Patents

Literature

42results about How to "Reduce water gushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

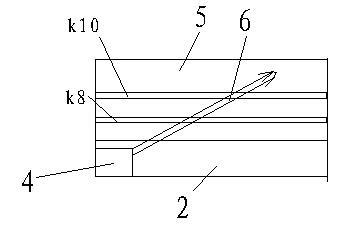

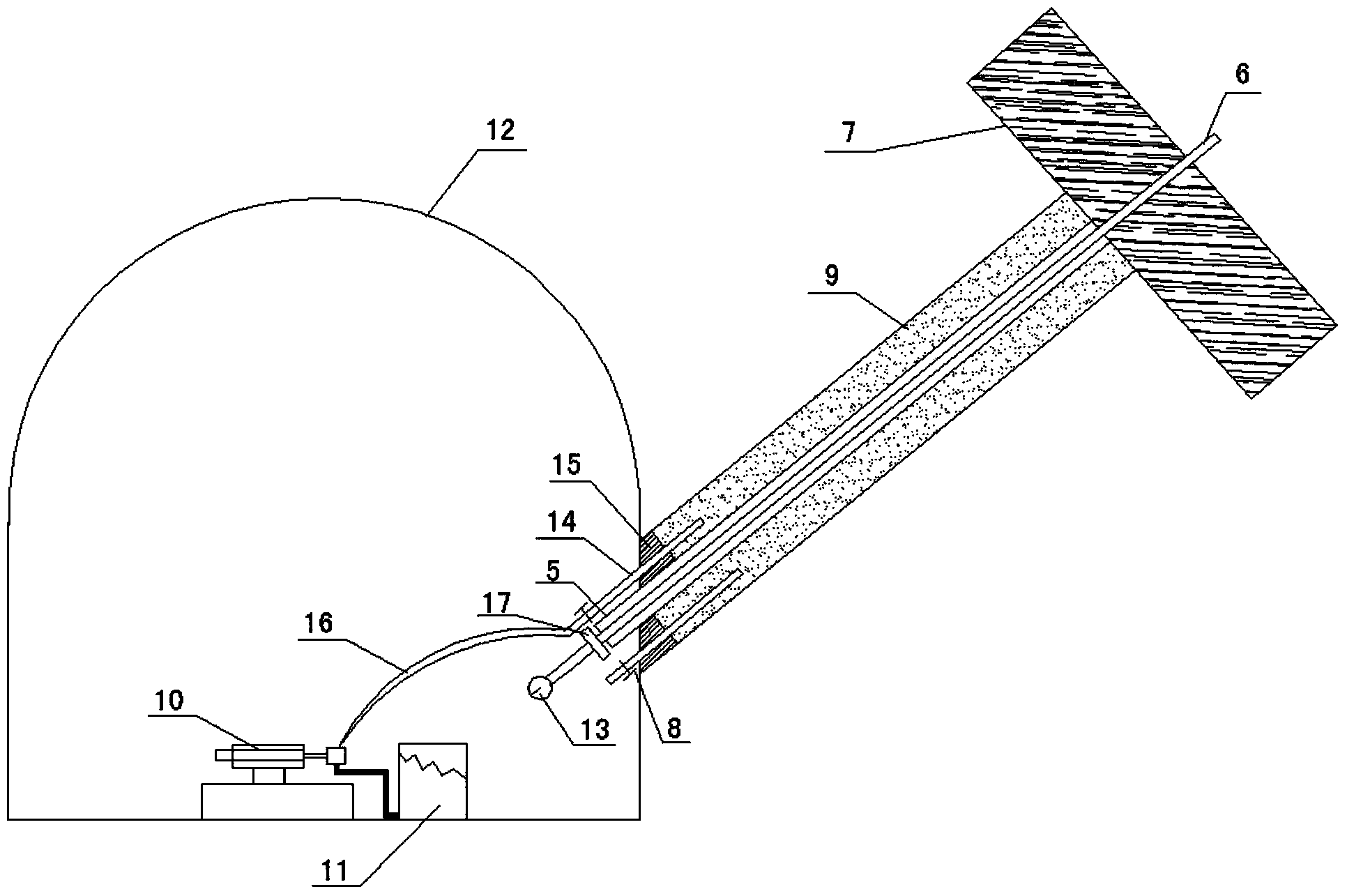

Construction method of high-tension water-rich extra-large-section weak breccia tunnel

