Accurate-metering charging device

A feeding device and precise technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of manual metering and feeding, and achieve the effect of reducing labor intensity, saving labor for feeding, and simplifying feeding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 Accurate metering and feeding device

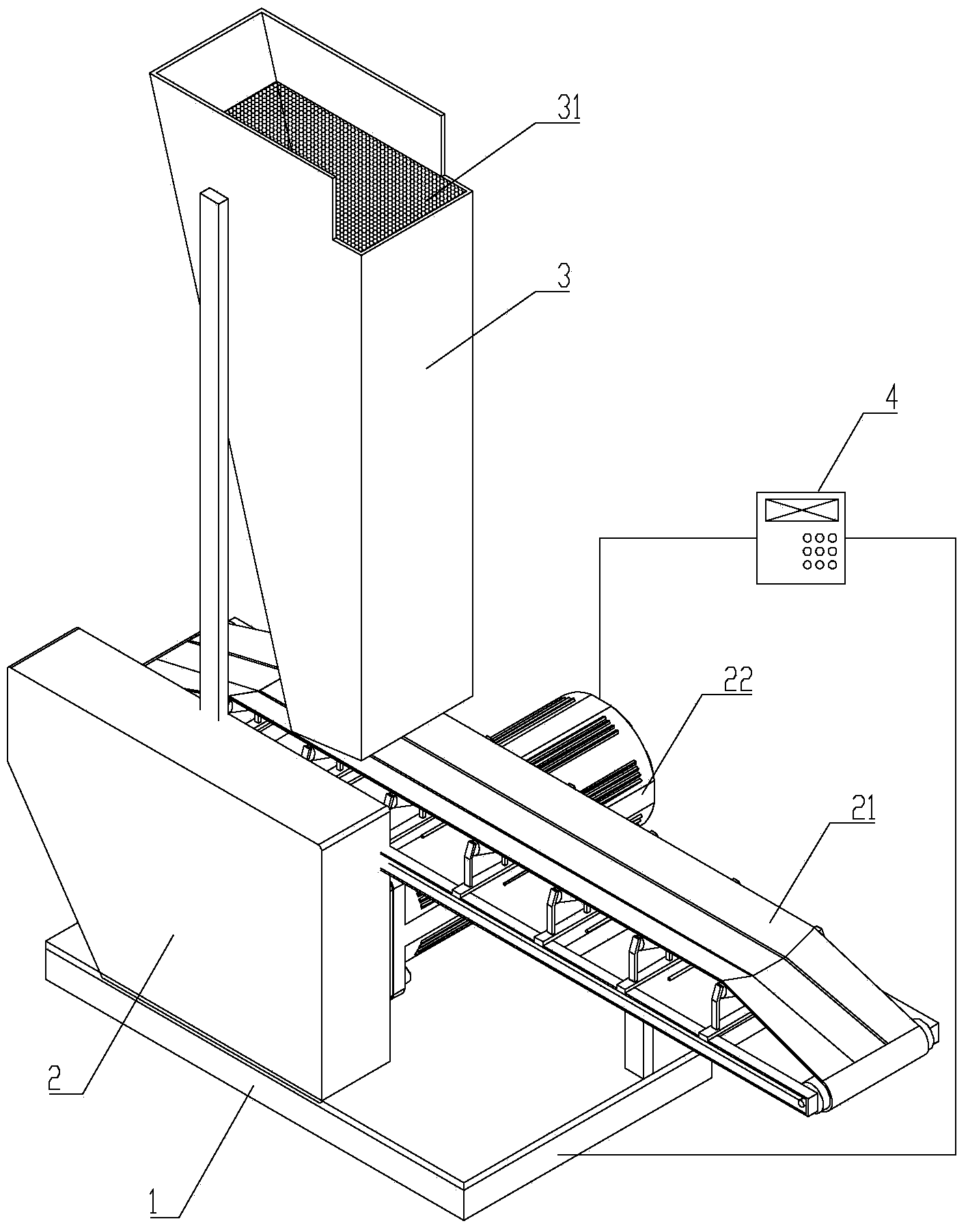

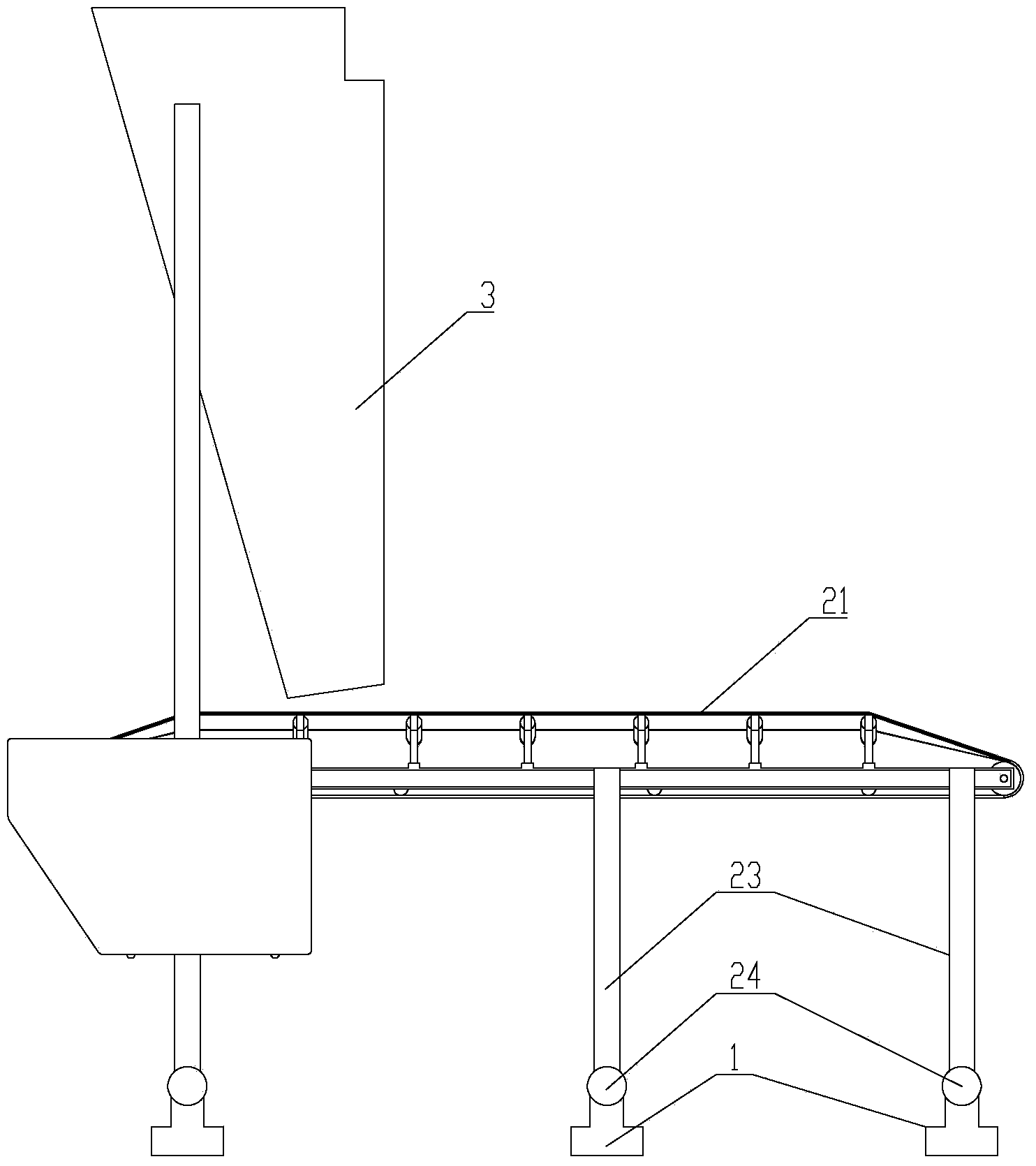

[0022] Such as figure 1 Shown: the precise metering and feeding device of this embodiment includes a weighing device 1, a belt conveyor 2, and a feeding box 3 arranged above the belt 21 at one end of the belt conveyor 2, and the feeding box 3 is fixedly arranged on the belt conveyor 2 Above, the belt conveyor 1 is set on the weighing device 1, and the weighing device 1 can weigh the belt conveyor 2 plus the feeding box 3 plus the belt conveyor 2 belt 21 and the material in the feeding box 3 Overall weight; also includes a controller 4, the belt conveyor 2 includes a motor 22, the weighing device 1 includes a weight sensor, and the controller 4 is connected to the motor 22 and the weight sensor respectively. The belt conveyor is set on the weighing device, so that the weighing device can weigh the overall weight of the belt conveyor, the feeding box and the materials on the machine, and the weight of the feeding box an...

