Preparation method of glass mosaic with marble patterns on the whole body

A technology of glass mosaic and marble pattern, which is applied in the field of building materials and decoration materials, can solve the problems of no three-dimensional effect, wear and tear of patterns, poor imitation stone effect, etc., and achieve the effect of clear structure, strong sense of hierarchy, and reduced production of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention provides a method for preparing a full-body marbled glass mosaic, comprising:

[0054] S101, mixing glass powder with additives to obtain a mixture;

[0055] The glass powder is obtained by mixing and ball milling scraps of glass mosaics and broken glass, and its particle size is 20-120 mesh.

[0056] The existing method mixes raw glass powder and waste glass powder in a certain ratio to prepare glass mosaic. As the number of firings of waste glass powder increases, its melting temperature will continue to rise, so it can be in a semi-fused state during the low-temperature firing process of glass mosaics, so it needs to be mixed with raw glass powder, due to the melting of raw glass powder The temperature is lower than that of the waste glass powder. During the firing process, the molten part of the waste glass powder can be fully fused with the raw glass powder and the surface of the glass body to form a stable glaze layer structure.

[0057]The inventi...

Embodiment 1

[0097] (1) Formula:

[0098] The base body powder includes: 100 parts of glass powder, 0.1 part of binder, and 5 parts of water, wherein the binder is methyl cellulose;

[0099] The colorant mixture comprises: 0.02 part of colorant and 1 part of flux, and the flux is a transparent frit.

[0100] (2) Preparation method

[0101] 1. Prepare glass powder: mix and ball-mill glass mosaic side material and cullet, and its particle size is 20-120 mesh;

[0102] 2. Mix glass powder and binder in proportion to obtain a mixture;

[0103] 3. Add water to the mixture and mix evenly, then granulate and sieve to obtain the basic green body powder;

[0104] 4. Mix the colorant and flux uniformly in proportion to obtain a powdery colorant mixture with a particle size of 20-120 mesh;

