Energy dissipating and shock absorbing system having dense reinforcement structure

A technology of dense ribs and systems, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of structural disaster resistance mode, wall panel performance degradation, low energy consumption, etc., and achieve easy construction and installation and repair costs The effect of low power consumption and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

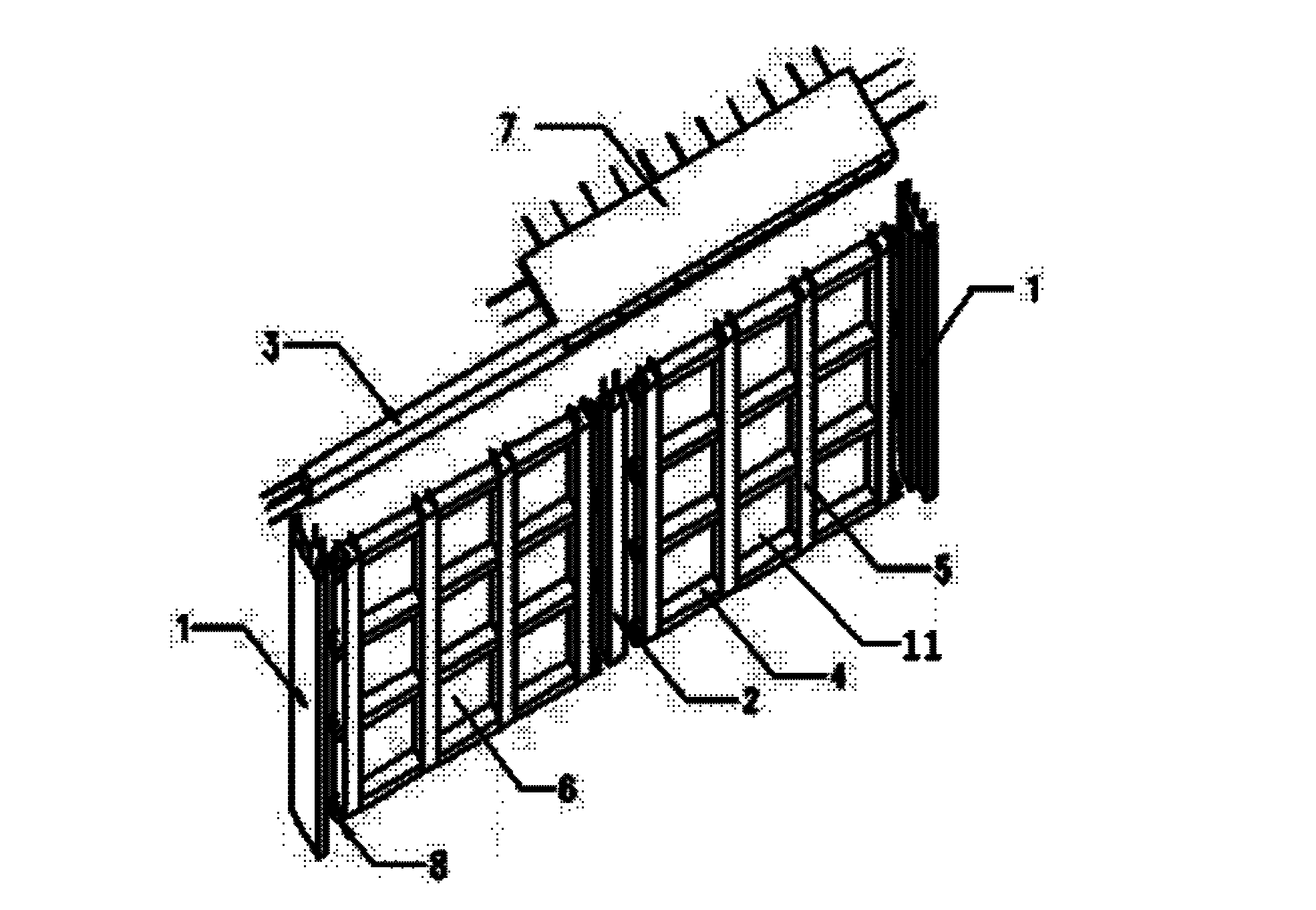

[0033] like figure 1As shown, the present invention is an energy-dissipating and shock-absorbing system of dense rib structure, which includes an invisible frame composed of outer frame columns 1, connecting columns 2 and hidden beams 3, and the hidden beams 3 are horizontally connected with floor slabs 7. Two kinds of composite wall panels are arranged in the invisible frame, wherein, a part of the invisible frame is provided with low-yield point steel dense rib composite wall panels, and the remaining part of the invisible frame is provided with lightweight filling block dense rib composite wall panels.

