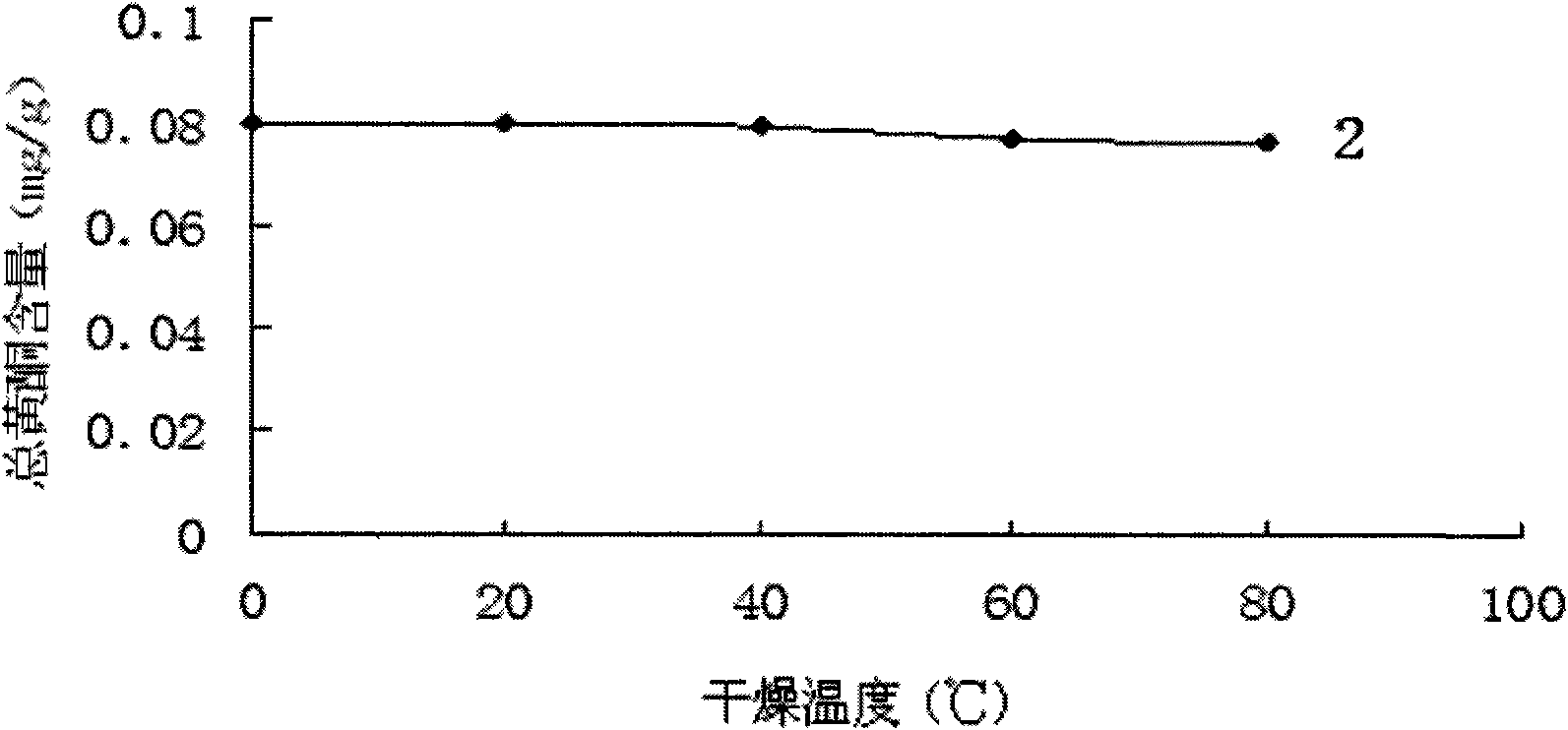

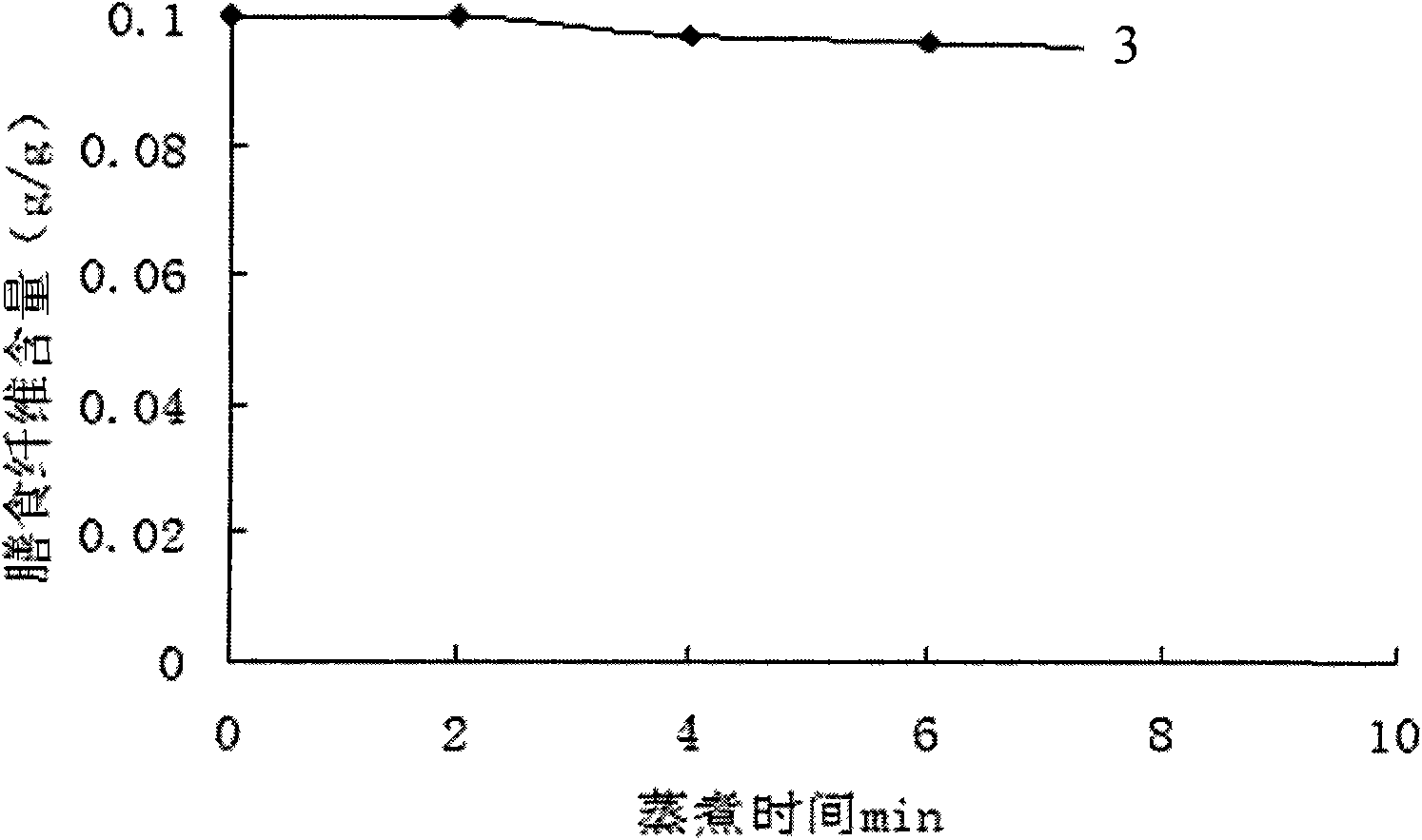

[0060] The quality of embodiment 1 gained water chestnut vermicelli finished product is compared with existing pure water chestnut vermicelli finished product, as shown in table 1, the stretching force of visible vermicelli has increased by 11.5%, and boiling loss rate has increased 25.0%, and swelling degree reduces The content of flavonoids increased by 8.0%, the content of flavonoids increased by 40mg / 500g, and the dietary fiber increased by 0.1g / g.

[0061] In addition, compared with the production of water chestnut powder skin by the traditional method, the production cost of embodiment 1 can also save 2.24 yuan / jin (the price of potatoes is 5 yuan / jin, sweet potato starch is 4 yuan / jin, cornstarch is 3 yuan / jin, Water chestnut starch is 11 yuan / jin).

[0062] Thereby it can be seen that the process of utilizing waste to produce water chestnut vermicelli in the present invention is not only beneficial to environmental protection, but also realizes waste recycling, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com