Room-temperature composite soft sheathing method for high-temperature alloy forge piece hot die forging and forging method of high-temperature alloy forge piece

A high-temperature alloy and deformed high-temperature alloy technology, which is applied in the driving device of forging presses, vehicle parts, transportation and packaging, etc., can solve problems such as poor safety and operability, unfavorable forging process consistency control, and different actual temperatures. Achieve the effect of saving machining cost, improving quality and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

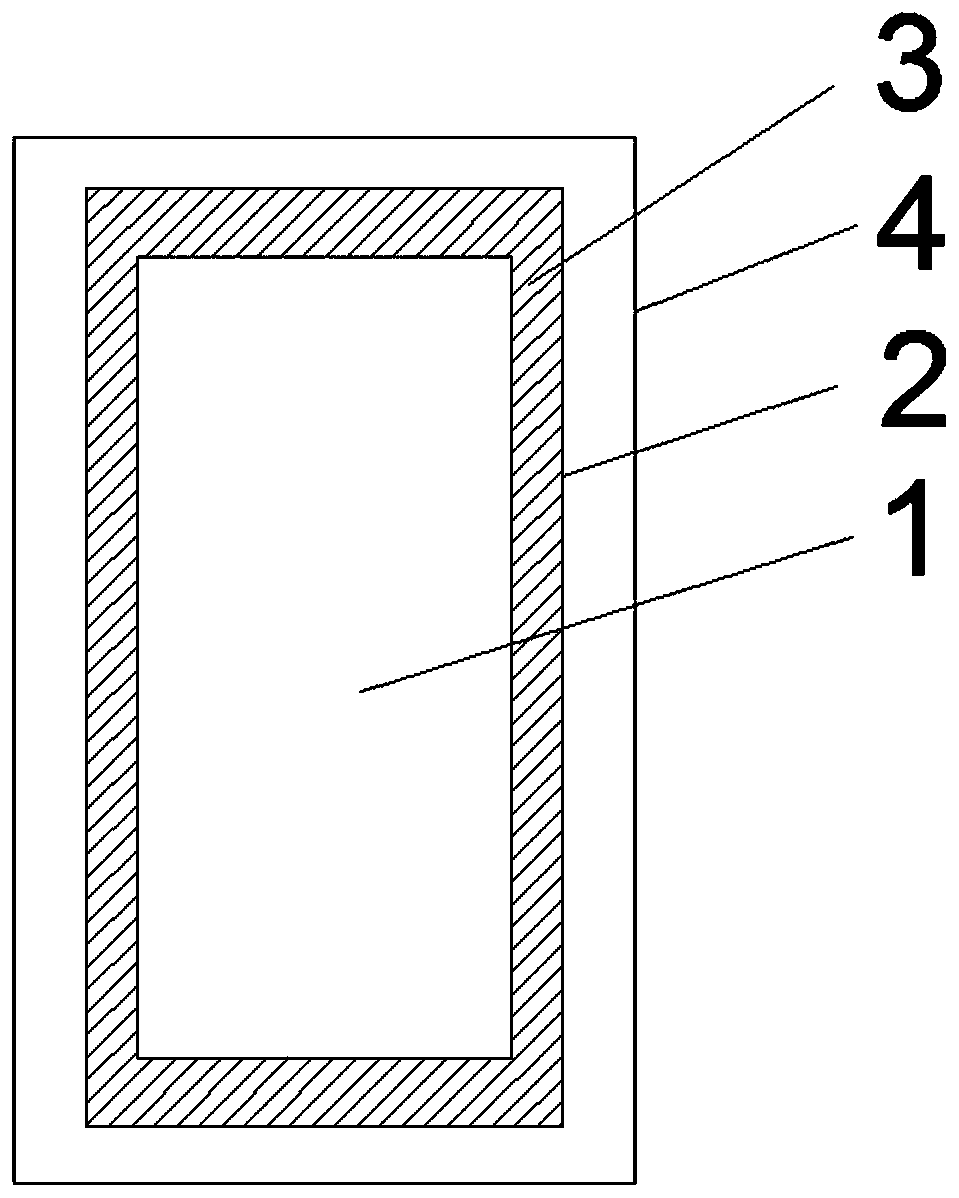

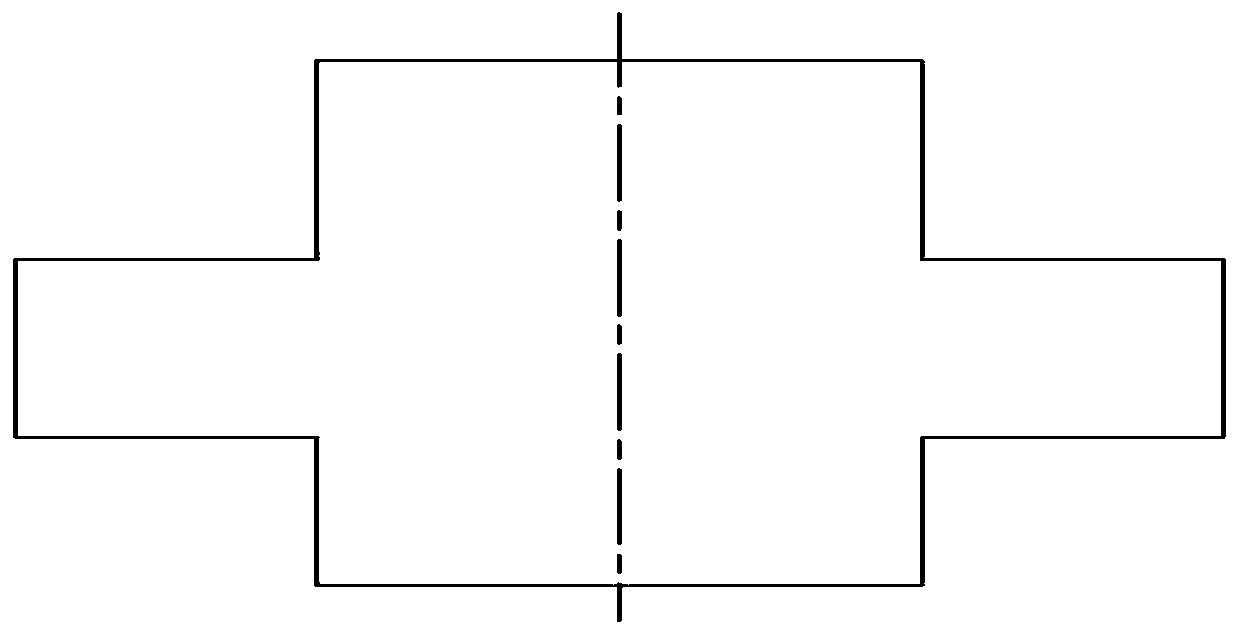

[0086] In this embodiment, a room temperature composite soft sheath for hot die forging of superalloy forgings is provided, which includes a blank 1, a cladding 2, a high-temperature binder 3 and a glass fiber cloth 4; the cladding 2 The surface of the blank 1 is covered by the high-temperature adhesive 3, and the glass fiber cloth 4 is tightly wrapped on the covering 2, and the covering 2 is an aluminum silicate fiber blanket or a silicic acid blanket. Aluminum felt. Among them, the blank 1 is a cylindrical blank in one-fire forming; the cladding 2 is an aluminum silicate felt with a thickness of 4mm; the high-temperature binder 3 is a glass binder with a thickness of 5mm; the thickness of the glass fiber cloth 4 is 1mm.

[0087] Multiple blanks 1 are wrapped and heated in the furnace at the same time. There is no frequent opening and closing of the furnace door in the middle, and the heating consistency of blanks 1 is good.

Embodiment 2

[0089] In this embodiment, a room temperature composite soft sheath for hot die forging of superalloy forgings is provided, which includes a blank 1, a cladding 2, a high-temperature binder 3 and a glass fiber cloth 4; the cladding 2 The surface of the blank 1 is covered by the high-temperature adhesive 3, and the glass fiber cloth 4 is tightly wrapped on the covering 2, and the covering 2 is an aluminum silicate fiber blanket or a silicic acid blanket. Aluminum felt. Among them, the blank 1 is the cake blank of the second fire in the two-fire molding; the covering 2 is an aluminum silicate fiber blanket with a thickness of 24mm; the high-temperature binder 3 is a glass binder with a thickness of 7mm; the glass fiber cloth 4 has a thickness of 1.5 mm.

