Wave-type mining method for inclined mining working face of deep heavy-water mine

A technology for large water mines and mining methods, which is applied to drainage, surface mining, mining equipment and other directions, can solve the problems of water and influence on the safety production of down-cut working faces, avoid hydration damage, avoid immersion, and improve bearing reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

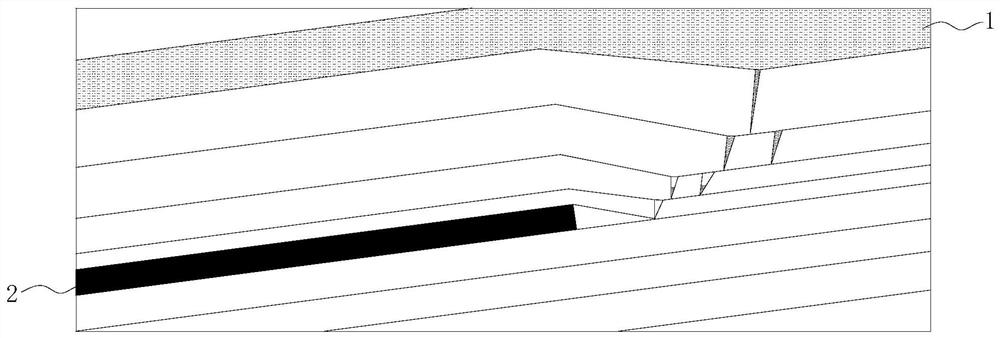

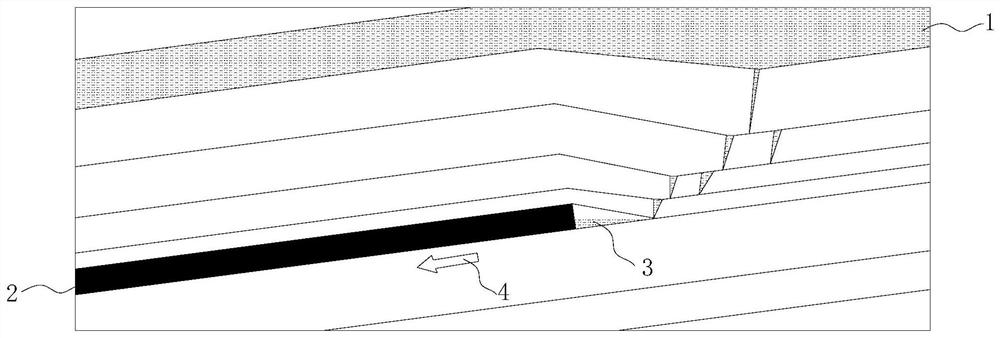

[0030] In order to fundamentally solve the water damage problem existing in the undercut working face of Dashui mine, a wave-type mining method for the undercut working face of deep Dashui mine is provided, which specifically includes:

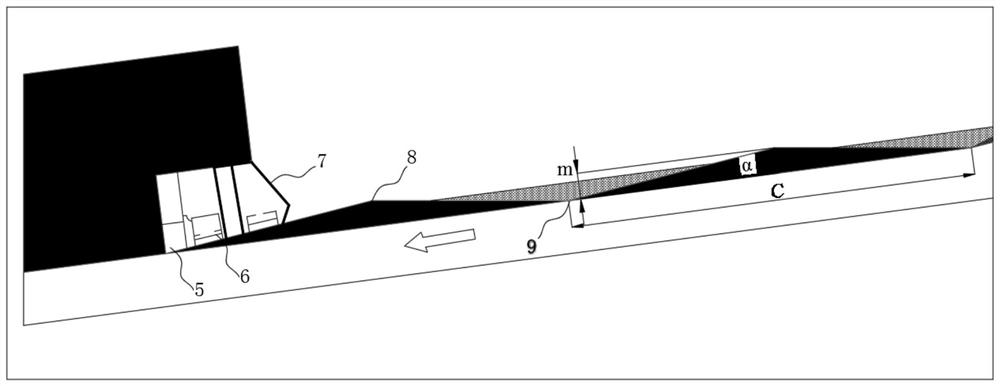

[0031] Step S1. Determine the cycle step distance of the working face mining, and determine the peaks and troughs in each mining segment according to the cycle step distance, set the elevation angle and depression angle of the shearer to cut coal, and the shearer according to the design A certain elevation angle and depression angle alternately advance the coal mining face, forming a wavy bottom plate behind the coal mining face, which can effectively block the water behind the working face from entering the coal mining face.

[0032] Among them, the periodic pressure step distance is the periodic pressure step distance of the basic roof. By monitoring and determining the working resistance of the hydraulic support on the working face, the peri...

Embodiment 2

[0040] In this embodiment, on the basis of Example 1, the beneficial effect of the wave mining method on the down mining face of a deep flood mine is described by taking the wave mining of the 101 working face of a certain mine as an example.

[0041] The 101 coal mining face of a certain mine is undercut mining as a whole, and a large amount of water gushes from the roof in the goaf, and the amount of water gushing behind the highest face is as high as 640m 3 / h, leading to poor production and operation environment on the working face, long-term immersion of coal mining machines and other equipment in the working face, affecting their performance and life, and the front scraper conveying water charcoal affects coal quality. In addition, the small coal pillars in the section have been eroded by water for a long time, which affects its strength and stability, and poses a serious threat to the safety and stability of the mining roadway. In order to solve the water hazard problem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com