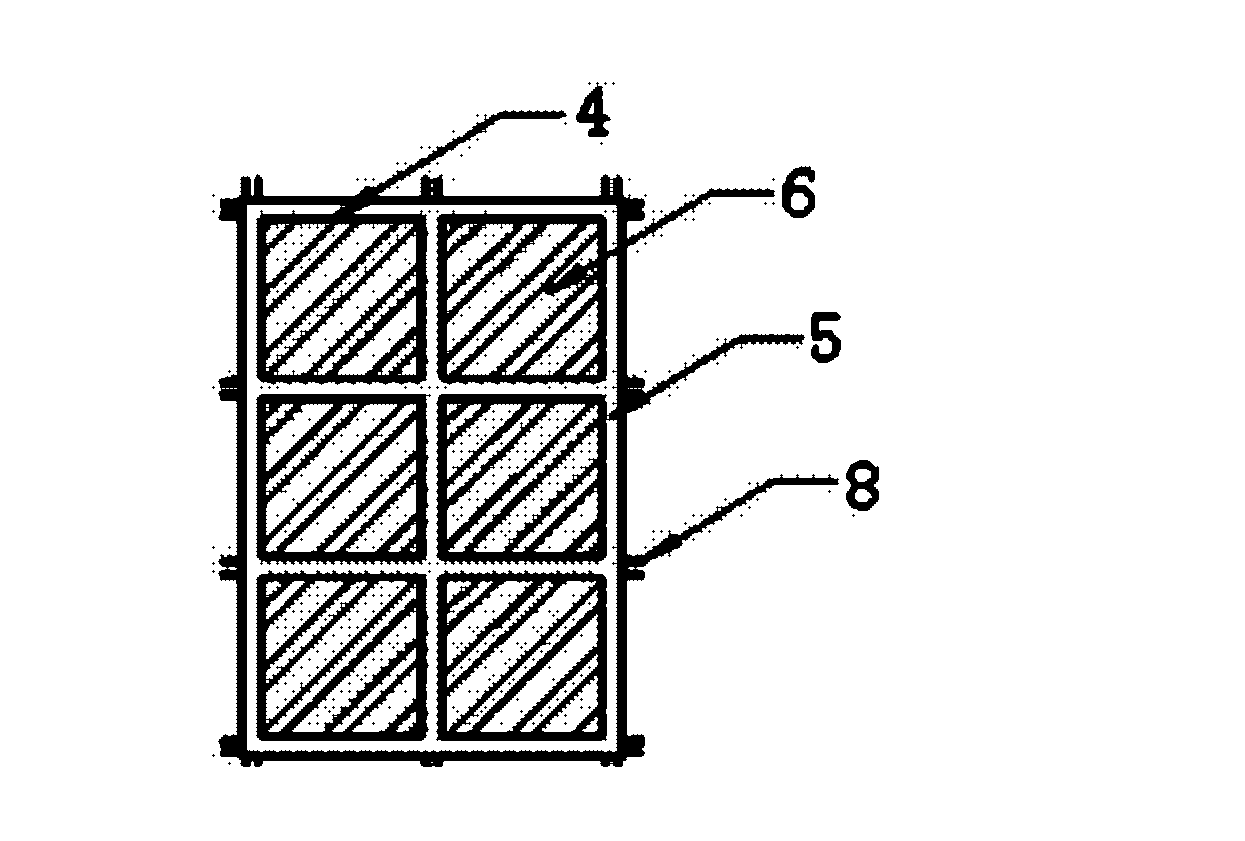

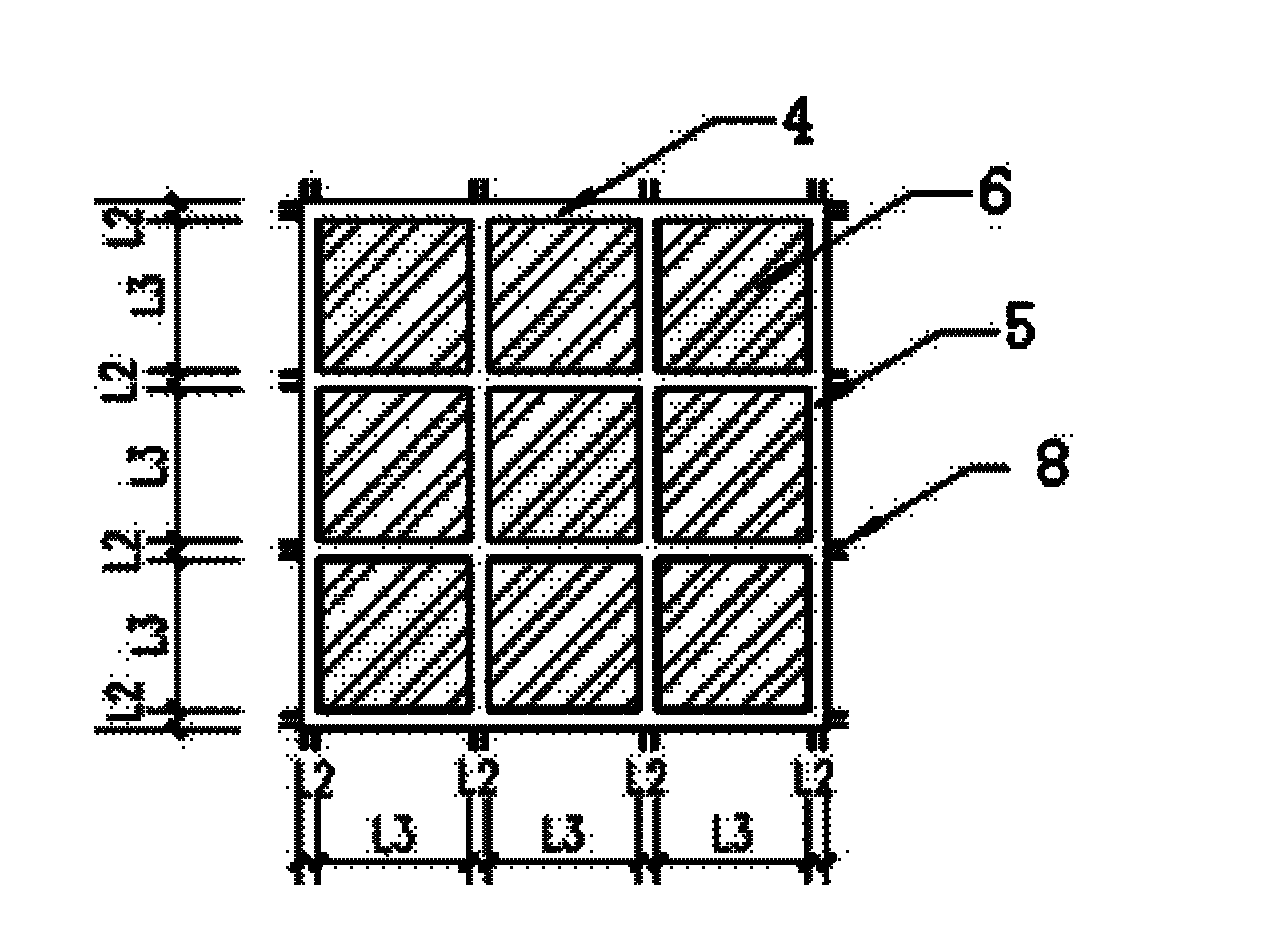

[0034] Among them, the low-yield-point steel dense-rib composite wallboard includes a plurality of rib beams 4 and rib columns 5 , and the rib beams 4 and rib columns 5 form a rectangular grid structure, and each grid is embedded with a low-yield point steel plate 6 . The yield strength of the steel plate used for the low yield point steel plate 6 is 100 MPa, 160 MPa or 225...

Embodiment 2

[0053] An energy-dissipating and shock-absorbing system of dense rib structure includes an invisible frame composed of outer frame columns 1, connecting columns 2 and hidden beams 3, and the hidden beams 3 are horizontally connected with floor slabs 7. The difference between this embodiment and the previous embodiment is that low-yield-point steel dense rib composite wall panels are all set in the invisible frame; other technical solutions are the same as the previous embodiment.

[0054] The low-yield point steel dense rib composite wallboard includes a plurality of rib beams 4 and rib columns 5, the rib beams 4 and the rib columns 5 form a rectangular lattice structure, and a low yield point steel plate 6 is embedded in each lattice. The upper and lower sides or four peripheries of the low yield point steel plate 6 are welded or bolted to the fishplate 9, and the corresponding rib beam 4 or rib column 5 is provided with embedded iron parts 10, and each fishplate 9 is welded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com