Device and method for testing permeation flowing property of geopolymer slurry

A technology of geopolymer and flow properties, which is applied in the field of geopolymer slurry seepage flow performance test equipment, can solve the problem of fluidity and particle size that cannot be used to evaluate the seepage flow performance of geopolymer slurry, the effect is very different, and the Large diameter difference and other problems, to achieve the effect of simple structure, simple operation, high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

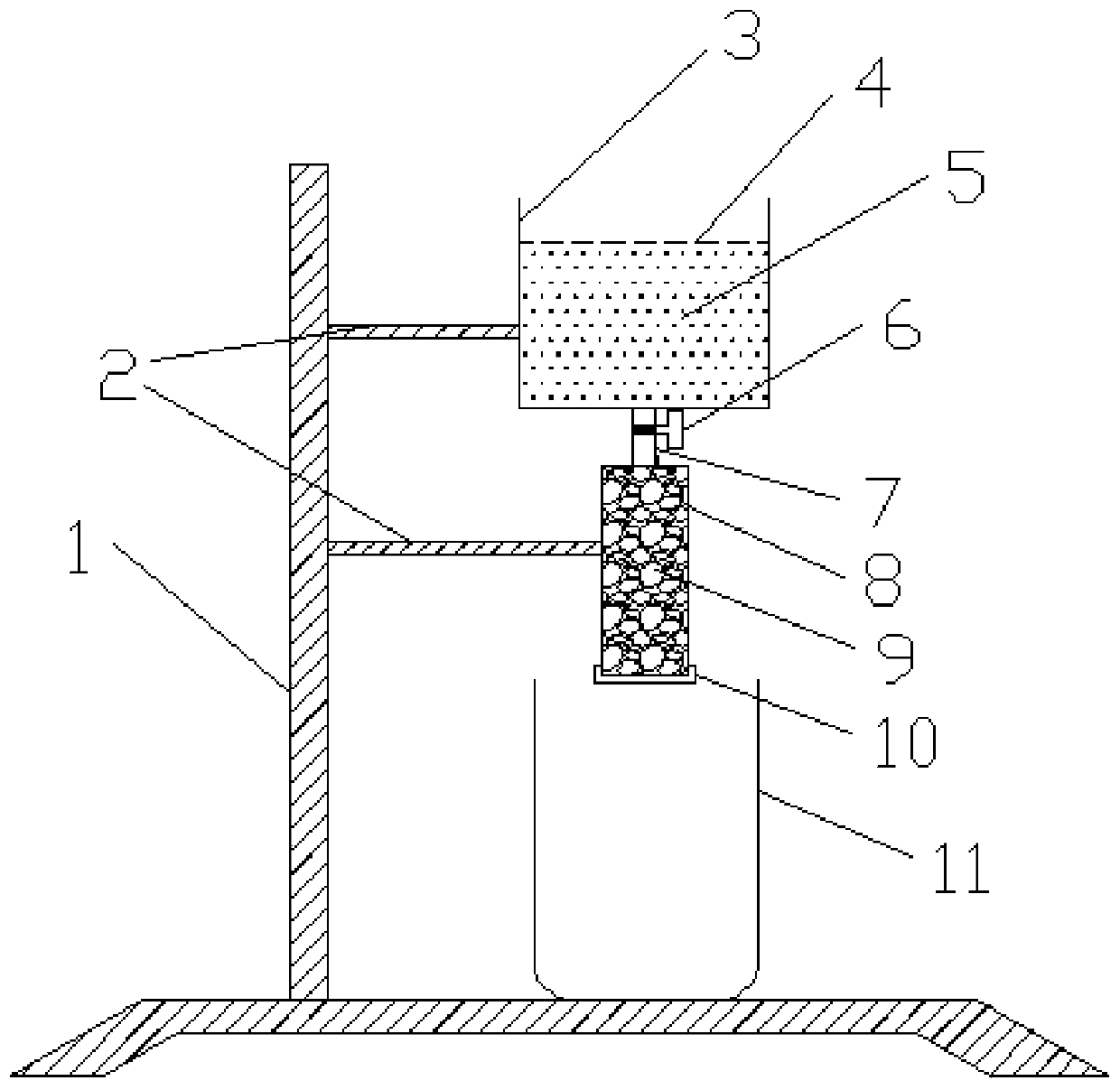

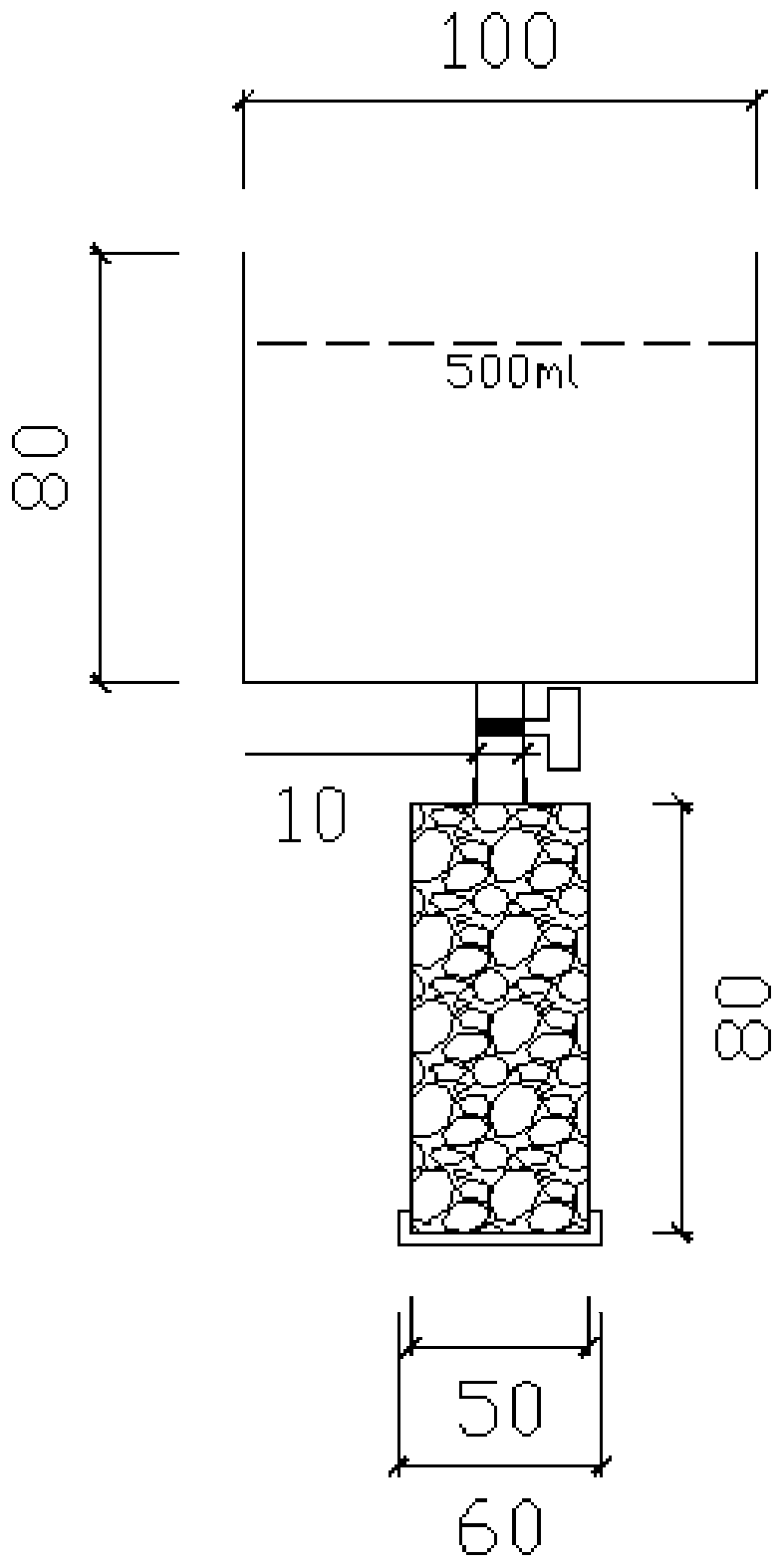

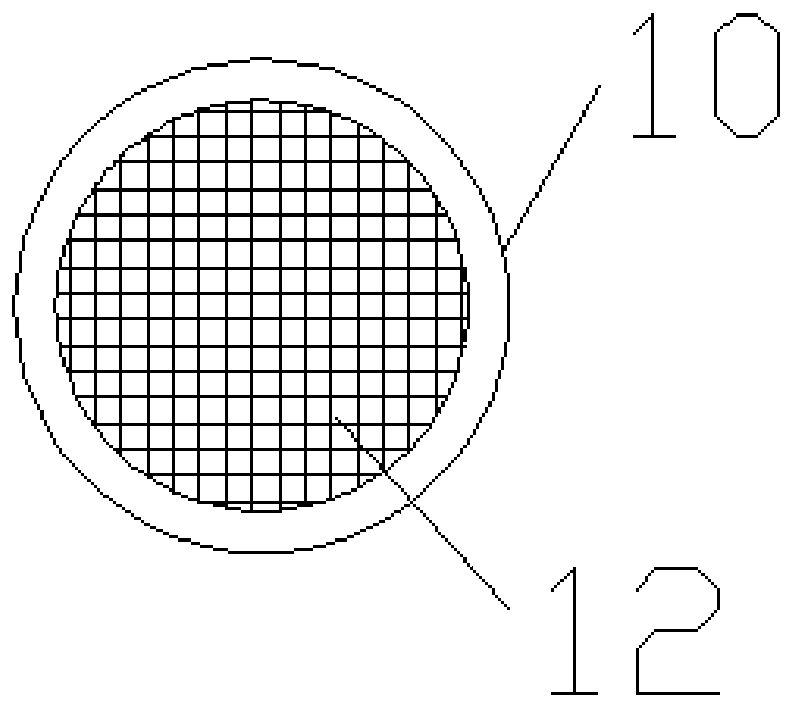

[0046] The slurry storage pipe 3 is suspended and fixed by the support 1 and the support rod 2, and the percolation pipe 8 is suspended above the central axis of the measuring cup 11 to ensure that the slurry enters the measuring cup 11 to measure the quality after flowing out. The used slurry storage pipe 3 has an inner diameter of 100mm and a height of 80mm, and the maximum slurry storage pipe 3 can store 628ml of slurry; the wall of the slurry storage pipe is provided with a 500ml scale line 4; the inner diameter of the connecting pipe 7 is 10mm, and the height is 30mm. The bottom end of the slurry storage pipe 3 and the top of the seepage pipe 8 are connected by spiral threads; a slurry material control valve 6 is arranged at the connection between the connecting pipe 7 and the slurry storage pipe 3, and the slurry material control valve 6 controls the flow of the slurry material; the inner diameter of the seepage pipe 8 50mm, height 80mm, filler 9 is added in the percolati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com