Critical experiment simulation equipment for permeation and separation grouting

A critical test and simulation equipment technology, applied in the field of geotechnical engineering, can solve problems such as wasting engineering costs and construction periods, reducing soil permeability coefficient, and failing to significantly improve soil shear strength, achieving high precision and improving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

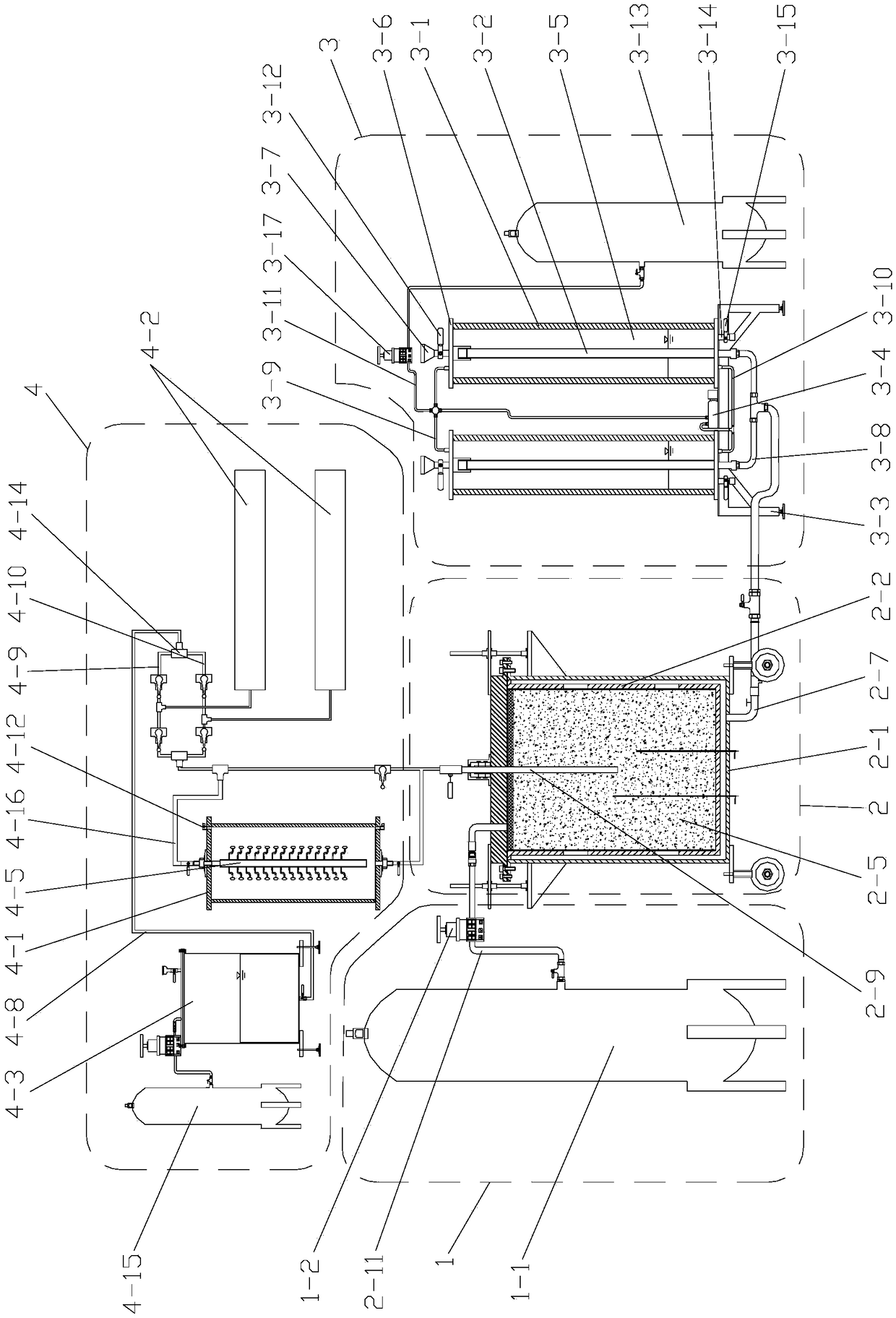

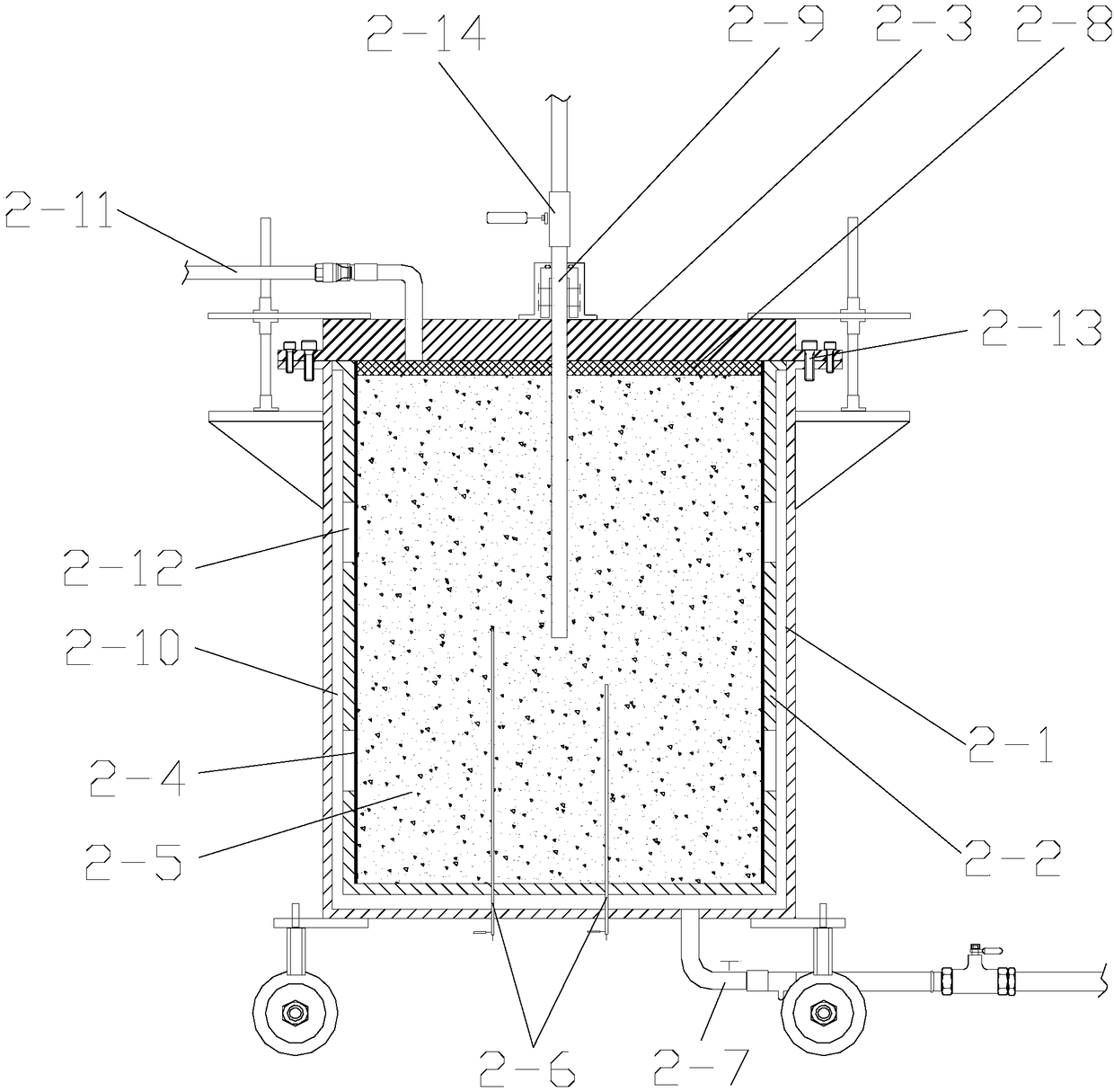