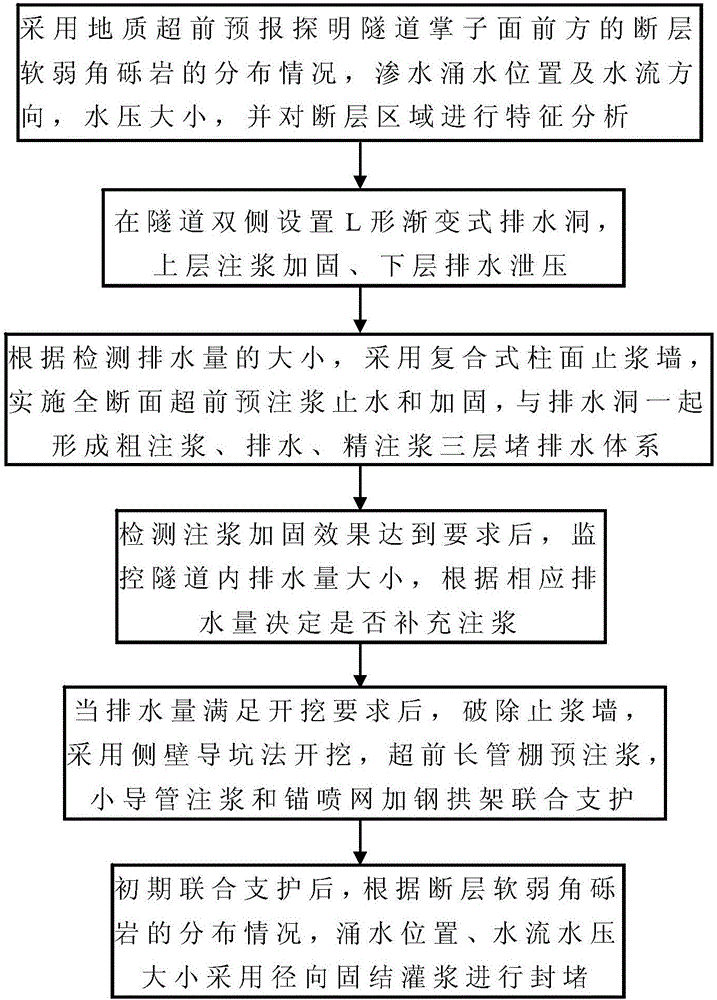

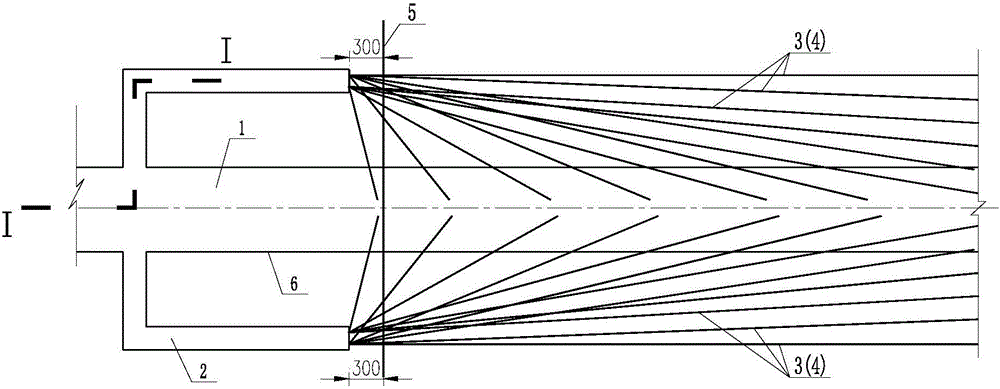

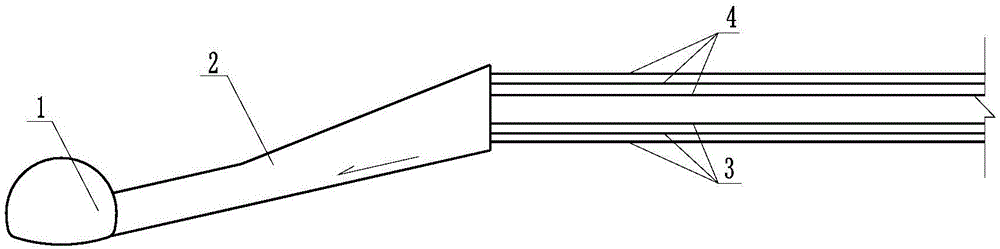

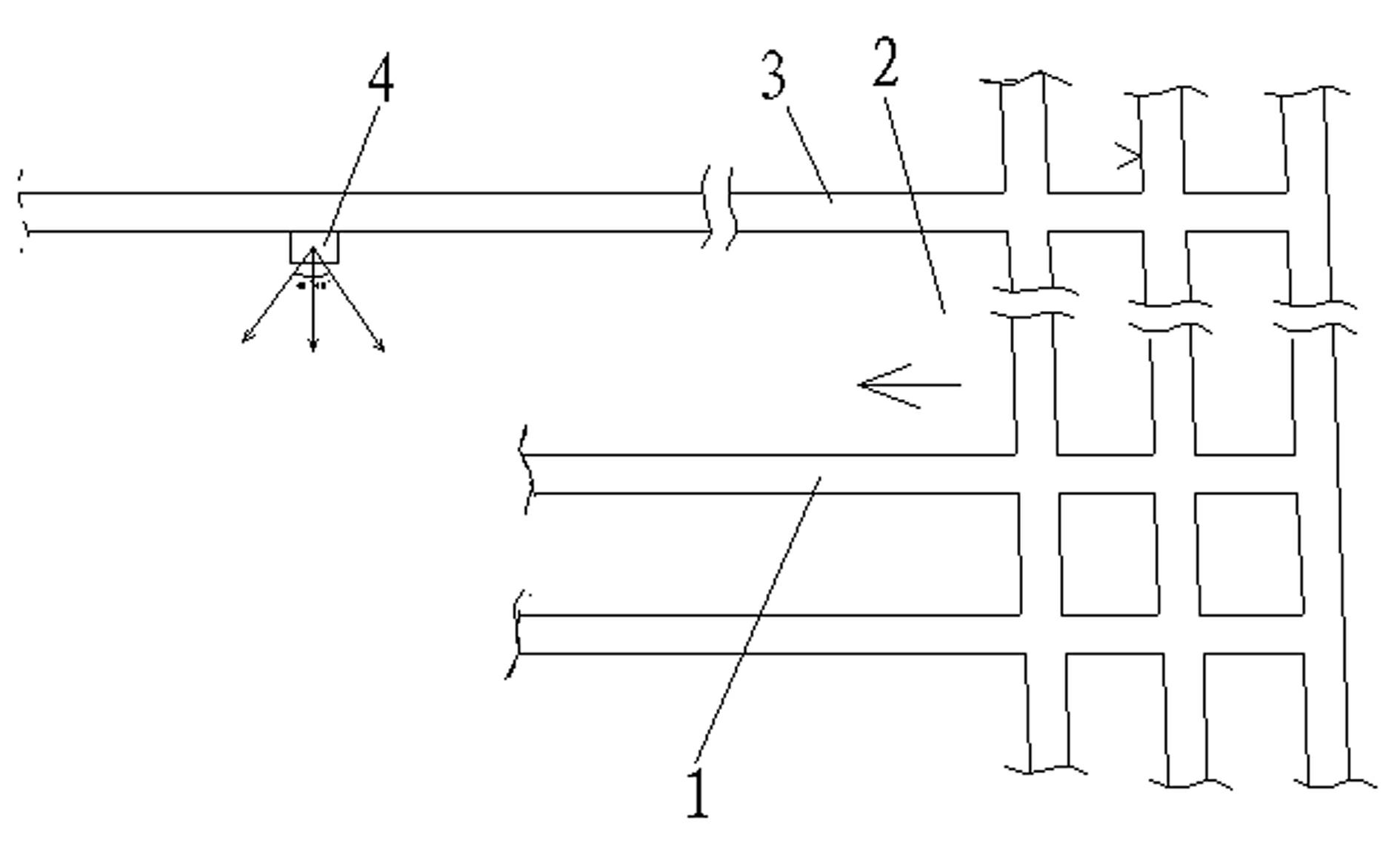

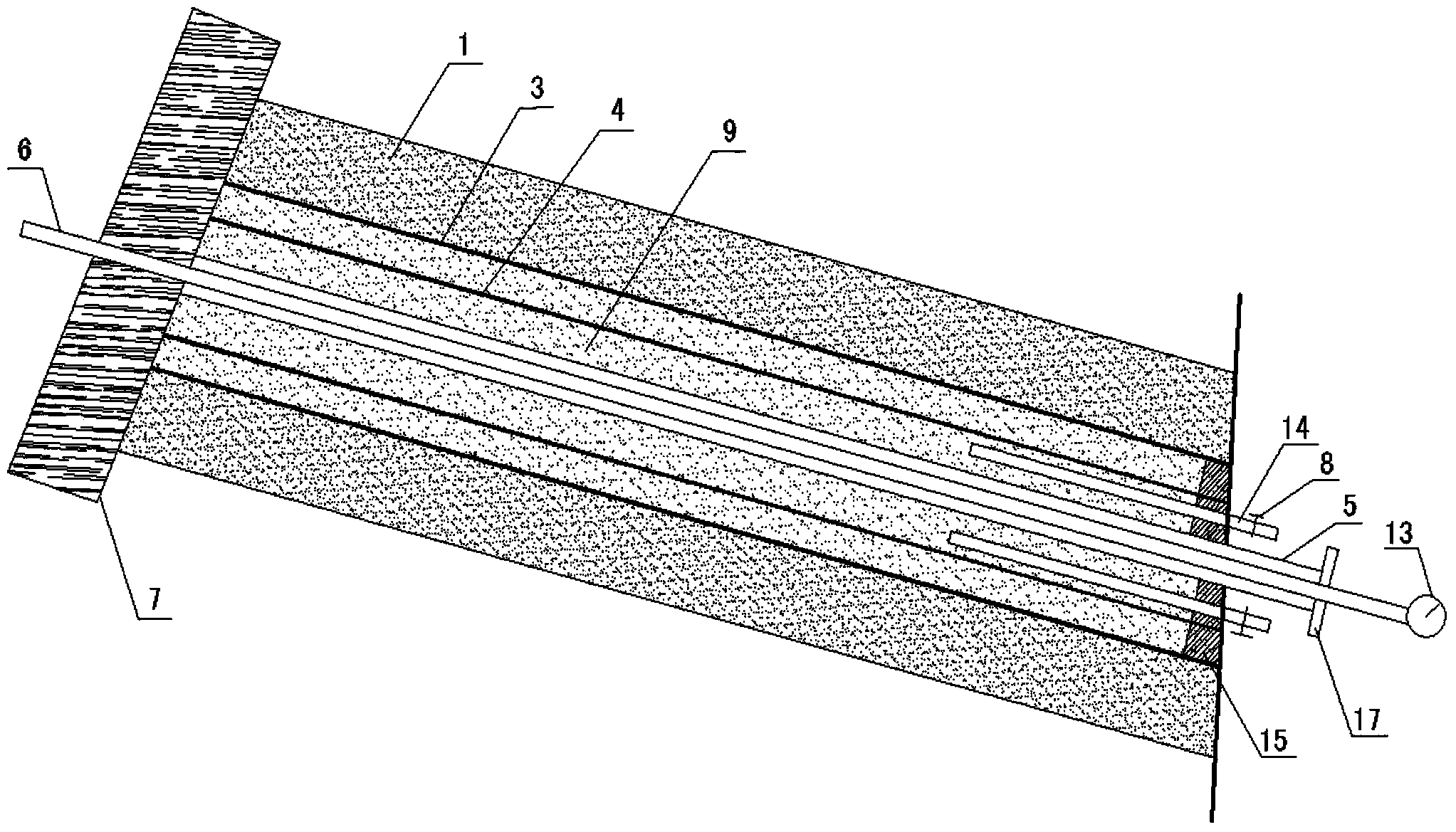

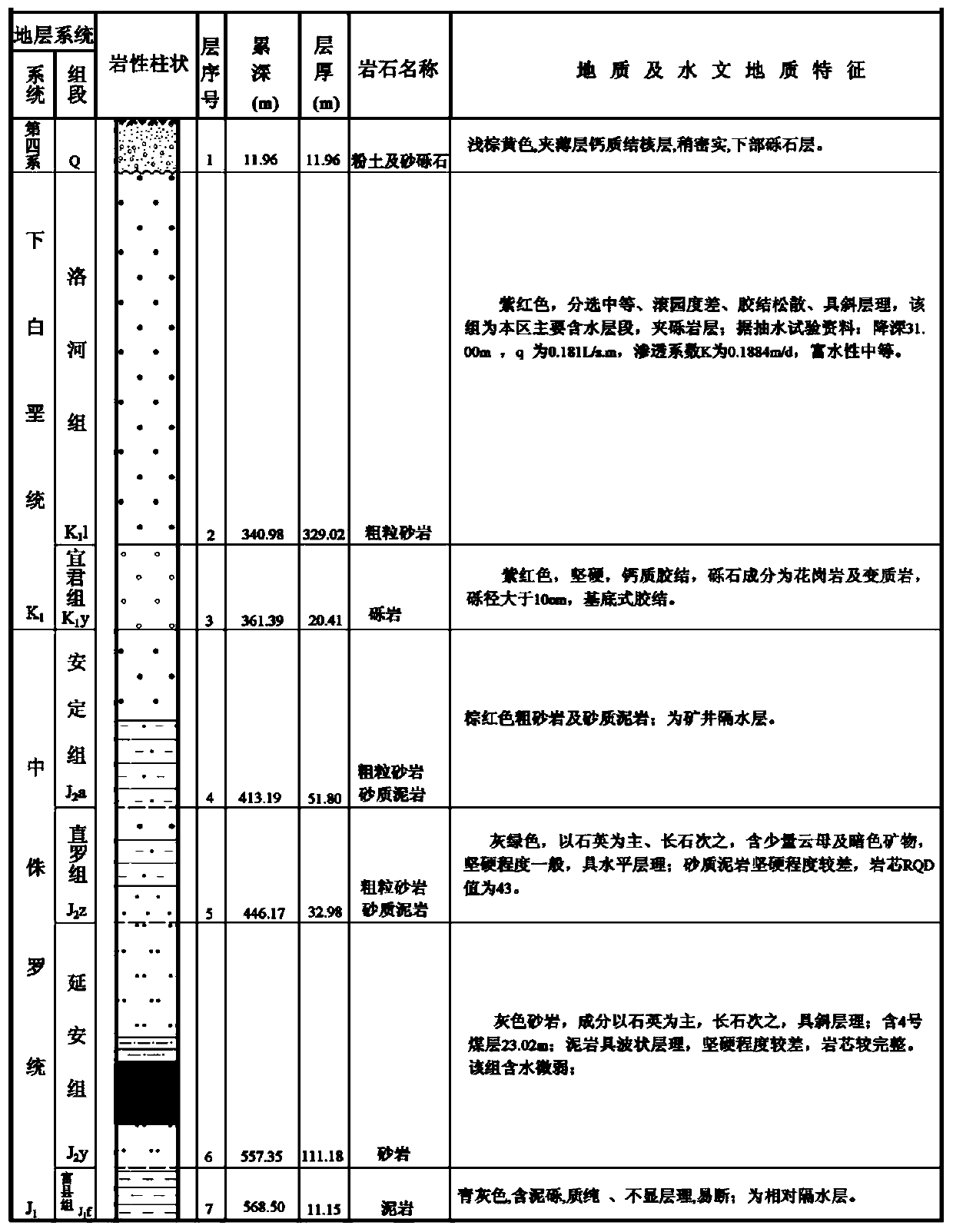

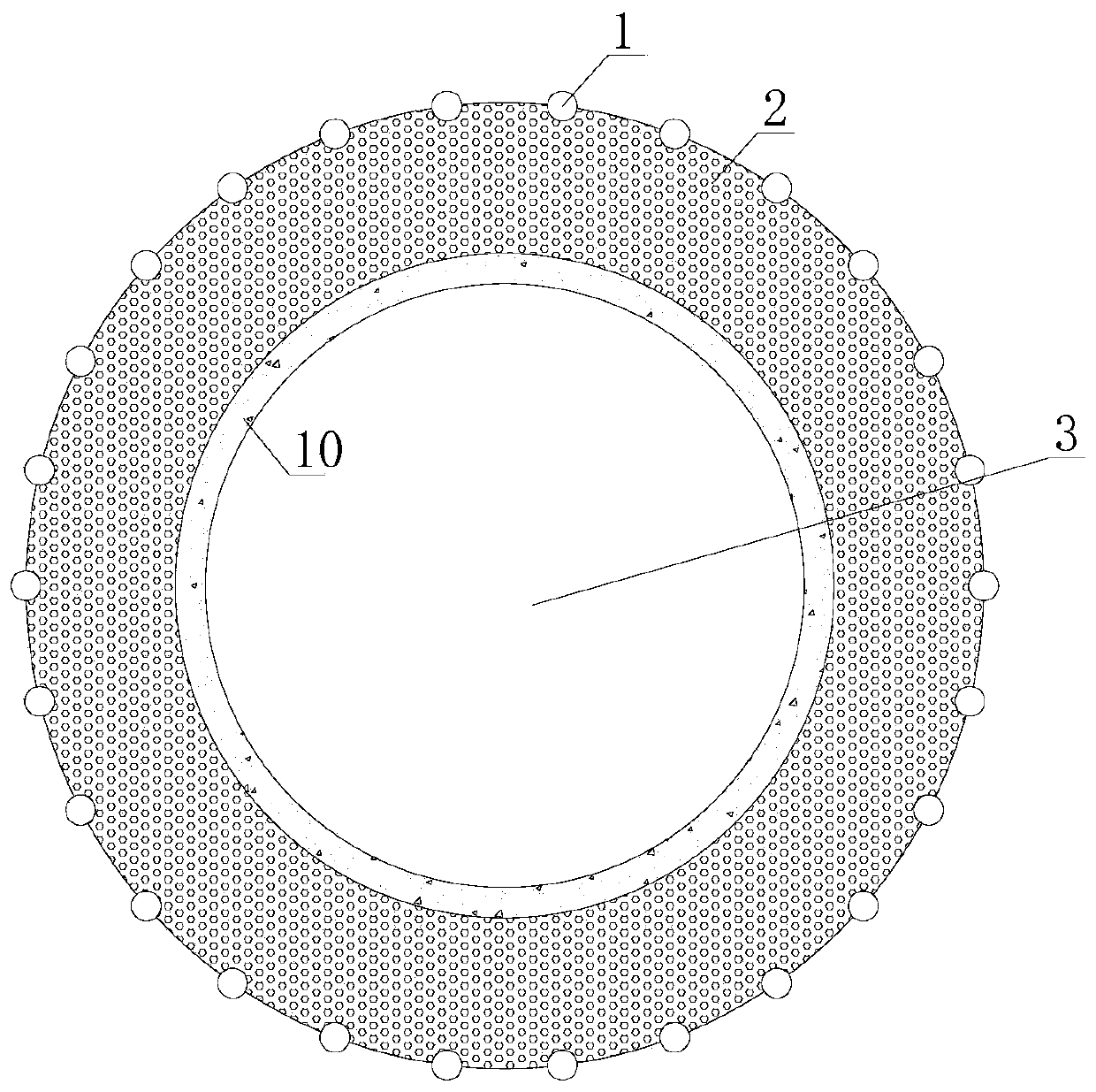

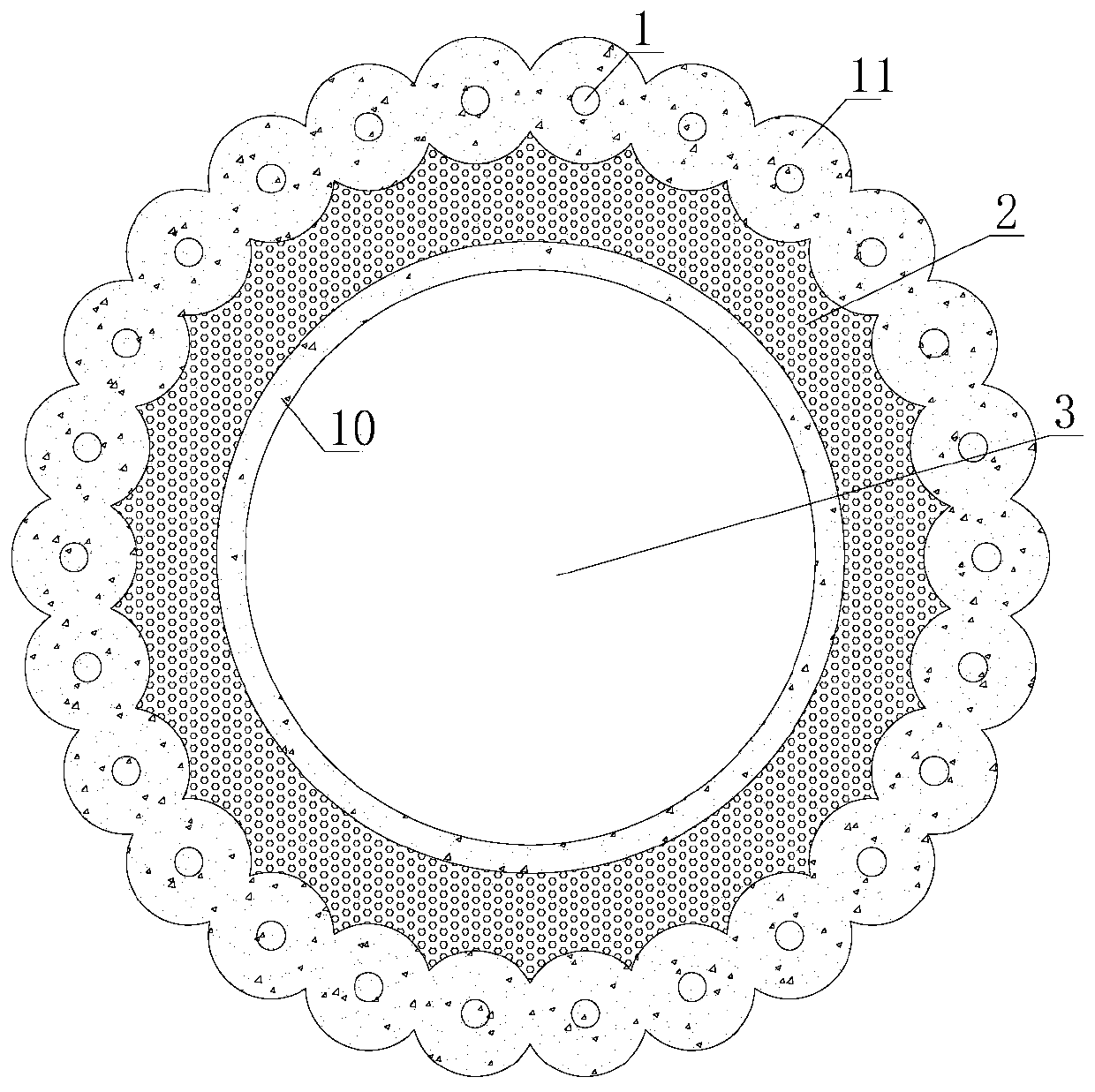

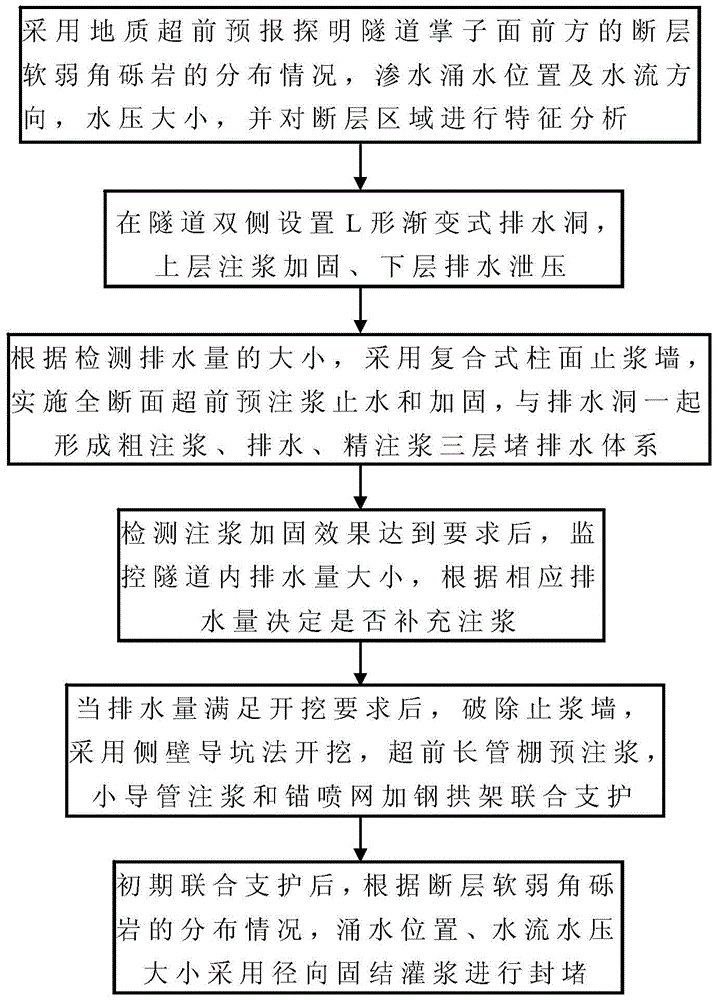

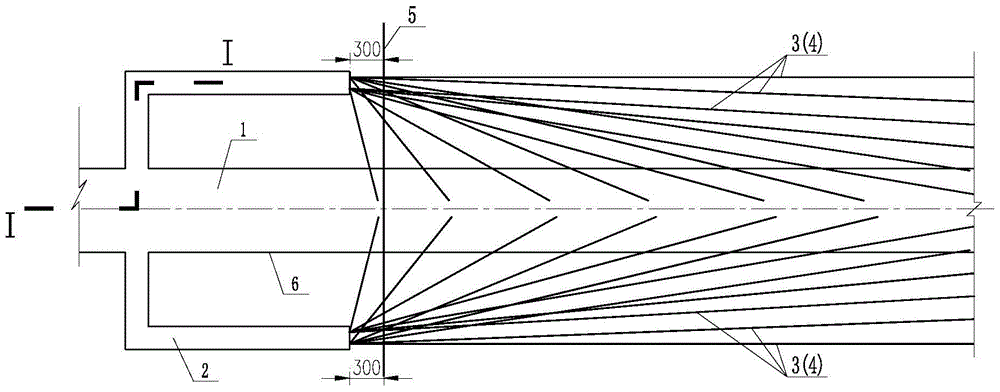

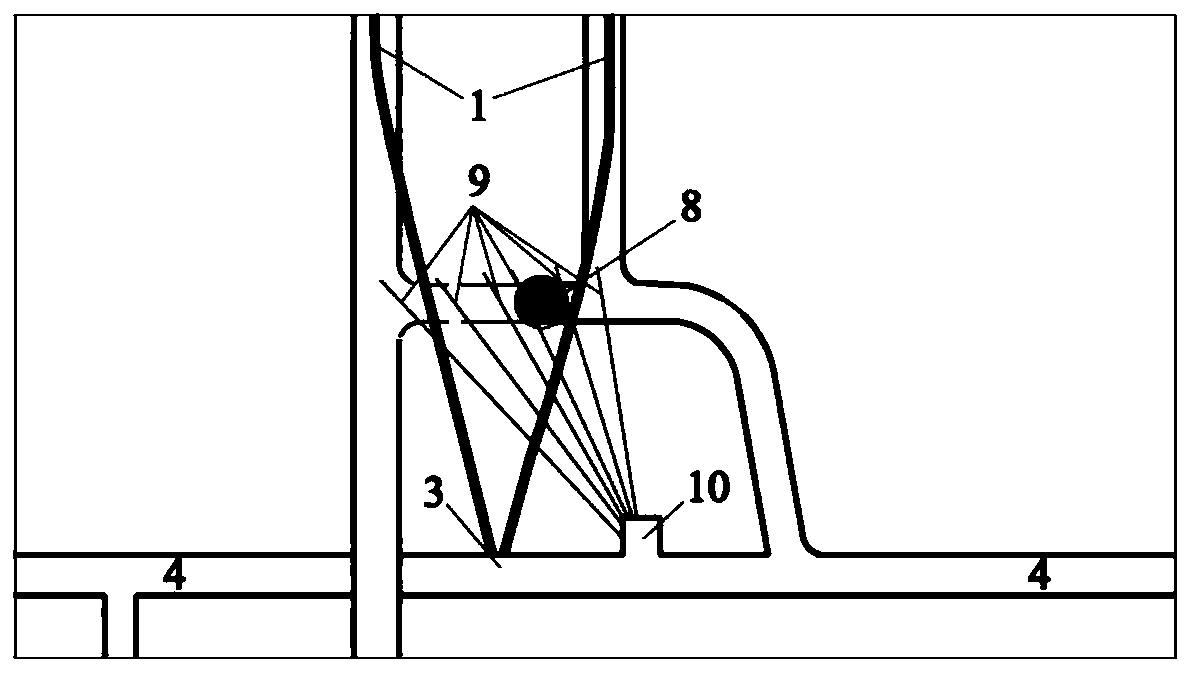

The invention discloses a construction method of a high-tension water-rich extra-large-section weak breccia tunnel. The method includes the steps of exploring distribution of fault weak breccia in front of a tunnel face by an advanced geological forecast method; distributing L-shaped gradient drain holes in two inner sides of the tunnel, providing sector drain holes and grouting holes, and allowing upper grouting and lower drainage; providing a combined cylinder grout-stopping wall, and performing a full-face advanced chemical grouting consolidation; constructing an advanced long tube shed with a circumferential closed advanced tube shed guide wall having a foundation, distributing tapered quincunx examining drain holes to detect grouting effect, and finally excavating the tunnel. Through the use of the techniques such as three-layer stereoscopic grouting and drainage, and cement-water glass and epoxy resin sequential grouting, the problem that a high-tension water-rich surrounding rock area with loose weak breccia has ineffective grouting consolidation and non-obvious water plugging effect is solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

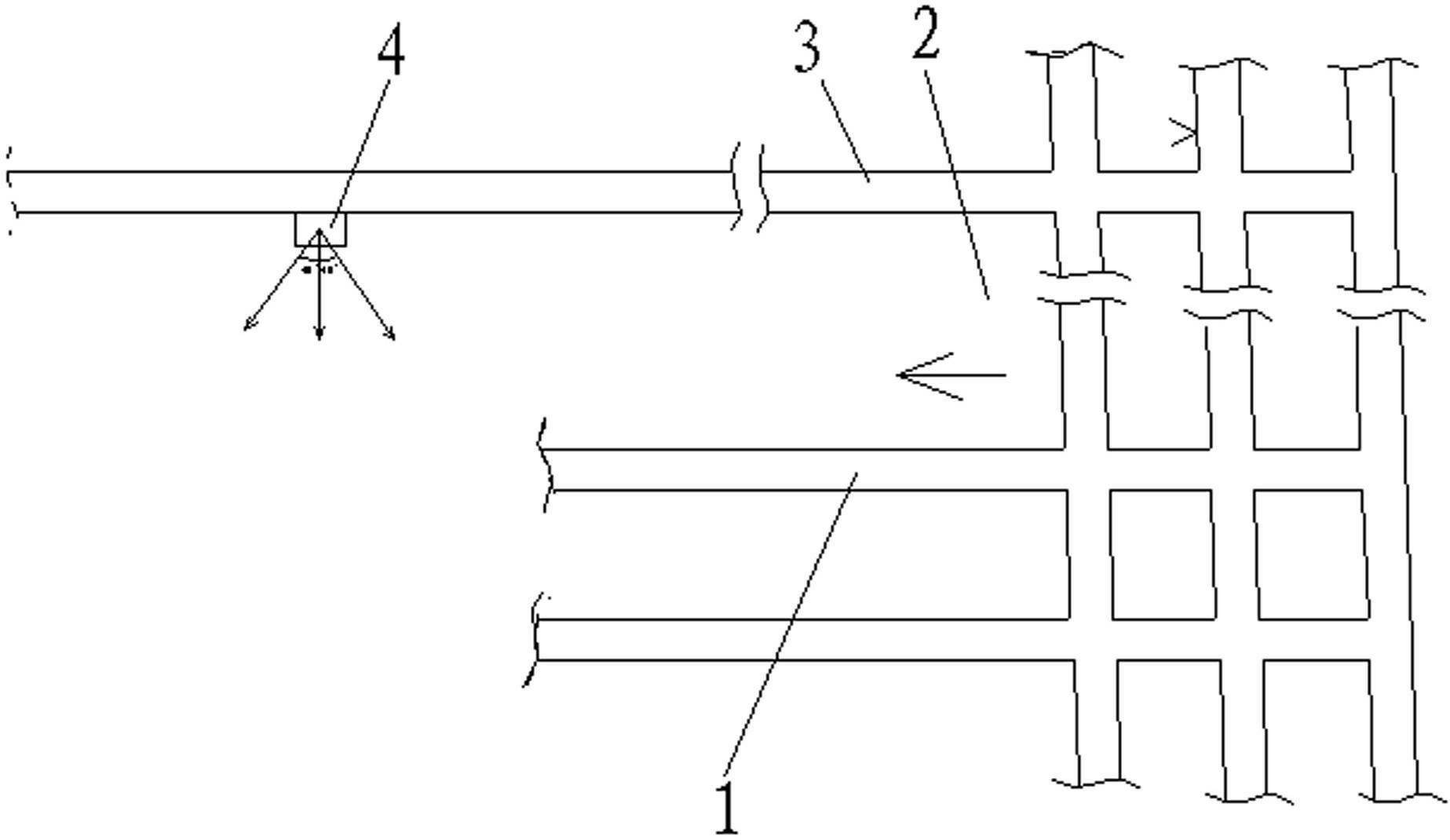

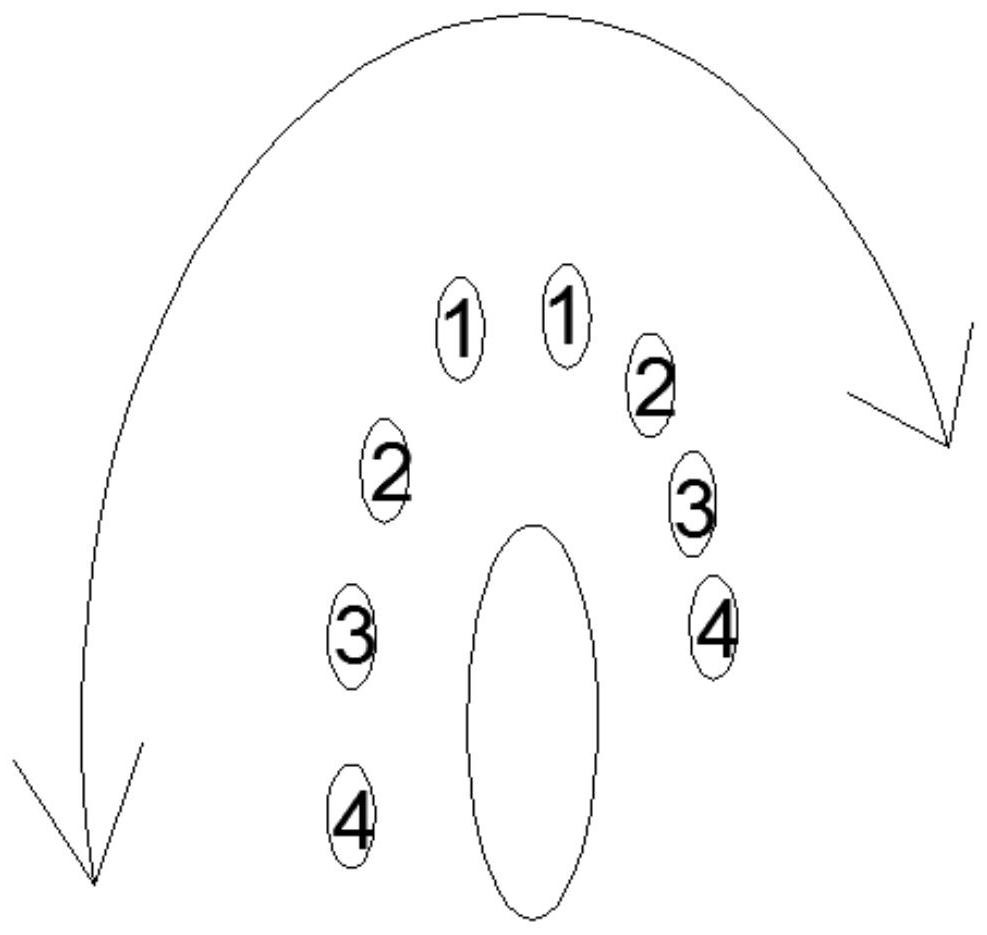

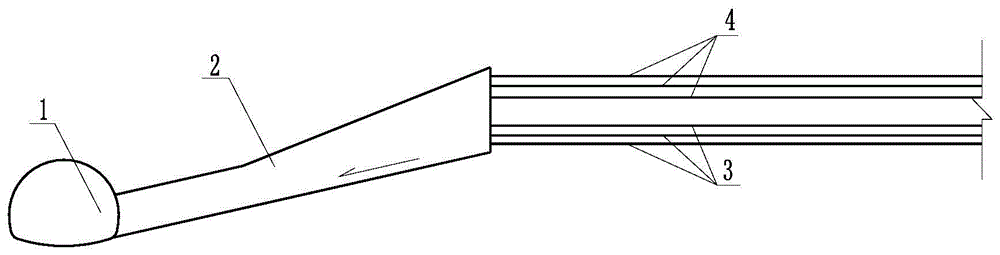

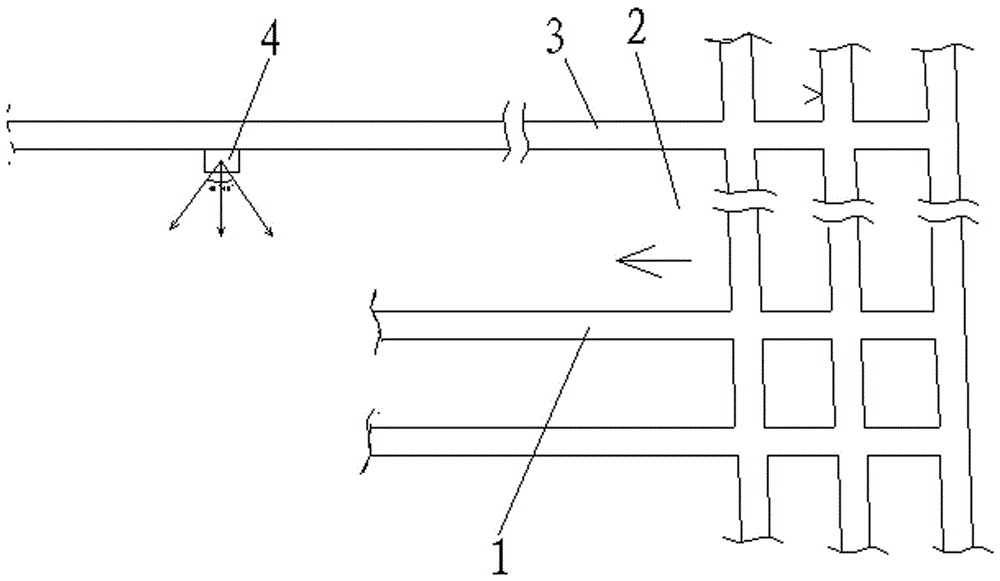

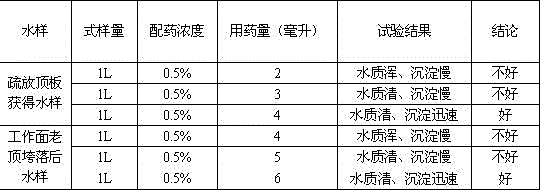

Stope face roof water pre-drainage construction method

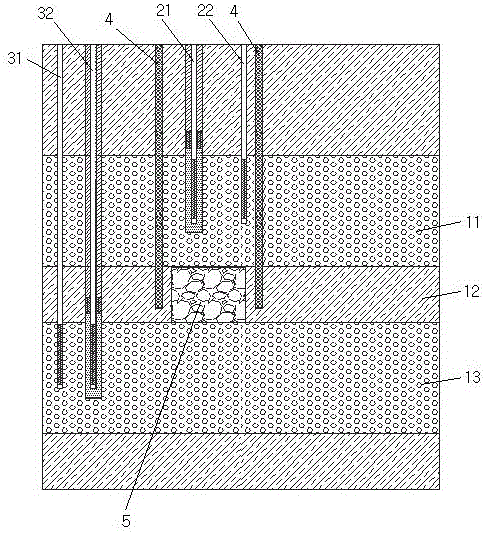

The invention relates to coal mine underwater treatment technology, in particular to a stope face roof water pre-drainage construction method, which solves the technical problem of treatment of a water-bearing bed on a coal seam of a stope face. As the process of stoping on the stope face includes down stoping firstly and up stoping secondly, stope face roof water is drained in advance through roadways beside the stope face before stoping, a drill site chamber and a water bin are constructed at the lowest position of each of the roadways, two drainage pipelines are paved on each of the roadways, an independent drainage system is utilized, drainage holes are drilled in the drill site chamber towards the stope face roof, and water for drilling is led into the water bin through hoses directly and is drained by the drainage system of the roadways. Since roof water is drained in advance, water inflow during the stoping process is reduced effectively, troubles to production of coal mines due to the roof water are eliminated, affection of flood disaster to production is avoided, a safe and comfortable working environment is provided for the stoping operation, and conditions for stability and high yield of the stope face are created.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