Embodiment 2

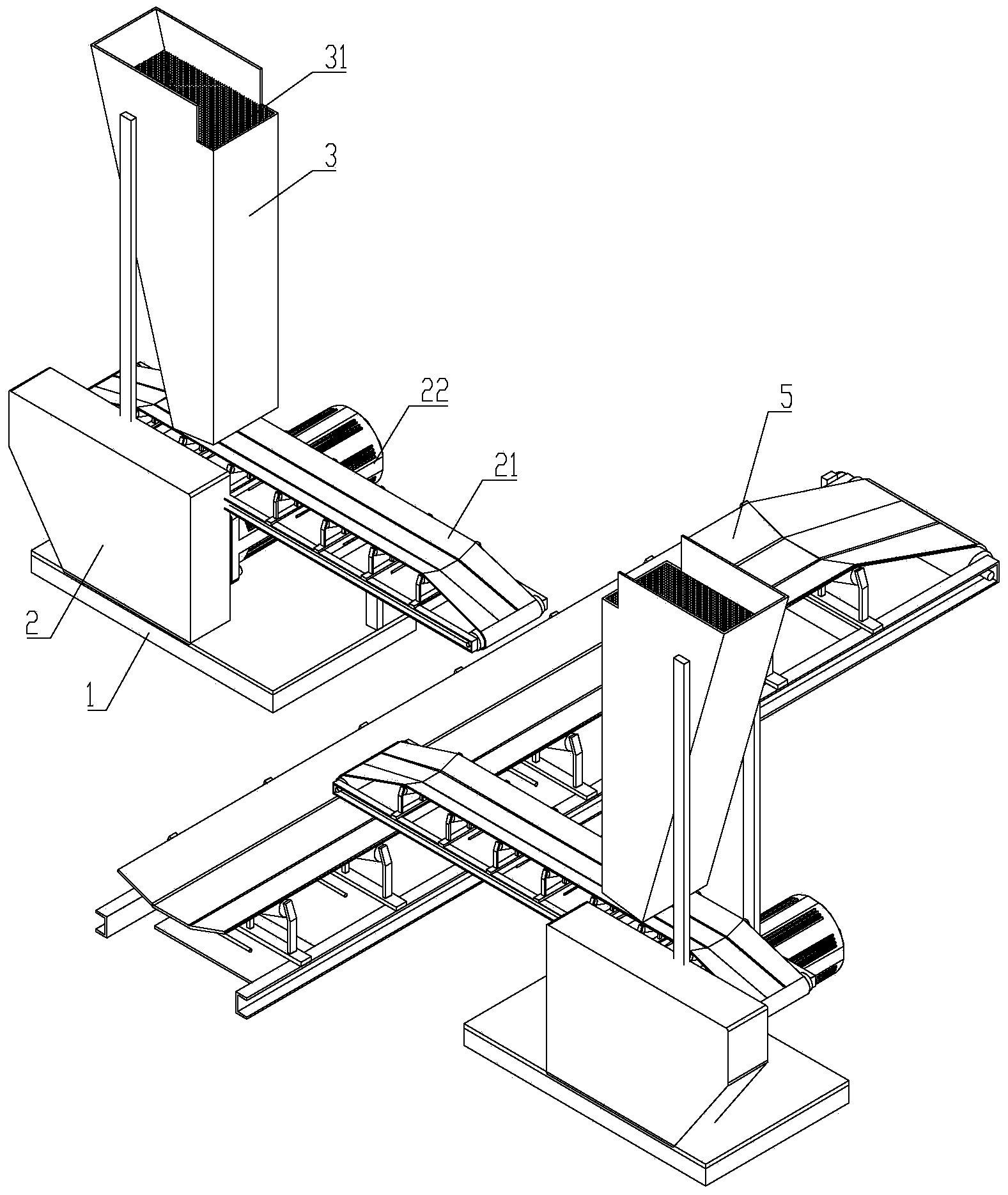

[0025] Embodiment 2 Automatic metering and feeding system

[0026] Such as image 3 As shown, the automatic metering and feeding system of the present invention includes a main conveyor belt 5 and a plurality of accurate metering and feeding devices distributed on both sides of the main conveyor belt 5, and the end of the belt 21 in the precise metering and feeding device is positioned at the main conveyor belt 5 above. The end of the belt 21 in the precise metering and feeding device is arranged above the main conveyor belt 5, so that the end of the belt 21 in the precise metering and feeding device does not have to extend to the total processing point, so that the precise metering and feeding device can be miniaturized.

[0027] As a further improvement of the above technical solution, the plurality of precise metering and feeding devices share one controller 4, which can realize unified control and simplify the equipment required by the system, so as to further reduce equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com