[0090] Multiple blanks 1 are wrapped and heated in the furnace at the same time. There is no frequent opening and closing of the furnace door in the middle, and the heating consistency of blanks 1 is good.

Embodiment 3

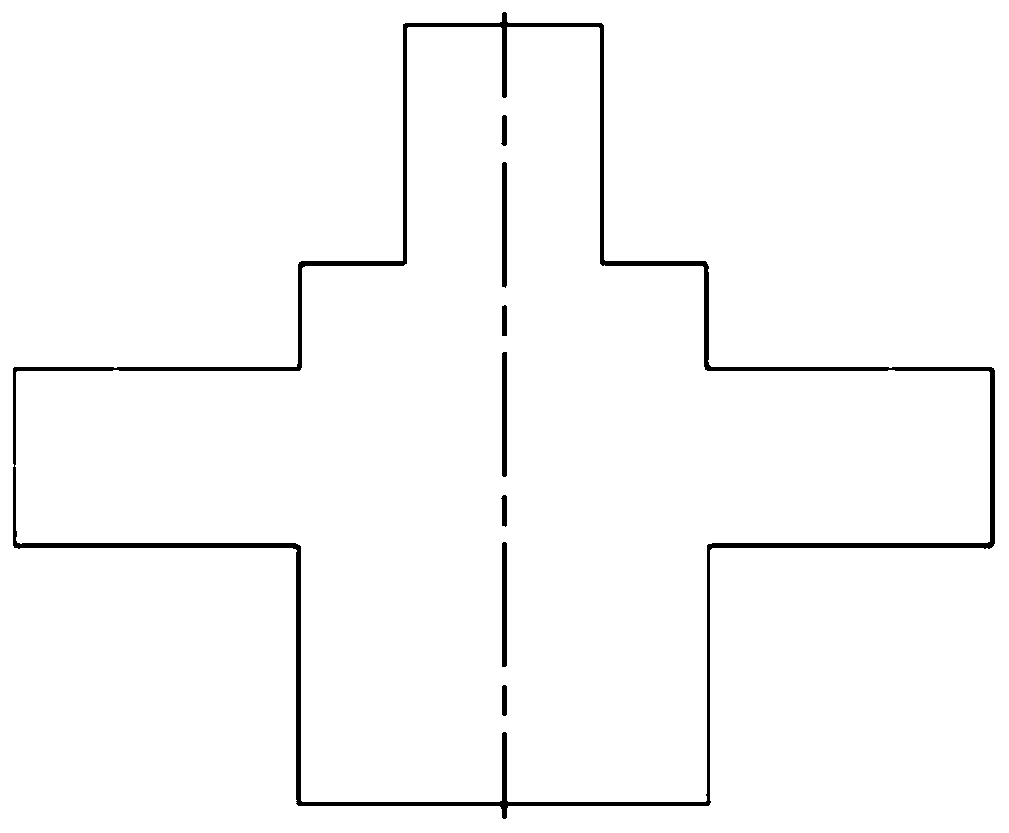

[0092]In this embodiment, a room temperature composite soft sheath for hot die forging of superalloy forgings is provided, which includes a blank 1, a cladding 2, a high-temperature binder 3 and a glass fiber cloth 4; the cladding 2 The surface of the blank 1 is covered by the high-temperature adhesive 3, and the glass fiber cloth 4 is tightly wrapped on the covering 2, and the covering 2 is an aluminum silicate fiber blanket or a silicic acid blanket. Aluminum felt. Among them, the blank 1 is the blank of the turbine disk forging; the cladding 2 is an aluminum silicate fiber blanket with a thickness of 18mm; the high-temperature binder 3 is a glass binder with a thickness of 10mm; the thickness of the glass fiber cloth 4 is 0.7 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com