Method for repairing anode steel stud

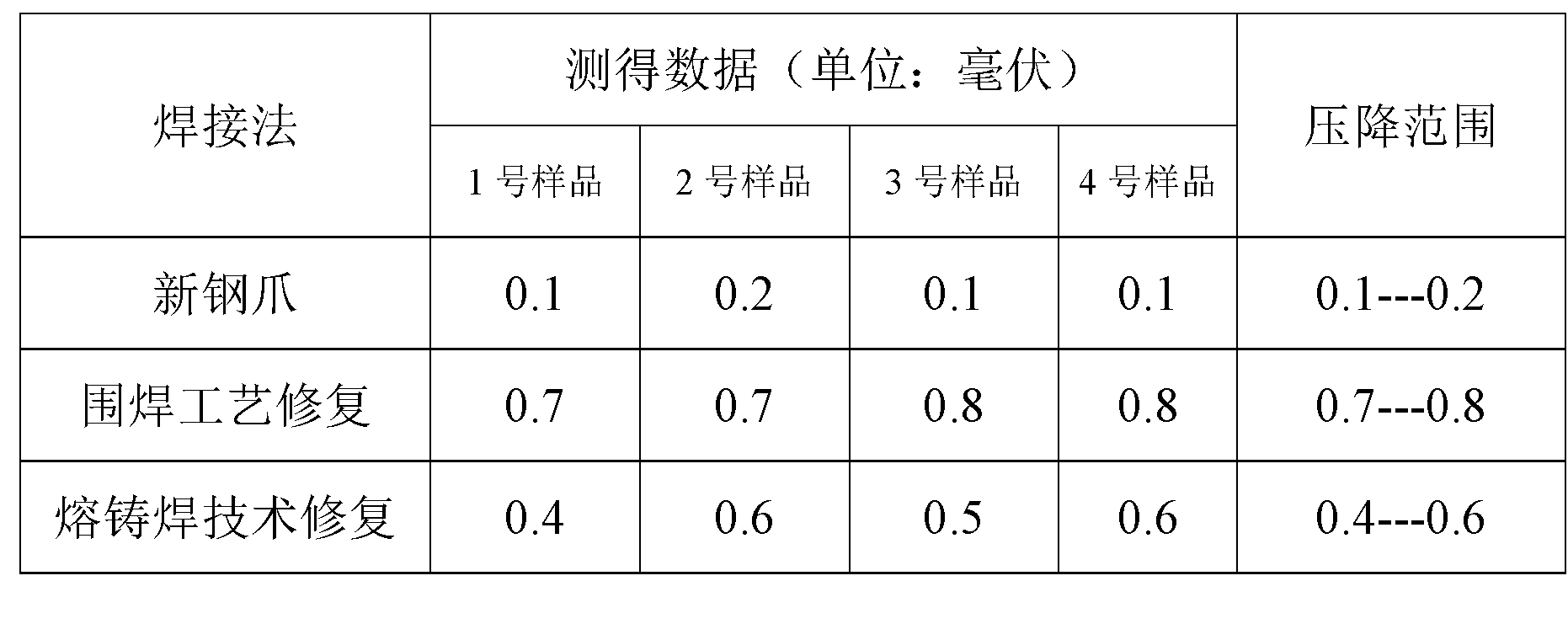

A repair method and technology of anode steel claws are applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., to achieve the effect of reducing power consumption, reducing pressure drop, and reliable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