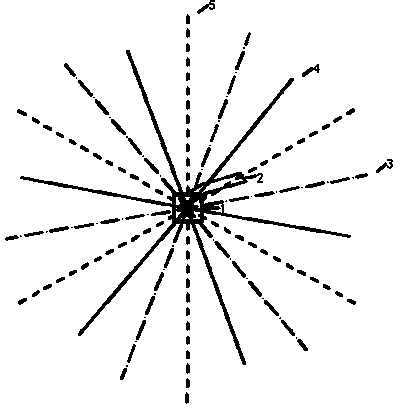

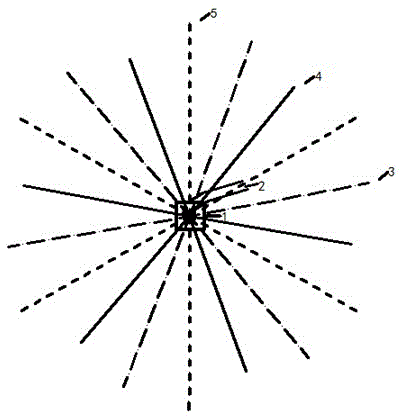

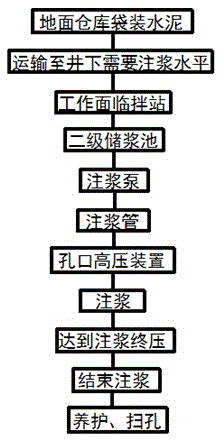

Curtain grouting process suitable for water-rich mine underground mining water plugging

ActiveCN103967507AStrong targetingLess ineffective drillingUnderground chambersTunnel liningKarstHigh pressure

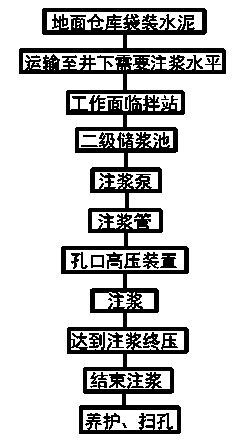

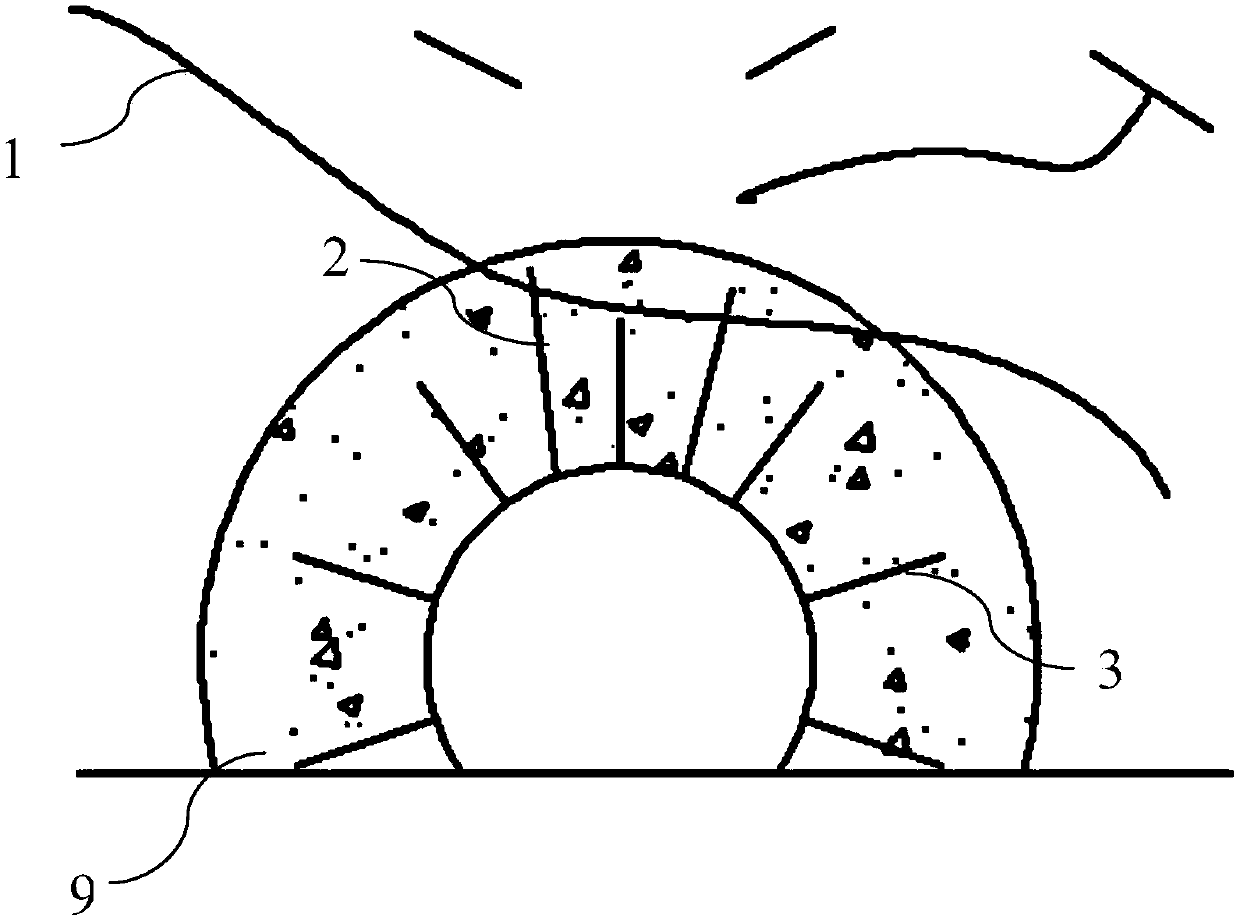

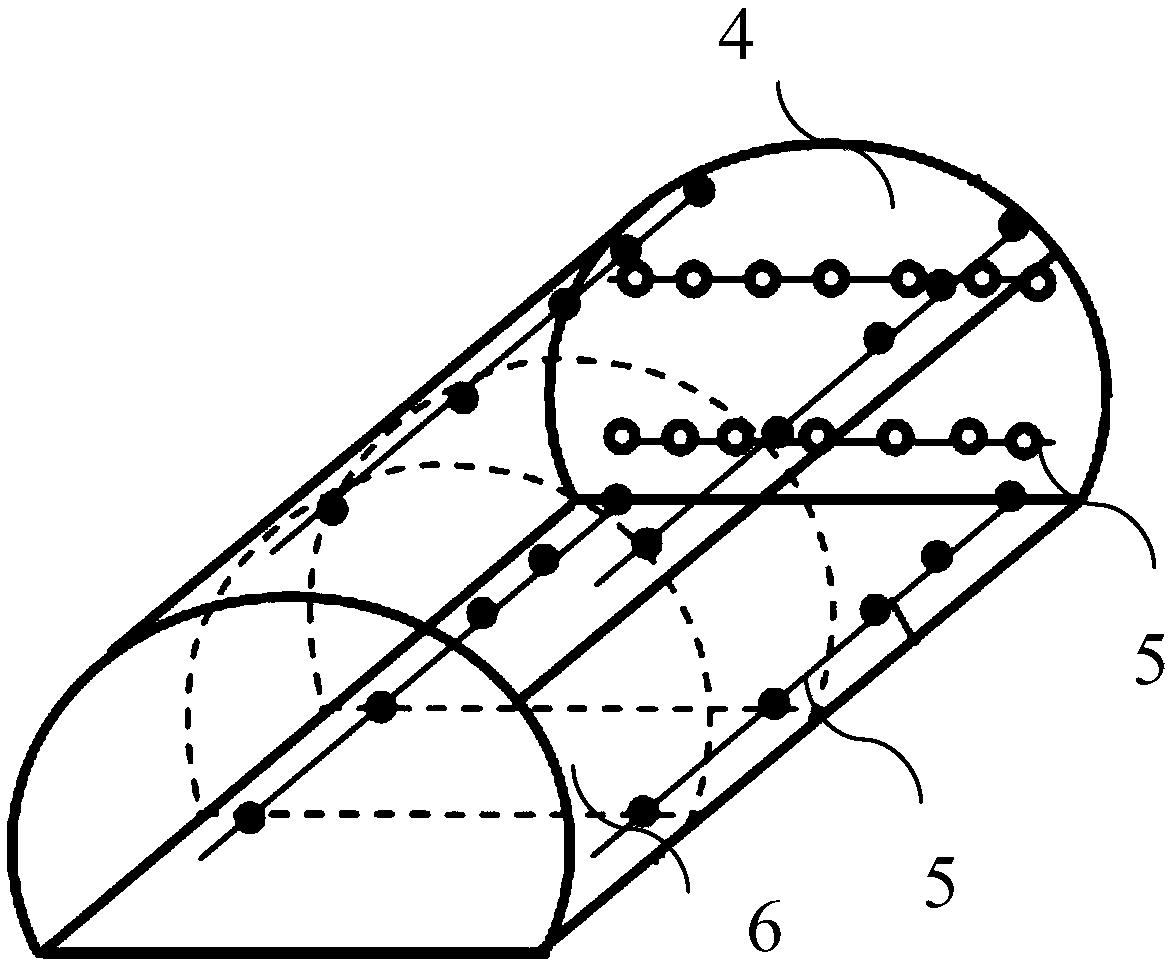

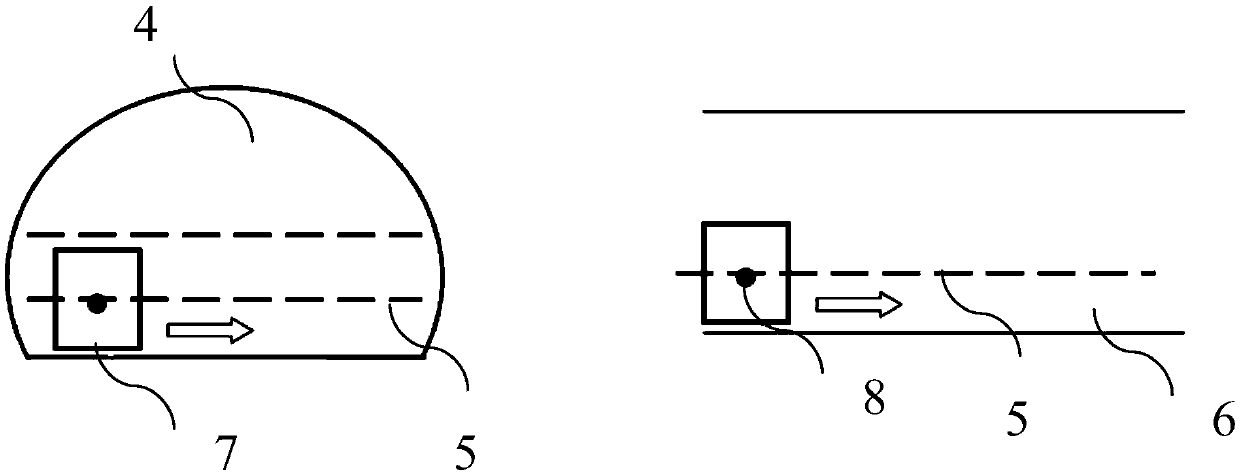

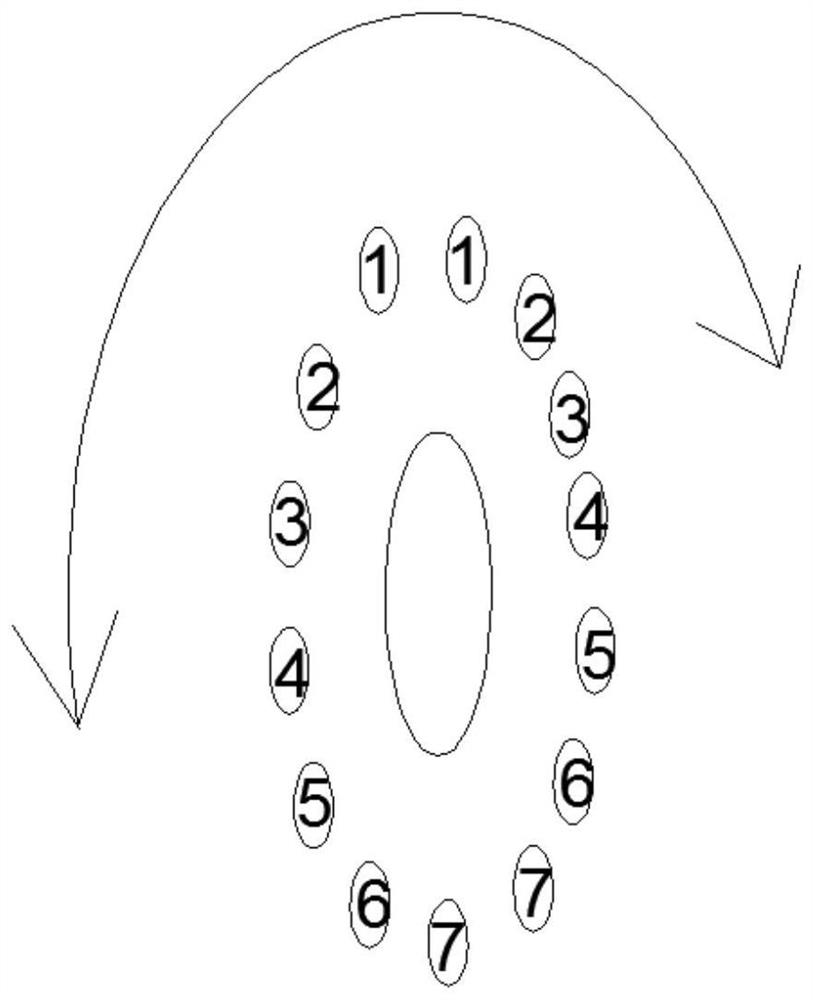

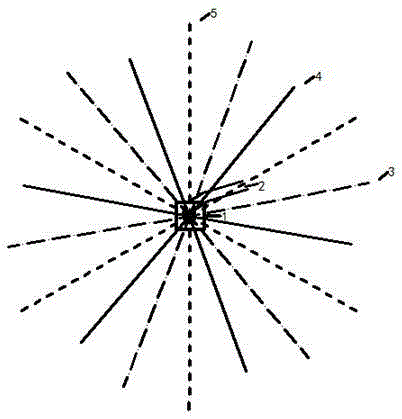

The invention discloses a curtain grouting process suitable for water-rich mine underground mining water plugging. According to the arrangement method of grouting holes, six grouting holes facing upwards by 5 degrees, six grouting holes facing upwards by 15 degrees and six grouting holes facing upwards by 25 degrees are formed in each chamber, the grouting holes facing upwards by 5 degrees, the six grouting holes facing upwards by 15 degrees and the six grouting holes facing upwards by 25 degrees are evenly distributed in the plane in a 60-degree staggered mode, and grouting holes facing downwards by -5 degrees, grouting holes facing downward by -30 degrees and grouting holes facing downwards by -60 degrees are formed outward in the chambers at the ends. According to the grouting process, bagged cement in a ground warehouse is transported to underground positions where grouting and leveling are needed, grouting is conducted through a working face temporary stirring station, a two-level pulp storage pond, a grouting pump, a grouting pipe and a hole opening high pressure device, grouting is completed after the designed final grouting pressure is reached, and the whole curtain grouting work is completed after further maintenance and hole cleaning. A grouting curtain with a high water plugging rate is set up underground for roof karst cracks, the water isolation function and the reinforcing function can be achieved, an ore body is safely and efficiently freed under protection of the grouting curtain, technical guarantees are provided for safe and efficient mining of the mine, project input is small, and the construction period is short.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

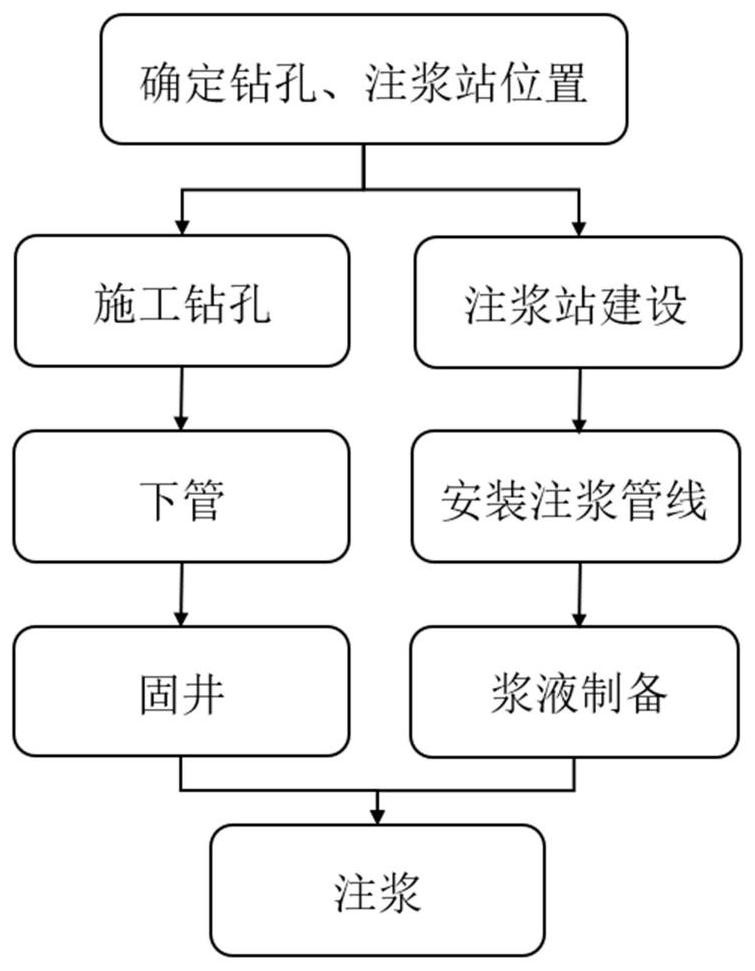

Grouting treatment method for broken water-rich section of diversion tunnel in karst area

ActiveCN109519220AReduce water gushingReduce water pressureUnderground chambersDrainageGeomorphologyKarst

The invention provides a grouting treatment method for a broken water-rich section of a diversion tunnel in a karst area. The method includes the following steps: S1) conducting geological explorationon the broken water-rich section of surrounding rock with water inrush to determine a major runoff path of fissure water and / or groundwater; S2) drilling a drainage hole from a tunnel wall of the broken water-rich section of the surrounding rock to the runoff direction of the fissure water and / or the groundwater in the surrounding rock for drainage of the fissure water and / or the groundwater; S3)drilling grouting holes at preset distance along the radial and circumferential directions of the tunnel wall of the broken water-rick section of the surrounding rock and inserting a grouting pipe into each grouting hole; S4) injecting grouting liquid into the surrounding rock through the drainage hole and the grouting pipes to form a water stop curtain circumferentially in the surrounding rock of the tunnel wall. According to the method, a better grouting treatment effect is achieved, the engineering safety is ensured, and the groundwater resource pollution is reduced.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

