Tree planting machine and application of same

A tree planting machine and tree pit technology, applied in application, planting methods, forestry, etc., can solve the problems of not being able to adapt to the requirements of different tree row spacing, difficult to control row spacing, high labor intensity, etc., and achieve good economic value and market benefits , saving manpower and material resources, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

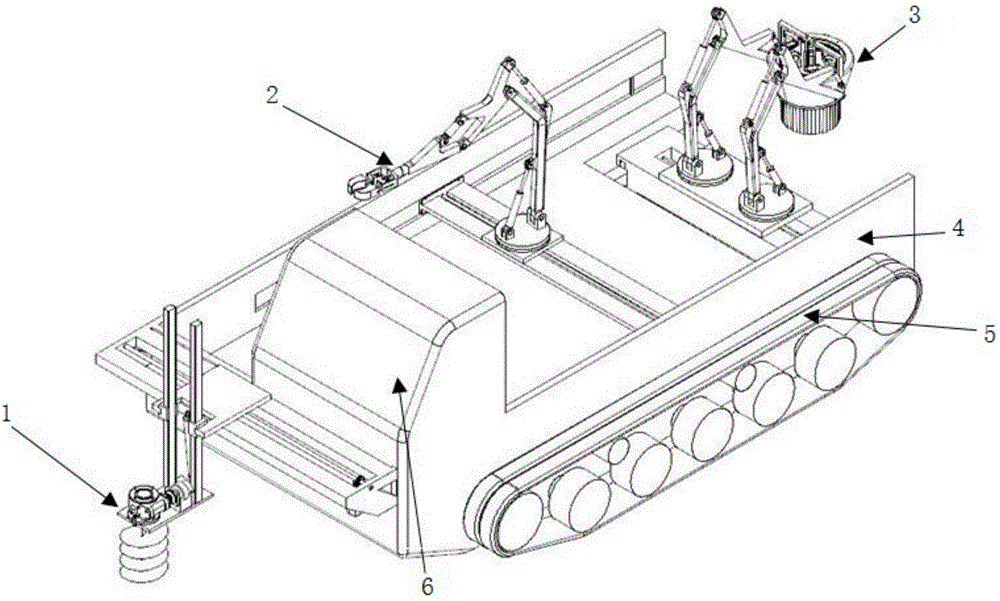

[0054] Such as Figure 1 to Figure 6 As shown, the present embodiment provides a tree planting machine, including a tractor, the driver's cab 6 of the tractor is located at the left front of the vehicle body 4, and the driver drives the tractor to move forward and can observe the tree planting situation. In this embodiment, the tractor is Caterpillar tractor.

[0055] The front portion of the tractor is provided with a digging mechanism 1 for digging out a tree pit for planting saplings;

