Catalytic-esterification-free acid-degrading process for continuous production of high-acid-value waste oil and fat glycerin

A technology for catalyzing esterification and production process, applied in the field of circular economy and waste recycling, can solve the problems of a large amount of waste acid water polluting the environment, slow esterification reaction speed, frequent and complicated operations, etc., to avoid equipment corrosion, oleic acid Thorough, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

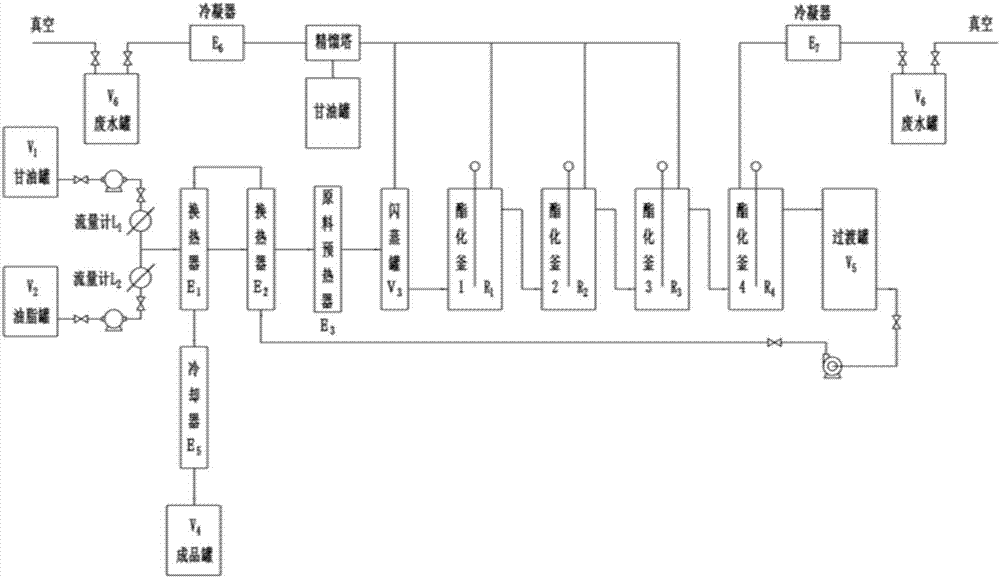

Image

Examples

Embodiment 1

[0025] (1) Mixing and distribution of raw materials: 12 tons / h of raw oil with an acid value of 48mgKOH / g and 1.32 tons / h of glycerin with a content of 95.7% are respectively transported through a centrifugal pump, measured by a flow meter, and mixed together into a heat exchanger. Glycerin and The mass ratio of oil and fat is 1.1:10.

[0026] (2) Heat exchange between mixed raw materials and finished products: the mixed raw materials and finished products pass through two shell-and-tube heat exchangers to exchange heat in countercurrent, the mixed raw materials are heated in series through the shell side of two shell-and-tube heat exchangers, and the finished oil passes through two shell-and-tube heat exchangers in series. The shell-and-tube tube pass is cooled. The mixed raw materials are heated to 116°C after heat exchange, and the temperature of the finished oil is reduced from 235°C to 142°C after heat exchange.

[0027] (3) Preheating of mixed raw materials after heat e...

Embodiment 2

[0032] (1) Mixing and distribution of raw materials: 13 tons / h of raw oil with an acid value of 26mgKOH / g and 1.3 tons / h of glycerol with a content of 96% are respectively transported through a centrifugal pump, measured by a flow meter, and mixed together into a heat exchanger. Glycerin and The mass ratio of oil and fat is 1:10.

[0033] (2) Heat exchange between mixed raw materials and finished products: the mixed raw materials and finished products pass through two shell-and-tube heat exchangers to exchange heat in countercurrent, the mixed raw materials are heated in series through the shell side of two shell-and-tube heat exchangers, and the finished oil passes through two shell-and-tube heat exchangers in series. The shell-and-tube tube pass is cooled. The mixed raw materials are heated to 110°C after heat exchange, and the temperature of the finished oil is reduced from 235°C to 148°C after heat exchange.

[0034] (3) Preheating of mixed raw materials after heat exchan...

Embodiment 3

[0039] (1) Mixing and distribution of raw materials: 11 tons / h of raw oil with an acid value of 71mgKOH / g and 1.32 tons / h of glycerin with a content of 96.1% are respectively transported through a centrifugal pump, measured by a flow meter, and mixed together into a heat exchanger. Glycerin and The mass ratio of oil and fat is 1.2:10.

[0040] (2) Heat exchange between mixed raw materials and finished products: the mixed raw materials and finished products pass through two shell-and-tube heat exchangers to exchange heat in countercurrent, the mixed raw materials are heated in series through the shell side of two shell-and-tube heat exchangers, and the finished oil passes through two shell-and-tube heat exchangers in series. The shell-and-tube tube pass is cooled. The mixed raw materials are heated to 122°C after heat exchange, and the temperature of the finished oil is reduced from 235°C to 137°C after heat exchange.

[0041] (3) Preheating of mixed raw materials after heat e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com