Transparent conductive film and capacitive touch screen comprising same

A technology of transparent conductive film and transparent base material, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of obvious adhesion of three-dimensional lines, achieve good performance, improve continuity, and make The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

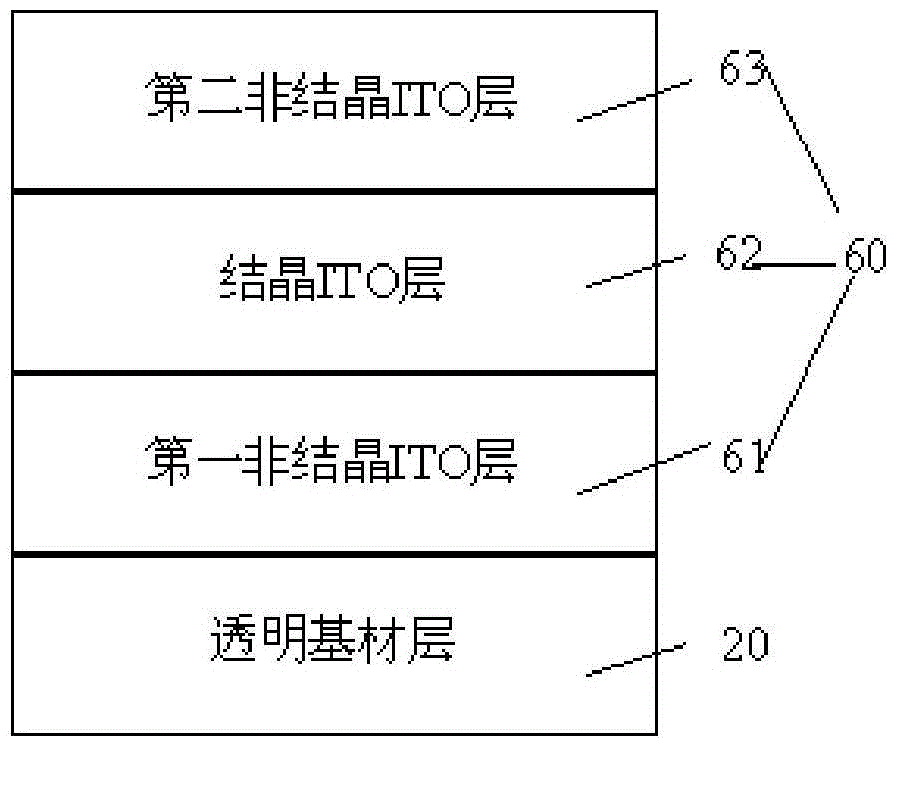

[0053] Using the magnetron sputtering process, the first amorphous ITO layer 61, the crystalline ITO layer 62 and the second amorphous ITO layer 63 are sequentially obtained on the surface of the transparent substrate layer 20, forming figure 1 The transparent conductive film shown.

