Anti-seismic prefabricated concrete solid square pile and production method thereof

A prefabricated concrete and earthquake-resistant technology is applied in the field of prefabricated concrete solid square piles and earthquake-resistant prefabricated concrete solid square piles. It can improve the safety, improve the distribution of force, and achieve the effect of high compressive bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The accompanying drawings disclose non-limiting specific embodiments of the present invention, which are further described as follows in conjunction with the accompanying drawings.

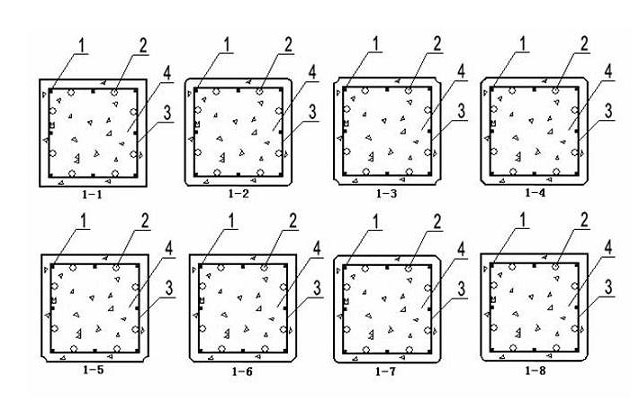

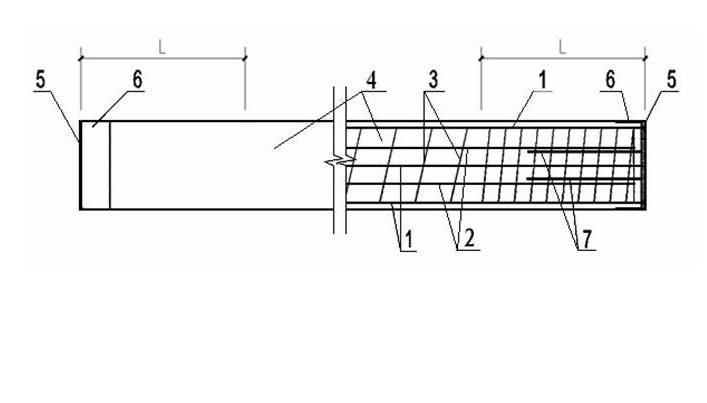

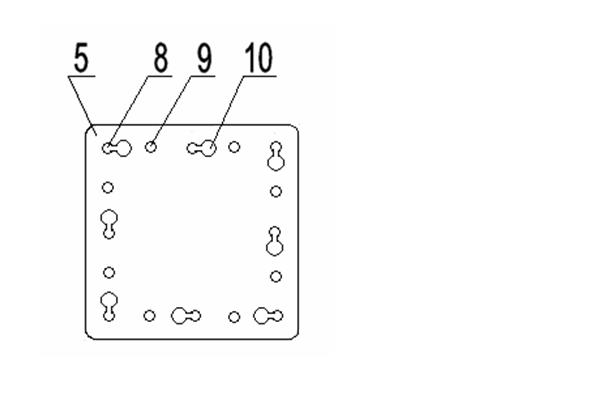

[0047] see figure 2 , the anti-seismic type prefabricated concrete solid square pile of the present invention comprises main reinforcement, stirrup 3, anchorage reinforcement 7, pile cap and concrete 4, and the main body of described pile body cross section is square, and main reinforcement is by prestressed main reinforcement 1 and common main reinforcement 2 successively Arrangement and combination, the main reinforcement runs through the pile body along the longitudinal axis of the pile body, the outer edge of the main reinforcement is the stirrup 3, and the stirrup 3 is a spiral square; the two ends of the pile body are pile caps, and the pile cap is composed of an end plate 5 and a skirt 6; The main reinforcement and the stirrup are connected by welding or binding to form a reinforcem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com