Flange assembly machine

An assembly machine and flange technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of no positioning steel pipe, poor fixation, and reduced flange assembly effect, saving human resources and saving Human and material resources, saving the effect of producing finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

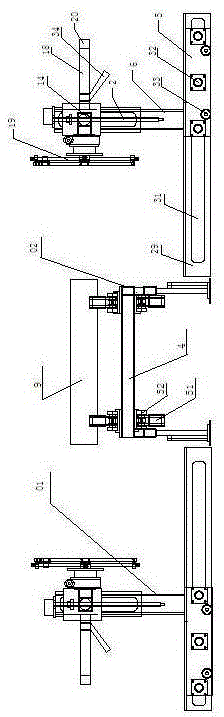

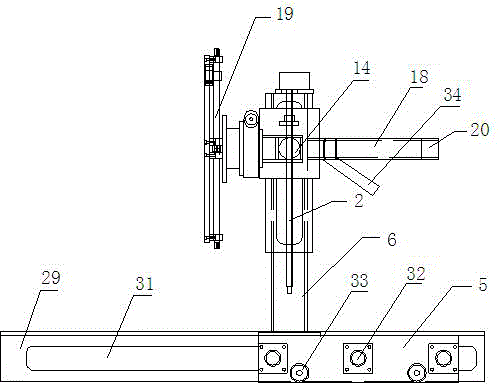

[0040]As shown in the figure, a flange assembly machine includes an adjustment mechanism 01 and a pipeline delivery mechanism 02; the adjustment mechanism 01 is located on both sides of the pipeline delivery mechanism 02, and the adjustment mechanism 01 is based on the pipeline delivery mechanism 02 Axis of symmetry, distributed symmetrically from left to right;

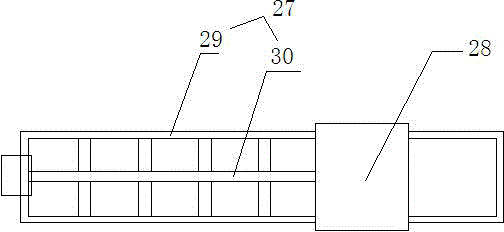

[0041] The adjustment mechanism 01 includes a horizontal displacement mechanism 27 and a grasping mechanism 28. The horizontal displacement mechanism 27 includes a base 29 and a telescopic pull rod 30. The base 29 is a rectangular parallelepiped frame structure, and the two sides of the base 29 are respectively provided with A sliding engagement channel 31, the telescopic end of the telescopic pull rod 30 is fixed on the grasping mechanism 28;

[0042] The grabbing mechanism 28 includes a main frame 1, a lifting device 2, a grabbing device 3 and a flange fixing plate 4, the main frame 1 includes a base 5 and a frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com