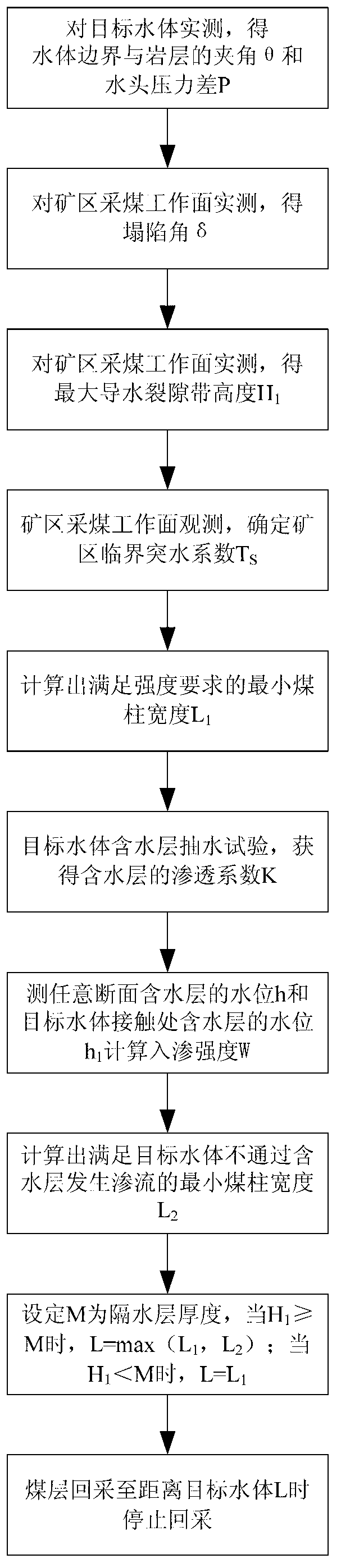

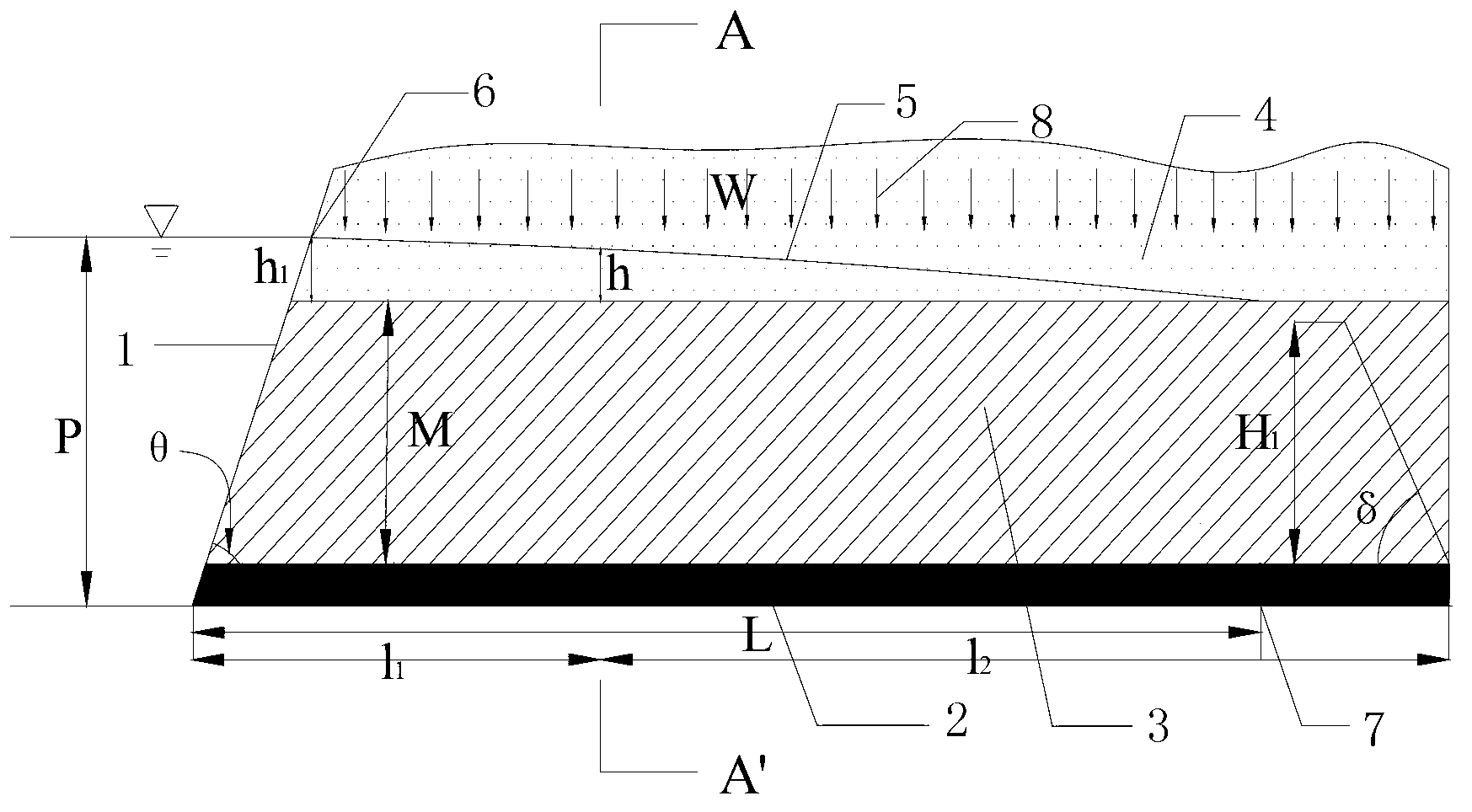

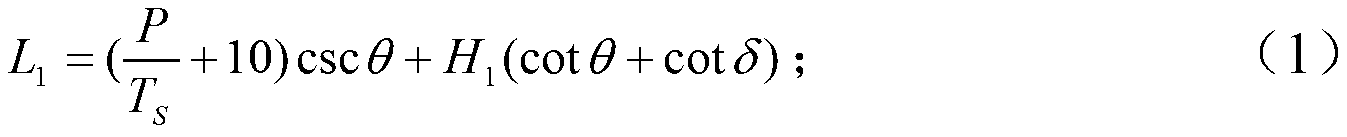

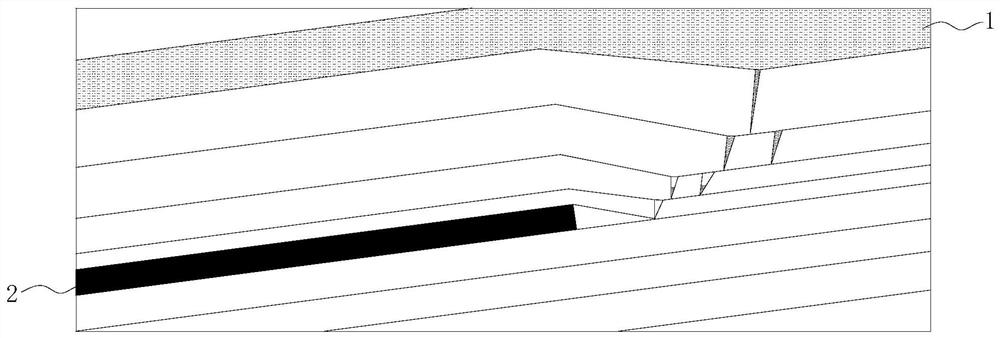

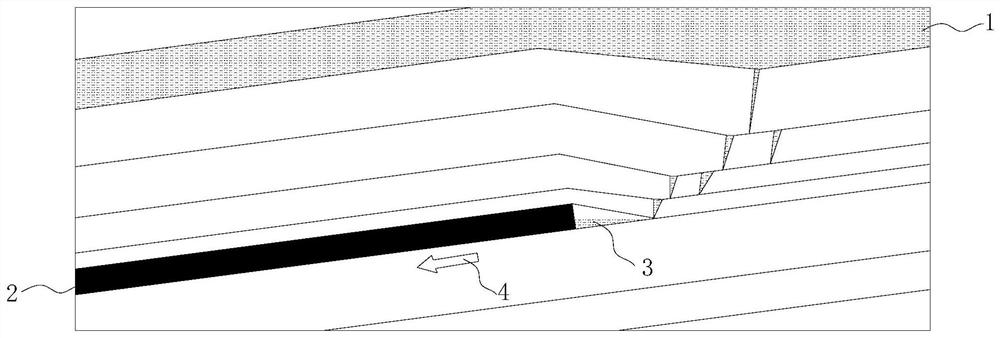

Coal pillar setting and extracting method for protecting important water body

ActiveCN103184871AEasy to implementProtect water resourcesUnderground miningSurface miningCoal pillarCoal

The invention discloses a coal pillar setting and extracting method for protecting an important water body, which comprises the following steps:1) measuring the target water body actually to gain an included angle theta between a water body boundary and a rock stratum, and a head pressure difference P between the target water body to a coal floor, 2) measuring a collapsing angle sigma actually, 3) measuring a coal face actually to gain a maximal water-flowing fractured zone height H1, 4) confirming an ore district critical water bursting coefficient TS, 5) calculating a minimum pillar coal setting width L1 satisfying strength needs, 6) pumping a target water body water-bearing bed and gaining an osmotic coefficient K, 7) measuring a water-bearing bed water level h of any fracture surfaces and a water-bearing bed water level h1 at a part in contact with the target water body, and calculating an infiltration strength W of a water-bearing bed 4, 8) calculating a minimum coal pillar setting width L2 without infiltration flow,9)taking a larger one between the minimum pillar coal width L1 and the minimum coal pillar width L2 as the optimal coal pillar setting width L when the maximal water-flowing fractured zone height H1 is more than or equal to the thickness M of the waterproof layer 3, and taking the minimum pillar coal width L1 as the optimal coal pillar setting width L when the maximal water-flowing fractured zone height H1 is less than the thickness M of the waterproof layer 3,and 10) stopping extraction when the coal floor is extracted to the optimal coal pillar setting width L from the protected target water body. The method has the advantages that implementation is simple and easy; the water resource can be protected efficiently; the mine hydraulic discharge is reduced; and the resource can be extracted safely.

Owner:SHAANXI COAL & CHEM TECH INST

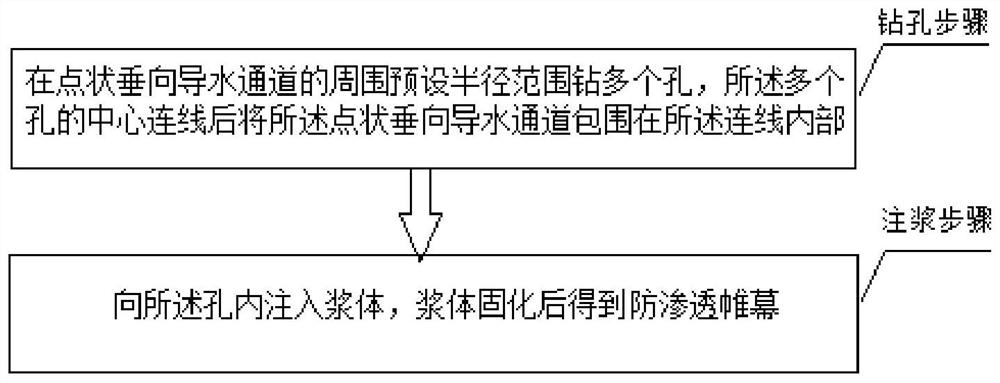

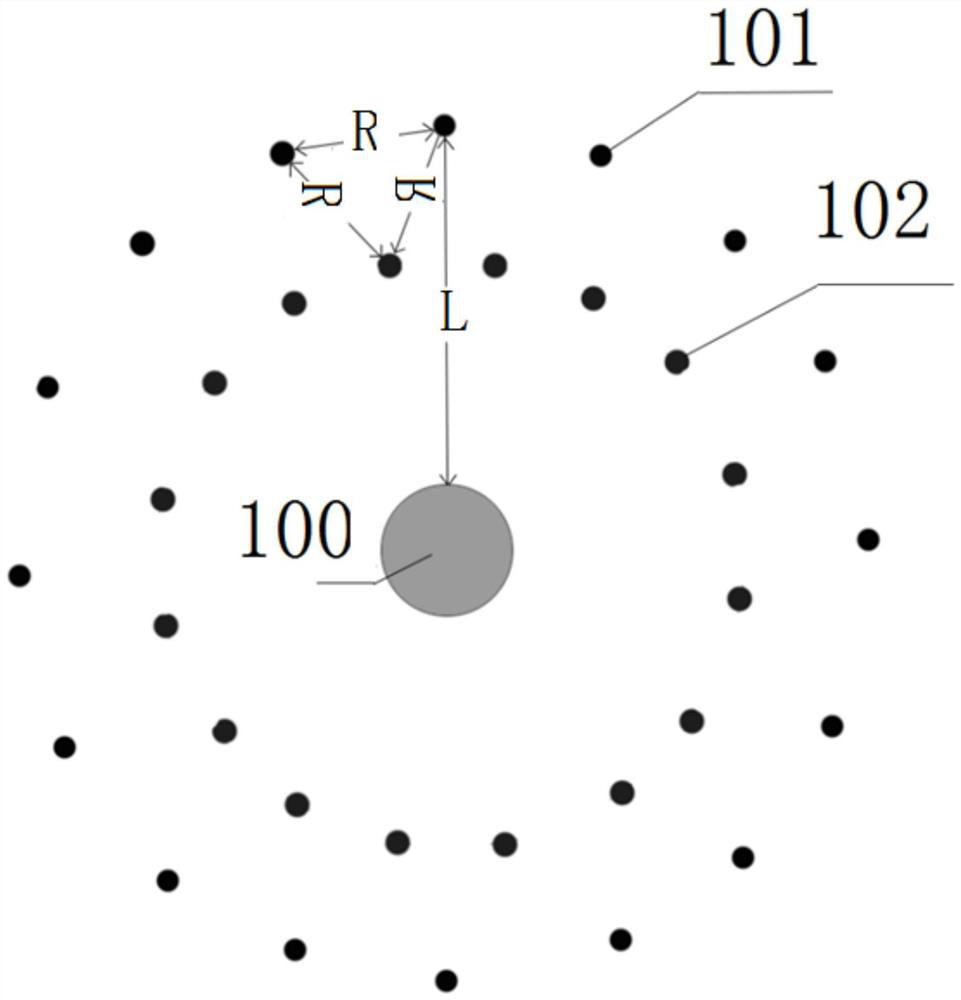

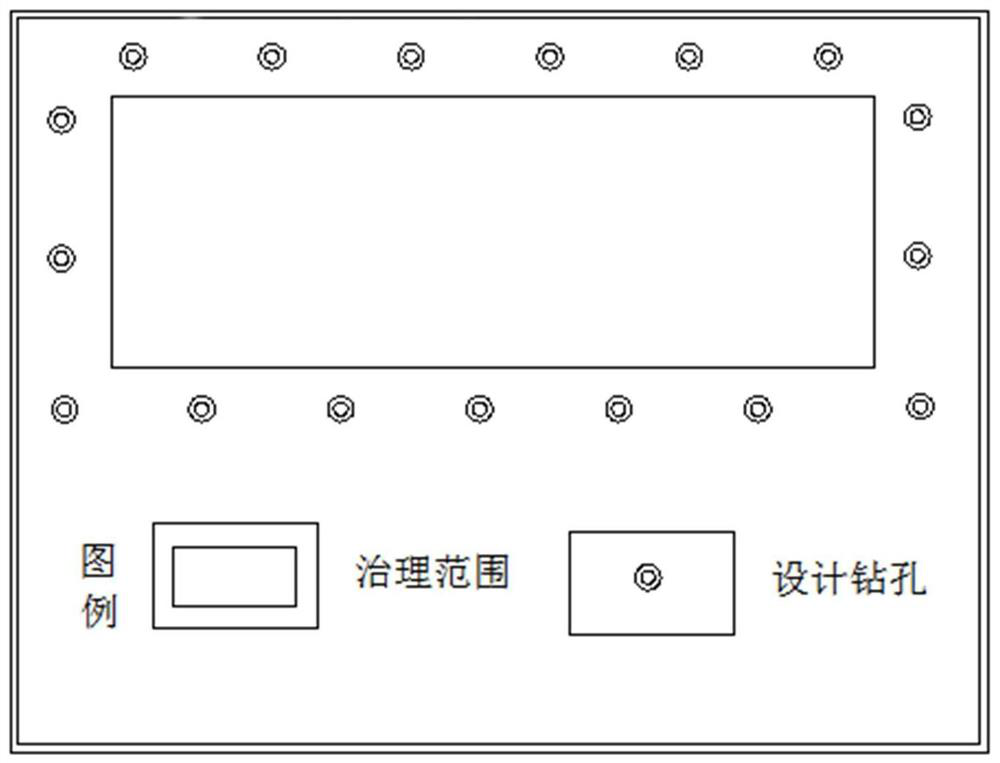

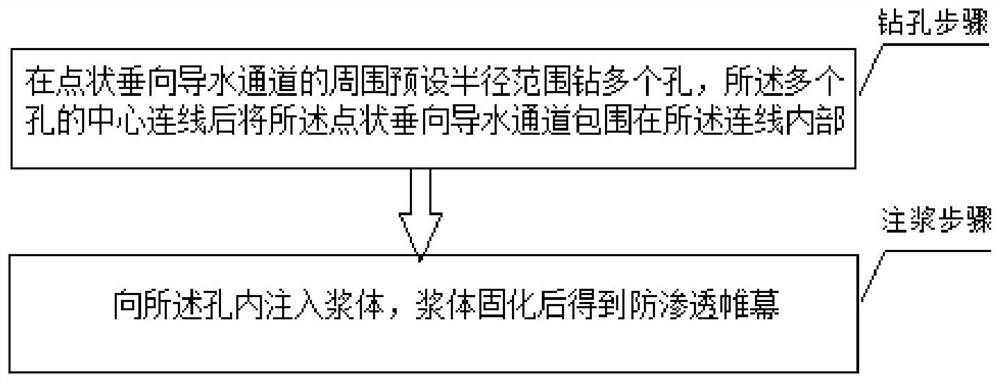

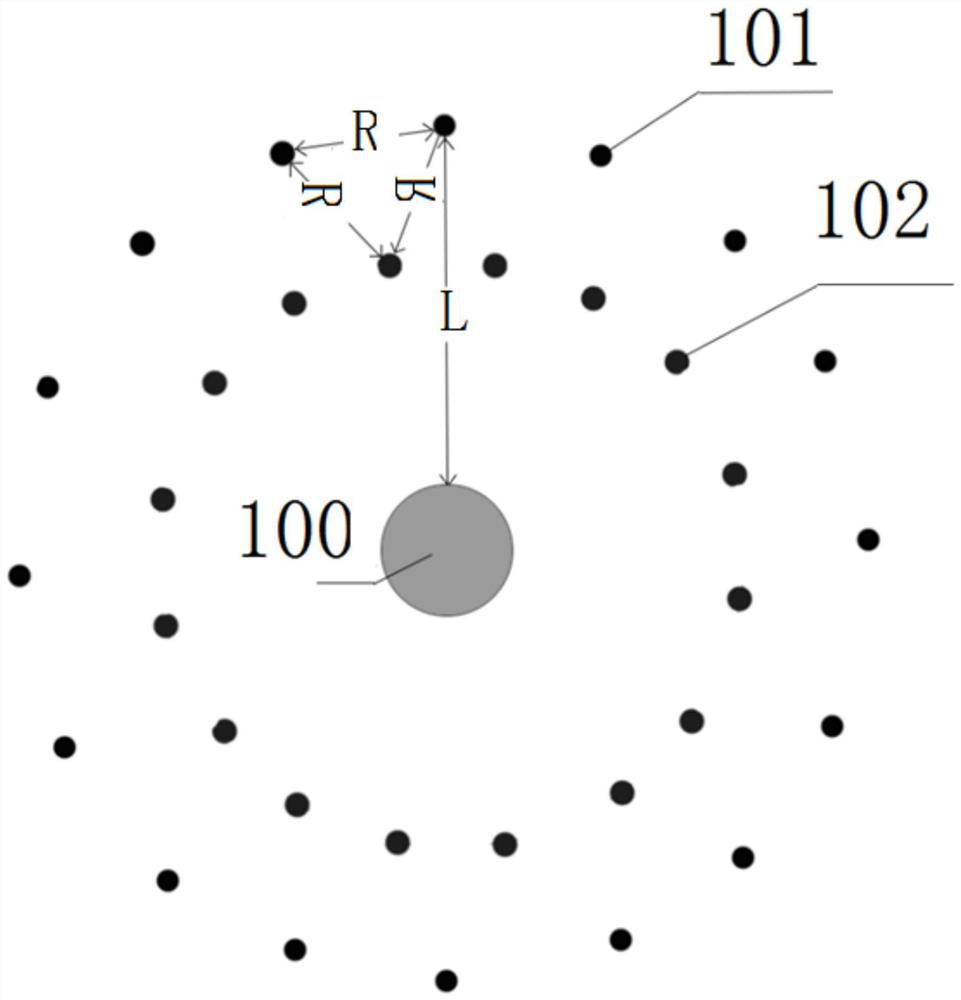

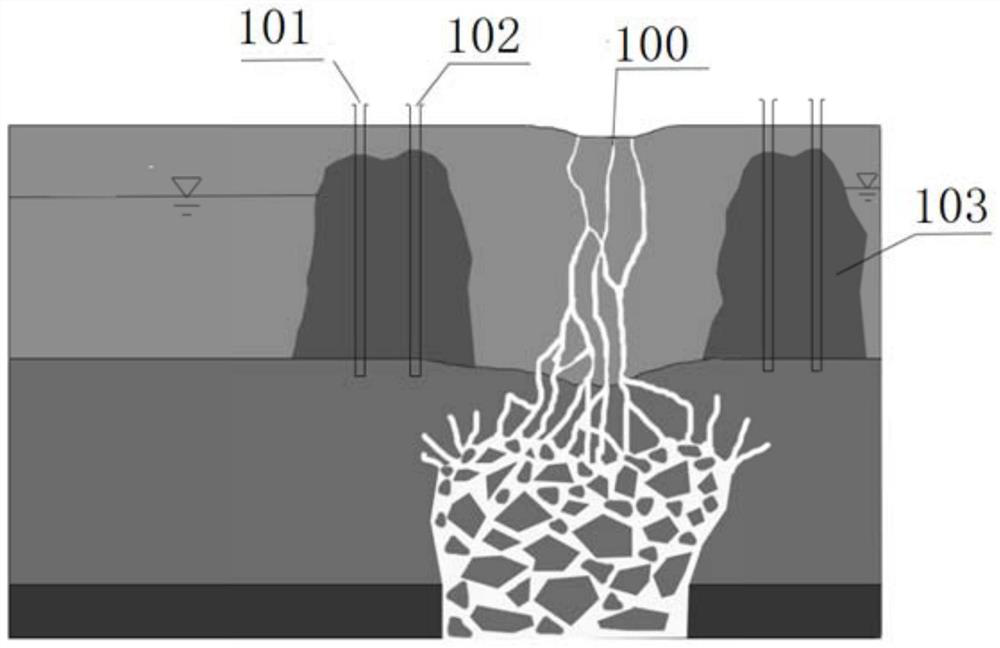

Curtain closure method for submersible aquifer dotted vertical water guiding channel

ActiveCN111810232AReduce water gushingEliminate water hazardsMining devicesMaterial fill-upWater sourceStructural engineering

The invention provides a curtain closure method for a submersible aquifer dotted vertical water guiding channel. The curtain closure method comprises the following steps of: drilling holes: drilling aplurality of holes within a preset radius range around the dotted vertical water guiding channel, and after the centers of the plurality of holes are connected, surrounding the dotted vertical waterguiding channel in connection lines; and grouting: injecting mortar into the holes, and after the mortar is solidified, obtaining an anti-seepage curtain. According to the above scheme provided by theinvention, an entrapment type curtain body is constructed around the aquifer dotted vertical water guiding channel so as to cut off a submersible aquifer supply water source, a mine water inflow is reduced, water disaster hidden dangers are eliminated, and meanwhile, cost input is greatly saved.