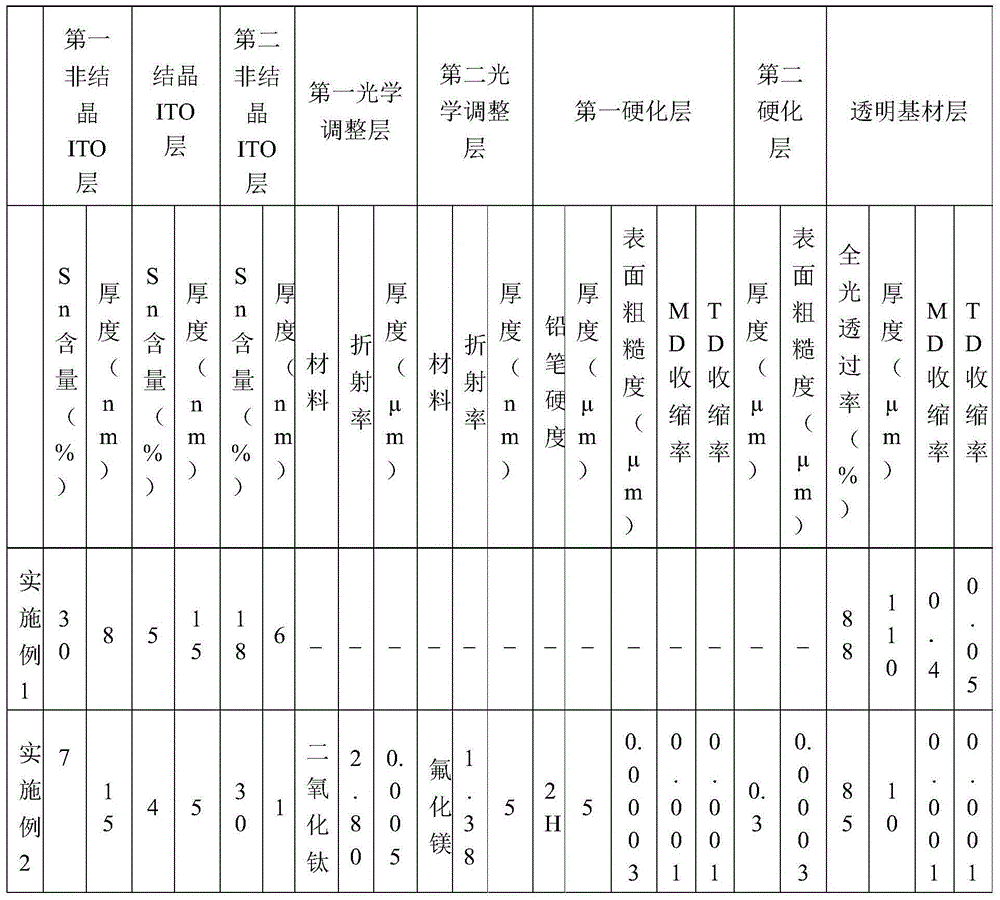

[0054] The ITO layer 60 of the transparent conductive film was etched by an ink screen printing etching method, and then baked at a temperature of 150° C. for 60 minutes. The specific structural parameters of the transparent conductive film are shown in Table 1.

Embodiment 2

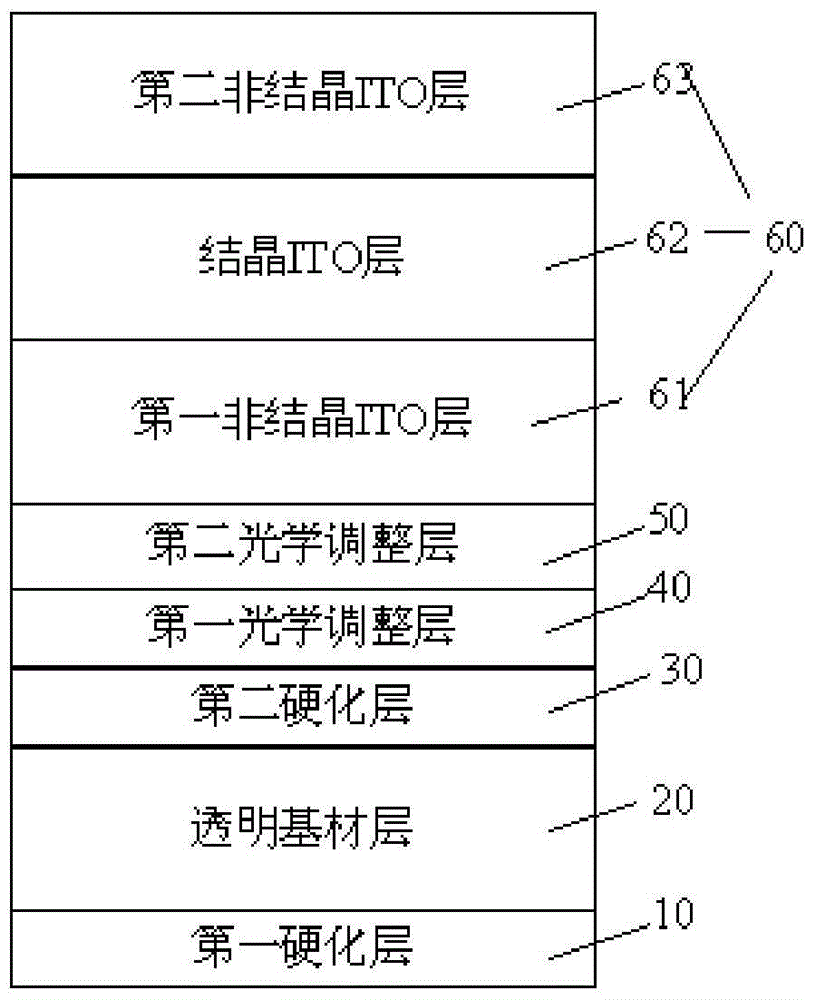

[0056] The surface of the transparent substrate layer 20 is coated with a hardening solution of the type FZ001 selected from Japan Arakawa Chemical Co., Ltd., dried and cured to form the first hardened layer 10 . Then, in the same manner, the surface of the transparent base layer 20 far away from the first hardened layer 10 is coated with a hardening solution selected from the Japanese DIC company with a model number of PC13-1082 to form the second hardened layer 30 .

[0057] Using a magnetron sputtering process, a film is coated on the surface of the second hardened layer 30 away from the transparent substrate layer 20, and the first optical adjustment layer 40, the second optical adjustment layer 50, and the ITO layer 60 are sequentially obtained, forming figure 2 The transparent conductive film shown.

[0058] The ITO layer 60 of the transparent conductive film was etched by an ink screen printing etching method, and then baked at a temperature of 150° C. for 60 minutes. ...

Embodiment 3

[0060] Prepared by the same method as in Example 2 figure 2 The transparent conductive film shown, the structural parameters of the prepared transparent conductive film are shown in Table 1, wherein, the hardening solution for coating the first hardening layer 10 is the hardening solution of FZ001 of Japan Arakawa Chemical Co., Ltd., and the second hardening solution for coating is FZ001. The hardening solution of the layer 30 is the hardening solution of the model number PC13-1082 of DIC Corporation of Japan, and the specific structural parameters of the transparent conductive film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com