Manufacturing method of a new type of rubber sleeve with built-in steel wire

A technology of rubber sleeve and manufacturing method, which is applied in the field of medical equipment and manufacturing technology, can solve problems such as high production cost, complicated process, and adverse reactions, and achieve the effects of improving toughness, simplifying the process flow, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described below in conjunction with specific embodiments.

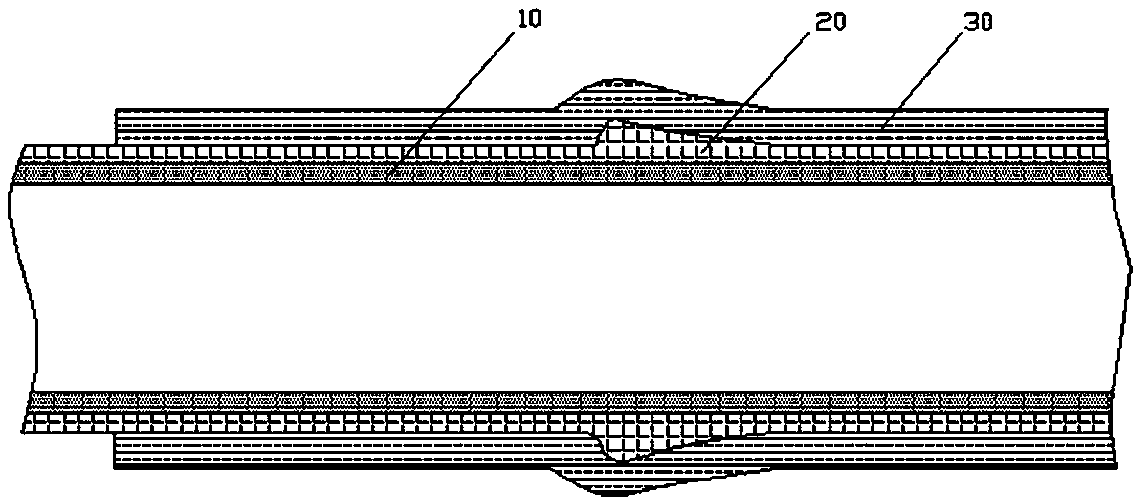

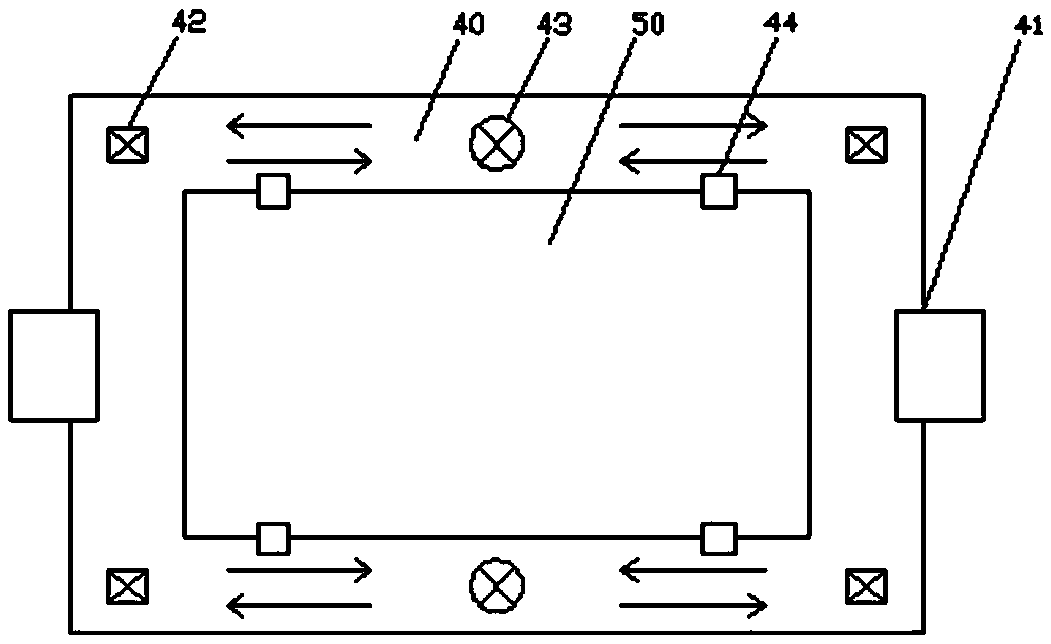

[0027] Such as Figure 1-2 As shown, it is a manufacturing method of a new type of rubber sleeve with built-in steel wire described in this embodiment. The rubber sleeve is provided with: an inner tube rubber layer 10, a reinforcing line layer 20 and an outer skin rubber layer 30, and the reinforcing line layer 20 is Weaving the outer surface of the rubber layer 10 of the inner tube, and the rubber layer 30 of the outer skin is set on the reinforcement layer 20;

[0028] The manufacturing method of the rubber bushing with built-in steel wire comprises the following steps:

[0029] Step 1: Straighten the spiral steel wire through a straightening mechanism, and then use a cutting machine to cut the straightened steel wire into equal lengths;

[0030] Step 2: dipping the steel wire cut in step 1, and then heating and curing;

[0031] Step 3: Put the cured steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com