Owner:SHENHUA XINJIANG ENERGY +1

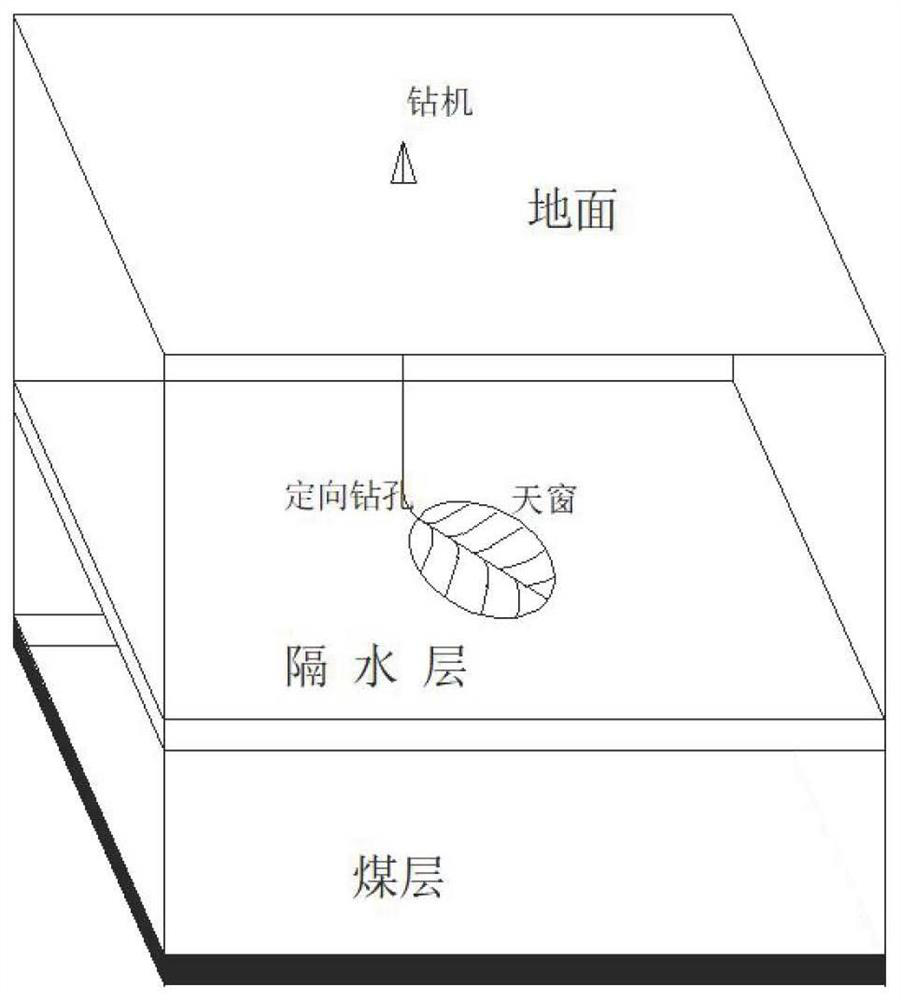

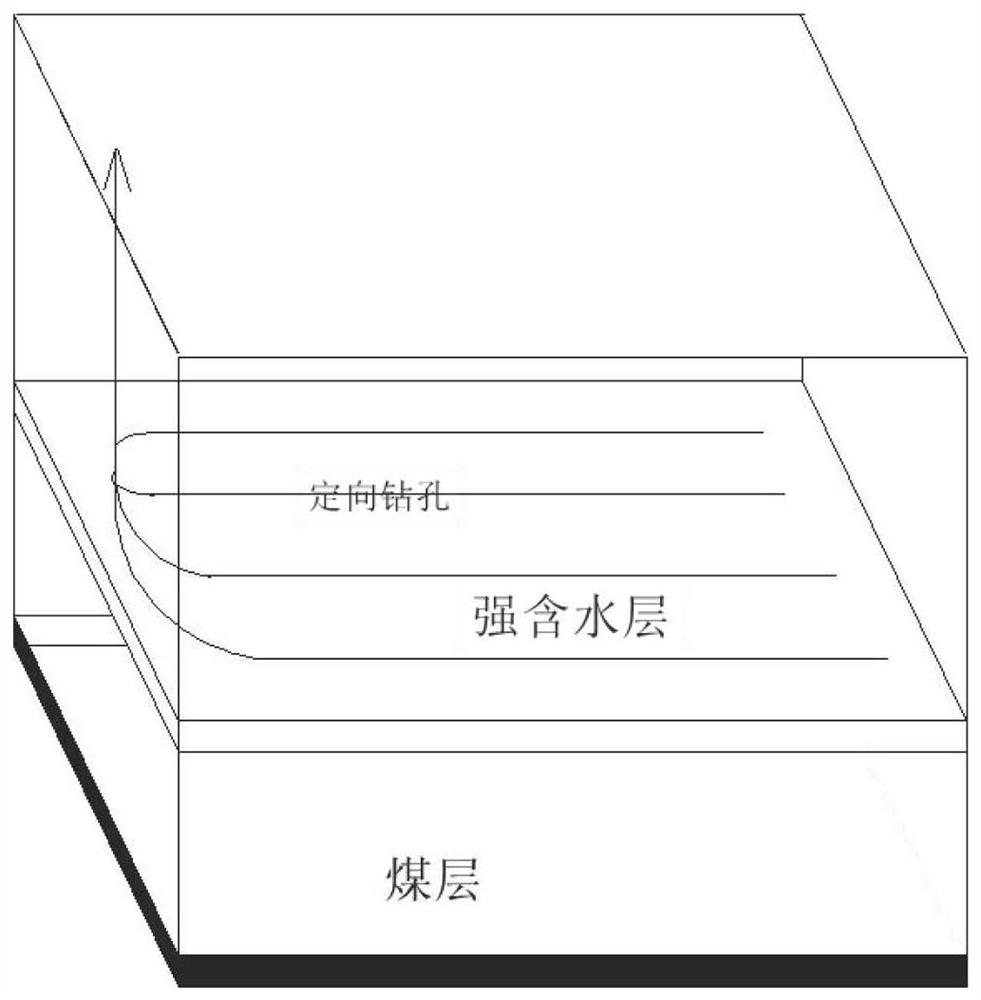

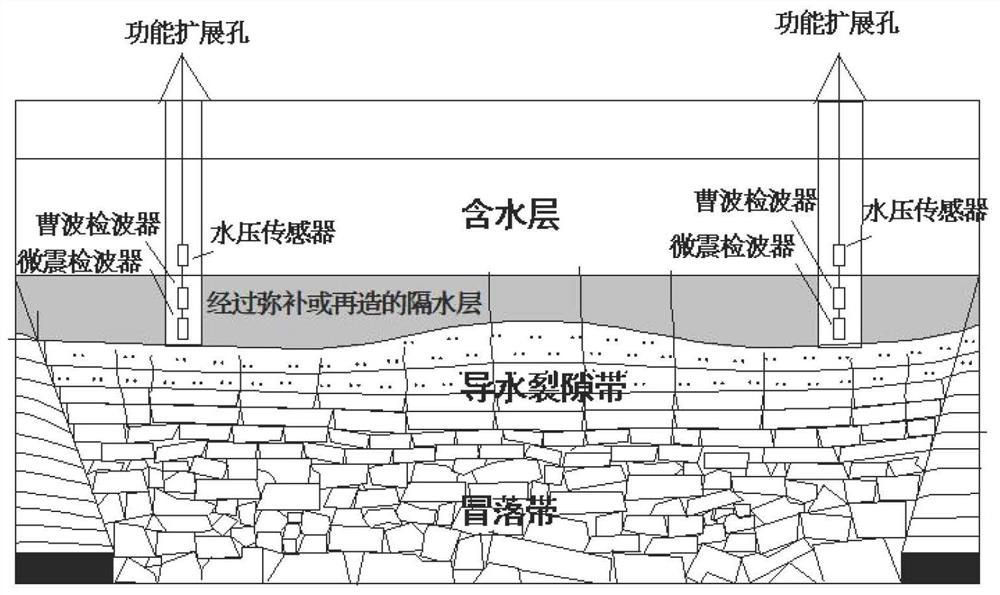

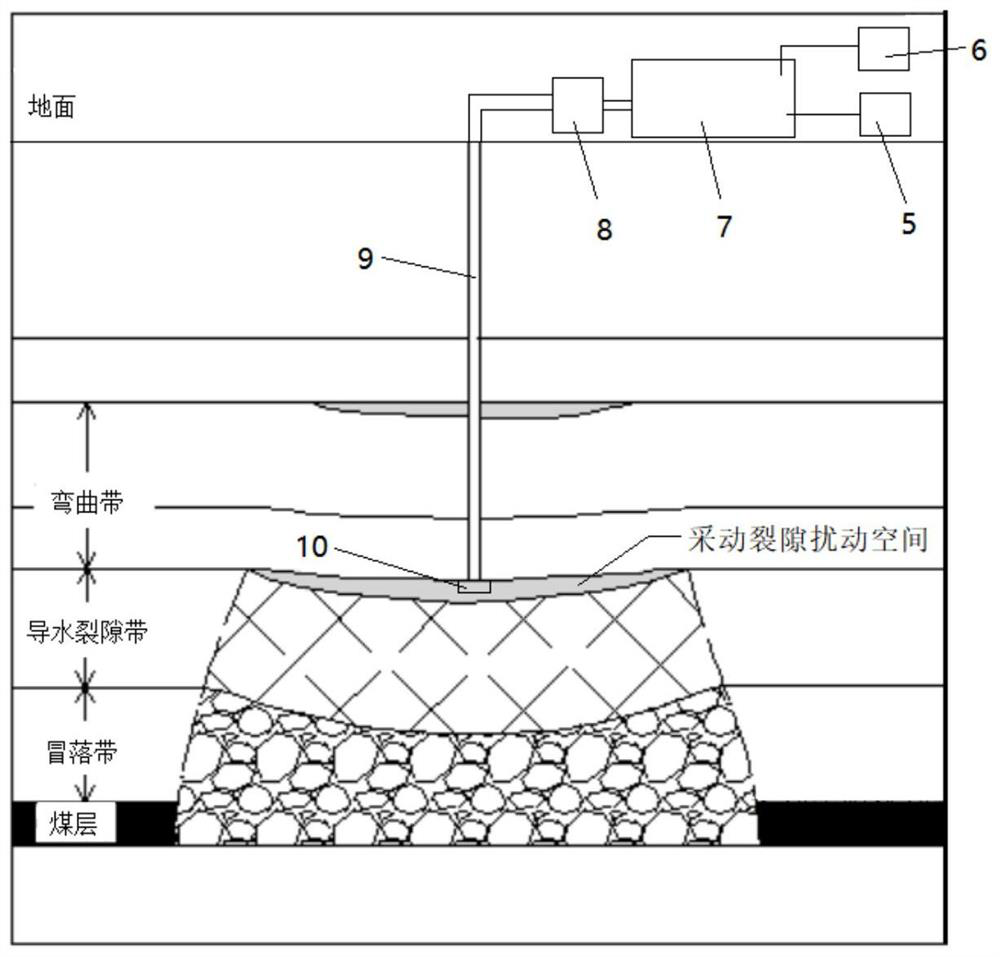

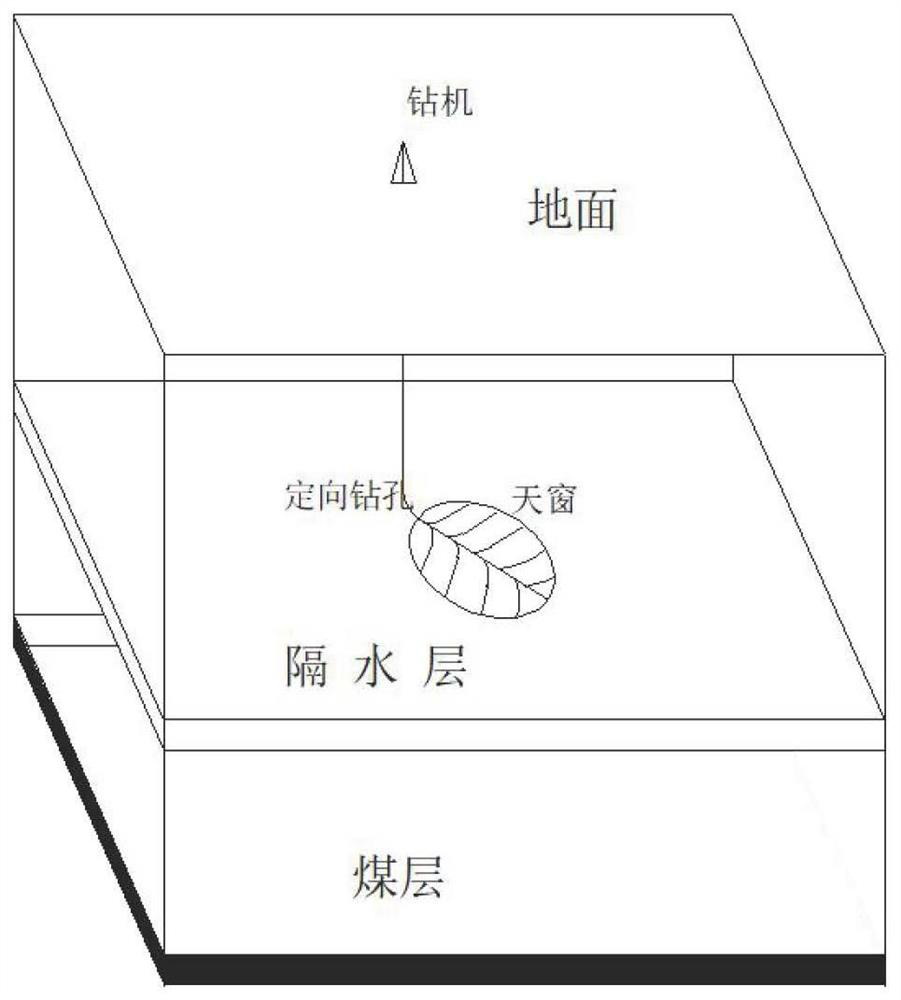

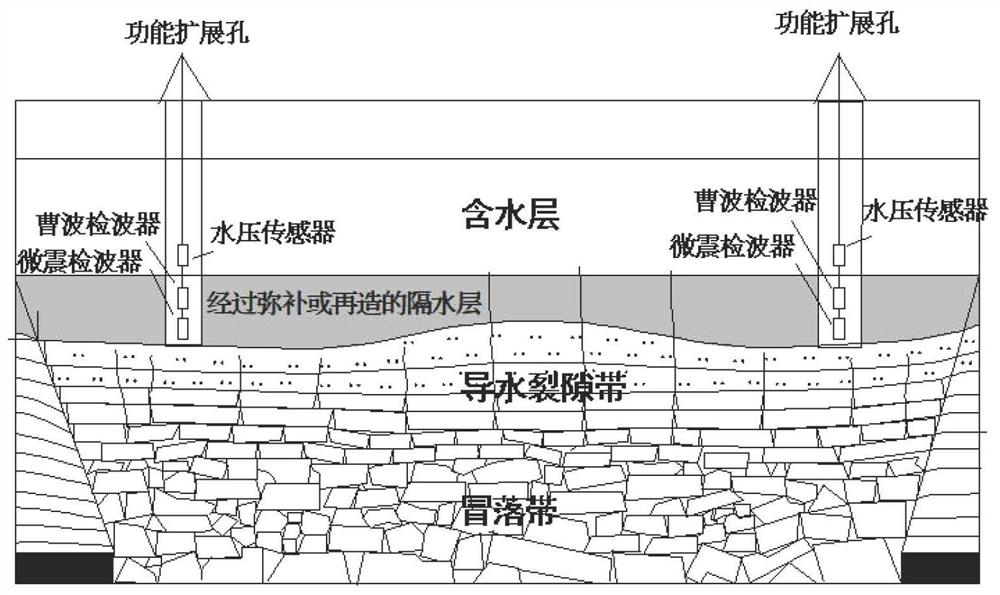

Grouting treatment method for coal seam roof quite-thick aquifer area

ActiveCN111894588AReduce thicknessReduce water gushingUnderground miningSeismic signal receiversCoal pillarAquifer

The invention provides a grouting treatment method for a coal seam roof quite-thick aquifer area. The grouting treatment method comprises the following stages: at the first stage, before mining, sedimentary facies analysis is conducted, a valley-flat facies stratum is selected as a target stratum, and if no valley-flat facies aquiclude exists, a strong-permeability aquifer is selected as the target stratum; at the second stage, probing positioning of a permeable skylight is conducted on the valley-flat facies target stratum, grouting making-up is conducted on the valley-flat facies target stratum, or the strong-permeability aquifer is grouted to be transformed into the aquiclude; at the thrid stage, after a roof is transformed before mining, stability of the aquiclude can be utilized for monitoring; and at the fourth stage, after mining, a slip seam generated in the roof of a coal pillar can be grouted to form a waterproof curtain. Before mining, the skylight of the aquiclude is subjected to grouting making-up, or the strong-permeability aquifer is transformed into the aquiclude, after mining, the slip seam is grouted to form the waterproof curtain, thus the purposes of decreasingthe thickness of the aquifer and decreasing the water inflow of a mine are achieved, the down-hole operating environment is improved, the cost is lowered, and normal production of an inactive coal mine is restored.

