Net-belt type vacuum filter

A mesh belt type and filter technology, applied in the field of filters, can solve the problems of non-reusability, high finished products, inconvenient maintenance, etc., and achieve the effects of low production cost, high work efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

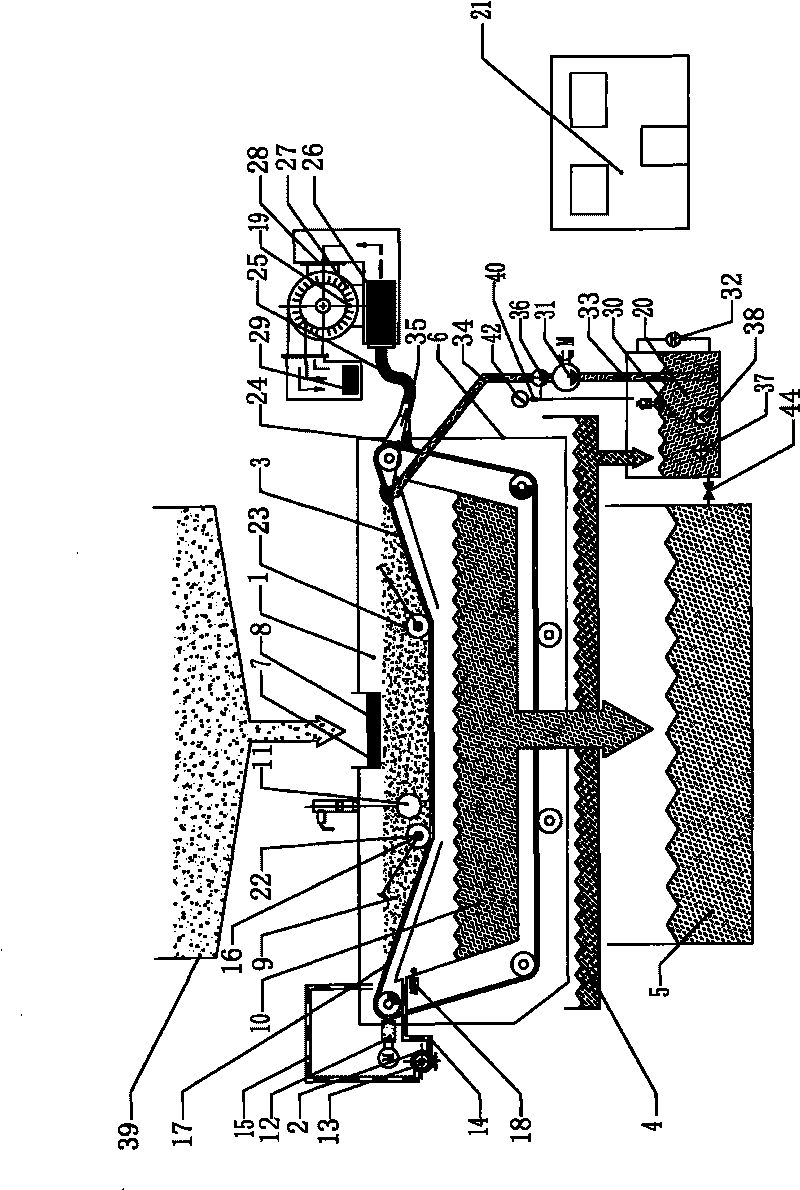

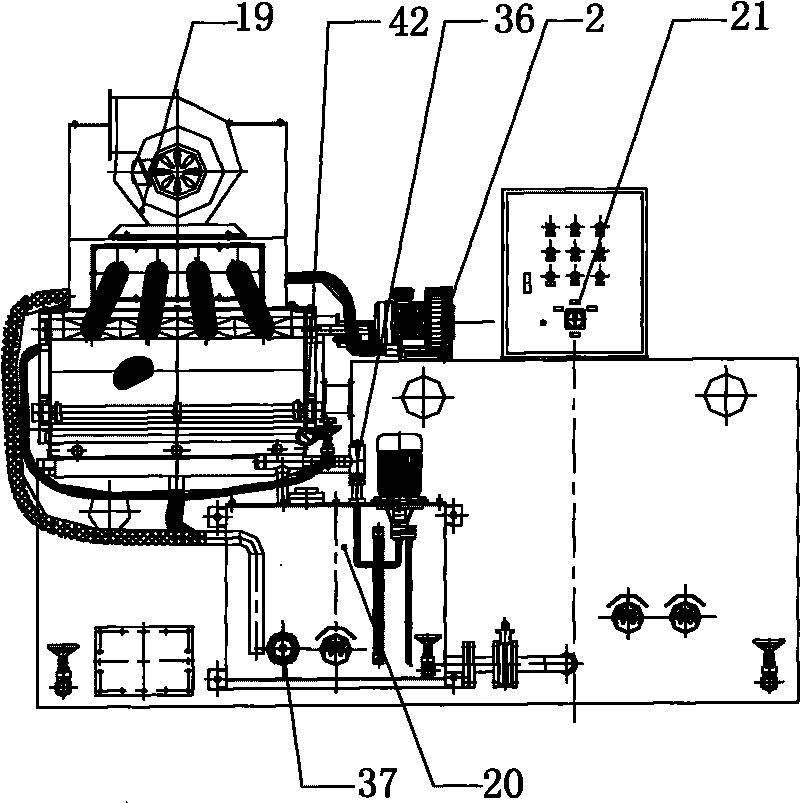

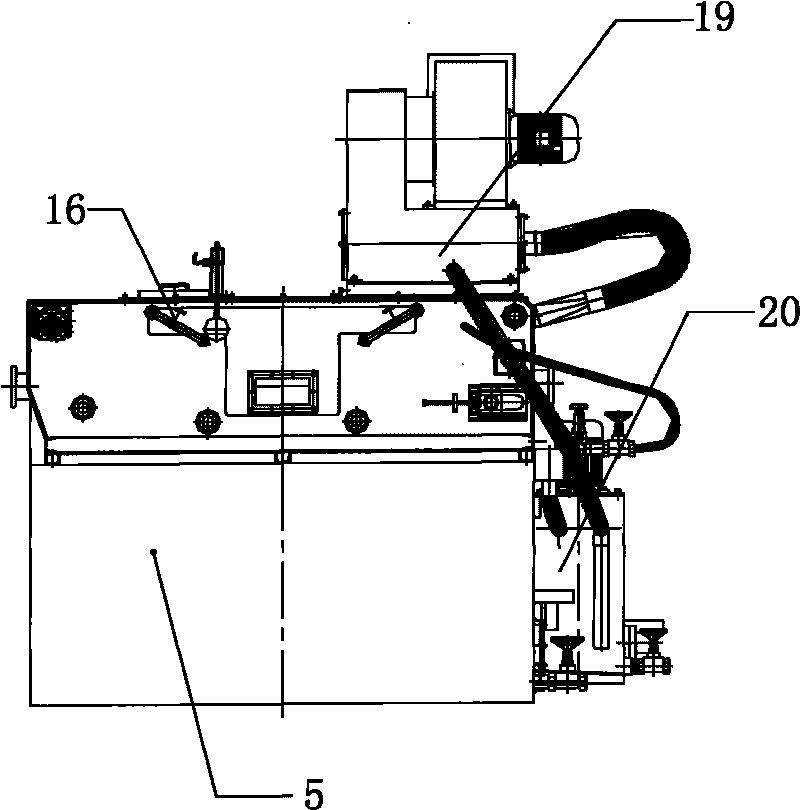

[0019] Such as Figure 1 to Figure 4 As shown, a mesh belt vacuum filter includes a vacuum filter box 1, a vacuum negative pressure device 2, a conveyor chain 3, an overflow tray 4 arranged below the vacuum filter box 1 and a lubricating oil filter arranged under the overflow tray 4 Station oil tank 5, the vacuum filter box 1 includes a box body 6, an oil inlet 7 is arranged on the top of the box body 6, and a coarse filter column 8 is arranged in the oil inlet 7, and the above-mentioned conveying chain 3 is arranged on the box body 6 Inside, and with the oil-resistant and heat-resistant rubber sealing strips 43 on both sides, the inside of the box body 6 is divided into upper and lower chambers. The upper chamber is the dirty liquid chamber 9, and the lower chamber is the clean liquid chamber 10. The liquid level control device 11 is provided with a reducer device 12 for driving the transmission chain 3 on one side wall of the box body 6, and the vacuum negative pressure devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com