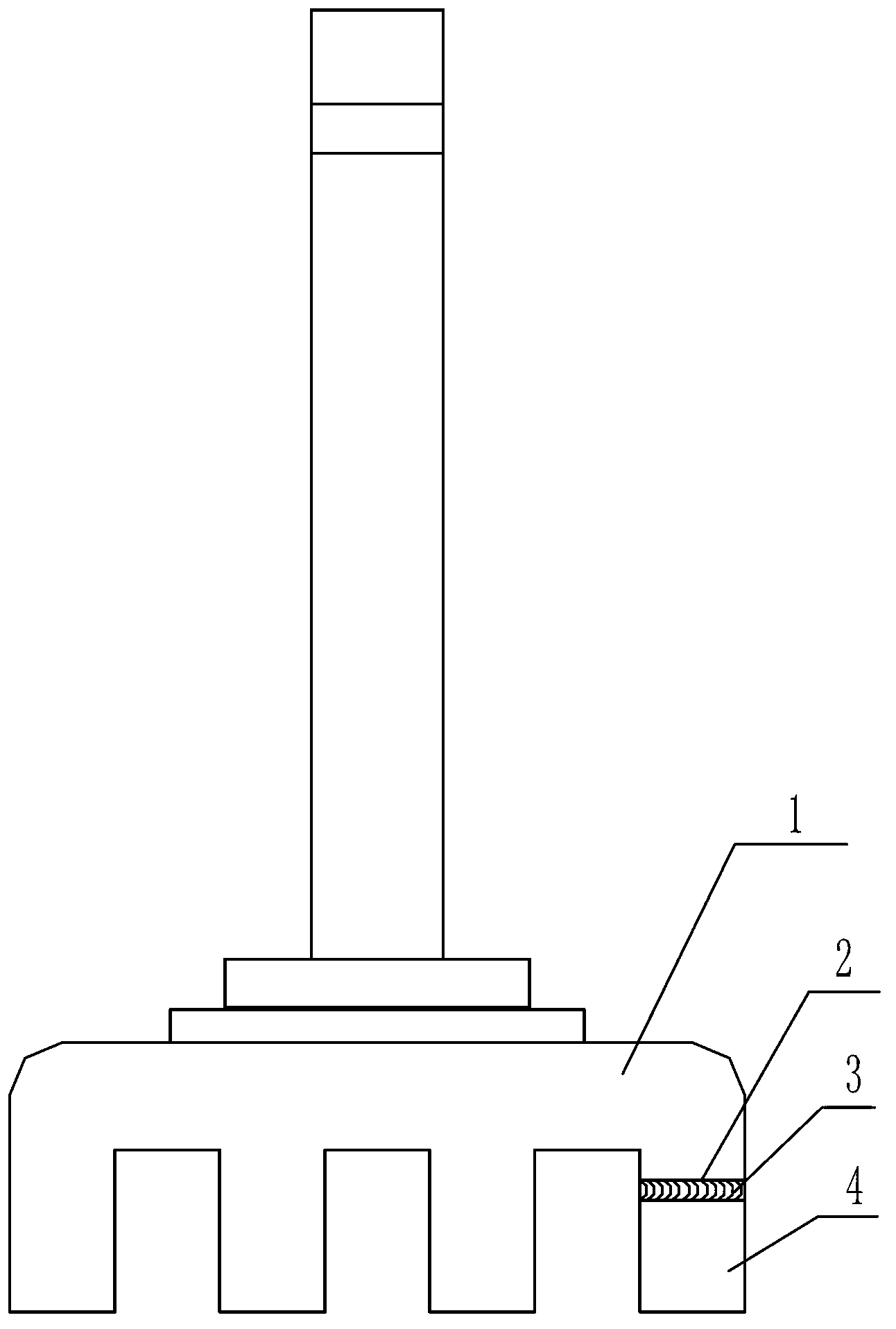

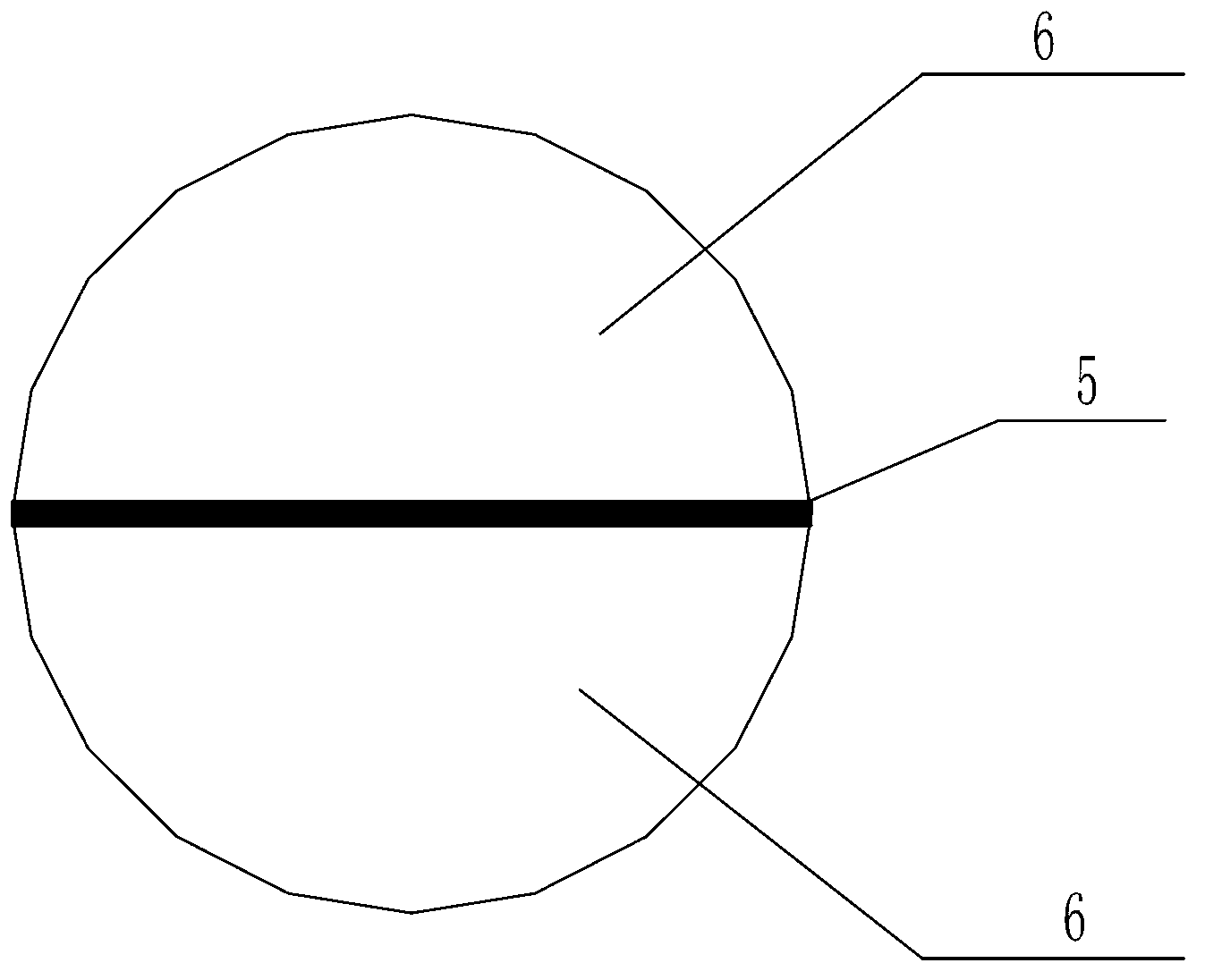

[0020] Aiming at repairing the anode steel claws of a single row of four steel claw heads in an aluminum factory, the repair method is: referring to the attached drawings, cut off a section of the burnt steel claw head on the steel claw body 1 by gas welding, and cut off the section The length is based on the design length of the steel claw head: 165-170 mm. Prepare a cylindrical steel rod 4 with a diameter equal to that of the steel claw head and a length of 140 mm. Weld a piece of auxiliary connecting piece 5 vertically on the cut section 2 of the steel claw head. In the middle part, the middle part of one end face of the cylindrical steel rod is welded and connected with the auxiliary connecting piece, so that the cylindrical steel rod is concentric with the remaining section of the steel claw head after cutting, and the length of the auxiliary connecting piece is consistent with the diameter of the steel claw head, and the width is 25 ~30 mm, thickness 3 mm, the length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com