Owner:CHINA COAL GEOLOGY GRP CO LTD

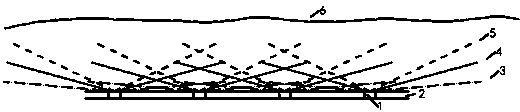

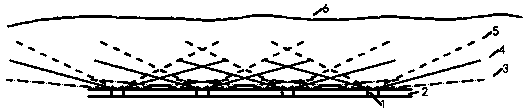

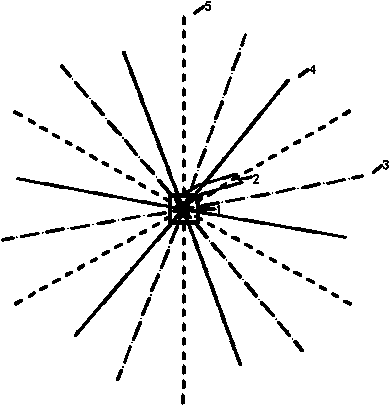

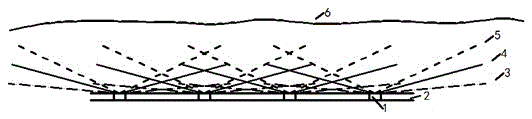

Curtain grouting technology for ore body roof karst fracture development and strong water-rich ore deposit

ActiveCN103967506AGuarantee safe miningReduce drainage costsUnderground chambersTunnel liningElevation angleGeomorphology

The invention discloses a curtain grouting technology for an ore body roof karst fracture development and strong water-rich ore deposit. According to the technical scheme, firstly, upward exploration and injection holes are distributed, six upward exploration and injection holes with an elevation angle of five degrees, six upward exploration and injection holes with an elevation angle of 15 degrees and six upward exploration and injection holes with an elevation angle of 25 degrees are distributed in each chamber, the exploration and injection holes are designed with the chambers as base points, all the exploration and injection holes of all the lengths are evenly distributed in the plane with a stagger angle of 60 degrees, the hole depth is 50 m, and the exploration and injection holes with the elevation angle of five degrees, the exploration and injection holes with the elevation angle of 15 degrees and the exploration and injection holes with the elevation angle of 25 degrees are evenly distributed in the plane with a stagger angle of 20 degrees; secondly, downward exploration and injection holes are distributed, the outward and downward exploration and injection holes with the angles of -5 degrees,-30 degrees and -60 degrees are distributed in end chambers, the hole depth is 50 m, all the downward exploration and injection holes are evenly distributed symmetrically in the plane, and the included angle is 10 degrees; thirdly, according to the requirement of accurate mining engineering, grouting is carried out, and a grouting curtain is formed. The grouting curtain with the high water plugging rate is built under a mine according to roof karst fractures, the functions of water separation and reinforcement can be achieved, ore bodies are released safely and efficiently under the protection of the grouting curtain, and technical guarantees are provided for safe and efficient mining of the mine.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

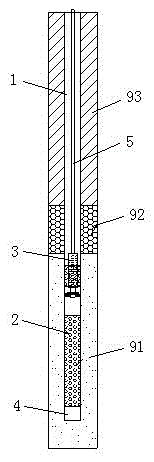

Standby and observation well for foundation pit dewatering

PendingCN105649096AReduce water gushingMeet the needs of different functionsFoundation engineeringWater levelFilter material

The invention relates to the technical field of civil construction, in particular to a standby and observation well for foundation pit dewatering to achieve the technical purposes that the water level measurement error is reduced, and the foundation pit surrounding environment influence is reduced. The well comprises a well pipe, a filtering pipe, a sediment pipe, a filter material layer, a clay ball layer and a backfill soil layer, wherein the well pipe, the filtering pipe and the sediment pipe are sequentially connected in series from top to bottom. The filtering pipe is divided into three pipe sections from top to bottom. The pipe wall in the middle section of the filtering pipe is waterproof, and the pipe walls of the other two pipe sections of the filtering pipe are permeable. An annular baffle is axially fixed in the middle section of the filtering pipe. An annular lower sealing cushion is fixed to the upper baffle face of the baffle. An immersible pump is arranged in the filtering pipe. A pull rope is fixed to the immersible pump. A connecting pipe is fixed to the lower end of the immersible pump and coaxially sleeved with an annular cover plate. An annular upper sealing cushion is fixed to the lower plate face of the cover plate. The standby and observation well for foundation pit dewatering can serve as a foundation pit dewatering observation well and can also serve as a foundation pit dewatering standby well.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

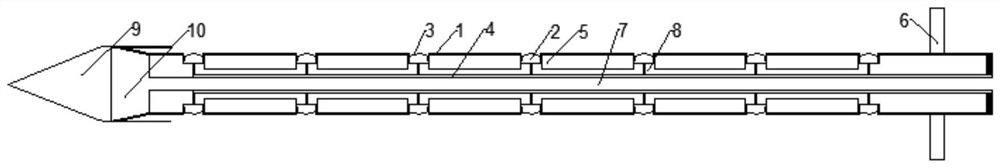

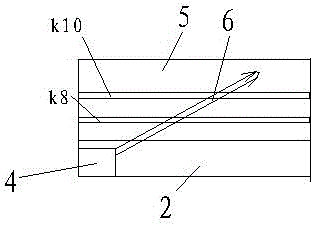

Quick measurement method of coal seam gas pressure

InactiveCN104389587AReduce air leakageReduce borehole water gushingSurveySealing/packingDrill holePetrology

The invention discloses a quick measurement method of coal seam gas pressure. The method is characterized in that the measurement operation of measuring the drilling pressure is divided into two phases: the first phase is to perform the large-diameter drilling in the pressure measuring position, a bushing is put in the large-diameter drill hole, and slurry is injected in the bushing, the large-diameter drilling hole and a surrounding rock microfissure zone for compacting; and the second phase is to perform the drilling again in the bushing to form a pressure measuring hole penetrating in a coal seam, a drill rod is taken out, and the coal seam gas pressure is directly measured by an original bushing. The slurry is injected in a fissure group of a coal rock body surrounding the drilling hole, the drilling hole and the bushing under the effect of high pressure, so that the peripheral compactness of the drilling hole is improved, the emission of fissure water in a rock stratum is largely reduced, the air leakage and the water yield in the drilling hole are obviously reduced; and in particular, aiming at a soft coal measure strata, the coal seam gas pressure is quickly and accurately measured.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Groundwater control method of composite water bearing structure of deep foundation pit

ActiveCN106193076AReduce water gushingEliminate secondary stress damageFoundation engineeringStructure of the EarthWater diversion

The invention relates to a groundwater control method of a composite water bearing structure of a deep foundation pit, which belongs to the technical field of civil construction and solves the technical problems of large construction difficulty and high construction cost. The method relates to the operation of the deep foundation pit in an area of the composite water bearing structure, and the composite water bearing structure comprises an upper water bearing layer and a lower water bearing layer. The method comprises the steps of constructing a vertical waterproof curtain when the deep foundation pit is operated, and partitioning the upper water bearing layer by utilizing the waterproof curtain; then constructing a water diversion filtering layer in a water partitioning layer which is arranged on the inner side of the waterproof curtain and is located between the two water bearing layers, so that the two water bearing layers communicate; then constructing a precipitation well and a precipitation observation well on the inner side of the waterproof curtain, and performing precipitation on the upper water bearing layer by utilizing the precipitation well and the precipitation observation well; and constructing a recharge well and a recharge observation well on the outer side of the waterproof curtain, and timely recharging the lower water bearing layer by utilizing the recharge well and the recharge observation well. The method provided by the invention is especially suitable for precipitation of the deep foundation pit in the area with a plurality of water bearing layers.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

Tunnel water gushing treatment method

InactiveCN112523803AReduce water gushingEasy to judge the location of water gushing pointUnderground chambersDrainageEngineeringEnvironmental engineering

The invention discloses a tunnel water gushing treatment method. The method comprises the following steps that a water gushing hole serves as a starting point to be drilled to form a water gushing channel. A grouting pipe penetrates through the flange plate and extends into the water gushing channel. A water guide port corresponding to the water gushing point is determined through inflation standing of the air inlet, a water guide cavity corresponding to the water guide port is determined, and then the water gushing depth is judged. A hole is drilled in the inner wall of the tunnel and locatedin the circumferential direction of the grouting pipe till a pressure relief channel communicating with the water gushing hole is found, and a pressure relief point is determined. If the connecting line of the water gushing point and the pressure relief point is located above the horizontal plane where the water gushing point is located, it is determined that the water gushing hole is a descending hole, otherwise, the water gushing hole is an ascending hole, and if the water gushing hole is a descending hole, grouting and water plugging are conducted in the pressure relief channel, and then grouting and water plugging are conducted in the grouting pipe. If the water gushing hole is an ascending hole, grouting and water plugging are conducted in the grouting pipe, and then grouting and water plugging are conducted in the pressure relief channel. The method has the beneficial effect of realizing accurate grouting on the basis of following 'blockage-based and limited discharge '.

Owner:福州市长乐区古槐星际商务咨询服务部

Shield end soil body ultra-deep reinforcement construction method under water-rich silty-fine sand geology

PendingCN112282767AEliminate the risk of entry and exitReduce water gushingUnderground chambersTunnel liningShield machineDrill hole

The invention discloses a shield end soil body ultra-deep reinforcement construction method under water-rich silty-fine sand geology. The shield end soil body ultra-deep reinforcement construction method comprises the following steps of pile forming test, preparation before construction, in-place of a stirring machine, slurry preparation, drilling grouting, lifting stirring, repeated up-down stirring and acceptance check. According to the shield end soil body ultra-deep reinforcement construction method under the water-rich silty-fine sand geology, soil body reinforcement is conducted throughultra-deep three-axis stirring piles, the ultra-deep three-axis stirring piles are additionally arranged on the outer sides of reinforcing bodies to serve as waterproof curtains and are used for preventing underground water and sand outside a foundation pit from gushing into an end well in the station entering and exiting period of a shield tunneling machine, the phenomena of water gushing and sand gushing which are most likely to happen in the in-out hole process of the shield tunneling machine are greatly reduced, and therefore the risk of shield tunneling in-out hole in a full-section siltlayer is eliminated.

Owner:江苏旭辰交通科技发展有限公司

A curtain grouting process suitable for water plugging in underground mining of water-rich mines

ActiveCN103967507BSafe and Efficient MiningReduce water gushingUnderground chambersTunnel liningKarstHigh pressure

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

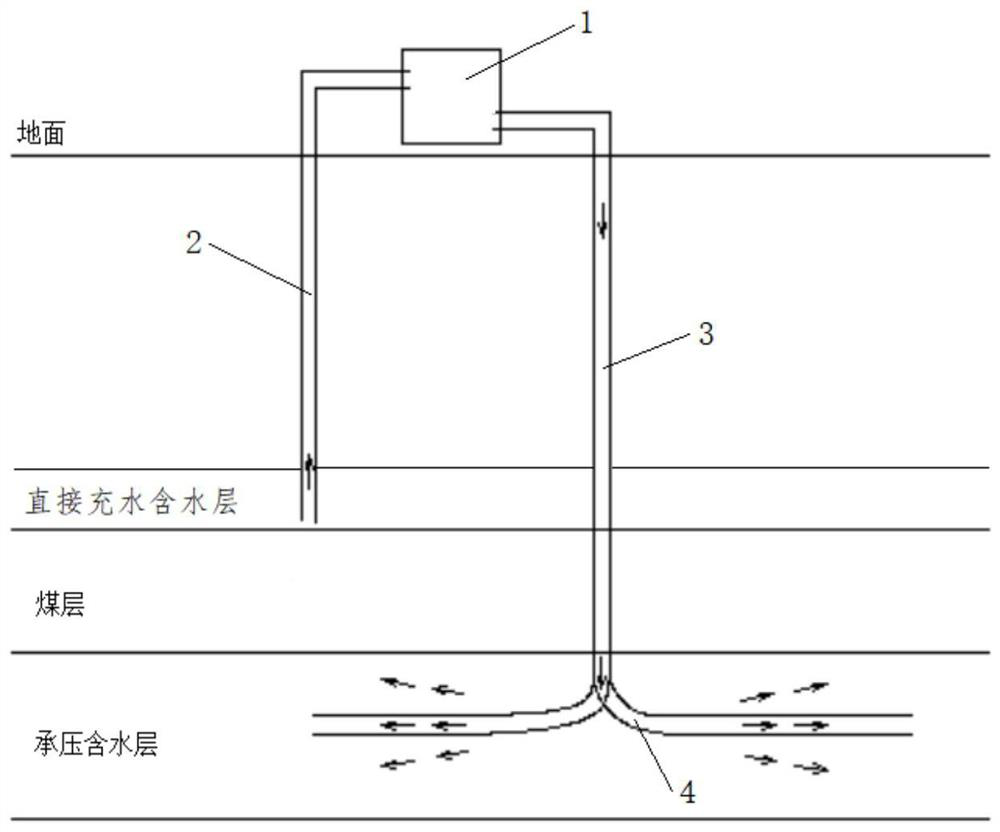

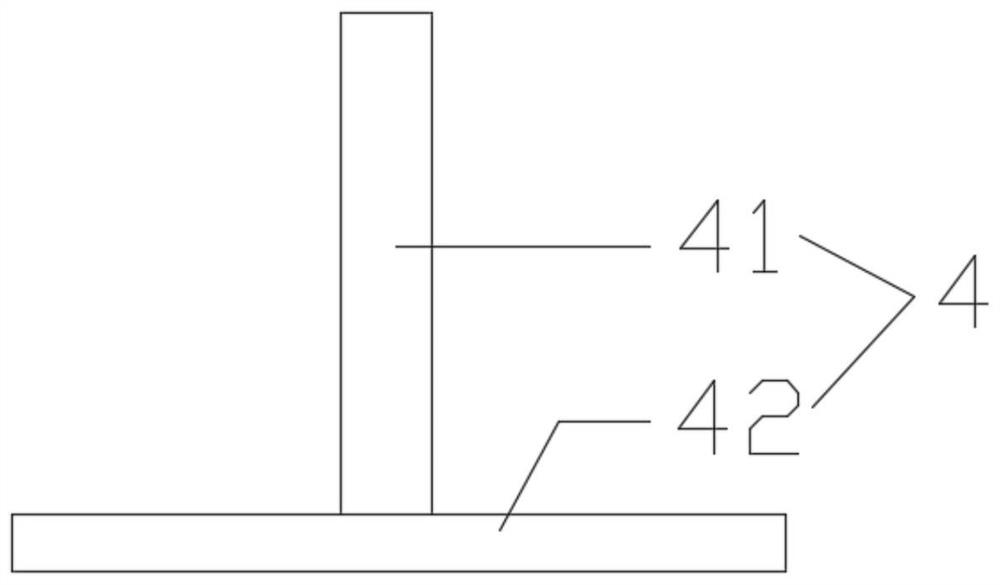

Mine underground water regulation and storage method and system

PendingCN112963199ADoes not affect production progressRealize resource utilizationMining devicesMaterial fill-upWater regulationAquifer

The invention relates to a mine underground water regulation and storage method and system, and belongs to the technical field of ecological environmental protection. The mine underground water regulation and storage method comprises the following steps that S1, hydrogeological exploration is carried out; and S2, a direct water filling aquifer of mine gushing water is determined, the direct water filling aquifer on a coal seam roof is selected as a water pumping layer, underground water of the water pumping layer is pumped out of the ground, and then the underground water pumped out of the ground is injected into a confined aquifer. The mine underground water regulation and storage system comprises a liquid pump, a liquid pumping well and a liquid injection well which are located on the ground, one end of the liquid pumping well extends into a liquid pumping layer, and the other end of the liquid pumping well is connected with a liquid inlet A of the liquid pump; and one end of the liquid injection well is connected with a liquid outlet A of the liquid pumping pump, and the other end of the liquid injection well extends into the confined aquifer. The direct water filling aquifer is underground water which is not polluted by the pit, a purification device does not need to be built, water treatment does not need to be carried out, cost is saved, and safety is high.

Owner:中煤水文局集团有限公司

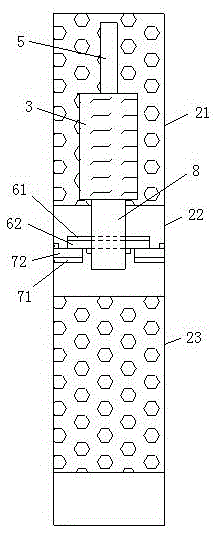

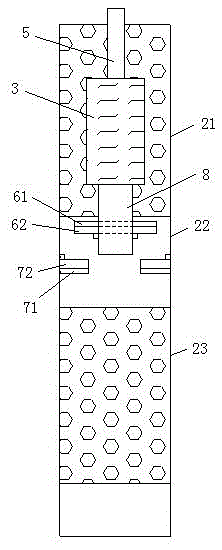

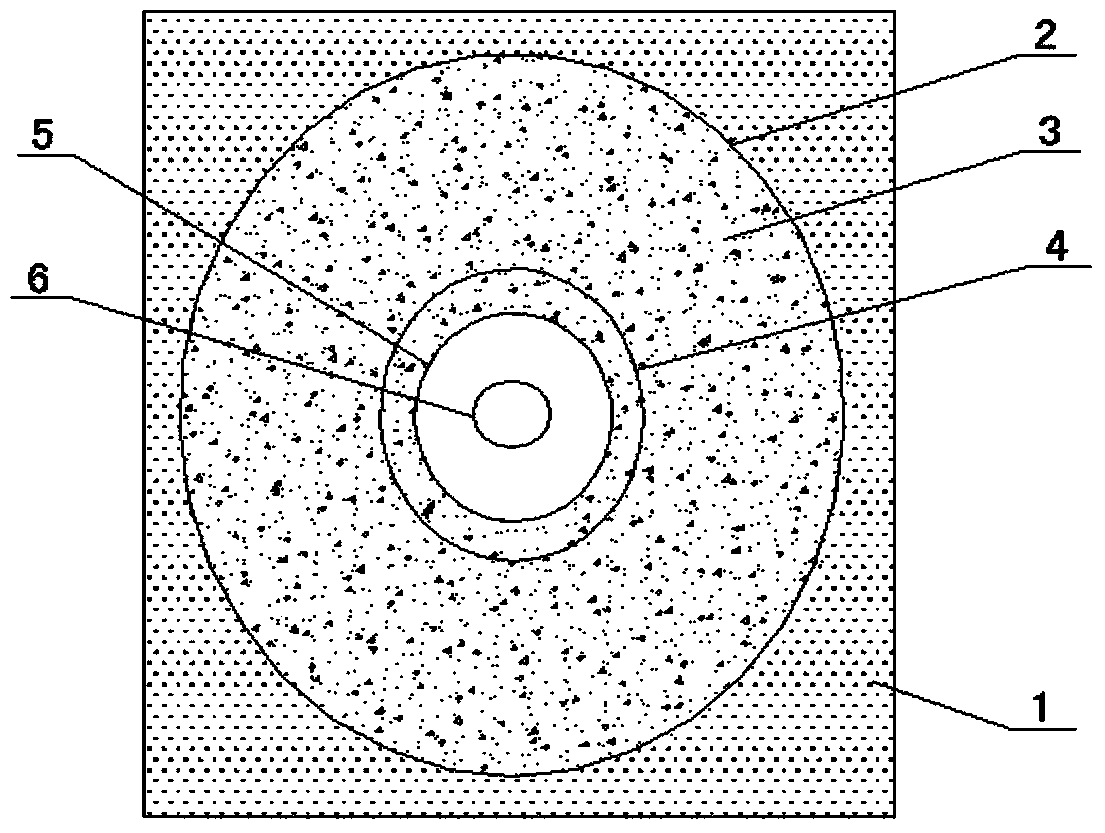

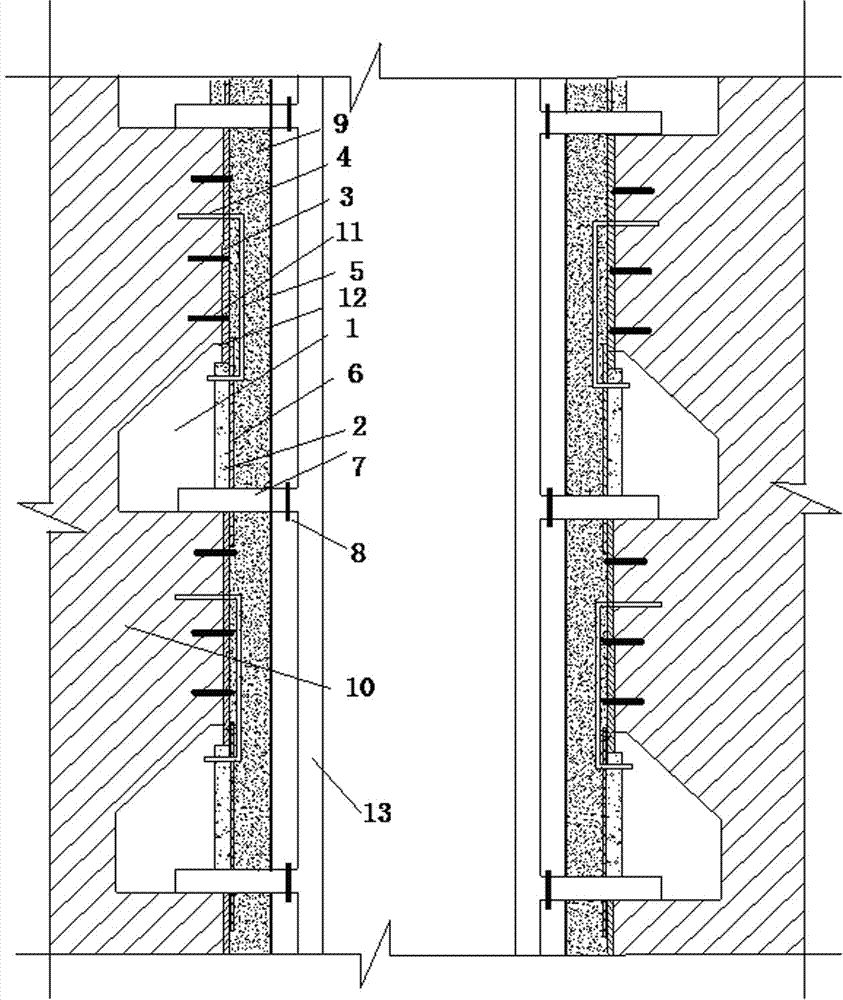

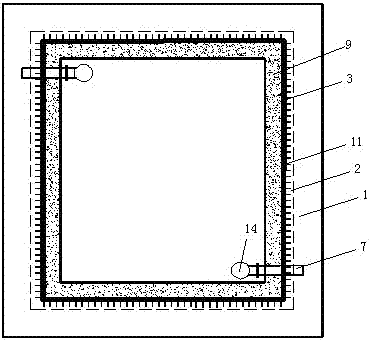

Segmented concealed cut-off structure of square shaft and its construction method

ActiveCN105443131BDoes not take up spaceEasy constructionDrainageShaft equipmentEngineeringRetaining wall

The invention discloses a square vertical-shaft sectioned hidden water interception structure and a construction method thereof. The square vertical-shaft sectioned hidden water interception structure comprises multiple hidden water interception grooves, a water guide pipe, a concrete support, small water draining pipes and large water draining pipes, wherein the multiple hidden water interception grooves are formed in the inner wall of a vertical shaft from top to bottom and are in closed square shapes, and a water retaining wall is arranged at the opening positions of the hidden water interception grooves. The concrete support is arranged on the inner wall of the vertical shaft. Each hidden water interception groove is communicated with the surrounding rock above the hidden water interception groove through a water guide pipe. The small water draining pipes are respectively arranged at the bottoms of the hidden water interception grooves and penetrate through the water retaining wall and the concrete support to be connected with the large water draining pipes. The square vertical-shaft sectioned hidden water interception structure adopts the hidden water interception grooves, guides scattered gushing water and concentrated gushing water into the water interception grooves, the hidden water interception grooves do not occupy a shaft space compared with visible water interception grooves, construction is convenient, the construction speed of the square shaft is improved, and meanwhile the quality of the inner wall of the shaft is ensured.

