Regulating mechanism for flange assembly machine

A technology of adjusting mechanism and assembling machine, applied in applications, auxiliary devices, household appliances, etc., can solve the problems of operation mode without automation and poor fixation, and achieve the effect of convenient and fast movement, saving manpower and material resources, and saving finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

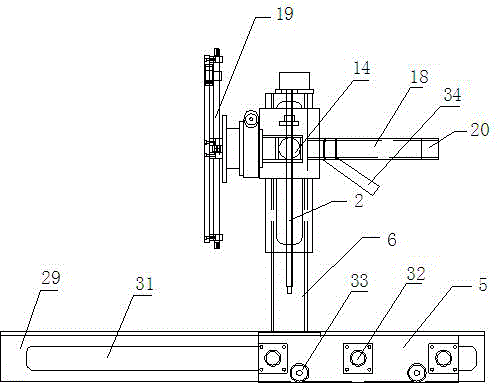

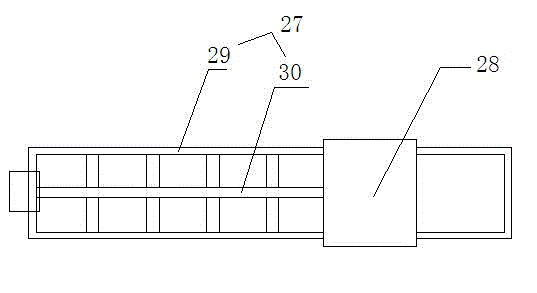

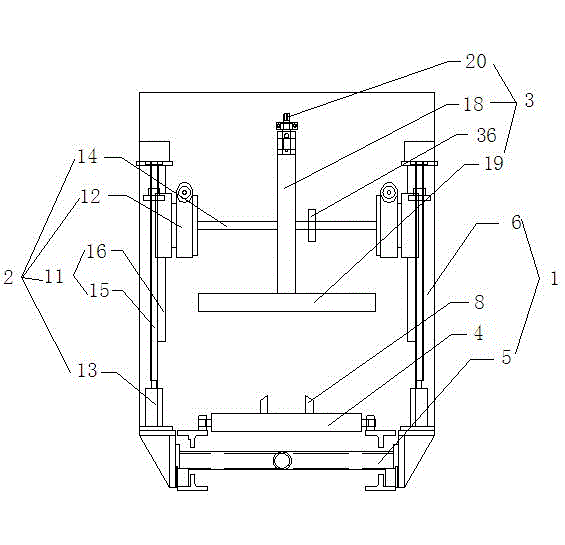

[0029] As shown in the figure, an adjustment mechanism for a flange assembly machine includes a horizontal displacement mechanism 27 and a grasping mechanism 28. The horizontal displacement mechanism 27 includes a base 29 and a telescopic pull rod 30. The base 29 is a rectangular parallelepiped frame structure. Two sides of 29 are respectively provided with a sliding engagement channel 31, and the telescopic end of the telescopic pull rod 30 is fixed on the grasping mechanism 28;

[0030] The grabbing mechanism 28 includes a main frame 1, a lifting device 2, a grabbing device 3 and a flange fixing plate 4, the main frame 1 includes a base 5 and a frame body 6, and the frame body 6 is fixed on the base 5 Above, the base 5 is a frame structure, and several second fixed sliders 32 are fixed between the inner walls of the base 5, and the base 5 is sleeved on the outside of the base 29 of the horizontal displacement mechanism, so that the second fixed The slider 32 is slidably arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com