Layered-hypophosphite flame-retardant and reinforced polypropylene composite material and preparation method thereof

A technology of hypophosphite and composite materials, applied in the direction of hypophosphorous acid, phosphorus oxyacids, nanotechnology, etc., can solve the problems of low strength of polypropylene composite materials, large particle size of hypophosphite, poor thermal stability, etc., and achieve thermal stability Good stability, improved surface properties, and improved flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

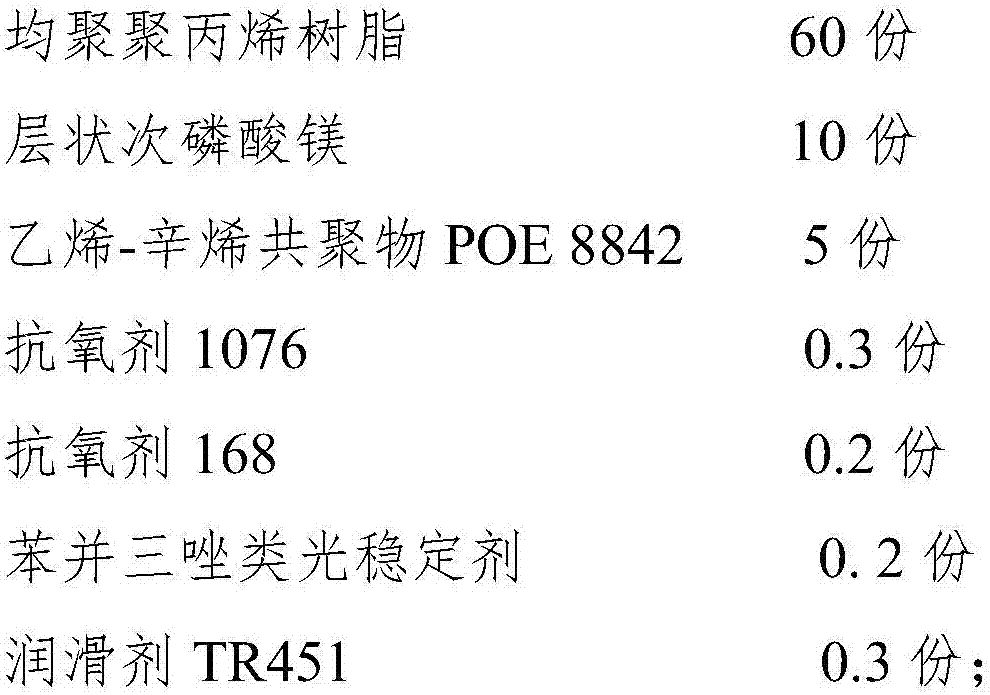

[0026] The layered hypophosphite flame-retardant reinforced polypropylene composite material of the present embodiment is made of the following raw materials by weight:

[0027]

[0028] The preparation method of the layered hypophosphite flame-retardant reinforced polypropylene composite material of the present embodiment includes the following steps:

[0029] S1. Place 100g of aluminum chloride, 200g of sodium hypophosphite and 1g of PVP in an autoclave, use absolute ethanol as a solvent, stir, after complete dissolution, treat in an oven at 230°C for 3h, filter with suction, and wash with water and ethanol respectively After drying, it was dried in a vacuum oven and ground to obtain layered aluminum hypophosphite;

[0030] S2. Add 75 parts of copolymerized polypropylene resin, 10 parts of toughening agent POE5070D, 0.3 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.2 part of light stabilizer 5585 and 0.3 part of lubricant silicone powder to the Mix in a high-s...

Embodiment 2

[0033] The layered hypophosphite flame-retardant reinforced polypropylene composite material of the present embodiment is made of the following raw materials by weight:

[0034]

[0035] The preparation method of the layered hypophosphite flame-retardant reinforced polypropylene composite material of the present embodiment includes the following steps:

[0036] S1. Place 100g of ferric sulfate, 210g of sodium hypophosphite, and 1g of PVP in an autoclave, use absolute ethanol as a solvent, stir, after complete dissolution, treat in an oven at 230 ° C for 3 hours, filter with suction, and wash with water and ethanol respectively. , placed in a vacuum oven for drying, and ground to obtain layered ferric hypophosphite;

[0037] S2. Add 75 parts of copolymerized polypropylene resin, 10 parts of toughening agent POE875L, 0.3 part of antioxidant 1076, 0.2 part of antioxidant 168, 0.2 part of light stabilizer V703 and 0.3 part of lubricant TR451 to the high-speed mixer Mixed for 5...

Embodiment 3

[0040] The layered hypophosphite flame-retardant reinforced polypropylene composite material of the present embodiment is made of the following raw materials by weight:

[0041]

[0042] The preparation method of the layered hypophosphite flame-retardant reinforced polypropylene composite material of the present embodiment includes the following steps:

[0043]S1. Place 200g of magnesium sulfate, 230g of sodium hypophosphite, and 5g of polyoxyethylene-polyoxypropylene copolymer in an autoclave, use absolute ethanol as a solvent, stir, and after complete dissolution, treat in an oven at 230 ° C for 3 hours, and extract Filtered, washed with water and ethanol respectively, dried in a vacuum oven, and ground to obtain layered magnesium hypophosphite;

[0044] S2. Mix 60 parts of homopolypropylene resin, 5 parts of ethylene-octene copolymer, 0.3 part of antioxidant 1076, 0.2 part of antioxidant 168, 0.2 part of benzotriazole light stabilizer and 0.3 part of lubricant TR451 was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com