Owner:HUNAN UNIV OF SCI & TECH

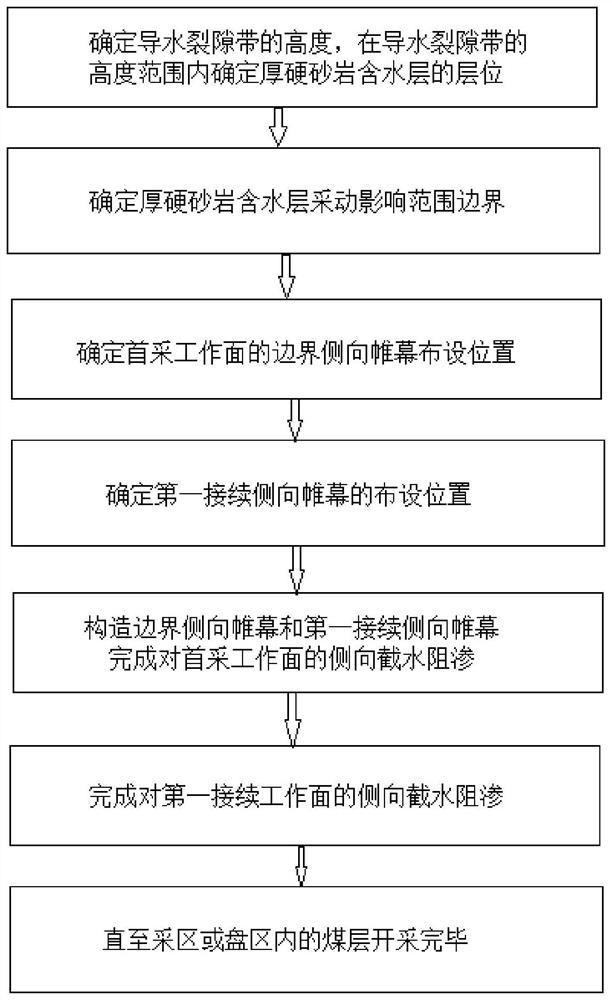

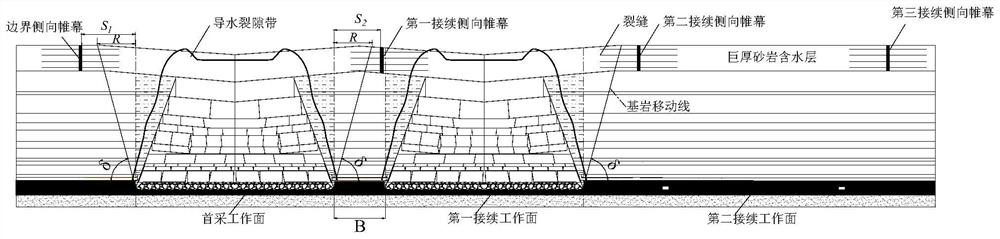

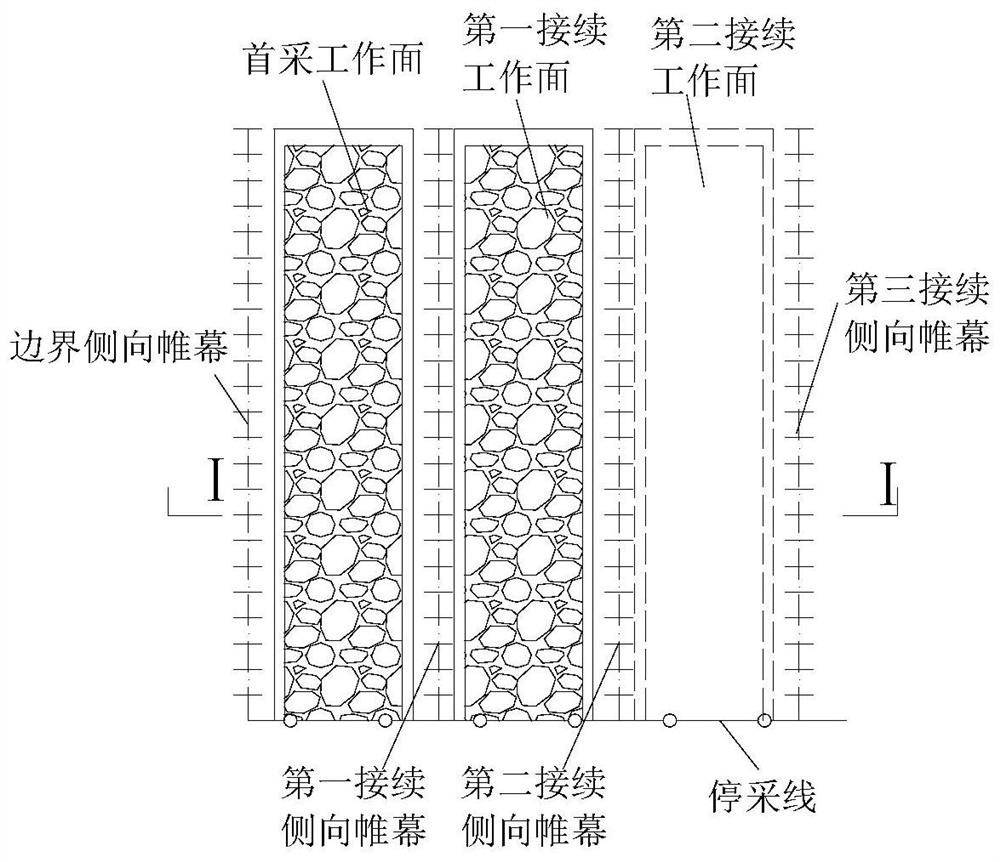

Coal mine thick and hard sandstone roof water disaster and rock burst composite disaster control method

ActiveCN114658485ARealize collaborative prevention and controlReduce water cross sectionMining devicesUnderground chambersSandstone aquiferMining engineering

The invention discloses a coal mine thick and hard sandstone roof water disaster and rock burst composite disaster treatment method which comprises the following steps: determining the height of a water flowing fractured zone, and then determining the position of a thick and hard sandstone aquifer within the height range of the water flowing fractured zone; determining a thick and hard sandstone aquifer mining influence range boundary R; determining the horizontal distance S1 between the lateral curtain of the boundary of the first mining working face and the lateral boundary of the goaf; the arrangement position of a first continuous lateral curtain is determined; a boundary lateral curtain and a first continuous lateral curtain are constructed through hydraulic fracturing grouting; lateral water interception and seepage prevention and normal stoping of the first mining working face are completed; lateral water interception and seepage prevention and normal stoping of the first continuous working face are completed; lateral water interception and seepage prevention are conducted on the second continuous working face; and so on, until the coal seam in the mining area or the panel is completely mined. According to the method, cooperative prevention and control of roof water disasters and rock burst disasters are achieved, the mine water inflow is greatly reduced finally, and the prevention and control effect of getting twofold results with half the effort can be achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

A construction method of mine seepage well grouting type sinking

The invention discloses a slurry injection type shaft sinking construction method of a seepage well of a mine. During construction, by use of seepage well principle, water of a target water containinglayer is drained to a to-be-injected water containing layer under the well. A water drainage and pressure releasing driller of an underground roadway or a kilometer directional driller is used for carrying out water drainage and pressure releasing on the water containing layer around a shaft, so a water drainage funnel is formed, an annular water interception well is formed and the shaft is capable of using a common borehole blasting method to carry out dry well operation. After the water containing layer is constructed by the well cylinder, a slurry injection pipe in the seepage well is usedfor carrying out slurry injection blocking on the seepage well and the surrounding rock. According to the invention, water inflow quantity can be reduced by use of a shaft sinking method where construction is performed by use a common method. The provided construction method is suitable for construction of quite big shafts where the water inflow in the later period of the mine.

Owner:中煤能源研究院有限责任公司

A Construction Method for High-Pressure Water-Rich Super-large Fault Weak Breccia Tunnel

ActiveCN105041325BConstruction applicableReduce water pressureUnderground chambersDrainageEpoxyChemical grouting

The invention discloses a construction method of a high-tension water-rich extra-large-section weak breccia tunnel. The method includes the steps of exploring distribution of fault weak breccia in front of a tunnel face by an advanced geological forecast method; distributing L-shaped gradient drain holes in two inner sides of the tunnel, providing sector drain holes and grouting holes, and allowing upper grouting and lower drainage; providing a combined cylinder grout-stopping wall, and performing a full-face advanced chemical grouting consolidation; constructing an advanced long tube shed with a circumferential closed advanced tube shed guide wall having a foundation, distributing tapered quincunx examining drain holes to detect grouting effect, and finally excavating the tunnel. Through the use of the techniques such as three-layer stereoscopic grouting and drainage, and cement-water glass and epoxy resin sequential grouting, the problem that a high-tension water-rich surrounding rock area with loose weak breccia has ineffective grouting consolidation and non-obvious water plugging effect is solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Construction Method of Dynamic Water Grouting and Solidification in Dense Sand Egg Layer

ActiveCN105220695BReduce hydraulic contactReduce water gushingExcavationsStructure of the EarthGroundwater

The invention discloses a compact sandy-pebble layer dynamic grouting curing construction method and an application layer structure. The method includes the following steps that (1) a drill machine is put in place and performs hole drilling and forming to form a grouting hole; (2) a grouting pipe is prepared and buried in the grouting hole; (3) grouting and hole sealing are performed, specifically, a permeating grouting mode is adopted for grouting, and the grouting hole is sealed; (4) curtain grouting is conducted, that is, all grouting holes in a curtain are grouted to form a finally curtain; (5) a pump-in test is performed, and the anti-permeability of the cured final curtain is detected. The compact sandy-pebble layer dynamic grouting curing construction method is applicable to foundation ditch waterproof curtain construction under the hydrogeological condition with a compact sandy-pebble layer rich in flowing underground water; high strength of the compact sandy-pebble layer is avoided by means of permeating grouting; grout is good in anti-permeability after being cured after a certain time; accordingly, hydraulic connection of inside and outside of a foundation ditch is reduced, and a manual waterproof barrier is formed.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

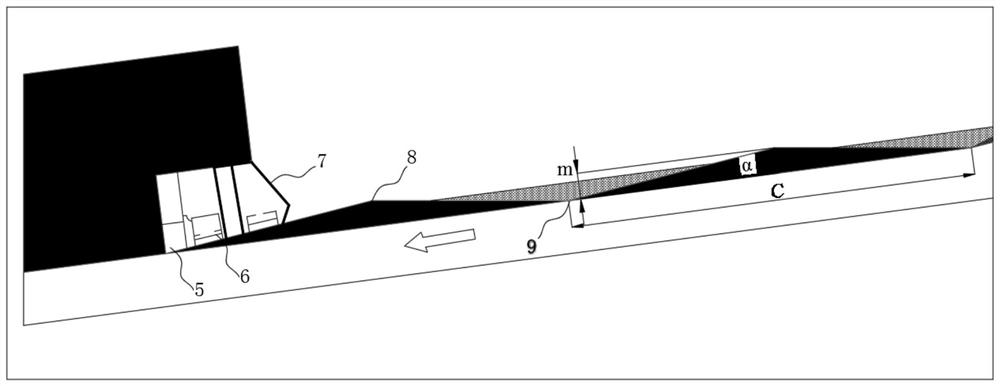

Wave-type mining method for inclined mining working face of deep heavy-water mine

PendingCN112377192ABarrier entryImprove the construction environmentUnderground miningSurface miningWater dischargeMining engineering

The invention provides a wave-type mining method for an inclined mining working face of a deep heavy-water mine, and relates to the technical field of coal mining. The problem of water accumulation ofthe inclined mining working face of the heavy-water mine is solved. The mining method comprises the steps that a periodic weighting length of working face mining is determined, the wave crest and thewave trough in each mining subsection are determined according to the weighting length, an elevation angle and a depression angle of coal cutting are determined, a coal mining machine alternately pushes a coal mining working face in each subsection according to the elevation angle and the depression angle, and a wavy bottom plate is formed behind the working face; drainage pipes are buried in thewave troughs behind the working face, drainage pipelines are arranged above ditches of an air return gate road, and the drainage amount of the gate road is increased; and an auxiliary conveying channel is formed to discharge sewage, a mechanical grid is installed in the auxiliary conveying channel, and coal slime of the mechanical grid is conveyed to a coal conveying system through an auxiliary conveying belt. According to the wave-type mining method, the working environment of the inclined mining working face is improved, long-term water soaking of equipment is avoided, the coal moisture content is decreased, and the coal pillar bearing performance is further improved.

Owner:SHANDONG UNIV OF SCI & TECH

A regional grouting treatment method for extremely thick aquifers on coal seam roof

ActiveCN111894588BReduce thicknessReduce water gushingUnderground miningSeismic signal receiversMining engineeringEnvironmental engineering

The invention provides a grouting treatment method for a huge thick aquifer area on the roof of a coal seam, including the following stages: the first stage: before mining, carry out sedimentary facies analysis, select floodplain strata as the target layer, if there is no floodplain separated water layer , select the highly permeable aquifer as the target layer; the second stage: probe and locate the permeable skylight for the target layer of the floodplain, and make up for it by grouting, or grouting the highly permeable aquifer to transform it into an aquifer; third Stage: Before mining, monitor the stability of the aquifer that can be used after roof reconstruction; Stage 4: After mining, grouting the slip joints generated on the roof of the coal pillar to form a water-proof curtain. The invention makes up the skylight of the water-resisting layer by grouting before mining or transforms the high-permeability aquifer into a water-resisting layer, and grouting the slip joint after mining to form a water-resisting curtain, so as to reduce the thickness of the aquifer and reduce the mine water inflow. The purpose is to improve the underground operating environment, reduce costs, and restore normal production to the discontinued coal mines.

Owner:CHINA COAL GEOLOGY GRP CO LTD

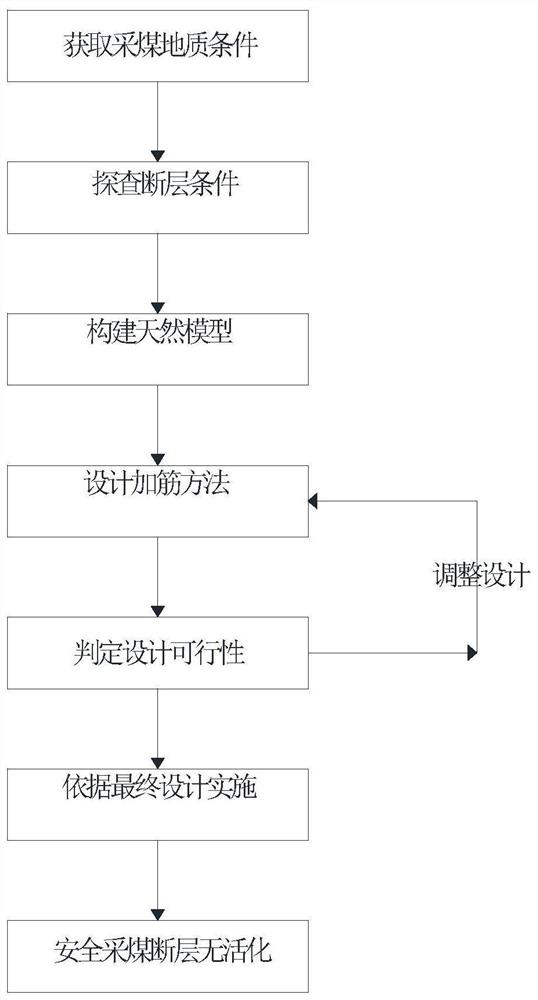

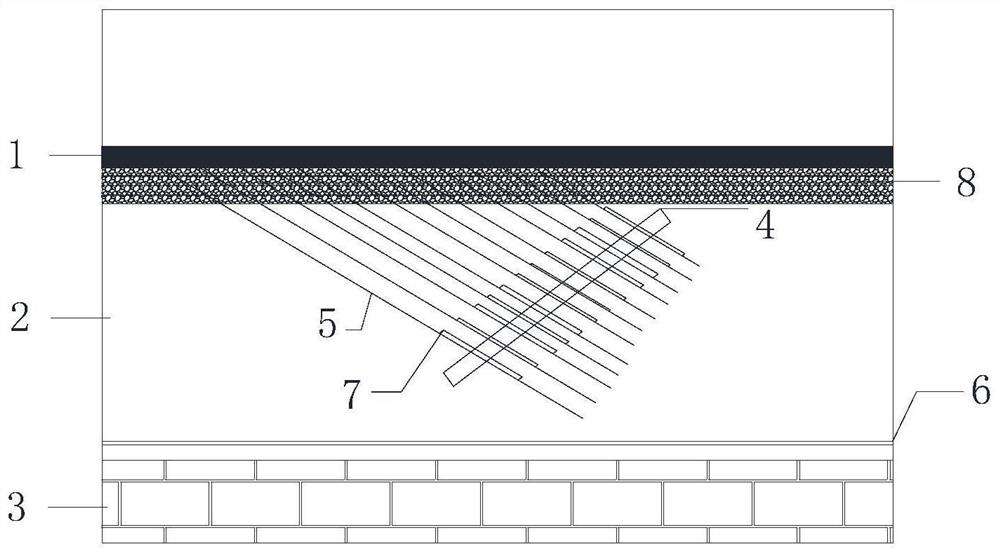

Method for preventing and controlling water damage reinforcement of coal seam floor fault

ActiveCN112780277AImprove tensile propertiesHelps control shrinkageUnderground chambersUnderground miningMining engineeringStructural engineering

The invention discloses a method for preventing and controlling water damage reinforcement of a coal seam floor fault. The method comprises the following steps of: S1, acquiring coal mining geological conditions; S2, exploring fault conditions; S3, establishing a natural numerical model according to the acquired coal mining geological conditions and fault conditions; S4, designing a reinforcement scheme, including laying reinforcement and a protective layer, wherein when the reinforcement is laid, the reinforcement is obliquely crossed with the fault and forms a preset included angle with the trend of a middle rock stratum, the laying range of the reinforcement is implemented at intervals along the extension range of the fault, and the reinforcement is positioned within a preset distance of a floor of a coal seam; designing the protective layer between a water damage source stratum and the fault; S5, adopting the natural numerical model, performing parameter assignment on the numerical model according to the reinforcement scheme, and performing mining simulation of the coal seam to obtain a final reinforcement design scheme; and S6, setting the reinforcement and the protective layer according to the final reinforcement design scheme. The method disclosed by the invention has good fault reinforcement and waterproof effects, and is environment-friendly.

Owner:LIUPANSHUI NORMAL UNIV

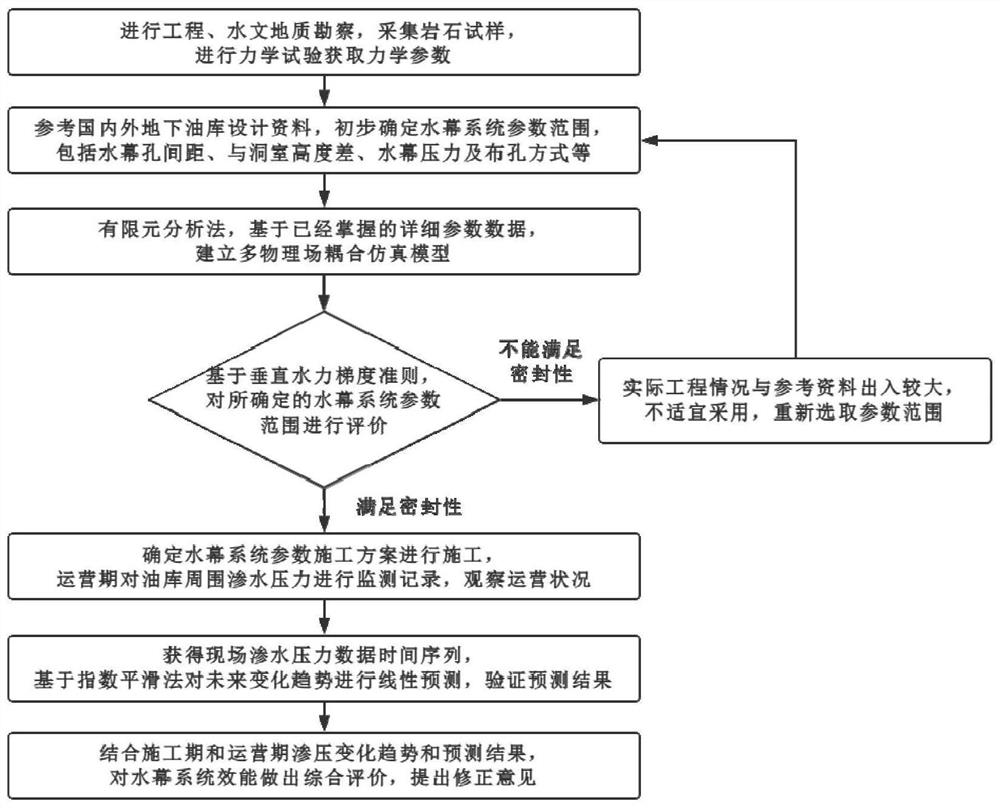

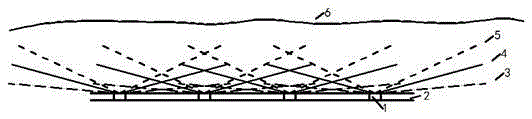

Analysis system and method for design and correction of water curtain system in underground water-sealed oil storage depot

ActiveCN111157346BNarrow down the parameter selection areaHigh feasibilitySurveyMaterial strength using tensile/compressive forcesElement analysisLaboratory test

This disclosure provides an analysis system and method for the design and correction of the water curtain system of an underground water-sealed oil storage depot. Study the case and obtain the relevant parameter data required for the scheme in the laboratory test. Through the finite element analysis method, the selection range of the specific parameters of the water curtain system can be quickly and accurately narrowed, and the final design and construction plan can be determined accurately, time-saving, highly feasible, and low oil leakage rate.