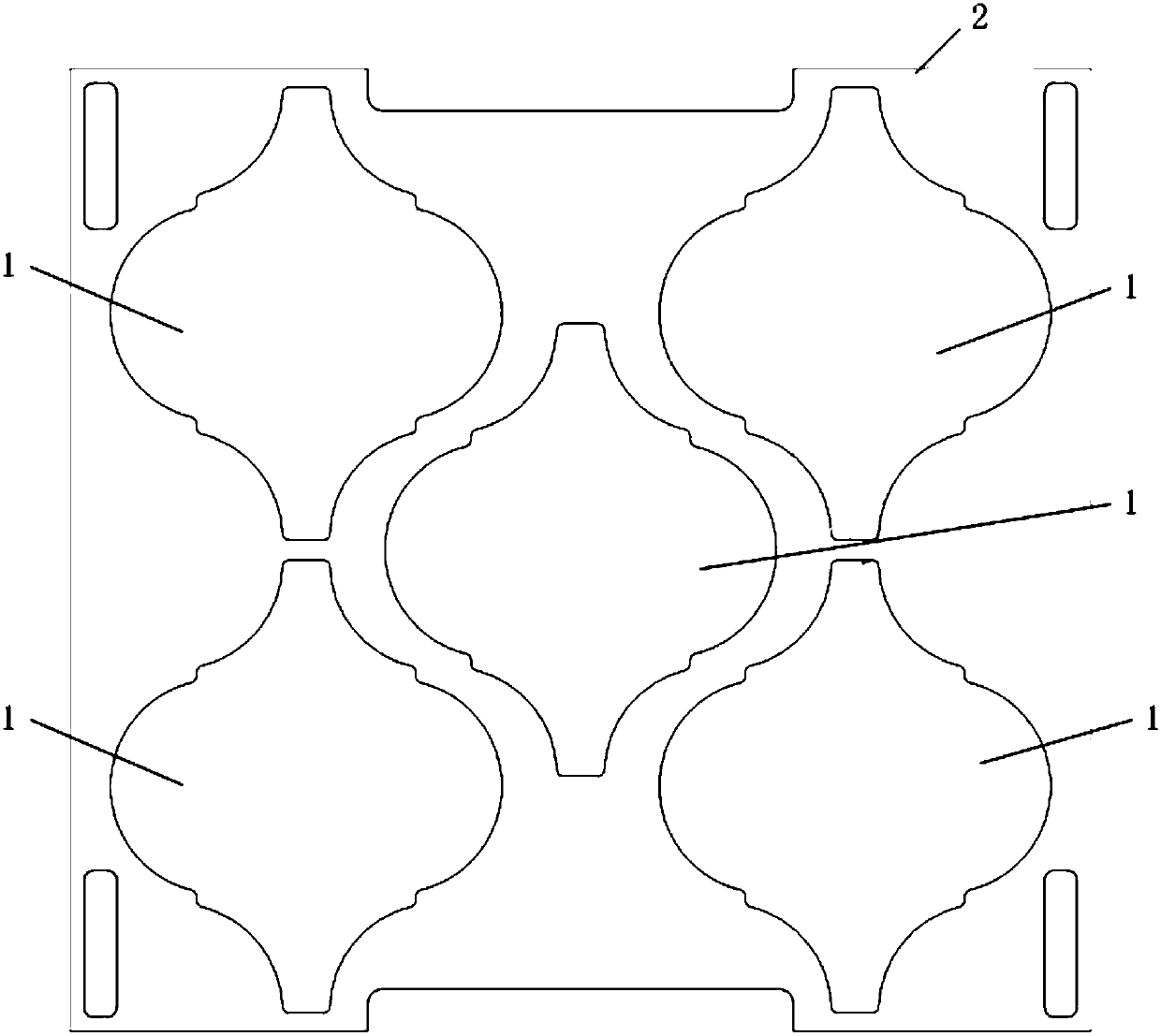

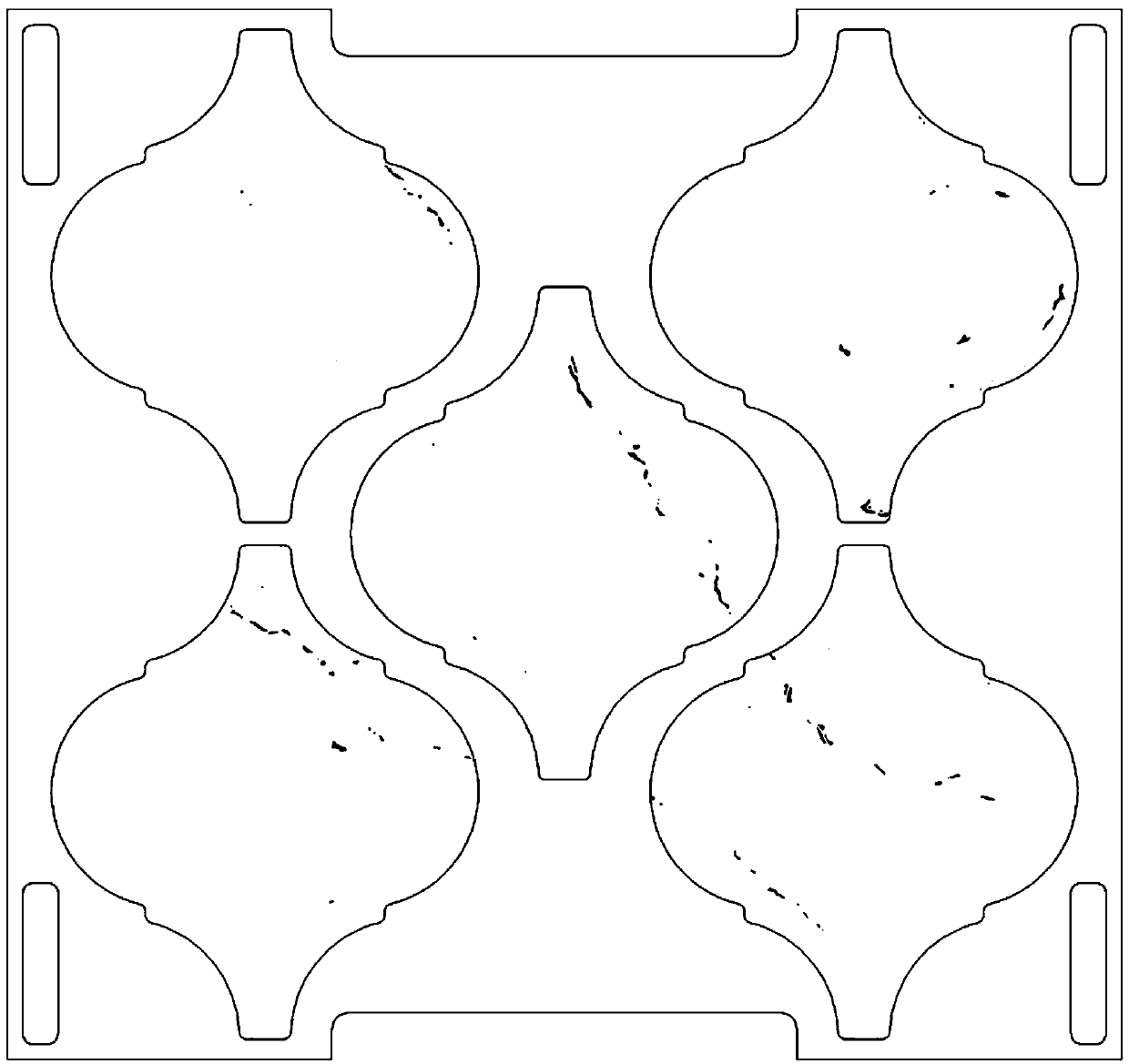

[0105] 5. Pass the base body powder and colorant mixture through figure 1 The mold shown is processed with five layers of cloth, pressed and formed to obtain a green body, such as image 3 shown;

[0106] 6....