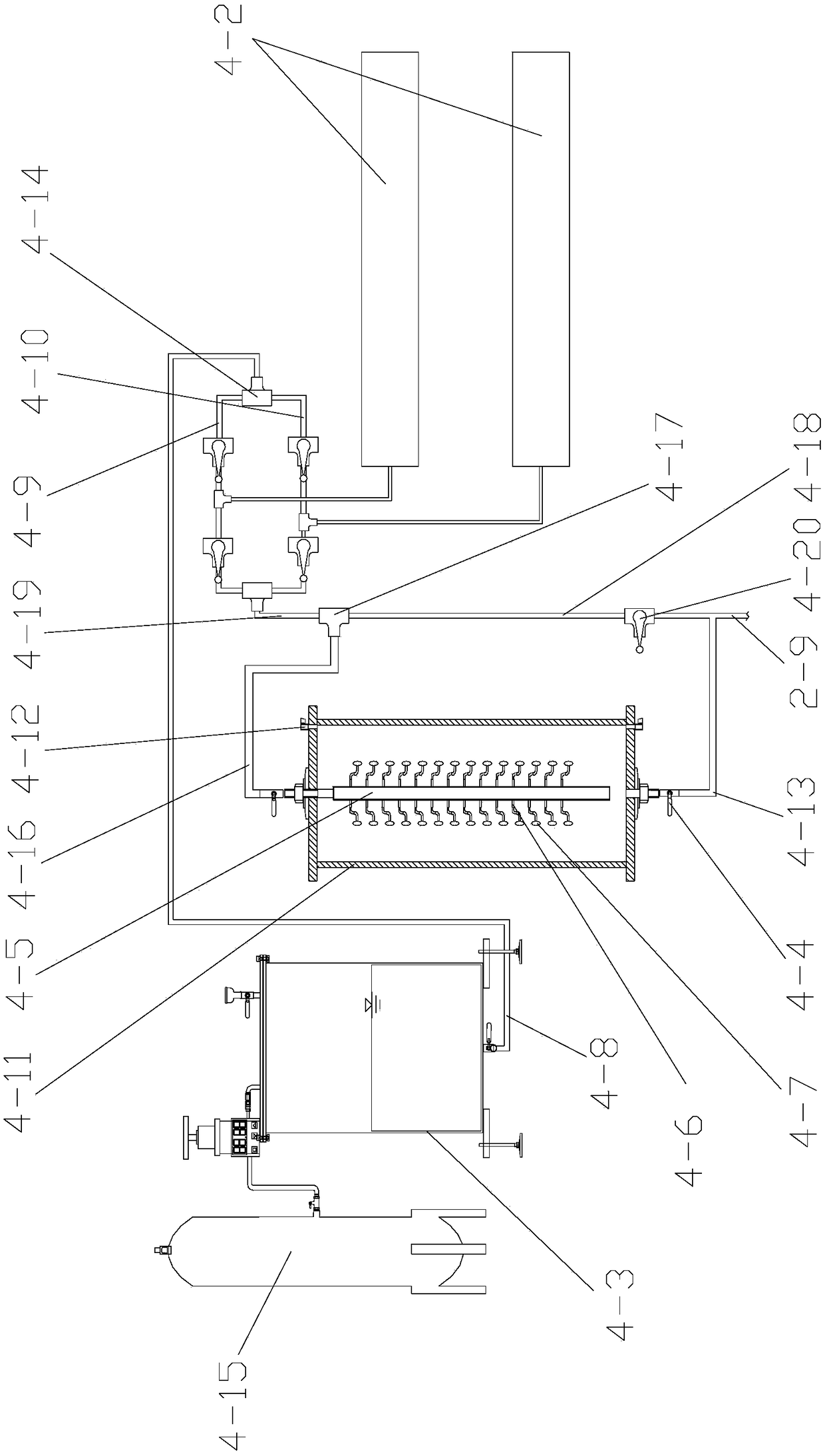

[0052] Such as figure 1 and figure 2 As shown, the critical test simulation equipment for permeation splitting grouting of the present invention includes a soil covering pressure simulation unit 1, a grouting test tank unit 2 and a confining pressure simulation unit 3, and the grouting test tank unit 2 includes a steel outer cylinder 2-1, the steel inner cylinder 2-2 located in the steel outer cylinder 2-1, and the soil sample 2-5 set in the steel inner cylinder 2-2, the steel outer cylinder 2-1 A first cover 2-3 is provided, a cavity 2-10 is formed between the steel outer cylinder 2-1 and the steel inner cylinder 2-2, and the side wall of the steel inner cylinder 2-2 is provided with The hole 2-12 communicating with the cavity 2-10, the inner wall of the steel inner cylinder 2-2 is provided with a geotextile 2-4, and the bottom of the grouting test tank unit 2 is equipped with a piezometer 2-6 and the first drainage pipe 2-7, the first drainage pipe 2-7 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com