Owner:SHANDONG UNIV

A curtain grouting method for a well-developed karst fracture on the roof of an ore body and a strong water-rich deposit

ActiveCN103967506BSafe and Efficient MiningReduce water gushingUnderground chambersTunnel liningElevation angleGeomorphology

The invention discloses a curtain grouting technology for an ore body roof karst fracture development and strong water-rich ore deposit. According to the technical scheme, firstly, upward exploration and injection holes are distributed, six upward exploration and injection holes with an elevation angle of five degrees, six upward exploration and injection holes with an elevation angle of 15 degrees and six upward exploration and injection holes with an elevation angle of 25 degrees are distributed in each chamber, the exploration and injection holes are designed with the chambers as base points, all the exploration and injection holes of all the lengths are evenly distributed in the plane with a stagger angle of 60 degrees, the hole depth is 50 m, and the exploration and injection holes with the elevation angle of five degrees, the exploration and injection holes with the elevation angle of 15 degrees and the exploration and injection holes with the elevation angle of 25 degrees are evenly distributed in the plane with a stagger angle of 20 degrees; secondly, downward exploration and injection holes are distributed, the outward and downward exploration and injection holes with the angles of -5 degrees,-30 degrees and -60 degrees are distributed in end chambers, the hole depth is 50 m, all the downward exploration and injection holes are evenly distributed symmetrically in the plane, and the included angle is 10 degrees; thirdly, according to the requirement of accurate mining engineering, grouting is carried out, and a grouting curtain is formed. The grouting curtain with the high water plugging rate is built under a mine according to roof karst fractures, the functions of water separation and reinforcement can be achieved, ore bodies are released safely and efficiently under the protection of the grouting curtain, and technical guarantees are provided for safe and efficient mining of the mine.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Construction method of water pre-draining on roof of mining face

The invention relates to coal mine underwater treatment technology, in particular to a stope face roof water pre-drainage construction method, which solves the technical problem of treatment of a water-bearing bed on a coal seam of a stope face. As the process of stoping on the stope face includes down stoping firstly and up stoping secondly, stope face roof water is drained in advance through roadways beside the stope face before stoping, a drill site chamber and a water bin are constructed at the lowest position of each of the roadways, two drainage pipelines are paved on each of the roadways, an independent drainage system is utilized, drainage holes are drilled in the drill site chamber towards the stope face roof, and water for drilling is led into the water bin through hoses directly and is drained by the drainage system of the roadways. Since roof water is drained in advance, water inflow during the stoping process is reduced effectively, troubles to production of coal mines due to the roof water are eliminated, affection of flood disaster to production is avoided, a safe and comfortable working environment is provided for the stoping operation, and conditions for stability and high yield of the stope face are created.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

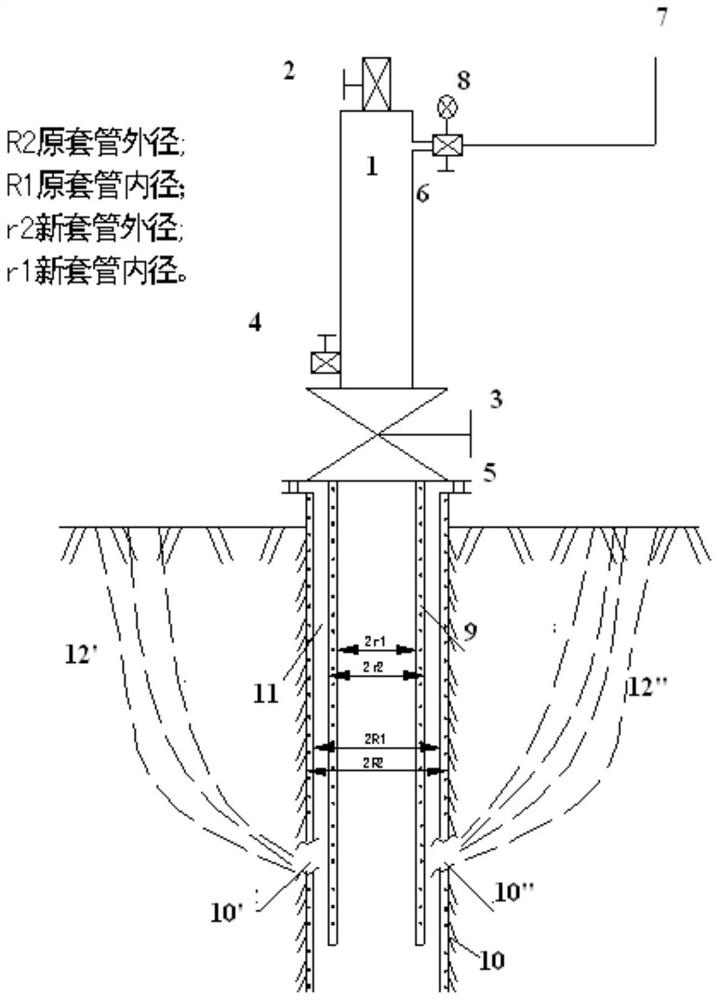

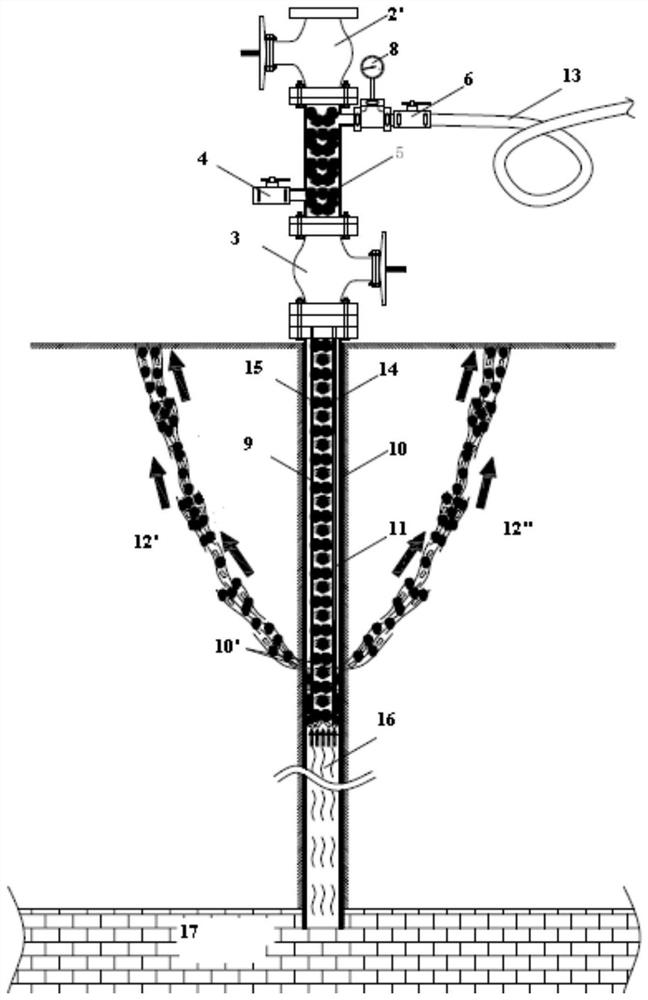

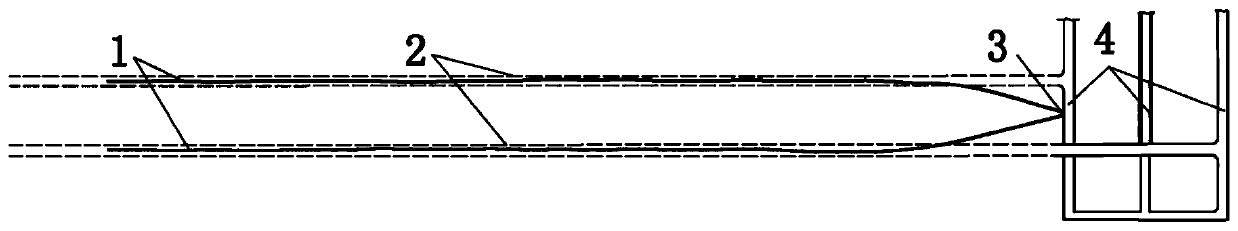

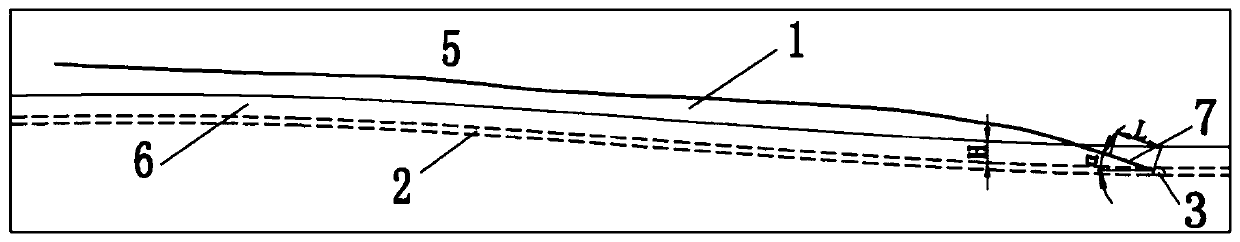

Downhole high pressure and large flow uncontrolled hydrological drilling plugging system and method

ActiveCN110847850BReduce water gushingReduce the cost of ineffective drainageDrilling compositionSealing/packingWood shavingsConfined water

The invention provides a system and method for downhole high-pressure, large-flow out-of-control hydrological drilling plugging. In the damaged hydrological drilling casing, a new casing of one level smaller is re-runned, and then a casing of an appropriate size is run in according to the gap between the old and new casings. Hard aggregate and soft aggregate (the specific gravity is smaller than water), inject a certain amount of soft and hard aggregate into the new casing in a certain proportion, and use the principle that water always flows along the direction of the least resistance. Under the action of pressurized water and the pump pressure above, it can only enter the gap between the new and old casings with low resistance. The hard aggregate fills the large gap between the new and old casings to act as a skeleton and support, and the soft aggregate fills the hard bone. The material gap, and then inject cement through the new casing to complete the treatment. The soft and hard aggregates are skillfully combined, which has both strength and flexibility, and a small specific gravity. The hard aggregates are mainly pine wood blocks and wooden wedges, and the soft aggregates are sawdust, Wood shavings are mainly used to solve the problem of high pressure and large flow damage hydrological drilling.

Owner:JIZHONG ENERGY FENGFENG GRP

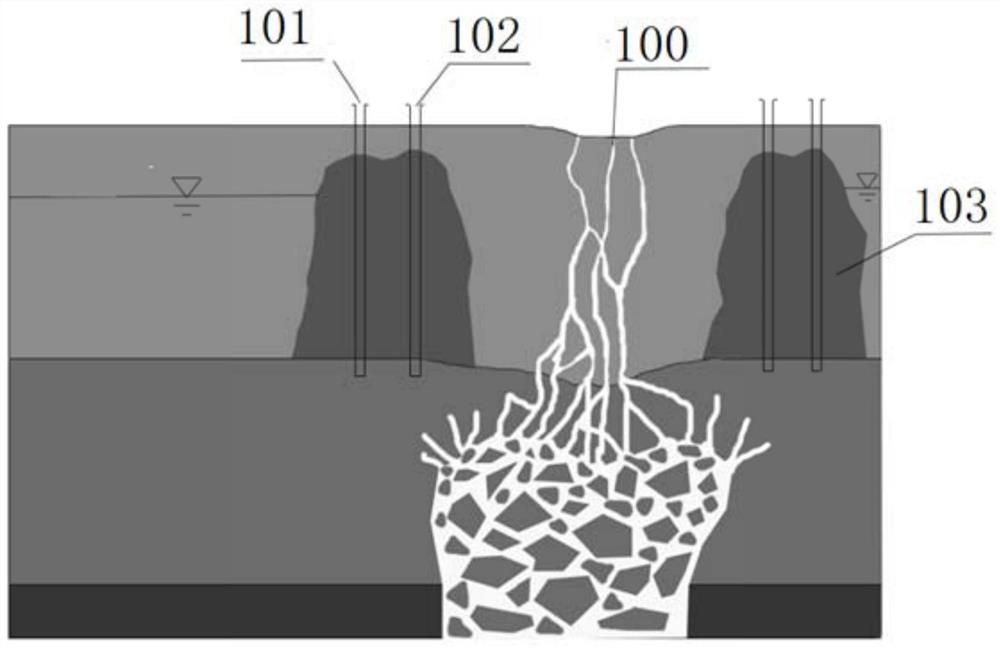

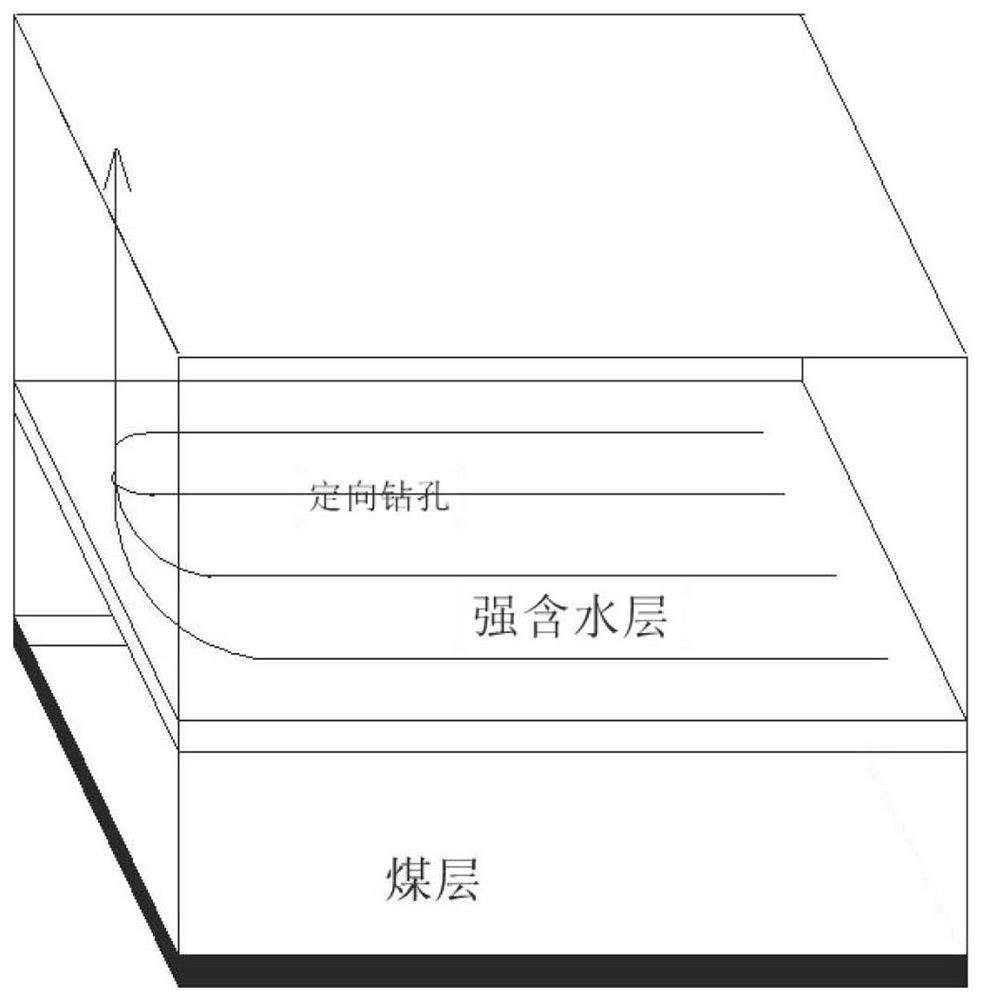

Water Hazard Prevention and Control Method for Roadway under Strongly Rich Water and Weakly Consolidated Aquifer

ActiveCN108915736BReduce water gushingAdd supportUnderground chambersTunnel liningWater volumeRock bolt

The invention discloses a method for preventing and controlling water hazards in tunnels under strong water-rich and weakly cemented aquifers, which include long-distance directional drilling for intercepting groundwater in the aquifer on the roof of the tunnel, conventional drilling, bolt grouting, and U-shaped steel shed support and other steps. The present invention combines the characteristics of the aquifer thickness, water-richness, cementability and water-resisting layer thickness of the roof of the tunneling roadway, adopts long-distance directional drilling to intercept and dredge the groundwater; drills and injects grout to seal the water seepage crack of the roadway; anchor rod grouting Cooperate with the technical scheme of U-shaped steel shed support, through long-distance directional drilling to intercept the water supply of the roadway roof aquifer to the roadway, and at the same time, drain and grout the conventional drilling and grouting bolts to seal the water seepage cracks and anchors in the roadway The water seepage channel between the rod, the anchor cable and the rock formation effectively reduces the water inflow of the excavation roadway and strengthens the support of the roadway, thus avoiding the occurrence of water damage and roof accidents in the excavation roadway under the strong water-rich and weakly cemented aquifer.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

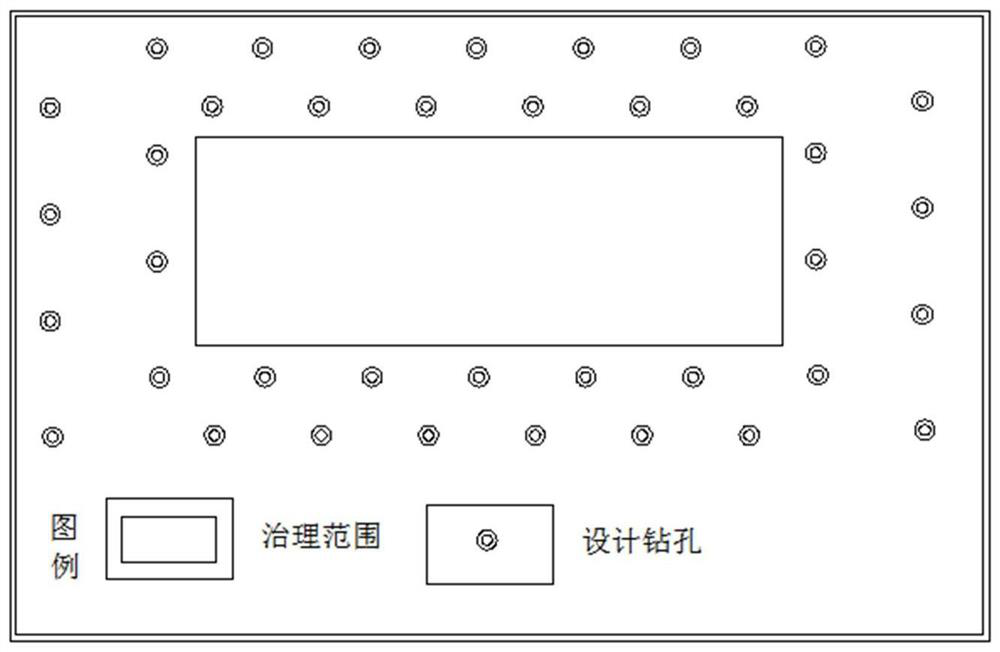

Treatment method for top plate sandstone water of Jurassic coal field

PendingCN113006795AReduce influxProtect groundwater resourcesUnderground chambersUnderground miningGroundwater resourcesMining engineering

The invention belongs to the field of mine water treatment, and particularly relates to a treatment method for top plate sandstone water of a Jurassic coal field. The method comprises the steps that overground grouting holes are constructed in the periphery of a working face or a mining area, and grouting is conducted in the grouting holes; and the working face or the mining area serves as the center, and the grouting holes are annularly distributed around the working face or the mining area. According to the treatment method, a channel for underground water to flow into a mine is blocked from the source, the underground water is sealed in a stratum, the influence of coal mining on the underground water is reduced, accordingly, the inflow amount of the mine water is reduced, and the underground water resource is protected.

Owner:中国煤炭地质总局勘查研究总院

Curtain interception method of point-like vertical aqueducts in unconfined aquifers

ActiveCN111810232BReduce water gushingEliminate water hazardsMining devicesMaterial fill-upWater sourceSlurry

Owner:SHENHUA XINJIANG ENERGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com