Embodiment 2

[0109] (1) Formula:

[0110] The base green body powder includes: 100 parts of glass powder, 0.5 parts of binder, 2 parts of whitening agent and 5 parts of water, wherein the binder is polyvinyl alcohol; the whitening agent is titanium dioxide.

[0111] The color material mixture comprises: 0.1 part of color material and 1 part of flux, and the flux is a transparent frit.

[0112] (2) Preparation method

[0113] 1. Prepare glass powder: mix and ball-mill glass mosaic side material and cullet, and its particle size is 20-120 mesh;

[0114] 2. Mix glass powder with binder and whitening agent in proportion to obtain a mixture;

[0115] 3. Add water to the mixture and mix evenly, then granulate and sieve to obtain the basic green body powder;

[0116] 4. Mix the colorant and flux uniformly in proportion to obtain a powdery colorant mixture with a particle size of 20-120 mesh;

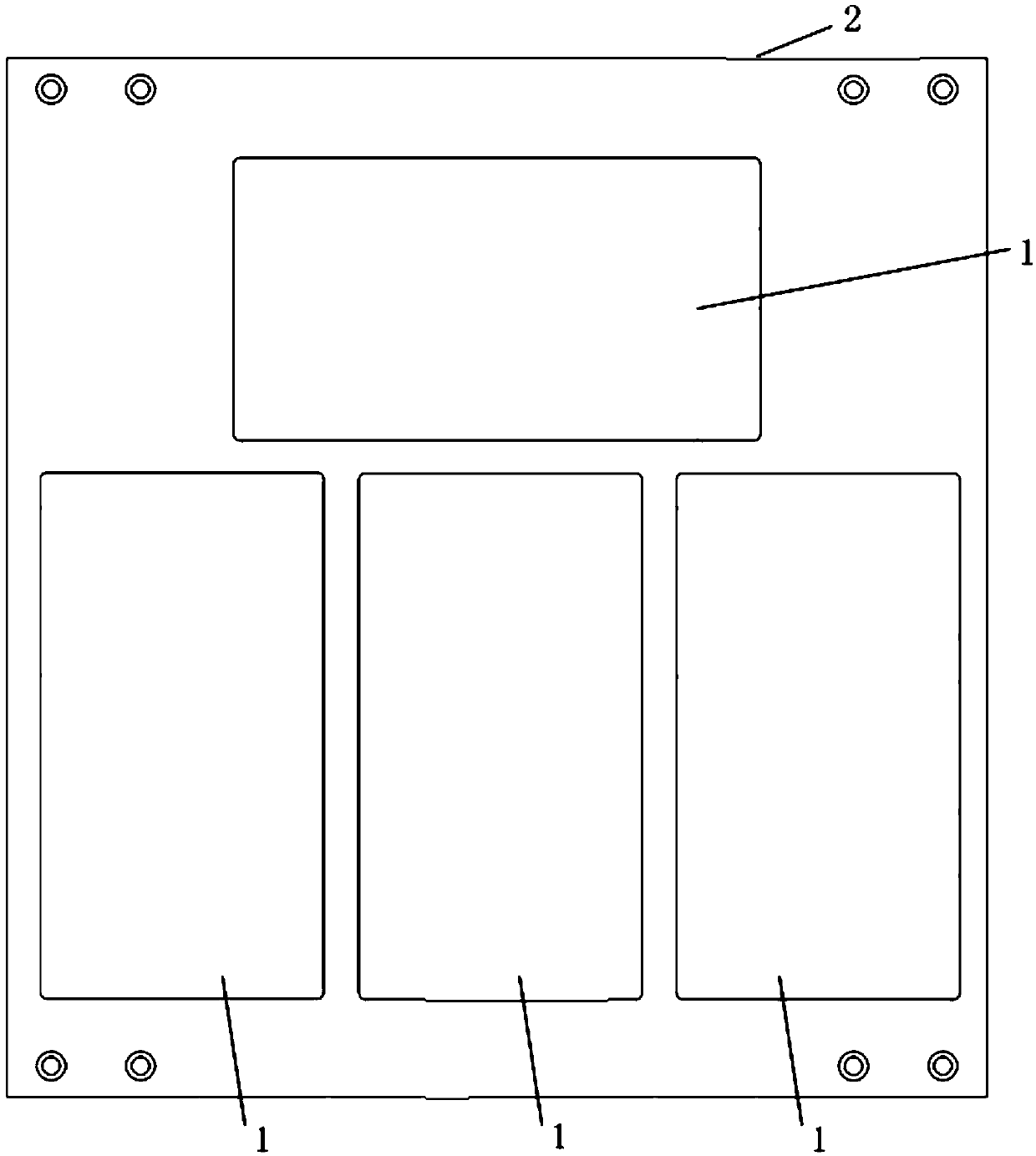

[0117] 5. Pass the base body powder and colorant mixture through figure 2 The mold shown is proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com