Deep extraction process for matcha-derived bioactive component

A technology for deep extraction of biologically active components, applied in the field of deep extraction of matcha-derived biologically active components, can solve problems such as the retention of tea residues, and achieve the effects of increasing the transmittance, ensuring the use effect and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

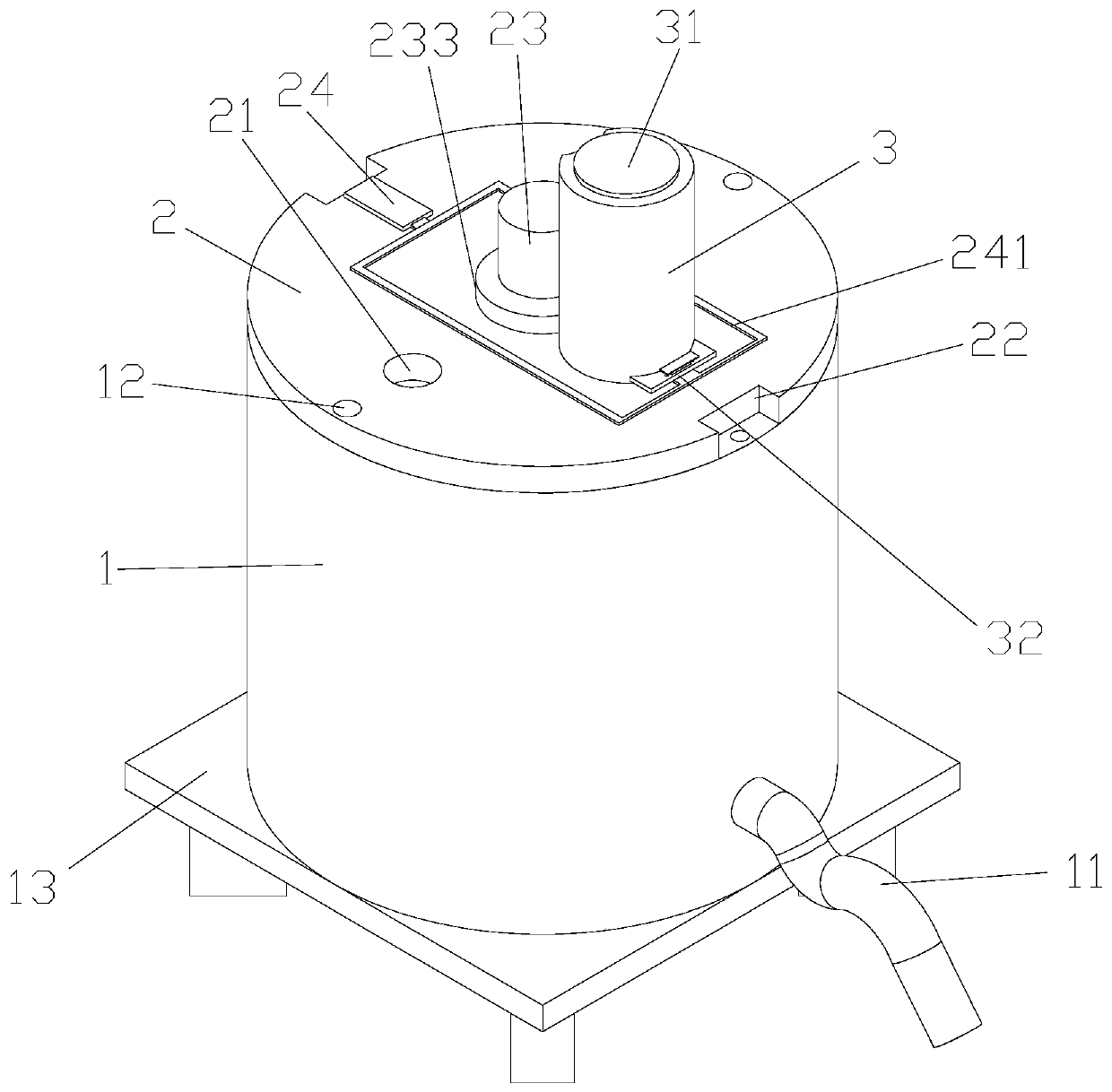

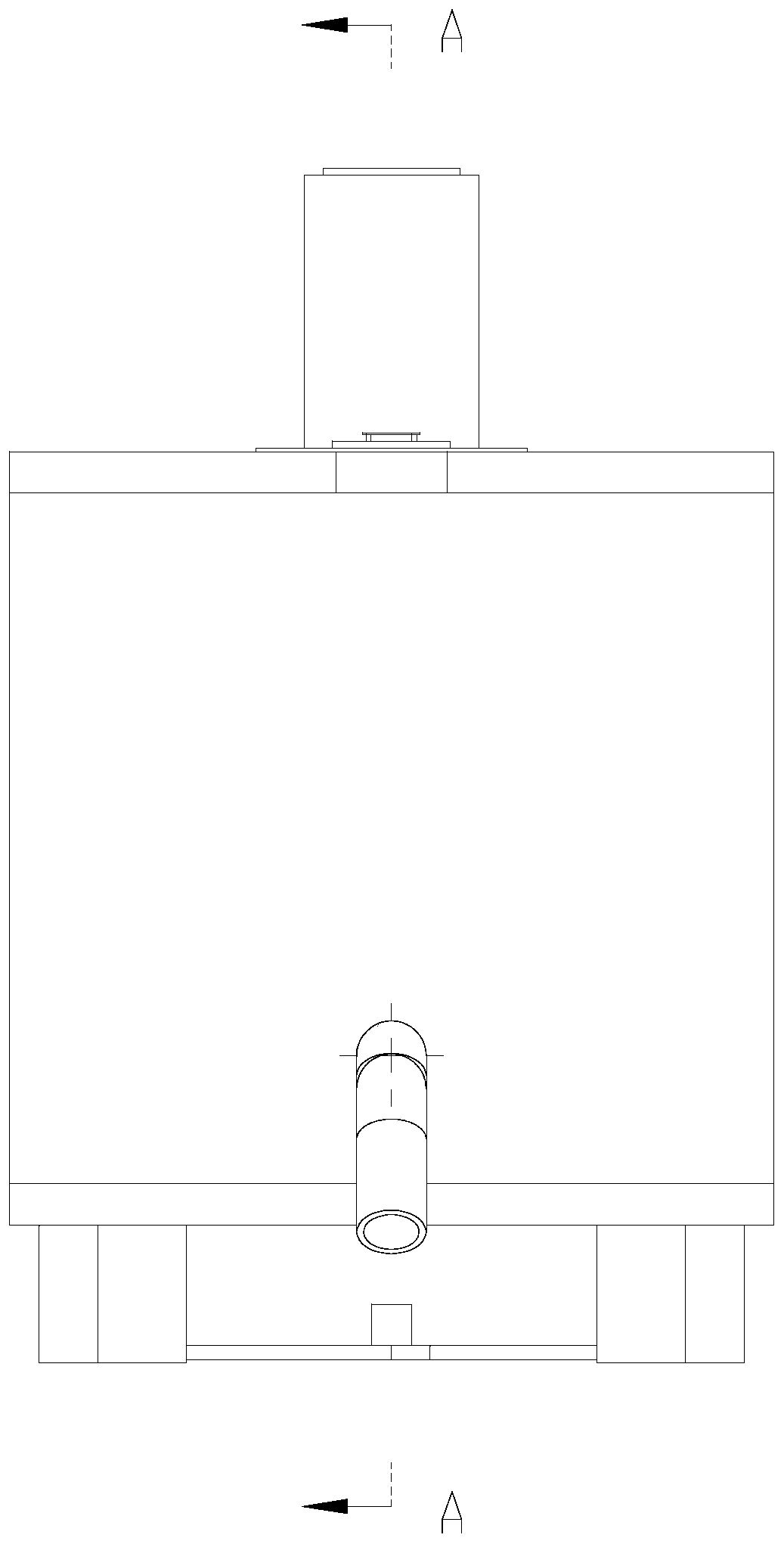

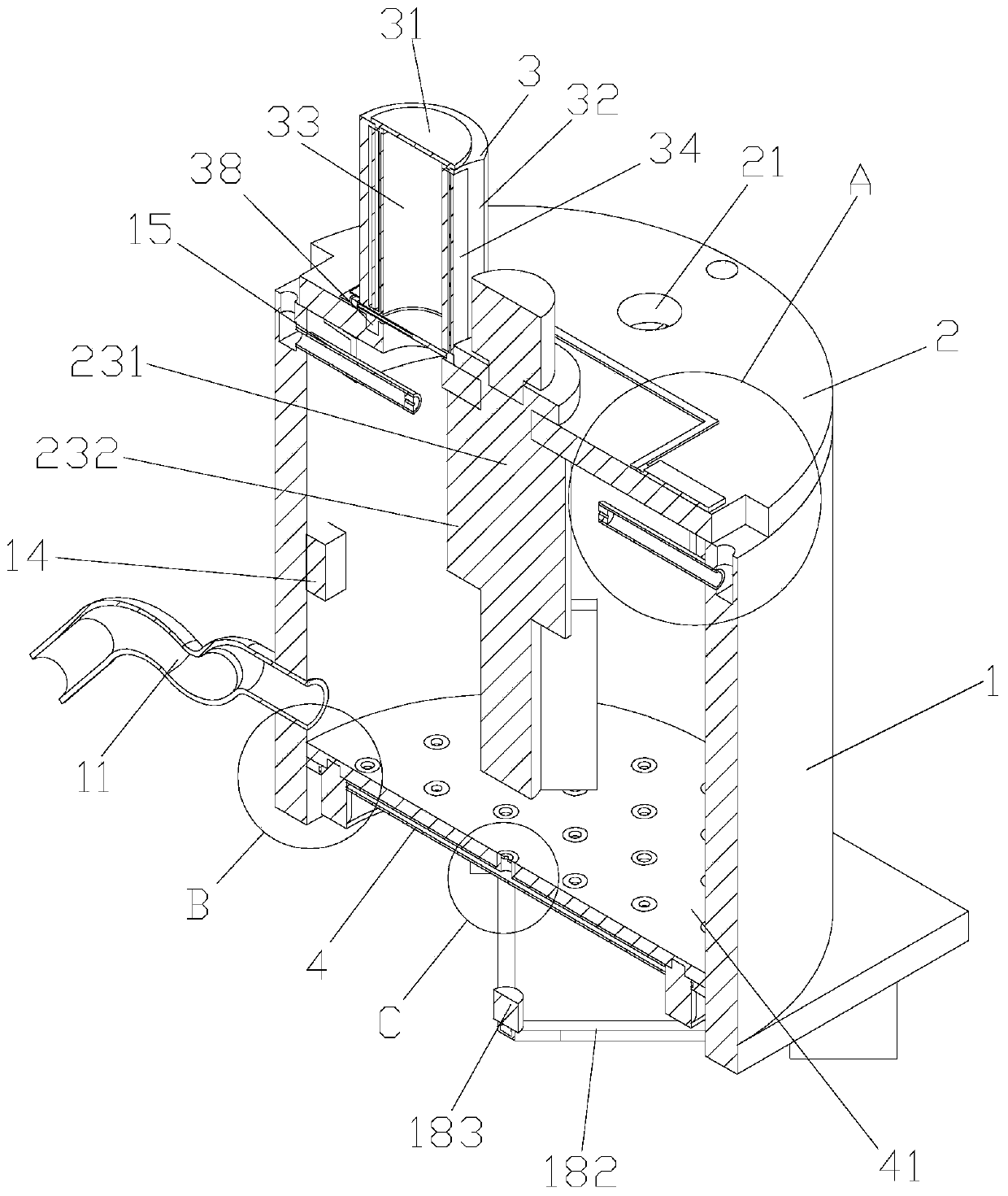

[0039] A process for the integrated extraction of multiple bioactive components in tea, comprising the following steps:

[0040] The tea leaves are dried, crushed, passed through a 60-mesh sieve, and filtered to obtain tea powder.

[0041] Take 10kg of tea powder, add it to the processing barrel, add pure water to 100L, heat to 80°C-90°C, keep stirring and extracting for 30min during the heating process, and then perform solid-liquid separation to obtain the first solid-phase separation and the first liquid phase separation.

[0042] The first liquid phase separation is filtered, concentrated by evaporation and dried to obtain concentrated instant tea. Specifically, the plate and frame filter press is used to separate the liquid phase and the solid phase first, and an appropriate amount of pure water is used for top pouring, and the pouring liquid is merged into the liquid phase. After that, the liquid phase passes through a ceramic membrane with a pore size of 50 μm to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com