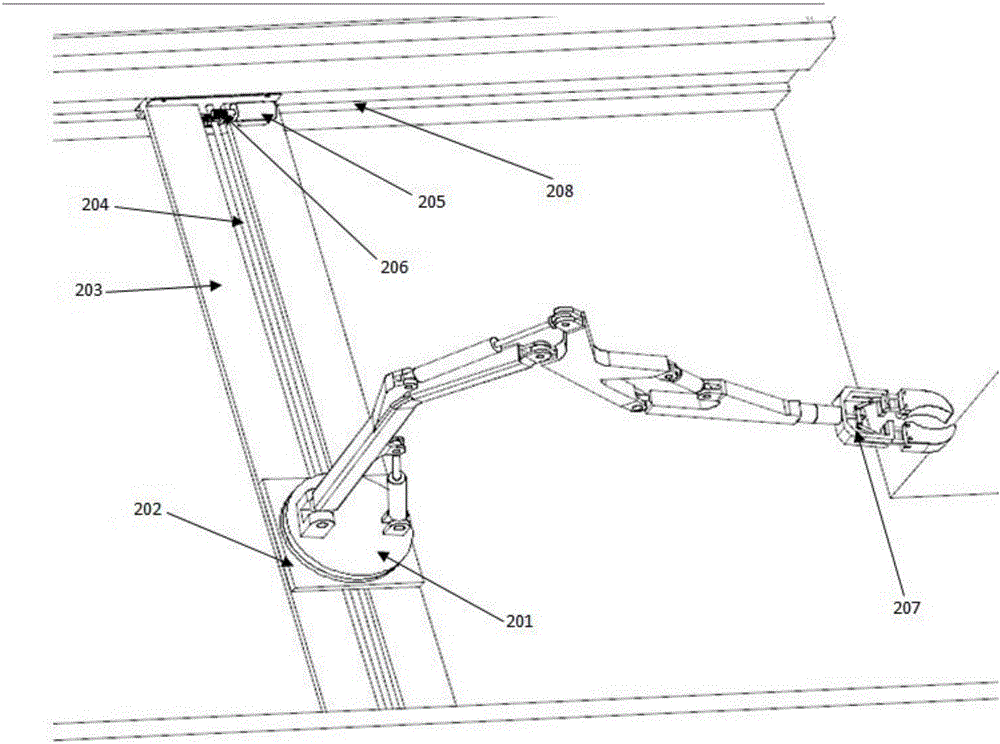

[0056] The middle part of the tractor is provided with a seedling-taking mechanism 2, and a side of the tractor is provided with a seedling box for storing saplings. It is used to take out the saplings in the seedling box and place them in the dug tree hole; multiple saplings can be placed in the seedling box, which is convenient for continuous large-scale operation.

[0057] The tail of the tractor is provided with a pushing mechanism 3, which is used to push the soil back into the tree p...

Embodiment 2

[0070]A kind of tree planting machine, structure is as described in embodiment 1, and its difference is: two layers of bulldozers comprise inner layer bulldozer 19 and outer layer bulldozer 18, inner layer bulldozer 19 and outer layer bulldozer The plates 18 are arranged in an offset manner. The inner and outer layers of bulldozing boards are misaligned, which can reduce the leakage of soil from between the two bulldozing boards.

Embodiment 3

[0072] A working method of tree planting machine as described in embodiment 2, specifically comprises the following steps,

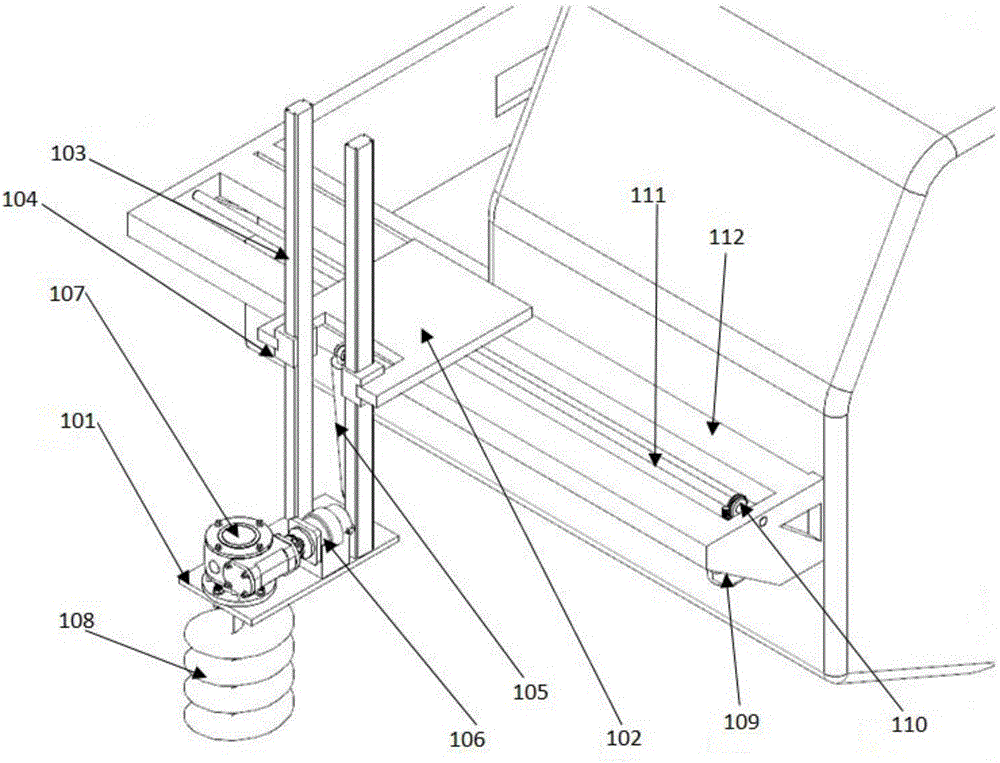

[0073] (1) Before the tree planting machine starts to work, input the tree planting program in the intelligent control system. The tree planting program includes row spacing parameters, tree pit depth parameters and filling radius parameters; then select the auger rod 108 that meets the requirements, and put into the saplings to be planted;

[0074] (2) Start the tree planting machine, the driver drives the tractor, and the digging mechanism drives the auger rod 108 to dig down by the first hydraulic telescopic cylinder 105 according to the set tree pit depth parameter and synchronously drives the auger rod by the hydraulic motor 106 108 rotation, after a tree pit is dug out, the digging mechanism is translated by the first slide plate 102 according to the set row spacing parameter, and the auger rod 108 is driven to move to the next tree pit position, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com